Professional Documents

Culture Documents

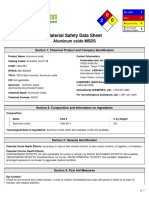

Sodium Aluminate SDS USALCO

Uploaded by

Michelle ErasmusCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Sodium Aluminate SDS USALCO

Uploaded by

Michelle ErasmusCopyright:

Available Formats

Sodium aluminate

MSDS No. 132

4/30/2013

Safety Data Sheet

Section 1 - Chemical Product and Company Identification

Product/Chemical Name:

Sodium aluminate, solution

Chemical Family:

General Use:

Emergency Contact:

Inorganic salt

Water Treatment Chemical

800-282-5322

Manufacturer:

USALCO, LLC

2601 Cannery Ave

Baltimore, MD 21226

Phone 410-354-0100 (7:00am 5:00pm)

FAX

410-354-1021

HMIS

H 3

F

0

R 0

PPE

Sec. 11

Section 2 - Composition / Information on Ingredients

Ingredient Name

Sodium aluminate

Sodium hydroxide

Water

Ingredient

Sodium aluminate

CAS Number

1302-42-7

1310-73-2

7732-18-5

OSHA PEL

TWA

STEL

none estab.

2 mg/m3

ACGIH TLV

TWA

STEL

none estab.

as aluminum

2 mg/m3

% wt

31-45

3-9

52-66

NIOSH REL

TWA

STEL

none estab.

as aluminum

2 mg/m3

NIOSH

IDLH

none estab.

as aluminum

Section 3 - Emergency Overview

Description: Viscous colorless to amber liquid with no or very mild odor. Not flammable. Not volatile

Hazards:

Corrosive; pH 14. Causes burns. Harmful by contact with skin and if swallowed. Risk of serious

damage to eyes. Not flammable, but may release toxic vapors if decomposed in a fire.

Section 4 - First Aid Procedures

Overview:

Inhalation:

Eye Contact:

Skin Contact:

Ingestion:

Direct contact can cause corrosive burns and permanent injury.

(mist or spray) Remove from exposure; seek medical treatment if any symptoms occur.

Immediately flush with large amounts of water for at least 15 minutes, occasionally

lifting upper and lower lids. Seek medical attention.

Remove contaminated clothing and flush contact area with large amounts of water for

at least 15 minutes. Seek medical attention if any symptoms are present.

Do not induce vomiting, drink milk or water and immediately seek medical attention.

After first aid, get appropriate in-plant, paramedic, or community medical support.

Section 5 - Physical and Chemical Properties

Physical State:

Characteristics

Odor:

Vapor Pressure:

Specific Gravity

(H2O=1, at 4 C):

Vapor Density (Air=1):

Liquid

Clear to amber liquid

Odorless

Not applicable

1.44-1.56

Not applicable

Water Solubility:

Melting/Freezing Point:

Boiling Point:

% Volatile:

Viscosity:

pH:

Complete

0 to 12 F (-18 to -11C)

220-240F (104-116 C)

0.0

>2000 cps. @ 20F

200-800 cps. @ 68F

14.0

Page 1 of 4

Sodium aluminate

MSDS No. 132

Section 6 - Fire-Fighting Measures

NFPA

NA

NA

NA

NA

NA

Not flammable

NA

None

None

Do not release runoff from fire control methods to sewers or waterways.

Flash Point:

Burning Rate:

Autoignition Temperature:

LEL:

UEL:

Flammability:

Extinguishing Media:

Unusual Fire or Explosion Hazards:

Hazardous Combustion Products:

Fire-Fighting Instructions:

Section 7 - Stability and Reactivity

Stability:

Polymerization:

Chemical Incompatibilities:

Hazardous Decomposition

Products:

Will generate heat on contact with water and will hydrolyze to sodium hydroxide and

aluminum hydroxide.

Hazardous polymerization does not occur.

Incompatible with acids.

None.

