Professional Documents

Culture Documents

MaterialData 11916 2

Uploaded by

Muhammad Shena GumilangOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

MaterialData 11916 2

Uploaded by

Muhammad Shena GumilangCopyright:

Available Formats

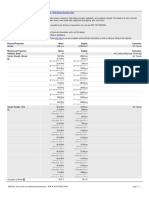

High-Strength Yellow Brass, UNS C86500, Copper Casting Alloy

Categories:

Metal; Nonferrous Metal; Copper Alloy; Copper Casting Alloy

Material Notes:

Casting methods recommended for this alloy: Centrifugal, Investment, Plaster, and Sand.

Applications: Machinery parts requiring strength and toughness, lever arm, valve stems, gears.

Classified under: Manganese and leaded manganese bronze alloys. ASTM B584; formerly ASTM B147-8A

As cast values below are for sand casting. Alloy does not respond to heat treating. Casting shrinkage allowance is 1.9%

Key Words:

Manganese Bronze, ASTM B584; ASTM B147-8A

Vendors:

Click here to view all available suppliers for this material.

Please click here if you are a supplier and would like information on how to add your listing to this material.

Physical Properties

Density

Mechanical Properties

Hardness, Brinell

Tensile Strength, Ultimate

Tensile Strength, Yield

Elongation at Break

Creep Strength

Modulus of Elasticity

Compressive Strength

Charpy Impact

Fatigue Strength

Machinability

Electrical Properties

Electrical Resistivity

Magnetic Permeability

Thermal Properties

CTE, linear 20C

Specific Heat Capacity

Thermal Conductivity

Melting Point

Solidus

Liquidus

Processing Properties

Annealing Temperature

Material Components Properties

Aluminum, Al

Copper, Cu

Iron, Fe

Lead, Pb

Manganese, Mn

Nickel, Ni

Tin, Sn

Zinc, Zn

Metric

8.30 g/cc

English

0.300 lb/in

Comments

at 20C (68F)

Metric

130

490 MPa

195 MPa

30.0 %

12.0 MPa

43.0 MPa

190 MPa

105 GPa

165 MPa

240 MPa

545 MPa

42.0 J

145 MPa

English

130

71100 psi

28300 psi

30.0 %

1740 psi

6240 psi

27600 psi

15200 ksi

23900 psi

34800 psi

79000 psi

31.0 ft-lb

21000 psi

Comments

@# of Cycles 1.00e+8

@# of Cycles 1.00e+8

26.0 %

26.0 %

UNS C36000 (free-cutting brass) = 100%

Metric

0.00000841 ohm-cm

1.09

English

0.00000841 ohm-cm

1.09

Comments

Calculated from 20.5% IACS, at 20C (68F)

16 kA/m field strength

Metric

20.3 m/m-C

0.373 J/g-C

87.0 W/m-K

862 - 880 C

862 C

880 C

English

11.3 in/in-F

0.0891 BTU/lb-F

604 BTU-in/hr-ft-F

1580 - 1620 F

1580 F

1620 F

Comments

from 21-93C (69.8-199.4F)

Metric

260 C

English

500 F

Comments

Metric

0.500 - 1.50 %

55.0 - 60.0 %

0.400 - 2.00 %

<= 0.400 %

<= 1.50 %

<= 1.00 %

<= 1.00 %

39.0 %

English

0.500 - 1.50 %

55.0 - 60.0 %

0.400 - 2.00 %

<= 0.400 %

<= 1.50 %

<= 1.00 %

<= 1.00 %

39.0 %

Comments

in 50 mm

for 0.1% creep in 10,000 h, at 230C

for 0.1% creep in 10,000 h, at 175C

for 0.1% creep in 10,000 h, at 120C

at permanent set of 0.1%

at permanent set of 1%

at permanent set of 10%

at 20C (68F)

References for this datasheet.

Some of the values displayed above may have been converted from their original units and/or rounded in order to display the information in a consistant format. Users requiring more precise data for scientific or

engineering calculations can click on the property value to see the original value as well as raw conversions to equivalent units. We advise that you only use the original value or one of its raw conversions in your

calculations to minimize rounding error. We also ask that you refer to MatWeb's disclaimer and terms of use regarding this information. Click here to view all the property values for this datasheet as they were originally

entered into MatWeb.

