Professional Documents

Culture Documents

DrillPipe, 80%, 3.500 OD, 0.449 Wall, EU, X-95.. XT39 (4.938 X 2.500)

Uploaded by

Johann ZabaletaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

DrillPipe, 80%, 3.500 OD, 0.449 Wall, EU, X-95.. XT39 (4.938 X 2.500)

Uploaded by

Johann ZabaletaCopyright:

Available Formats

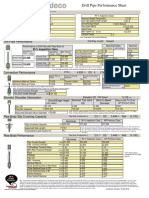

Drill Pipe Performance Sheet

www.NOV.com/GrantPrideco

Phone: +1 (281) 878-8000

Drill Pipe Configuration

Pipe Body OD

Pipe Body Wall Thickness

Pipe Body Grade

Drill Pipe Length

Connection

Tool Joint OD

Tool Joint ID

Pin Tong

Box Tong

(in)

(in)

(in)

(in)

(in)

(in)

80 % Inspection Class

Nominal Weight Designation

15.50

(ft) 31.8

Drill Pipe Approximate Length

(in) 3/32 Raised

SmoothEdge Height

(psi) 120,000

Tool Joint SMYS

Upset Type

EU

(in) 3.875

Max Upset OD (DTE)

Friction Factor

1.0

3.500

0.449

X-95

Range2

XT39

4.938

2.500

10

15

Note: Tong space may include hardfacing.

Drill-Pipe Length

Drill Pipe Performance

Best Estimates

Performance of Drill Pipe with Pipe Body at

(without Coating)

80 % Inspection Class

Applied Make-up

Torque

Max Tension

Operational

Torque (ft-lbs)

(lbs)

(ft-lbs)

Maximum MUT

23,900

Minimum MUT

19,900

Tension Only

Combined Loading

Tension Only

Combined Loading

0

18,100

317,500

149,100

0

18,800

317,500

126,600

Drill Pipe Adjusted Weight

Fluid Displacement

Fluid Displacement

Fluid Capacity

Fluid Capacity

Drift Size

17.89

0.27

(Bbls/ft) 0.0065

(gal/ft) 0.26

(Bbls/ft) 0.0063

(in) 2.375

XT39

4.938

Applied Make-up

Tension at Shoulder

Torque

Separation

(ft-lbs)

23,900

19,900

(ft-lbs)

(lbs)

Tensile Limited

720,700

SmoothEdge Height

(in)

(lbs)

3/32 Raised

5.125

909,200

Assumed Elevator Bore Diameter

17.28

0.26

0.0063

0.27

0.0065

(lbs/ft)

0.26

0.0062

(lbs)

OD X

(in)

2.500

Tension at Connection

Yield

(lbs)

646,800

753,900

ID

(in)

120,000

(psi)

Tool Joint Dimensions

Balanced OD

(in)

Minimum Tool Joint OD for API

(in)

Premium Class

Minimum Tool Joint OD for

Counterbore

(in)

5.024

4.653

4.653

39,800

753,900

Elevator Shoulder Information

Box OD

Elevator Capacity

(least accurate)

(gal/ft)

Note: The maximum make-up torque should be applied when possible.

Note: To maximize connection operational tensile, a MUT (T4) = 20,800 (ft-lbs) should be applied.

Tool Joint Torsional Strength

Tool Joint Tensile Strength

Nominal

(with Coating)

Note: Oil field barrel equals 42 US gallons.

Note: Drill pipe assembly values are best estimates and may vary due to pipe body mill tolerance, internal plastic coating, and other factors.

Connection Performance

Maximum Make-up Torque

Minimum Make-up Torque

Range2

(in)

Elevator OD 3/32 Raised

Nominal Tool Joint

Worn to Bevel

OD

Diameter

Worn to Min TJ OD for

API Premium Class

4.938

746,000

4.653

510,100

Pipe Body Slip Crushing Capacity

Pipe Body Configuration

Nominal

Assumed Slip Length

Transverse Load Factor (K)

(lbs)

(in)

Pipe Body Performance

318,800

(ft-lbs)

(ft-lbs)

(psi)

(psi)

(in)

(in)

(in)

(in^2)

(in^2)

(in^2)

(in^3)

(in^3)

3.5 (in) OD

80 % Inspection Class

250,800

Pipe Body Configuration

(lbs)

0.449 (in) Wall

X-95 )

API Premium Class

250,800

Note: Slip Crushing: Slip crushing load is calculated with the Spiri-Reinhold equation from Why Does Drill Pipe

Fail in the Slip Area World Oil, 1959 for the slip length and transverse load factor shown and is for reference

only. Slip crushing is dependent on the slip design and condition, coefficient of friction, loading conditions, time in

slips, drill pipe OD and wall variation, and other factors. Consult with the slip manufacturer for additional

information.