Section 8 - Health Hazard Information

Primary Entry Routes:

Target Organs:

Acute Effects:

Eye:

Skin:

Ingestion:

Carcinogenicity:

Medical Conditions

Aggravated by LongTerm Exposure:

Chronic Effects:

Ingestion, contact

N/A

Chemical (caustic) burns

Chemical burn

Chemical burn

Burns, nausea, vomiting, diarrhea, stomach pain

IARC, NTP, and OSHA do not list Sodium aluminate as a carcinogen

Skin rashes

IARC, NTP, and OSHA do not list

Section 9 - Spill, Leak, and Disposal Procedures

Spill /Leak Procedures:

Small Spills:

Large Spills:

Cleanup:

Regulatory Requirements:

Disposal:

Container Cleaning and

Disposal:

4/30/2013

Wear appropriate personal protective equipment. Do not come in contact with spilled

material.

Neutralize with sodium bicarbonate or weak acid solution.

Dike and transfer spill to container for reuse and reprocessing. Can flush

contaminated areas with large amounts of water and direct rinsing to chemical sewer

or collect for treatment.

Recover liquid when possible. Wash impacted areas with water to remove residues.

Waste Sodium aluminate is not a RCRA listed hazardous waste. Waste material can

be a RCRA Characteristic Waste (D002) if not neutralized.

Contact your supplier or a licensed contractor for detailed recommendations. Follow

applicable Federal, State, and local regulations.

Rinse with water, dispose of containers in accordance with State and local regulations.

Page 2 of 4

Sodium aluminate

MSDS No. 132

Section 10 - Regulatory Information

EPA Regulations:

RCRA Hazardous Waste Classification:

CERCLA Hazardous Substance (40 CFR 302.4):

CERCLA Reportable Quantity (RQ):

SARA 311/312 Codes:

SARA Toxic Chemical (40 CFR 372.65):

SARA EHS (Extremely Hazardous Substance) (40 CFR 355):

OSHA Regulations:

Air Contaminant (29 CFR 1910.1000, Table Z-1, Z-1-A):

OSHA Specifically Regulated Substance (29CFR 1910.):

State Regulations:

D002 (Corrosive) if the pH of the waste is 12.5

Not listed CWA, Sec. 311 (b)(4)

Not listed

Immediate (acute) health hazard

Not listed

Not listed

Not listed

Not listed

USALCO, LLC has not determined regulatory

requirements for individual states.

Section 11 - Exposure Controls / Personal Protection

Ventilation:

Respiratory Protection:

Protective

Clothing/Equipment:

Safety Stations:

Contaminated

Equipment:

Comments:

Under normal conditions, Sodium aluminate solution will not generate mists or vapors. No

special ventilation is recommended.

Seek professional advice prior to respirator selection and use. Follow OSHA respirator

regulations (29 CFR 1910.134) and, if necessary, wear a MSHA/NIOSH-approved respirator.

Select respirator based on its suitability to provide adequate worker protection for given

working conditions, level of airborne contamination, and presence of sufficient oxygen. For

emergency or non-routine operations (cleaning spills, reactor vessels, or storage tanks), wear

an SCBA. Warning! Air-purifying respirators do not protect workers in oxygen-deficient

atmospheres. If respirators are used, OSHA requires a written respiratory protection program

that includes at least: medical certification, training, fit-testing, periodic environmental

monitoring, maintenance, inspection, cleaning, and convenient, sanitary storage areas.

Wear chemically protective gloves, boots, aprons, and gauntlets to prevent prolonged or

repeated skin contact. Wear protective chemical safety goggles, per OSHA eye- and faceprotection regulations (29 CFR 1910.133). Contact lenses are not eye protective devices.

Appropriate eye protection must be worn instead of, or in conjunction with contact lenses.

Make emergency eyewash stations, safety/quick-drench showers, and washing facilities

available in work area.

Separate contaminated work clothes from street clothes. Launder before reuse. Remove this

material from your shoes and clean personal protective equipment.

Never eat, drink, or smoke in work areas. Practice good personal hygiene after using this

material, especially before eating, drinking, smoking, using the toilet, or applying cosmetics.

Section 12 - Special Precautions and Comments

Handling Precautions:

Storage Requirements:

4/30/2013

Ensure that all containers are labeled in accordance with OSHA regulations. Avoid skin and

eye contact. Wear appropriate protective clothing. Material is slippery; use caution if walking

on spilled material.

