Professional Documents

Culture Documents

Design and Construction of Stone Building

Uploaded by

Muhafeez GoolabCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Design and Construction of Stone Building

Uploaded by

Muhafeez GoolabCopyright:

Available Formats

Design and Construction details of stone building...

http://www.aboutcivil.org/Design-and-Constructio...

Stone Wall Construction , stone construction

details

Search

Civil Engineering Engineering Materials Stones Design and Construction of stone buildings

Stone Construction

Emulsified Asphalt

Design and Construction of stone buildings

Use Applications of

Stones

Classification of

Stones

How to construct a stone wall:

Stone Introduction

Properties of Stones

Engineering Metals

GeoTextiles |

Bitumen

Civil Engg. Subjects

Professional Ethics

Advertisements

Ace Building Contractor

contractor.mu

Soil Mechanics I

Construction, Renovation, Design

Villas,Houses,Commercial Buildings

Engineering

Economics

Siding Panel Suppliers

Technical Report

Skills

Steel Buildings Is Our

Surveying &

Leveling II

AAA-Mr.Level Foundations

Differential

Equations

Strength of

materials

Engineering

Geology

Building

Construction

Steel Structures

Hydraulics

Reinforced

Concrete

Step 1: To assist in your stacking, sort the stone by size; setting aside

the smallest pieces to use as shims (these will help level unsteady

larger stones).

Prepare for this activity by stretching well and always lift using your

arms and legs, not your back Shims (shown far right), or smaller

stones, help level unsteady larger pieces.

Step 2: Map out the design by digging a trench about 6" deep and as

wide as your largest stone.

Step 3: Pack down and level earth. Cut filter fabric at least 3 feet wider

than the trench. Lay down filter fabric inside trench so that excess is on

the backside of trench. Filter fabric keeps dirt from migrating while

allowing water to drain through your wall.

Step 4: Place a thin layer of crushed stone (1"-2") in the trench to help

level stones and assist drainage.

Step 5: Start with the largest stones first. Lay them flat from one end of

the trench to the other. Continue to stack stones, working back and

forth, one level at a time.

Step 6: As you stack your wall, make sure that it slopes back slightly to ensure stability. Position stone tightly together,

mixing small and large pieces. Stagger joints between stones to create more stability.

Step 7: As you build up, fill in the area behind the wall with crushed stone, and then fill dirt, compacting as you go. Keep

your filter fabric between the fill and stonewall.

Step 8: When wall is stacked to desired height, fold the filter fabric back over the fill dirt area and finish with your choice

of top soil, mulch, gravel, etc. Run water to settle dirt behind the wall and into its services.

Problems in construction of buildings with stones:

Hydrology

Past Papers

Project Planning

Hydraulics

Structures

Civil Engineering

Ebooks

Overall, it can be stated that the improved element performed better than the traditional element in the series of

earthquake simulations. This statement is based on an assessment of the risk of causing injury posed by each structure.

The walls of the traditional corners were independent and unstable.

Any additional force, such as another tremor or a strong wind or impact, could cause either wall to topple over, in an

inward or outward direction. This represents an unacceptable level of risk. These buildings are one of the most deficient

building systems from earthquake-resistance point of view. The main deficiencies include excessive wall thickness,

absence of any connection between the two withes of the wall, and use of round stones.

Video Training

Tutorial

1 of 2

02/09/2016 05:02 PM

Design and Construction details of stone building...

Factors to be considered in stone construction

AutoCAD Videos

VICO Constructor

SAP2000 Training

MS Project Tutorials

Civil Related Links

Jobs

Engineering

Projects

Suggest us, What to

Add

Starting a

New

Business?

Reduce your

Office costs.

Get a

Business

Address

instead!

http://www.aboutcivil.org/Design-and-Constructio...

Factors to be considered in stone construction

1. Important buildings were once designed and put together by master masons who knew how to work with stone,

and understood the advantages and limitations of the material. Stone structure should be a combination of

structural firmness, technical commodity and aesthetic delight.

2. Ensure proper wall construction. The wall thickness should not exceed 450mm.

3. Round stone boulders should not be used in the construction! Instead, the stones should be shaped using chisels

and hammers.

4. Use of mud mortar should be avoided in higher seismic zones. Instead, cement-sand mortar should be 1:6 (or

richer) and lime-sand mortar 1:3 (or richer) should be used.