16.5

4.2

Nominal

Pipe Tensile Strength

Pipe Torsional Strength

TJ/PipeBody Torsional Ratio

80% Pipe Torsional Strength

Burst

Collapse

Pipe OD

Wall Thickness

Nominal Pipe ID

Cross Sectional Area of Pipe Body

Cross Sectional Area of OD

Cross Sectional Area of ID

Section Modulus

Polar Section Modulus

(in)

Note: Elevator capacity based on assumed Elevator Bore, no wear factor, and contact stress of 110,100psi.

Note: A raised elevator OD increases elevator capacity without affecting make-up torque.

3.969

Slip Crushing Capacity

4.786

618,600

5.125

408,800

26,700

1.49

21,400

21,328

21,247

3.500

0.449

2.602

4.304

9.621

5.317

2.923

5.847

3.5 (in) OD

80 % Inspection Class

317,500

20,500

1.95

16,400

19,499

18,331

3.320

0.359

2.602

3.342

8.659

5.317

2.239

4.477

0.449 (in) Wall

X-95 )

API Premium Class

317,500

20,500

1.95

16,400

19,499

18,331

3.320

0.359

2.602

3.342

8.659

5.317

2.239

4.477

Note: Nominal Burst

calculated at 87.5% RBW

per API.

Note: The technical information contained herein, including the product performance sheet and other attached documents, is for reference only and should not be construed as a recommendation. The user is fully

responsible for the accuracy and suitability of use of the technical information. NOV Grant Prideco cannot assume responsibility for the results obtained through the use of this material. No expressed or implied

warranty is intended. Drill pipe assembly properties are calculated based on uniform OD and wall thickness. No safety factor is applied. The information provided for various inspection classes and for various wear

conditions (remaining body wall) is for information only and does not represent or imply acceptable operating limits. It is the responsibility of the customer and the end user to determine the appropriate performance

ratings, acceptable use of the product, maintain safe operational practices, and to apply a prudent safety factor suitable for the application. For API connections that have different pin and box IDs, tool joint ID refers to

the pin ID. Per Chapter B, Section 4 VII of the IADC drilling manual, it is recommended that drilling torque should not exceed 80% of MUT.

www.NOV.com/GrantPrideco/CustomerFeedback

Customer Created 02-03-2014

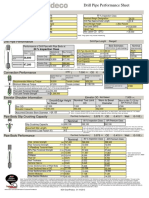

Operational Limits of Drill Pipe

Connection

Pipe Body

XT39

80 % Inspection Class

Tool Joint OD

(in)

4.938

Tool Joint ID

Pipe Body OD

(in)

3.5

Wall Thickness (in) 0.449

(in)

Combined Loading for Drill Pipe at

Maximum Make-up Torque = 23,900

Operational Assembly

Torque

Max Tension

(ft-lbs)

0

1,000

1,900

2,900

3,800

4,800

5,700

6,700

7,600

8,600

9,500

10,500

11,400

12,400

13,300

14,300

15,200

16,200

17,100

18,100

(lbs)

317,500

317,100

316,100

314,200

311,900

308,600

304,900

299,900

294,700

288,000

281,100

272,400

263,600

252,400

241,200

227,000

212,400

193,800

174,100

149,100

Pipe Body Grade

Minimum Make-up Torque = 19,900

(ft-lbs)

Operationa Assembly

l Torque

Max Tension

(ft-lbs)

(lbs)

Pipe Body

Max Tension

(lbs)

(lbs)

(lbs)