Keep containers tightly closed when not in use.

Page 3 of 4

Sodium aluminate

MSDS No. 132

Section 13 - DOT Transportation Data (49 CFR 172.101)

Proper Shipping Name:

Shipping Symbols:

Hazard Class:

DOT No.:

Packing Group:

Label:

Special Provisions (172.102):

2008 Emergency Response

Guidebook:

UN1819, Sodium aluminate,

solution, 8, II

8

UN1819

II

Corrosive

IB3,T4,TP1

Guide 154

Packaging Authorizations

a) Exceptions:

b) Non-bulk Packaging:

c) Bulk Packaging:

Quantity Limitations

a) Passenger, Aircraft, or Railcar:

b) Cargo Aircraft Only:

Vessel Stowage Requirements

a) Location:

b) Other:

173.154

173.203

173.241

1L

30 L

A

52

Prepared By: Craig T. Owen

Effective Date: 2/1/2012 Supercedes: NA

Disclaimer: The information presented herein is believed to be accurate and reliable, but is given without guaranty or

warranty, expressed or implied. The user should not assume that all safety measures are indicated so that other measures may

not be required. The user is responsible for assuring that the product and equipment are used in a safe manner that complies

with all appropriate legal standards and regulations.

4/30/2013

Page 4 of 4

You might also like

- Material Safety Data Sheet: Section 1 - Chemical Product and Company IdentificationDocument5 pagesMaterial Safety Data Sheet: Section 1 - Chemical Product and Company IdentificationSafqur RahmanNo ratings yet

- SMS ASTM 187 192 KrollsDocument5 pagesSMS ASTM 187 192 KrollsRavi TejaNo ratings yet

- Boulder Creek Brick and Tile MSDSDocument5 pagesBoulder Creek Brick and Tile MSDSAlexi MilanNo ratings yet

- Material Safety Data Sheet: Revision Date: 07/11/05 Supercedes: 04/08/05 Activated AluminaDocument4 pagesMaterial Safety Data Sheet: Revision Date: 07/11/05 Supercedes: 04/08/05 Activated Aluminasakura_jNo ratings yet

- Polyaluminium Chloride MSDS DikonversiDocument7 pagesPolyaluminium Chloride MSDS DikonversiPUJI ASTUTINo ratings yet

- Safety Data Sheet for Sulfuric AcidDocument4 pagesSafety Data Sheet for Sulfuric AcidphyphoNo ratings yet

- PDMS MSDSDocument6 pagesPDMS MSDSRazleen RashidiNo ratings yet

- MSDS Barium ChlorideDocument6 pagesMSDS Barium ChloriderozanNo ratings yet

- ISO9001:2000 Certified Zinc Sulfate MSDSDocument6 pagesISO9001:2000 Certified Zinc Sulfate MSDSMerry PaembonanNo ratings yet

- 175 PacDocument7 pages175 PacRACHMAD ARIFUDDINNo ratings yet

- Msds AluminaDocument6 pagesMsds AluminayaderNo ratings yet

- Novec1230 MSDSDocument6 pagesNovec1230 MSDSoscarninanNo ratings yet

- MSDS - Robond L-330 - ISS130910Document7 pagesMSDS - Robond L-330 - ISS130910Anonymous pXU4tefJNo ratings yet

- RTV GasDocument5 pagesRTV GasNathan De Los SantosNo ratings yet

- MSDS LyeDocument5 pagesMSDS LyeAditya BayuNo ratings yet

- Material Safety Data Sheet for IronDocument7 pagesMaterial Safety Data Sheet for IronRiza ApreliaNo ratings yet

- Material Safety Data Sheet for IronDocument7 pagesMaterial Safety Data Sheet for IronIlham NugrahaNo ratings yet

- Msds Al2o3 PDFDocument6 pagesMsds Al2o3 PDFNazuah Ushwatun HassanahNo ratings yet

- Msds Dow 732 Sealant PDFDocument7 pagesMsds Dow 732 Sealant PDFJake WestlakeNo ratings yet

- Sodium Acetate MSDSDocument6 pagesSodium Acetate MSDSZella ElfiraNo ratings yet

