Professional Documents

Culture Documents

GSM-based monitoring and control of smart grid

Uploaded by

Mukuro RokudoOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

GSM-based monitoring and control of smart grid

Uploaded by

Mukuro RokudoCopyright:

Available Formats

World Academy of Science, Engineering and Technology

International Journal of Electrical, Computer, Energetic, Electronic and Communication Engineering Vol:7, No:12, 2013

GSM Based Automated Embedded System for

Monitoring and Controlling of Smart Grid

Amit Sachan

International Science Index, Electrical and Computer Engineering Vol:7, No:12, 2013 waset.org/Publication/9997170

AbstractThe purpose of this paper is to acquire the remote

electrical parameters like Voltage, Current, and Frequency from

Smart grid and send these real time values over GSM network using

GSM Modem/phone along with temperature at power station. This

project is also designed to protect the electrical circuitry by operating

an Electromagnetic Relay. The Relay can be used to operate a Circuit

Breaker to switch off the main electrical supply. User can send

commands in the form of SMS messages to read the remote electrical

parameters. This system also can automatically send the real time

electrical parameters periodically (based on time settings) in the form

of SMS. This system also send SMS alerts whenever the Circuit

Breaker trips or whenever the Voltage or Current exceeds the

predefined limits.

KeywordsGSM Modem, Initialization of ADC module of

microcontroller, PIC-C compiler for Embedded C programming, PIC

kit 2 programmer for dumping code into Micro controller, Express

SCH for Circuit design, Proteus for hardware simulation.

I. INTRODUCTION

HE time complicated interlocking and operation

controlling requirements usually noticed in the Smartgrid

working, which lead to necessity of automation of the

undergoing process. In this respect, Smartgrid automation,

which is the creation of a highly reliable, self-healing power

system that rapidly responds to real time events with

appropriate actions, ensures to maintain uninterrupted power

services to the end users.

II. PROPOSED METHOD

This research paper aims at continuously monitor the load

conditions of the Smartgrid. It also monitors the temperature

of the devices present in the Smartgrid. If the load increases

beyond the Smartgrids rated capacity, the microcontroller

will automatically shut down the Smartgrid and intimates the

same to the operator by sending a message through a GSM

modem. A modem provides the communication interface. It

transports device protocols transparently over the network

through a serial interface. A GSM modem is a wireless

modem that works with a GSM wireless network. A wireless

modem behaves like a dial-up modem. The main difference

between them is that a dial-up modem sends and receives data

through a fixed telephone line while a wireless modem sends

and receives data through radio waves. If the temperature of

the Smartgrid increases, then the microcontroller will

automatically starts the cooling system for the Smart grid. At

any point, if the operator wants to know the loads conditions

Amit Sachan is with the Electr. Com. Scien. Tech, India; He is now with

the Department of Electrical Engineering (e-mail: amitsachan55@gmail.com).

International Scholarly and Scientific Research & Innovation 7(12) 2013

and the temperature, he has to send a predefined message to

the modem which is interfaced with the microcontroller and

the controller acknowledges the operator with the required

information.

1. Sensing different electrical parameters (voltage, current,

temperature).

2. Forwarding the electrical parameters over GSM network.

3. Producing buzzer alerts (if necessary).

4. Automatic circuit breaking operation.

An embedded system is a combination of software and

hardware to perform a dedicated task. Some of the main

devices used in embedded products are Microprocessors and

Microcontrollers. Microprocessors are commonly referred to

as general purpose processors as they simply accept the inputs,

process it and give the output. In contrast, a microcontroller

not only accepts the data as inputs but also manipulates it,

interfaces the data with various devices, controls the data and

thus finally gives the result.

The research paper GSM Based Embedded System for

Smartgrid Monitoring and Control System using according to

the instructions given by the above said microcontroller.

Distributed transformers are prone to damages due to the rise

in oil temperature when there is an overload or huge current

flows through the internal winding of the transformer. When

the oil temperature rises, it increases the probability of getting

damages in the transformers. The transformers are to be

monitored very cautiously during these situations. The

proposed system consists of a monitoring unit that is

connected with the distribution transformer for the purpose of

monitoring the same. Hence, we introduce a simulation model

which details the operation of the system to rectify the

mentioned problem. The monitoring system is constituted by

three major units, namely,

1. Data processing and transmitter unit

2. Load and Measurement Systems

3. Receiver and PC display unit

We have designed a system based on microcontroller that

monitors and controls the voltage, current and oil temperature

of a distribution transformer present in a Smartgrid. The

monitored output will be displayed on a PC at the main station

that is at a remote place, through RF communication. The

parameters monitored at the distribution transformer are

compared with the rated values of the transformer.

Additionally the breakdowns caused due to the overload and

high voltage are sensed and the signals are transmitted to the

main station using RF communication. The software in the PC

compares the received values with the rated measurements of

the distribution transformer and shuts down the transformer so

1748

scholar.waset.org/1999.5/9997170

International Science Index, Electrical and Computer Engineering Vol:7, No:12, 2013 waset.org/Publication/9997170

World Academy of Science, Engineering and Technology

International Journal of Electrical, Computer, Energetic, Electronic and Communication Engineering Vol:7, No:12, 2013

that it can be prevented from damages and performances can

be enhanced quiet to a remarkable level. The controller

consists of a sensing unit which collects the essential

parameters such as current, voltage and the oil temperature

within the distribution transformer. The digital display

connected to the processing unit displays corresponding

parameter values at the Smartgrid for any technical operations.