MCUDBK

MatWeb, Your Source for Materials Information - WWW.MATWEB.COM /

Page 1 / 1

You might also like

- AISI 4140 - 42Cr4Mo2Document2 pagesAISI 4140 - 42Cr4Mo2rajbir_singh75% (4)

- Zamak 5Document1 pageZamak 5san moedanoNo ratings yet

- AISI 1038 Steel Round BarDocument1 pageAISI 1038 Steel Round BaredraelmxNo ratings yet

- Free-Cutting Brass, UNS C36000, H02 (Cold Drawn 20%) Temper 25 MM RodDocument2 pagesFree-Cutting Brass, UNS C36000, H02 (Cold Drawn 20%) Temper 25 MM Rodkahutzed666No ratings yet

- Astm A228Document2 pagesAstm A228Rakesh S IndiaNo ratings yet

- 4140 HTDocument2 pages4140 HTwillys8No ratings yet

- Aisi 5140 PDFDocument2 pagesAisi 5140 PDFTasha AnaNo ratings yet

- AISI Type O2 Tool Steel for Hardening at 800°C & Tempering at 260°CDocument1 pageAISI Type O2 Tool Steel for Hardening at 800°C & Tempering at 260°CedraelmxNo ratings yet

- MaterialData - 14076 HDS H13Document2 pagesMaterialData - 14076 HDS H13Amol KulkarniNo ratings yet

- AISI 1035 Steel, Cold Drawn, High Temperature, Stress Relieved, 16-22 MM (0.625-0.875 In) RoundDocument2 pagesAISI 1035 Steel, Cold Drawn, High Temperature, Stress Relieved, 16-22 MM (0.625-0.875 In) RoundJakJhonNo ratings yet

- Alluminium SheetsDocument7 pagesAlluminium SheetsVaibhav ShuklaNo ratings yet

- Aisi E 52100 Steel: Advertise With Matweb!Document2 pagesAisi E 52100 Steel: Advertise With Matweb!ankitsarvaiyaNo ratings yet

- Aco AISI 1020 PDFDocument1 pageAco AISI 1020 PDFIbsonhNo ratings yet

- 304Document2 pages304julianmorantesNo ratings yet

- 316L-SS-annealed BarDocument2 pages316L-SS-annealed BarARUNKANNANNo ratings yet

- Aisi 1043 Steel - Hot Rolled Bar (Uns g10430)Document1 pageAisi 1043 Steel - Hot Rolled Bar (Uns g10430)feltofsnakeNo ratings yet

- Special Metals NIMONIC® Alloy 90: Categories: Material NotesDocument3 pagesSpecial Metals NIMONIC® Alloy 90: Categories: Material NotesDragomirescu AlinaNo ratings yet

- Aisi 316Document2 pagesAisi 316denihendrawanNo ratings yet

- Arsenical Admiralty Copper, Uns C44300, Oso25 Temper Tubing: Advertise With Matweb!Document2 pagesArsenical Admiralty Copper, Uns C44300, Oso25 Temper Tubing: Advertise With Matweb!David LluguinNo ratings yet

- Aisi 1030 SteelDocument2 pagesAisi 1030 SteelKhairul KaiNo ratings yet

- MaterialData 11240 PDFDocument1 pageMaterialData 11240 PDFPengelana KehidupanNo ratings yet

- Aluminum 2014-T6; 2014-T651: High Strength Al-Cu-Mg AlloyDocument3 pagesAluminum 2014-T6; 2014-T651: High Strength Al-Cu-Mg Alloyvishwanadh kNo ratings yet

- 303-Cruicible SteelDocument2 pages303-Cruicible SteelARUNKANNANNo ratings yet

- Aluminum 6061-T6 6061-T651: Metal Nonferrous Metal Aluminum Alloy 6000 Series Aluminum AlloyDocument3 pagesAluminum 6061-T6 6061-T651: Metal Nonferrous Metal Aluminum Alloy 6000 Series Aluminum AlloyBea Dri HdezNo ratings yet

- 316L-SS-annealed Bar and Cold DrawnDocument2 pages316L-SS-annealed Bar and Cold DrawnARUNKANNANNo ratings yet

- AISI 1045 SteelDocument3 pagesAISI 1045 Steelsenthil4youNo ratings yet

- 304 Stainless Steel: Metal Ferrous Metal Heat Resisting Stainless Steel T 300 Series Stainless SteelDocument2 pages304 Stainless Steel: Metal Ferrous Metal Heat Resisting Stainless Steel T 300 Series Stainless SteelTomy GeorgeNo ratings yet