- Material Safety Data SheetDocument7 pagesMaterial Safety Data SheetZahra AnnisaNo ratings yet

- Modelo de Ficha de SegurançaDocument8 pagesModelo de Ficha de SegurançaGUSTAVONo ratings yet

- Naval JellyDocument4 pagesNaval JellyjohnsopranaNo ratings yet

- MSDS - Test ADocument4 pagesMSDS - Test AjrewingheroNo ratings yet

- CBS Material Safety Data SheetDocument3 pagesCBS Material Safety Data SheetHerdianNo ratings yet

- ESM-MBF Material Safety Data SheetDocument4 pagesESM-MBF Material Safety Data SheetDamien OlverNo ratings yet

- CD Msds For Ups SeriesDocument4 pagesCD Msds For Ups Seriesapi-170472102No ratings yet

- Material Safety Data Sheet: I - Product IdentificationDocument2 pagesMaterial Safety Data Sheet: I - Product IdentificationAndini Nur PaujiahNo ratings yet

- Hoja de Seguridad 242Document6 pagesHoja de Seguridad 242Gabo TellezNo ratings yet

- Material Safety Data Sheet Gold - Core Material: Section 1: Product and Company IdentificationDocument4 pagesMaterial Safety Data Sheet Gold - Core Material: Section 1: Product and Company Identificationfabiosan5No ratings yet

- 00019023Document4 pages00019023Dgek LondonNo ratings yet

- JD Sunlight Liq DishDocument4 pagesJD Sunlight Liq DishmansuraquelNo ratings yet

- Material Safety Data Sheet: Section 1 - Chemical Product and Company IdentificationDocument5 pagesMaterial Safety Data Sheet: Section 1 - Chemical Product and Company IdentificationManikandan VijayanNo ratings yet

- Acetaldol MsdsDocument6 pagesAcetaldol Msdsdlr1233No ratings yet

- Safety Data Sheet: Air-Shield Flashing Tape W. R. Meadows®, IncDocument2 pagesSafety Data Sheet: Air-Shield Flashing Tape W. R. Meadows®, IncsebaversaNo ratings yet

- Asia Wd40 Aerosol Msds 2012Document4 pagesAsia Wd40 Aerosol Msds 2012Sarliza JafarNo ratings yet

- Silver Iodide MSDS SheetDocument6 pagesSilver Iodide MSDS SheetMichael Janitch100% (1)

- Sodium Sulfate MSDSDocument5 pagesSodium Sulfate MSDSVickiNo ratings yet

- Material Safety Data Sheet: Ammonium Chloride PureDocument6 pagesMaterial Safety Data Sheet: Ammonium Chloride PureApriliaPuspitaSNo ratings yet

- Bostex 817 Masterbatch Cure Dispersion For Nitrile Latex MSDSDocument3 pagesBostex 817 Masterbatch Cure Dispersion For Nitrile Latex MSDShemya7No ratings yet

- Safety Data Sheet: Section 1 - Chemical Product and Company IdentificationDocument5 pagesSafety Data Sheet: Section 1 - Chemical Product and Company IdentificationnilNo ratings yet

- NaOH MSDSDocument4 pagesNaOH MSDSTeguh PambudiNo ratings yet

- Material Safety Data Sheet: 1. Product and Company IdentificationDocument6 pagesMaterial Safety Data Sheet: 1. Product and Company Identificationsarvan shivaNo ratings yet

- Acetylsalicylic Acid MSDSDocument4 pagesAcetylsalicylic Acid MSDSMichelle100% (1)

- Material Safety Data Sheet: Section 1 - Chemical Product and Company IdentificationDocument7 pagesMaterial Safety Data Sheet: Section 1 - Chemical Product and Company Identificationsuraj rawatNo ratings yet

- Safety Data Sheet: SECTION 1. Identification of The Substance/mixture and of The Company/undertakingDocument11 pagesSafety Data Sheet: SECTION 1. Identification of The Substance/mixture and of The Company/undertakingBalaji NamachivayamNo ratings yet