317,500

317,500

720,700

317,500

646,800

317,100

646,800

1,000

317,100

317,100

720,700

646,800

2,000

315,900

315,900

720,700

720,700

314,200

646,800

3,000

314,000

314,000

311,900

646,800

3,900

311,600

311,600

720,700

308,600

646,800

4,900

308,200

308,200

720,700

304,900

646,800

5,900

304,000

304,000

720,700

646,800

6,900

298,800

298,800

720,700

646,800

7,900

292,800

292,800

720,700

646,800

8,900

285,800

285,800

720,700

720,700

299,900

294,700

288,000

281,100

646,800

9,900

277,800

277,800

272,400

646,800

10,900

268,600

268,600

720,700

263,600

646,800

11,800

259,300

259,300

720,700

252,400

646,800

12,800

247,600

247,600

720,700

646,800

13,800

234,300

234,300

720,700

646,800

14,800

219,100

219,100

720,700

201,600

201,600

720,700

720,700

241,200

227,000

212,400

15,800

646,800

193,800

646,800

16,800

181,000

181,000

174,100

646,800

17,800

156,300

156,300

720,700

149,100

646,800

18,800

126,600

126,600

720,700

Operational drilling torque is limited by the torsional strength of the pipe

body.

(ft-lbs)

Connection

Max Tension

316,100

X-95

Combined Loading for Drill Pipe at

Connection Max

Pipe Body

Max Tension Tension

(lbs)

Tool Joint Specified Minimum

120,000

(psi)

Yield Strength

2.500

Operational drilling torque is limited by the Make-up Torque.

Connection

Make-up Torque Range

Make-up Torque

(ft-lbs)

Min MUT

Max MUT

19,900

20,300

20,800

21,200

21,700

22,100

22,600

23,000

23,500

23,900

Connection Max

Tension

(lbs)

720,700

735,200

753,300

740,600

723,200

709,300

691,900

678,000

660,700

646,800

Note: Recommended MUT should always be used when possible. If not possible, MUT should be as close to Recommended MUT as possible.

Note: The technical information contained herein, including the product performance sheet and other attached documents, is for reference only and should not be construed as a recommendation. The user is fully responsible for the accuracy and

suitability of use of the technical information. NOV Grant Prideco cannot assume responsibility for the results obtained through the use of this material. No expressed or implied warranty is intended. Drill pipe assembly properties are calculated

based on uniform OD and wall thickness. No safety factor is applied. The information provided for various inspection classes and for various wear conditions (remaining body wall) is for information only and does not represent or imply acceptable

operating limits. It is the responsibility of the customer and the end user to determine the appropriate performance ratings, acceptable use of the product, maintain safe operational practices, and to apply a prudent safety factor suitable for the

application. For API connections that have different pin and box IDs, tool joint ID refers to the pin ID. Per Chapter B, Section 4 VII of the IADC drilling manual, it is recommended that drilling torque should not exceed 80% of MUT.

02-03-2014

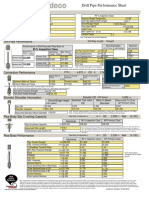

Connection Wear Table

Connection

XT39

Tool Joint OD

Connection

Wear

Tool

Joint OD

New OD

(in)

4.938

4.912

4.886

4.86

4.834

4.808

4.782

4.756

4.731

4.705

4.679

4.653

Worn OD

(in)

4.938

Tool Joint ID

(in)

Tool Joint Specified Minimum

120,000

(psi)

Yield Strength

2.500

Connection Max

Tension

Connection

Torsional

Strength (ft-lbs)

Max

MUT

39,800

39,000

38,100

37,300

36,500

35,700

34,800

34,000

33,300

32,500

31,700

30,900

23,900

23,400

22,900

22,400

21,900

21,400

20,900

20,400

20,000

19,500

19,000

18,600

(ft-lbs)

Connection Max

Tension

Min MUT

(lbs)

(lbs)

(ft-lbs)

646,800

661,100

675,200

689,100

702,900

708,000

698,500

688,200

675,000

640,600

605,800

575,100

19,900

720,700

19,500

709,500

19,100

698,300

18,700

687,000

18,200

672,100

17,800

652,900

17,400

621,400

17,000

590,700

16,600

561,400

16,200

532,200

15,900

507,000

15,500

479,200

Pipe Body

Combined Loading Table (Torque-Tension)