5. Ensure proper bond in masonry courses: The masonry walls should be built in construction lifts not exceeding 600

mm.

6. Through-stones (each extending over full thickness of wall) or a pair of overlapping bond-stones (each extending

over at least this thickness of wall) must be used at every 600mm along the height and at a maximum spacing

of 1.2m along the length.

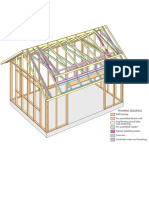

7. The stone masonry dwellings must have horizontal bands roof and gable bands). These bands can be

constructed out of wood or reinforced Concrete, and chosen based on economy. It is important to provide at least

one band (either lintel band or roof band) in stone masonry construction.

8. Care should be taken to ensure that the fixing method adopted for the construction is appropriate to the type of

stone being used.

The energy needed to collapse a structure comes from the structure itself. The high frequencies can cause high vertical

inter-stone vibrations that result in irreversible relative displacements of the stones, which is mainly due to the non

required shape of the stones, thus stone walls mainly crumble under their own weight.

A. Leita Steel

Experts in commercial, industrial and mining steel solutions.

Related Pages

Related Pages

Manufacture of Lime

Properties Fat Lime

Uses of Fat Lime

AutoCAD

About Us | Site Map | Privacy Policy | Contact Us |

2 of 2

Properties Hydraulic Lime

Uses of Hydraulic Lime

Lime as an Engineering Material

MegaStructures

2014 WebTechTix

02/09/2016 05:02 PM

You might also like

- Practical hints to builders and those contemplating buildingFrom EverandPractical hints to builders and those contemplating buildingNo ratings yet

- Stone Masonry Guide: Types, Principles & SupervisionDocument30 pagesStone Masonry Guide: Types, Principles & Supervisionhari prasad100% (1)

- Installing a Garage Door and Opener- Special Bundle: Cake Decorating for BeginnersFrom EverandInstalling a Garage Door and Opener- Special Bundle: Cake Decorating for BeginnersNo ratings yet

- Timber Frame Construction Project PresentationDocument18 pagesTimber Frame Construction Project PresentationscegtsNo ratings yet

- 2020 Inspiration HouseDocument22 pages2020 Inspiration HouseHeidi StevensonNo ratings yet

- How House Construction WorksDocument29 pagesHow House Construction WorksMithun Murthy GNo ratings yet

- Wood Garage Doors Owners ManualDocument2 pagesWood Garage Doors Owners ManualRonnie DoberNo ratings yet

- Cast Stone Association Technical Manual PDFDocument52 pagesCast Stone Association Technical Manual PDFneilattardNo ratings yet

- Roof Sheathing FasteningDocument4 pagesRoof Sheathing Fasteningnumber_25No ratings yet

- Bricklayers Tool Kit PDFDocument4 pagesBricklayers Tool Kit PDFYounes BarakaNo ratings yet

- A Review of Rammed Earth ConstructionDocument118 pagesA Review of Rammed Earth ConstructionLuciana Pinto100% (2)

- MinimumStandards - (Ext Wall Framing)Document14 pagesMinimumStandards - (Ext Wall Framing)Samia H. BhuiyanNo ratings yet

- Drywall-Steel Framed SystemsDocument52 pagesDrywall-Steel Framed SystemsbuboynanayNo ratings yet

- Flat Roof Quick Guide 9th Issue Feb 16Document40 pagesFlat Roof Quick Guide 9th Issue Feb 16aadrian_xyzNo ratings yet

- 9 Types of Wood Framing To KnowDocument19 pages9 Types of Wood Framing To KnowMarion LauritoNo ratings yet

- Victorian Guide To Standards And-Tolerances 2007Document60 pagesVictorian Guide To Standards And-Tolerances 2007yyanan1118No ratings yet

- Retaining WallsDocument4 pagesRetaining Wallssnorburn1No ratings yet

- FoundationDocument6 pagesFoundationAnonymous dK9Qi2XjNo ratings yet

- Roof Tile: Insulated Panel SystemDocument48 pagesRoof Tile: Insulated Panel SystemCormac DooleyNo ratings yet

- Iglu'® Green Roof - Systems For Roof GardensDocument12 pagesIglu'® Green Roof - Systems For Roof GardensDaliform GroupNo ratings yet