- 346msds 0Document2 pages346msds 0RAY NEIL B. MARZANNo ratings yet

- Bostex 827 Masterbatch Cure Dispersion For Natural Latex Balloons MSDSDocument3 pagesBostex 827 Masterbatch Cure Dispersion For Natural Latex Balloons MSDShemya7No ratings yet

- Proven Citrus Degreaser MSDS 56536Document3 pagesProven Citrus Degreaser MSDS 56536Andika WidriantamaNo ratings yet

- Oil Eater Degreaser Cleaner Kafko InternationalDocument3 pagesOil Eater Degreaser Cleaner Kafko InternationalstevgonNo ratings yet

- MSDS Yellow No 010 Aluminum Lake-7Document8 pagesMSDS Yellow No 010 Aluminum Lake-7Vanti_805100% (1)

- Seachem Laboratories, Inc. Safety Data Sheet Cover Multitest: IronDocument19 pagesSeachem Laboratories, Inc. Safety Data Sheet Cover Multitest: IronJorge Restrepo HernandezNo ratings yet

- Dow 1111Document7 pagesDow 1111Jorge PerezNo ratings yet

- MSD Standapol WAQ-LC PDFDocument8 pagesMSD Standapol WAQ-LC PDFarguijNo ratings yet

- Gas Sweetening and Processing Field ManualFrom EverandGas Sweetening and Processing Field ManualRating: 4 out of 5 stars4/5 (7)

- Case Studies of Material Corrosion Prevention for Oil and Gas ValvesFrom EverandCase Studies of Material Corrosion Prevention for Oil and Gas ValvesNo ratings yet

- The Health & Safety Guide for Film, TV & Theater, Second EditionFrom EverandThe Health & Safety Guide for Film, TV & Theater, Second EditionRating: 4 out of 5 stars4/5 (1)

- FAQs Smart Broadband Wireless LTEAv 2Document5 pagesFAQs Smart Broadband Wireless LTEAv 2Michelle ErasmusNo ratings yet

- Fan Selection GuideDocument29 pagesFan Selection GuideLeonardoTellezCastellanosNo ratings yet

- Blower DesignDocument5 pagesBlower DesignMichelle ErasmusNo ratings yet

- Optimal Cost Design of Water Distribution NetworksDocument49 pagesOptimal Cost Design of Water Distribution NetworksYoussefNo ratings yet

- Report - Design of Water Distribution MethodsDocument17 pagesReport - Design of Water Distribution MethodsMichelle ErasmusNo ratings yet

- Design of Drinking Water Distribution Network: Fig. 8.1 - Fire HydrantDocument8 pagesDesign of Drinking Water Distribution Network: Fig. 8.1 - Fire Hydrantmbadshah2113No ratings yet

- Best Technologies in Litter ManagmentDocument7 pagesBest Technologies in Litter ManagmentMichelle ErasmusNo ratings yet

- Urban River RestorationDocument22 pagesUrban River RestorationMichelle Erasmus100% (1)

- RED Book Volume - IIDocument379 pagesRED Book Volume - IIImraanNo ratings yet

- Study Water Distribution Using EPANET SoftwareDocument9 pagesStudy Water Distribution Using EPANET SoftwareMichelle ErasmusNo ratings yet

- Ceramic Materials Guide: Properties, Classification and ProcessingDocument16 pagesCeramic Materials Guide: Properties, Classification and ProcessingJanarthanan. J.SNo ratings yet

- Block Diagram New DM PlantDocument1 pageBlock Diagram New DM PlantDevraj RoyNo ratings yet

- Ameridex O M 2.0Document21 pagesAmeridex O M 2.0Jamil Moreira QuirozNo ratings yet

- To Study The Presence of Oxalate Ion in Guava Fruit at Different Stages of RipeningDocument10 pagesTo Study The Presence of Oxalate Ion in Guava Fruit at Different Stages of RipeningKapeesh Tapadia0% (1)

- Fungal degradation of microbial and synthetic polyestersDocument10 pagesFungal degradation of microbial and synthetic polyestersJUAN SEBASTIAN BUSTOS GARNICANo ratings yet

- Topic 9 and 10 - Weathering ReportDocument9 pagesTopic 9 and 10 - Weathering ReportTylenol-.-No ratings yet