Pipe Body

Pipe Body OD

80 % Inspection Class

Pipe Body Torque

(in)

3.5

Wall Thickness (in) 0.449

Pipe Body Grade

X-95

1,900

3,700

5,600

7,400

9,300

11,200

13,000

14,900

16,700

18,600

20,400

316,100

312,200

305,300

295,900

282,700

265,600

245,100

217,500

183,300

132,000

22,600

(ft-lbs)

Pipe Body Max

317,500

Tension

(lbs)

Note: The technical information contained herein, including the product performance sheet and other attached documents, is for reference only and should not be construed as a recommendation. The user is fully responsible for the accuracy and

suitability of use of the technical information. NOV Grant Prideco cannot assume responsibility for the results obtained through the use of this material. No expressed or implied warranty is intended. Drill pipe assembly properties are calculated

based on uniform OD and wall thickness. No safety factor is applied. The information provided for various inspection classes and for various wear conditions (remaining body wall) is for information only and does not represent or imply acceptable

operating limits. It is the responsibility of the customer and the end user to determine the appropriate performance ratings, acceptable use of the product, maintain safe operational practices, and to apply a prudent safety factor suitable for the

application. For API connections that have different pin and box IDs, tool joint ID refers to the pin ID. Per Chapter B, Section 4 VII of the IADC drilling manual, it is recommended that drilling torque should not exceed 80% of MUT.

02-03-2014

You might also like

- Sizing Ambient VaporizersDocument4 pagesSizing Ambient VaporizersUrMil SoniNo ratings yet

- Assembly-Install STD Control Dryer PDFDocument106 pagesAssembly-Install STD Control Dryer PDFdonyaNo ratings yet

- Install and configure Microsoft Loopback Adapter and SPLM for license managementDocument2 pagesInstall and configure Microsoft Loopback Adapter and SPLM for license managementprasoon_eilNo ratings yet

- Calibrate Coating Thickness GagesDocument5 pagesCalibrate Coating Thickness GagesJose OcañaNo ratings yet

- Soundwel SUB100 Ultrasonic Flaw DetectorDocument26 pagesSoundwel SUB100 Ultrasonic Flaw DetectorSatwant SinghNo ratings yet

- 28.GOMA Pump T-8000 CatalougeDocument2 pages28.GOMA Pump T-8000 Catalougeramesh babuNo ratings yet

- Standard Shredder Manual PDFDocument31 pagesStandard Shredder Manual PDFalvaroNo ratings yet

- ABSC 2452 Blast MachineDocument8 pagesABSC 2452 Blast MachineMehman NasibovNo ratings yet

- Single Chamber Blast Machines ABSC-24524: Owner'S ManualDocument7 pagesSingle Chamber Blast Machines ABSC-24524: Owner'S ManualBiggie Tafadzwa GanyoNo ratings yet

- Tracerase: Operating and Instruction ManualDocument16 pagesTracerase: Operating and Instruction ManualKrishnaNo ratings yet

- Sae j700 2020 King Pin Servicio RegularDocument3 pagesSae j700 2020 King Pin Servicio RegularCristian GordilloNo ratings yet

- Manual Algor TuberiasDocument0 pagesManual Algor TuberiascaletonesNo ratings yet

- Feam Junction Box EnclosureDocument36 pagesFeam Junction Box EnclosureMiky MooseNo ratings yet

- TRICOR TCM Coriolis Flow Meters - Range CatalogueDocument26 pagesTRICOR TCM Coriolis Flow Meters - Range CatalogueMedab Abd El MalekNo ratings yet

- Odin Elastopipe Eng Oct 2019 PDFDocument2 pagesOdin Elastopipe Eng Oct 2019 PDFHafidzManaf100% (1)

- 07-01 MafDocument5 pages07-01 MafJuan Roberto López BetanzosNo ratings yet

- SBC (Safety Break-Away Couplings) v140630Document16 pagesSBC (Safety Break-Away Couplings) v140630Robert Villavicencio0% (1)