- LP® Shed Assembly Instructions Hawthorne Place 10'X12' Gable Roof ShedDocument10 pagesLP® Shed Assembly Instructions Hawthorne Place 10'X12' Gable Roof ShedMinuteman ModelworksNo ratings yet

- Design A Deck Planning PDFDocument18 pagesDesign A Deck Planning PDFdvsNo ratings yet

- Dreaming Creek Architectural Technical Specifications Timber FramesDocument151 pagesDreaming Creek Architectural Technical Specifications Timber FramesMat Gai100% (2)

- Householders Guide To Flat RoofingDocument24 pagesHouseholders Guide To Flat RoofingBudi SudrajatNo ratings yet

- Building TechnologyDocument4 pagesBuilding TechnologyDanica LuarezNo ratings yet

- EnerSIP Construction ManualDocument53 pagesEnerSIP Construction ManualIvan Klyuchka100% (2)

- Figure B Framing: Pre-Assembled Dormer Wall Roof Framing (Install After Wall Sheathing) Wall FramingDocument13 pagesFigure B Framing: Pre-Assembled Dormer Wall Roof Framing (Install After Wall Sheathing) Wall FramingMúsica viajera MX0% (1)

- Architects, Desginers and Certified TimberDocument6 pagesArchitects, Desginers and Certified TimberPEFC InternationalNo ratings yet

- Complex Roof Framing HandoutDocument23 pagesComplex Roof Framing HandoutMaria ComanNo ratings yet

- Polycarbonate JointDocument27 pagesPolycarbonate JointPeter ChristianNo ratings yet

- PHC Developers GuideDocument16 pagesPHC Developers GuidePrasaf100% (1)

- 04 Descrip Shipping Container HomesDocument2 pages04 Descrip Shipping Container Homesbattlefury100% (1)

- Screws Design Guide VU 1.1 PDFDocument52 pagesScrews Design Guide VU 1.1 PDFLoma100% (1)

- Osb HandbookDocument48 pagesOsb HandbookVladislavs PozņaksNo ratings yet

- Construction Technology Revision GuideDocument38 pagesConstruction Technology Revision GuideKeemeNo ratings yet

- 5 Roof Structure Types ExplainedDocument5 pages5 Roof Structure Types ExplainedFathi RashidNo ratings yet

- Tiny House ProjectDocument10 pagesTiny House ProjectAndrew StirrupNo ratings yet

- Building Your Shipping Container HomeDocument7 pagesBuilding Your Shipping Container HomeMukhtar Oyewo100% (1)

- Wall Framing Power PointDocument18 pagesWall Framing Power Pointapi-347440938No ratings yet

- Affordable House 2010Document23 pagesAffordable House 2010Ionut SavaNo ratings yet

- Ceiling TechnologyDocument6 pagesCeiling Technologypdf2004No ratings yet

- How to Make Fiberglass Molds in Simple StepsDocument7 pagesHow to Make Fiberglass Molds in Simple StepsDanial Iskandar MusliNo ratings yet

- Deck ConstructionDocument8 pagesDeck ConstructionCA_KenNo ratings yet

- 13 Ext Walls FramingDocument35 pages13 Ext Walls FramingAnonymous 4SVSd7jN100% (1)

- Earthquake-Resistant Adobe ConstructionDocument19 pagesEarthquake-Resistant Adobe ConstructionNikhil Saxena100% (1)

- Installing A Pre-Hung DoorDocument3 pagesInstalling A Pre-Hung DoorEng_20140% (1)

- Log Home ConstructionDocument23 pagesLog Home ConstructionJP VersterNo ratings yet

- Types of WindowsDocument16 pagesTypes of WindowsShivamNo ratings yet

- 2016 Masonry Systems Guide Northwest EditionDocument185 pages2016 Masonry Systems Guide Northwest EditionDavidNo ratings yet

- Understanding The Passivhaus StandardDocument12 pagesUnderstanding The Passivhaus StandarddarulrajNo ratings yet

- Morerava CabinsDocument31 pagesMorerava Cabinsterezia28No ratings yet

- Successful Timber Floors: A Guide to Real Timber FlooringFrom EverandSuccessful Timber Floors: A Guide to Real Timber FlooringRating: 3 out of 5 stars3/5 (2)

- Residential Residential Attic Insulation Attic Insulation: AG AG U UDocument24 pagesResidential Residential Attic Insulation Attic Insulation: AG AG U Uorlando47777No ratings yet