- Aluminum 6061-T6 6061-T651: Metal Nonferrous Metal Aluminum Alloy 6000 Series Aluminum AlloyDocument3 pagesAluminum 6061-T6 6061-T651: Metal Nonferrous Metal Aluminum Alloy 6000 Series Aluminum AlloySaad SaudNo ratings yet

- Sandvik 316 Plate, Sheet and CoilDocument2 pagesSandvik 316 Plate, Sheet and CoilJesús Leal CarvajalinoNo ratings yet

- 316L SS CrucibleDocument2 pages316L SS CrucibleARUNKANNANNo ratings yet

- Aluminum 6061 Data SheetDocument2 pagesAluminum 6061 Data SheetASHOK100% (1)

- AISI 1015 Steel, Cold Drawn: Metal Ferrous Metal Carbon Steel AISI 1000 Series Steel Low Carbon SteelDocument3 pagesAISI 1015 Steel, Cold Drawn: Metal Ferrous Metal Carbon Steel AISI 1000 Series Steel Low Carbon SteelAleesha RehanNo ratings yet

- AISI 1035 SteelDocument2 pagesAISI 1035 SteelCarlos Andres Garcia MuñozNo ratings yet

- Aluminum 5052-O: Metal Nonferrous Metal Aluminum Alloy 5000 Series Aluminum AlloyDocument3 pagesAluminum 5052-O: Metal Nonferrous Metal Aluminum Alloy 5000 Series Aluminum Alloyrezaeibehrouz100% (1)

- ASM Material Data SheetDocument3 pagesASM Material Data SheetMadhu MithaNo ratings yet

- Aisi A2: Cold Work Tool SteelDocument21 pagesAisi A2: Cold Work Tool SteelRahul NambiarNo ratings yet

- Steel UserguideDocument50 pagesSteel UserguideBhanu Pratap ChoudhuryNo ratings yet

- 304 Stainless Steel SpecificationDocument4 pages304 Stainless Steel SpecificationRendra FirmansyahNo ratings yet

- MaterialData - Aço 1045Document2 pagesMaterialData - Aço 1045Victhor AraujoNo ratings yet

- Userguide For SSDocument26 pagesUserguide For SSehsan4uNo ratings yet

- 316-SS-annealed Bar and Cold DrawnDocument2 pages316-SS-annealed Bar and Cold DrawnARUNKANNANNo ratings yet

- Material SpecificationDocument50 pagesMaterial SpecificationSangyt Karna0% (2)

- Titanium Properties GuideDocument2 pagesTitanium Properties GuideAbhishek JhaNo ratings yet

- Alloy 6005A: We Are AluminumDocument2 pagesAlloy 6005A: We Are AluminumLeo PardNo ratings yet

- Aluminio 6061-T6 6061-T651Document2 pagesAluminio 6061-T6 6061-T651leroniusNo ratings yet

- Mueller Alloy 3600 Free Cutting Brass (UNS C36000)Document1 pageMueller Alloy 3600 Free Cutting Brass (UNS C36000)Surya NarayanNo ratings yet

- Web Datasheet A2.2Document7 pagesWeb Datasheet A2.2ks2000n1No ratings yet

- Assab Stavax EsrDocument6 pagesAssab Stavax EsrAnonymous Wi2Pd2UgPINo ratings yet

- Bronze (Low-Silicon) UNS C65100, OSO35 (Tornillos Maquinas)Document2 pagesBronze (Low-Silicon) UNS C65100, OSO35 (Tornillos Maquinas)Carlos Andres Garcia MuñozNo ratings yet

- IRCE Salflex180Document1 pageIRCE Salflex180grasia77No ratings yet

- Mueller C36000 Free Cutting BrassDocument1 pageMueller C36000 Free Cutting Brasskahutzed666No ratings yet

- Weld Like a Pro: Beginning to Advanced TechniquesFrom EverandWeld Like a Pro: Beginning to Advanced TechniquesRating: 4.5 out of 5 stars4.5/5 (6)

- Welding the Inconel 718 Superalloy: Reduction of Micro-segregation and Laves PhasesFrom EverandWelding the Inconel 718 Superalloy: Reduction of Micro-segregation and Laves PhasesNo ratings yet

- Pipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsFrom EverandPipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsRating: 4.5 out of 5 stars4.5/5 (10)

- Proceedings of the 8th International Symposium on Superalloy 718 and DerivativesFrom EverandProceedings of the 8th International Symposium on Superalloy 718 and DerivativesNo ratings yet