- Victaulic 2D BlocksDocument8 pagesVictaulic 2D BlocksdemdiinNo ratings yet

- Ipc2022-87060 - Estimating Measurement Performance With Truncated Data SetsDocument8 pagesIpc2022-87060 - Estimating Measurement Performance With Truncated Data SetsOswaldo MontenegroNo ratings yet

- Operation Manual: Conveyor ScalesDocument88 pagesOperation Manual: Conveyor ScalesJavier Alejandro Castejon Hernandez100% (1)

- 4505 DiaphragmValves RWDocument49 pages4505 DiaphragmValves RWdbmingoNo ratings yet

- Valvula CompuertaDocument1 pageValvula CompuertaRobertoNo ratings yet

- Marine FlexenDocument67 pagesMarine FlexenpayaljeevaNo ratings yet

- BLADDER TANK PROPORTIONING SYSTEMDocument12 pagesBLADDER TANK PROPORTIONING SYSTEMakshay MahajanNo ratings yet

- Archer DP 5.875 Inch XT 57 SpecsDocument3 pagesArcher DP 5.875 Inch XT 57 SpecsMamani Vargas Wiljho100% (1)

- WPS 1.1Document1 pageWPS 1.1Juan Diego Carvajal100% (1)

- From ASME B31.3 para 304.5.3: T D SQRT (3P/ (16SE) ) +C: Variable Description Variable Value UnitDocument10 pagesFrom ASME B31.3 para 304.5.3: T D SQRT (3P/ (16SE) ) +C: Variable Description Variable Value UnitSong TaoNo ratings yet

- Rabo Rotary Gas Meter: Instruction ManualDocument12 pagesRabo Rotary Gas Meter: Instruction Manualmfg_serviciosNo ratings yet

- Example E4.3.1Document6 pagesExample E4.3.1Dario100% (1)

- Astm A105Document1 pageAstm A105Isaac SamuelNo ratings yet

- Welding ManualDocument9 pagesWelding Manualkawsar98No ratings yet

- 800 1500lb ValvoletDocument1 page800 1500lb ValvoletAugusto Manuel Inga SánchezNo ratings yet

- Mandatory Minimum NDE for Pressure WeldsDocument1 pageMandatory Minimum NDE for Pressure Weldsagustin100% (1)

- LX37 Rotary Screw Compressor Specs and DetailsDocument2 pagesLX37 Rotary Screw Compressor Specs and DetailsMAZENNo ratings yet

- Trico Bond EpDocument2 pagesTrico Bond EpBrandon TrocNo ratings yet

- Pressure safety valve sizing for gas serviceDocument66 pagesPressure safety valve sizing for gas servicePROCESOS PROCESOSNo ratings yet

- Pressure Regulators For Natural Gas: A Cavagna Group CompanyDocument24 pagesPressure Regulators For Natural Gas: A Cavagna Group CompanyTeguh SilaNo ratings yet

- Clamps, Utility, Laboratory, and Holders, Buret and Clamp: Standard Specification ForDocument6 pagesClamps, Utility, Laboratory, and Holders, Buret and Clamp: Standard Specification ForAhmed AlzubaidiNo ratings yet

- SHORTSTOPP 300D Split Tees With Guide BarsDocument3 pagesSHORTSTOPP 300D Split Tees With Guide BarsMartin AndradeNo ratings yet

- Shipyard Review FormDocument10 pagesShipyard Review FormBala Murugan100% (1)

- Use and Maintenance Manual Obl Dosing Pump M - MeDocument44 pagesUse and Maintenance Manual Obl Dosing Pump M - Mephandang_tNo ratings yet

- 731 AaDocument101 pages731 AaasdasdNo ratings yet

- IPC2022 87194 Enhancing MFL A Ultra UtilizingFEM JSpille FinalDocument5 pagesIPC2022 87194 Enhancing MFL A Ultra UtilizingFEM JSpille FinalOswaldo MontenegroNo ratings yet

- 130801512SHA-001 TRDocument17 pages130801512SHA-001 TRUsman AliNo ratings yet

- PCR PCRH Full lit-SP PDFDocument18 pagesPCR PCRH Full lit-SP PDFjuanfco1965100% (1)

- 8008 ControlSwitches EK00 III enDocument8 pages8008 ControlSwitches EK00 III enLaurence Malanum100% (1)