- Plan 1Document24 pagesPlan 1ParZiValNo ratings yet

- American Eagle Men's & Women's Clothing, Shoes ... : People Also AskDocument2 pagesAmerican Eagle Men's & Women's Clothing, Shoes ... : People Also AskMuhafeez GoolabNo ratings yet

- Af - Google SearchDocument2 pagesAf - Google SearchMuhafeez GoolabNo ratings yet

- Ad - Google SearchDocument2 pagesAd - Google SearchMuhafeez GoolabNo ratings yet

- British Airways: Prime: Encore Moins CherDocument2 pagesBritish Airways: Prime: Encore Moins CherMuhafeez GoolabNo ratings yet

- A - Google SearchDocument2 pagesA - Google SearchMuhafeez GoolabNo ratings yet

- Culvert - Google SearchDocument3 pagesCulvert - Google SearchMuhafeez GoolabNo ratings yet

- About 8,720,000,000 Results (0.57 Seconds) : Rating Hours Your Past VisitsDocument2 pagesAbout 8,720,000,000 Results (0.57 Seconds) : Rating Hours Your Past VisitsMuhafeez GoolabNo ratings yet

- L - Google SearchDocument2 pagesL - Google SearchMuhafeez GoolabNo ratings yet

- Boxes - Google SearchDocument3 pagesBoxes - Google SearchMuhafeez GoolabNo ratings yet

- C - Google SearchDocument3 pagesC - Google SearchMuhafeez GoolabNo ratings yet

- Culvert Design - Google SearchDocument3 pagesCulvert Design - Google SearchMuhafeez GoolabNo ratings yet

- Kendrick Lamar - I (Official Video) - Youtube: LyricsDocument3 pagesKendrick Lamar - I (Official Video) - Youtube: LyricsMuhafeez GoolabNo ratings yet

- Box Culvert - Google SearchDocument3 pagesBox Culvert - Google SearchMuhafeez GoolabNo ratings yet

- PDF To Rar - Google SearchDocument2 pagesPDF To Rar - Google SearchMuhafeez GoolabNo ratings yet

- PDF To Outlook - Google SearchDocument2 pagesPDF To Outlook - Google SearchMuhafeez GoolabNo ratings yet

- PDF To Word - Google SearchDocument2 pagesPDF To Word - Google SearchMuhafeez GoolabNo ratings yet

- JANUARY 2020 EdDocument12 pagesJANUARY 2020 EdNa ToyNo ratings yet

- Box - Google SearchDocument2 pagesBox - Google SearchMuhafeez GoolabNo ratings yet

- People Also Ask: About 4,750,000,000 Results (0.77 Seconds)Document3 pagesPeople Also Ask: About 4,750,000,000 Results (0.77 Seconds)Muhafeez GoolabNo ratings yet

- PDF To Excel - Google SearchDocument2 pagesPDF To Excel - Google SearchMuhafeez GoolabNo ratings yet

- PDF To JPG - Google SearchDocument2 pagesPDF To JPG - Google SearchMuhafeez GoolabNo ratings yet

- Jan Feb: New Year'S Day Mlkingday Valentine'S Day Presidents' DayDocument5 pagesJan Feb: New Year'S Day Mlkingday Valentine'S Day Presidents' DayMuhafeez GoolabNo ratings yet

- 2021 Calendar with HolidaysDocument5 pages2021 Calendar with HolidaysMuhafeez GoolabNo ratings yet

- PDF To Autocad - Google SearchDocument3 pagesPDF To Autocad - Google SearchMuhafeez GoolabNo ratings yet

- Fiscal Year Calendar: April July October JanuaryDocument1 pageFiscal Year Calendar: April July October JanuaryMuhafeez GoolabNo ratings yet

- JANUARY 2020 EdDocument12 pagesJANUARY 2020 EdNa ToyNo ratings yet

- 2021 Yearly Blank Calendar TemplateDocument1 page2021 Yearly Blank Calendar TemplateMuhafeez GoolabNo ratings yet

- 2017 Retail Accounting Calendar 4 4 5Document2 pages2017 Retail Accounting Calendar 4 4 5Soh amNo ratings yet

- 2017 Retail Accounting Calendar 4 4 5Document2 pages2017 Retail Accounting Calendar 4 4 5Soh amNo ratings yet