- Fabrication and Analysis of Thermocol Sandwiched Between Bamboo Fiber-Reinforced Phenol Formaldehyde Composite LaminatesDocument6 pagesFabrication and Analysis of Thermocol Sandwiched Between Bamboo Fiber-Reinforced Phenol Formaldehyde Composite LaminatesShiva ChandrasekharanNo ratings yet

- RESERVOIR MANAGEMENT PLAN (RMP) Rev 1Document17 pagesRESERVOIR MANAGEMENT PLAN (RMP) Rev 1Mohd RezalNo ratings yet

- Organometallic ChemistryDocument7 pagesOrganometallic ChemistryBrinzei Lucian0% (1)

- NAILS Bar Stock Monthly ReportDocument20 pagesNAILS Bar Stock Monthly ReportcaliyaNo ratings yet

- ميد Fire behaviourDocument117 pagesميد Fire behaviourOmar NaimatNo ratings yet

- Disintegration TestDocument75 pagesDisintegration TestJanine Marie Barnachea63% (8)

- The Role of Energy Valuation of Agroforestry Biomass On The Circular economy2020EnergiesOpen AccessDocument13 pagesThe Role of Energy Valuation of Agroforestry Biomass On The Circular economy2020EnergiesOpen AccessRômulo FreitasNo ratings yet

- Chapter 4 The Structure of The Atom Worksheet 1Document2 pagesChapter 4 The Structure of The Atom Worksheet 1Joy LeannaNo ratings yet

- PC Boiler Corrosion Erosion White Paper r3Document16 pagesPC Boiler Corrosion Erosion White Paper r3José AndradeNo ratings yet

- Topological Properties of Doxorubicin Conjugated PEG-PAsp CopolymerDocument15 pagesTopological Properties of Doxorubicin Conjugated PEG-PAsp CopolymerBilal HassanNo ratings yet

- Iodine Value of OilDocument3 pagesIodine Value of OilUsman Ghani100% (2)

- Daftar Harga Ekatalog PT. IGM 2020Document6 pagesDaftar Harga Ekatalog PT. IGM 2020naelarizqiNo ratings yet

- NTEP PD Meters (92-141A6)Document5 pagesNTEP PD Meters (92-141A6)Jesus JavierNo ratings yet

- Electro Isola Material ClassificationDocument1 pageElectro Isola Material ClassificationFelix SelorioNo ratings yet

- Candour Lifecure India Pvt. LTDDocument2 pagesCandour Lifecure India Pvt. LTDPawan YadavNo ratings yet

- Saluyot Corchorous Olitorius Leaf Extract As An Alternative All Pupose SuperglueDocument95 pagesSaluyot Corchorous Olitorius Leaf Extract As An Alternative All Pupose SuperglueZIAN LABADIA100% (2)

- Natural Gas Production, Transportation - StorageDocument36 pagesNatural Gas Production, Transportation - StorageNeeraj YadavNo ratings yet

- Chapter 8. Ethers and EpoxidesDocument10 pagesChapter 8. Ethers and Epoxideshanna liuNo ratings yet

- Notre Dame Microbiology ModuleDocument6 pagesNotre Dame Microbiology ModuleAlpha-z PrinNo ratings yet

- SDS-Copper Zinc Catalyst - WOLF TRAX - Copper - KOCH Agronomic Services US-CAN 2021-0602Document9 pagesSDS-Copper Zinc Catalyst - WOLF TRAX - Copper - KOCH Agronomic Services US-CAN 2021-0602AlNo ratings yet

- Repair and Reinforcing Techniques for Steel ComponentsDocument108 pagesRepair and Reinforcing Techniques for Steel ComponentsValy CoulibalyNo ratings yet

- Errors in The Construction Site and How To Avoid ThemDocument6 pagesErrors in The Construction Site and How To Avoid ThemAriana CabellonNo ratings yet

- Lesson 2.2 Substituted Hydrocarbons ContinuedDocument20 pagesLesson 2.2 Substituted Hydrocarbons Continuedb00097187No ratings yet

- PCP Approved Curriculum For Industrial PharmacyDocument1 pagePCP Approved Curriculum For Industrial PharmacySyed ShahzaidNo ratings yet