- Experienciasd en La Inspeccion de Calentadores de Aceite Termico Segun API RP573Document10 pagesExperienciasd en La Inspeccion de Calentadores de Aceite Termico Segun API RP573edgarmerchanNo ratings yet

- Product Data Sheet SP-2888 RGDocument8 pagesProduct Data Sheet SP-2888 RGJR RZNo ratings yet

- Engrasadora NEUMATICAFLOWSERVERDocument16 pagesEngrasadora NEUMATICAFLOWSERVERLuis E. Barcelo TovarNo ratings yet

- 1098 EgrDocument44 pages1098 EgrPat AuffretNo ratings yet

- Dic Pps Weld StrengthDocument1 pageDic Pps Weld StrengthWoong KimNo ratings yet

- REPORT-MT 20.10.2022. M C TinhDocument7 pagesREPORT-MT 20.10.2022. M C TinhNhien ManNo ratings yet

- Electrode E8018 DetailsDocument1 pageElectrode E8018 DetailskapsarcNo ratings yet

- Series 1500/2500 Safety Relief ValvesDocument12 pagesSeries 1500/2500 Safety Relief ValvesSandro ChiliquingaNo ratings yet

- Astm F1041Document2 pagesAstm F1041Anonymous wze4zU75% (4)

- Drill Pipe Performance Data SheetDocument3 pagesDrill Pipe Performance Data SheetGarcia C L Alberto100% (1)

- DrillPipe, 80%, 5.500 OD, 0.415 Wall, IEU, G-105.. XT57 (7.000 X 4.000)Document3 pagesDrillPipe, 80%, 5.500 OD, 0.415 Wall, IEU, G-105.. XT57 (7.000 X 4.000)Johann ZabaletaNo ratings yet

- Drill Pipe Performance and SpecificationsDocument3 pagesDrill Pipe Performance and SpecificationsИнженер Луис А. ГарсиаNo ratings yet

- Drill Pipe Performance Sheet 5.875 XT57 G105Document3 pagesDrill Pipe Performance Sheet 5.875 XT57 G105Garcia C L AlbertoNo ratings yet

- DrillPipe, 80%, 5.000 OD, 0.362 Wall, IEU, X-95.. XT50 (6.625 X 3.938)Document3 pagesDrillPipe, 80%, 5.000 OD, 0.362 Wall, IEU, X-95.. XT50 (6.625 X 3.938)Johann ZabaletaNo ratings yet

- 3.5 In. 15.50# EU S-135 R2 XT39 (5.125 X 2.4375) - 10P.15BDocument3 pages3.5 In. 15.50# EU S-135 R2 XT39 (5.125 X 2.4375) - 10P.15BGarcia C L Alberto100% (1)

- Blanking Chart XT - XT-M Pin 1d68Document2 pagesBlanking Chart XT - XT-M Pin 1d68Johann ZabaletaNo ratings yet

- 5-7 - 8-In .750-In Wall S-135 XT57 (7-1 - 4 X 3-1 - 2) 10p 15b R2Document3 pages5-7 - 8-In .750-In Wall S-135 XT57 (7-1 - 4 X 3-1 - 2) 10p 15b R2Johann ZabaletaNo ratings yet

- Performance Sheet Drill Pipe: Pipe Body: Tubular AssemblyDocument1 pagePerformance Sheet Drill Pipe: Pipe Body: Tubular AssemblyJohann ZabaletaNo ratings yet

- 5-7 - 8-In .750-In Wall S-135 XT57 (7-1 - 4 X 3-1 - 2) 10p 15b R2Document3 pages5-7 - 8-In .750-In Wall S-135 XT57 (7-1 - 4 X 3-1 - 2) 10p 15b R2Johann ZabaletaNo ratings yet

- 3.5 In. 15.50# EU S-135 R2 XT39 (5.125 X 2.4375) - 10P.15BDocument3 pages3.5 In. 15.50# EU S-135 R2 XT39 (5.125 X 2.4375) - 10P.15BGarcia C L Alberto100% (1)

- For Reference Only: Drill Pipe Performance Characteristics ©Document3 pagesFor Reference Only: Drill Pipe Performance Characteristics ©doploveNo ratings yet