- 2017 Retail Accounting Calendar 4 4 5Document2 pages2017 Retail Accounting Calendar 4 4 5Soh amNo ratings yet

- SpecsDocument1,051 pagesSpecsمعاذ كروبينNo ratings yet

- BOQ SampleDocument5 pagesBOQ SampleSumit yadavNo ratings yet

- Bill of Materials: Item Description EarthworksDocument3 pagesBill of Materials: Item Description EarthworksjoemarNo ratings yet

- Yim018x AnnualbookASTM StandardDocument14 pagesYim018x AnnualbookASTM StandardMohammed Gabr AgamyNo ratings yet

- Power Actuated FastenersDocument8 pagesPower Actuated FastenersNicolaNo ratings yet

- Chapter 2 PDFDocument35 pagesChapter 2 PDFJeisther Timothy Galano0% (1)

- Sahaspur-A SoR MORTHDocument70 pagesSahaspur-A SoR MORTHSamNo ratings yet

- BoQ Hilsa Bypass EastDocument11 pagesBoQ Hilsa Bypass EastsarsijNo ratings yet

- Black Elegant Architecture PresentationDocument3 pagesBlack Elegant Architecture Presentationshreya partiNo ratings yet

- Analysis For Deviation ItemsDocument91 pagesAnalysis For Deviation Itemsattanti nNo ratings yet

- Ra-09 Abstract SheetDocument23 pagesRa-09 Abstract SheetYash DeoreNo ratings yet

- Toyota Gujrat Motors Civil Works BoqDocument3 pagesToyota Gujrat Motors Civil Works BoqJahanzeb KhanNo ratings yet

- Cement and Concrete Research 35 (2005) 1472 – 1479 Concrete blocks for thermal insulation in hot climateDocument8 pagesCement and Concrete Research 35 (2005) 1472 – 1479 Concrete blocks for thermal insulation in hot climateaduquegoNo ratings yet

- Cement ConclusionDocument8 pagesCement ConclusionMunira Husain100% (1)

- Detailed Estimate of Stree Shakti BhavanDocument9 pagesDetailed Estimate of Stree Shakti BhavanObuladas MNo ratings yet

- Unit 7 Modern Trends in Construction: StructureDocument27 pagesUnit 7 Modern Trends in Construction: StructureRaj BakhtaniNo ratings yet

- Bill NR 02 - Consolidated Building WorksDocument20 pagesBill NR 02 - Consolidated Building Worksmoh amohNo ratings yet

- 2015 Nepal Earthquake Damage Assessment Survey PDFDocument8 pages2015 Nepal Earthquake Damage Assessment Survey PDFDiwash DahalNo ratings yet

- ASHRAE 2019 Thermal Evaluation of Masonry Shelf Angle SupportsDocument9 pagesASHRAE 2019 Thermal Evaluation of Masonry Shelf Angle SupportsSugarPOP666No ratings yet

- Brick BondsDocument2 pagesBrick BondsPradeep Chowdary ManneNo ratings yet

- Contractors' Submittals ChecklistDocument2 pagesContractors' Submittals ChecklistAvinaash VeeramahNo ratings yet

- Waterproofing Handbook HB-1 PDFDocument162 pagesWaterproofing Handbook HB-1 PDFDianna LambertNo ratings yet

- Vasant Matsagar (Eds.) - Advances in Structural Engineering - Materials, Volume Three 3 (2015, Springer India) PDFDocument1,033 pagesVasant Matsagar (Eds.) - Advances in Structural Engineering - Materials, Volume Three 3 (2015, Springer India) PDFKarnalPreeth100% (2)

- Bs 6073 11981 14414Document3 pagesBs 6073 11981 14414VasaNo ratings yet

- Material Progress 2Document217 pagesMaterial Progress 2severalchanceNo ratings yet

- AnconDocument40 pagesAnconRobbie van LeeuwenNo ratings yet

- Key Notes: Roof-Wall DetailDocument2 pagesKey Notes: Roof-Wall DetailJaouad IDBOUBKERNo ratings yet

- Stone Masonry and Precast Block Masonry Work: NotesDocument9 pagesStone Masonry and Precast Block Masonry Work: NotesVarma ChintamaneniNo ratings yet

- Introduction of Seismic Design Categories in IS 1893Document8 pagesIntroduction of Seismic Design Categories in IS 1893vatsalgokaniNo ratings yet