- Wiki ZirconiumDocument9 pagesWiki Zirconiumtruth.sayerNo ratings yet

- 2011 Prep Problems With Solutions 110215Document115 pages2011 Prep Problems With Solutions 110215RSLNo ratings yet

- Pre-Medical: Chemistry Allen: Carbonyl Compounds, Acids and It'S Derivatives Carbonyl CompoundsDocument18 pagesPre-Medical: Chemistry Allen: Carbonyl Compounds, Acids and It'S Derivatives Carbonyl CompoundsJK JHANo ratings yet

- PolarityDocument22 pagesPolarityEvangelene Esquillo SanaNo ratings yet

- Solutions Suspensions and ColloidsDocument10 pagesSolutions Suspensions and ColloidsAfesha DanielNo ratings yet

- Technoeconomic Analysis of Alternative Pathways of Isopropanol ProductionDocument13 pagesTechnoeconomic Analysis of Alternative Pathways of Isopropanol ProductionSUTHIWAT YIMYAMNo ratings yet

- Anderol General BrochureDocument12 pagesAnderol General BrochureepesanoNo ratings yet

- General Cat PDFDocument16 pagesGeneral Cat PDFmail4ccpNo ratings yet

- Thermal PropertiesDocument14 pagesThermal PropertiesLivian TeddyNo ratings yet

- Im Dissociation PDFDocument10 pagesIm Dissociation PDFRamesh SNo ratings yet

- Subject: Chemistry Student Name: Grade: 9 Date: Worksheet-2: Atoms, Elements, and Compounds. MarksDocument25 pagesSubject: Chemistry Student Name: Grade: 9 Date: Worksheet-2: Atoms, Elements, and Compounds. Markssaeeda shoaibNo ratings yet

- Cross Index MaterialDocument4 pagesCross Index MaterialioancNo ratings yet

- PHPA TestDocument2 pagesPHPA TestRagha RagNo ratings yet

- Ammonia: Valves For Ammonia ServiceDocument2 pagesAmmonia: Valves For Ammonia ServiceArun Babu0% (1)

- Lesson 2 Dna Structure and Dna ExtractionDocument8 pagesLesson 2 Dna Structure and Dna ExtractionGreatel Elijah TorregosaNo ratings yet

- Mott - HyPulse Element FilterDocument12 pagesMott - HyPulse Element FilterCristhian CuevaNo ratings yet

- Benzene Quiz Questions - Footprints-Science GCSE Science Animations and Quizzes GCSE Science RevisionDocument1 pageBenzene Quiz Questions - Footprints-Science GCSE Science Animations and Quizzes GCSE Science RevisionlollNo ratings yet

- US4450090Document6 pagesUS4450090Abdulrahman HamdanNo ratings yet

- Effects of Silicon Surfactant in Rigid Polyurethane FoamsDocument7 pagesEffects of Silicon Surfactant in Rigid Polyurethane Foamsธนพล กัตติยบุตรNo ratings yet

- ASTM D6224 Eksploataciono Praćenje UljaDocument14 pagesASTM D6224 Eksploataciono Praćenje UljaDejan DejanovicNo ratings yet

- Maleic AnhydrideDocument6 pagesMaleic AnhydrideTechnologist ChemicalNo ratings yet

- Copper Recovery Flotation: Slag Composition Loses Priority To Controlled Cooling of The SlagDocument6 pagesCopper Recovery Flotation: Slag Composition Loses Priority To Controlled Cooling of The SlagBenito Quispe A.No ratings yet

- Flushing and Passivation SystemDocument2 pagesFlushing and Passivation Systemmyo myint aungNo ratings yet

- Experiment 3 KineticsDocument20 pagesExperiment 3 KineticsNItha100% (1)

- ChemistryDocument22 pagesChemistrymacaronloverNo ratings yet

- Mp4f01 Ceramics 1 Khor 2011Document40 pagesMp4f01 Ceramics 1 Khor 2011Vincent KohNo ratings yet

- ISC ChemistryDocument8 pagesISC Chemistrysamrounder100% (3)

- Alkaline Earth MetalsDocument16 pagesAlkaline Earth MetalsSavio SibiNo ratings yet

- The Future of Composites in Gas Turbine EnginesDocument4 pagesThe Future of Composites in Gas Turbine EnginessenthilNo ratings yet

- Antacid AnalysisDocument4 pagesAntacid AnalysispankajNo ratings yet