- 5-7 - 8-In .750-In Wall S-135 XT57 (7-1 - 4 X 3-1 - 2) 10p 15b R2Document3 pages5-7 - 8-In .750-In Wall S-135 XT57 (7-1 - 4 X 3-1 - 2) 10p 15b R2Johann ZabaletaNo ratings yet

- 3.5 In. 15.50# EU S-135 R2 XT39 (5.125 X 2.4375) - 10P.15BDocument3 pages3.5 In. 15.50# EU S-135 R2 XT39 (5.125 X 2.4375) - 10P.15BGarcia C L Alberto100% (1)

- Casing Repair-15062015080103Document16 pagesCasing Repair-15062015080103Johann ZabaletaNo ratings yet

- Grant Prideco Rotary Shoulder HandbookDocument112 pagesGrant Prideco Rotary Shoulder Handbookrlk2806No ratings yet

- 5-7 - 8-In .750-In Wall S-135 XT57 (7-1 - 4 X 3-1 - 2) 10p 15b R2Document3 pages5-7 - 8-In .750-In Wall S-135 XT57 (7-1 - 4 X 3-1 - 2) 10p 15b R2Johann ZabaletaNo ratings yet

- 3.5 In. 15.50# EU S-135 R2 XT39 (5.125 X 2.4375) - 10P.15BDocument3 pages3.5 In. 15.50# EU S-135 R2 XT39 (5.125 X 2.4375) - 10P.15BGarcia C L Alberto100% (1)

- DrillPipe, 80%, 5.500 OD, 0.415 Wall, IEU, G-105.. XT57 (7.000 X 4.000)Document3 pagesDrillPipe, 80%, 5.500 OD, 0.415 Wall, IEU, G-105.. XT57 (7.000 X 4.000)Johann ZabaletaNo ratings yet

- DrillPipe, 80%, 5.000 OD, 0.362 Wall, IEU, X-95.. XT50 (6.625 X 3.938)Document3 pagesDrillPipe, 80%, 5.000 OD, 0.362 Wall, IEU, X-95.. XT50 (6.625 X 3.938)Johann ZabaletaNo ratings yet

- DrillPipe, 80%, 4.000 OD, 0.330 Wall, IU, G-105.. XT39 (4.875 X 2.563)Document3 pagesDrillPipe, 80%, 4.000 OD, 0.330 Wall, IU, G-105.. XT39 (4.875 X 2.563)Johann ZabaletaNo ratings yet

- 3.5 In. 15.50# EU S-135 R2 XT39 (5.125 X 2.4375) - 10P.15BDocument3 pages3.5 In. 15.50# EU S-135 R2 XT39 (5.125 X 2.4375) - 10P.15BGarcia C L Alberto100% (1)

- ChE212 Implicit Eqn Soln and OptimizationDocument3 pagesChE212 Implicit Eqn Soln and OptimizationJohann ZabaletaNo ratings yet

- MatrixDocument1 pageMatrixJohann ZabaletaNo ratings yet

- LDW LogDocument9 pagesLDW LogJohann ZabaletaNo ratings yet

- Tool and Curve Mnemonics for Reeves TechnologiesDocument47 pagesTool and Curve Mnemonics for Reeves TechnologiesJohann ZabaletaNo ratings yet

- EnglishDocument1 pageEnglishJohann ZabaletaNo ratings yet

- Hydrostatic Pressure CalculationDocument2 pagesHydrostatic Pressure CalculationJohann ZabaletaNo ratings yet

- MusicDocument1 pageMusicJohann ZabaletaNo ratings yet

- Estilo IndirectoDocument2 pagesEstilo IndirectoLelyLealGonzalezNo ratings yet

- 6 Chemical FloodingDocument73 pages6 Chemical FloodingJohann ZabaletaNo ratings yet

- Lista de Verbos Regulares e Irregulares en InglesDocument33 pagesLista de Verbos Regulares e Irregulares en InglesAdmirador Bueno67% (21)

- List of Comparative and Superlative AdjectivesDocument3 pagesList of Comparative and Superlative AdjectivesJohann ZabaletaNo ratings yet