The controller also senses the overload and high current flow

conditions in the internal windings that may lead to

breakdown of the corresponding unit. The microcontroller is

programmed in such a manner so as to continuously scan the

transformer and update the parameters at a particular Time

interval. The parameter values sensed by the microcontroller

are transmitted through the RF transmitter connected to the

microcontroller unit. The transmitted signals are received at

the main station using the RF receiver. The received signals

are then passed to the PC. The software loaded in the PC is

used to monitor the changes in the parameters that are

measured from the distribution transformer. When a

remarkable change is noticed in the measured values it

controls the unit by ending it from any serious damages.

The values of voltage, current and temperature of the

transformer is directly applied to Port A (one of the input ports

of the microcontroller). Along with this, a display is connected

in the Port B (another input port of the microcontroller). The

RF transmitting section and the load variation control are

connected to the Port C (one of the output ports in the

microcontroller).

The monitoring PC is connected to the main station. The

microcontroller at the Smartgrid monitors and captures the

current, voltage and temperature values for a particular period

of time interval. The captured values are stored in the data

register and displayed using the LCD display.

The monitored voltage, current and temperature values of

the transformer are transmitted using the RF transmitter for

each and every time interval. Any antenna tuned for the

selected RF frequency can be utilized for the transmission of

the RF signal but the antenna has to exhibit a unidirectional

radiation pattern. In the receiver side of the proposed system,

the receiver antenna converts the RF signal into electrical

signal and acquires the information which has been

transmitted by the transmitter. Based on the received

information, controlling operation is performed. If the receiver

receives the transformer parameters which is greater than the

fixed threshold level, then immediately the units is shutdown

so as to protect the same. The voltage level is reduced using

transformers and power is transferred to customers through

electric power distribution systems. Power starts from the

transmission grid at distribution Smartgrid where the voltage

is stepped-down (typically to less than 10kV) and carried by

smaller distribution lines to supply commercial, residential,

and industrial users. Novel electric power systems

encompassing of power transmission and distribution grids

consist of copious number of distributed, autonomously

managed, capital-intensive assets.

International Scholarly and Scientific Research & Innovation 7(12) 2013

A. Real Time System Design

Real time systems have to respond to external interactions

in a predetermined amount of time. Successful completion of

an operation depends upon the correct and timely operation of

the system. Design the hardware and the software in the

system to meet the Real time requirements. Designing real

time systems is a challenging task. Most of the challenge

comes from the fact that Realtime systems have to interact

with real world entities. These interactions can get fairly

complex. A typical Realtime system might be interacting with

thousands of such entities at the same time. Real time

Response, Recovering from Failures, Working with

Distributed Architectures, Asynchronous Communication,

Race Conditions and Timing

B. Architecture and Working of GSM Networks

A GSM network consists of several functional entities

whose functions and interfaces are defined. The GSM network

can be divided into following broad parts. The Mobile Station

(MS), The Base Station Subsystem (BSS), The Network

Switching Subsystem (NSS), The Operation Support

Subsystem (OSS). The added components of the GSM

architecture include the functions of the databases and

messaging systems: Home Location Register (HLR), Visitor

Location Register (VLR), Equipment Identity Register (EIR),

Authentication Center (AuC), SMS Serving Center (SMS SC),

Gateway MSC (GMSC), Chargeback Center (CBC),

Transcoder and Adaptation Unit (TRAU)The MS and the BSS

communicate across the Um interface, also known as the air

interface or radio link. The BSS communicates with the

Network Service Switching center across the A interface.

In a GSM network, the following areas are defined:

Cell: Cell is the basic service area: one BTS covers one

cell. Each cell is given a Cell Global Identity (CGI), a number

that uniquely identifies the cell.

Location Area: A group of cells form a Location Area.

This is the area that is paged when a subscriber gets an

incoming call. Each Location Area is assigned a Location

Area Identity (LAI). Each Location Area is served by one or

more BSCs.

MSC/VLR Service Area: The area covered by one MSC is

called the MSC/VLR service area.

PLMN: The area covered by one network operator is called

PLMN. A PLMN can contain one or more MSCs.

C. Debugging Tolls

Embedded debugging may be performed at different levels,

depending on the facilities available. From simplest to most

sophisticate they can be roughly grouped into the following

areas [1], [2]:

1. Interactive resident debugging, using the simple shell

provided by the embedded operating system (e.g. Forth

and Basic)

2. External debugging using logging or serial port output to

trace operation using either a monitor in flash or using a

debug server like the Remedy Debugger which even

works for heterogeneous multi core systems.

1749

scholar.waset.org/1999.5/9997170

World Academy of Science, Engineering and Technology

International Journal of Electrical, Computer, Energetic, Electronic and Communication Engineering Vol:7, No:12, 2013

International Science Index, Electrical and Computer Engineering Vol:7, No:12, 2013 waset.org/Publication/9997170

3.

An in-circuit debugger (ICD), a hardware device that

connects to the microprocessor via a JTAG or Nexus

interface. This allows the operation of the microprocessor

to be controlled externally, but is typically restricted to

specific debugging capabilities in the processor.

4. An in-circuit emulator replaces the microprocessor with a

simulated equivalent, providing full control over all

aspects of the microprocessor.

5. A complete emulator provides a simulation of all aspects

of the hardware, allowing all of it to be controlled and

modified and allowing debugging on a normal PC.

6. Unless restricted to external debugging, the programmer

can typically load and run software through the tools,

view the code running in the processor, and start or stop

its operation. The view of the code may be as assembly

code or source-code. [2]

Because an embedded system is often composed of a wide

variety of elements, the debugging strategy may vary. For

instance, debugging a software (microprocessor) centric

embedded system is different from debugging an embedded

system where most of the processing is performed by

peripherals (DSP, FPGA, and co-processor). An increasing

number of embedded systems today use more than one single

processor core. Embedded development makes up a small

fraction of total programming. There are also a large number

of embedded architectures, unlike the PC world where 1

instruction set rules, and the UNIX world. Where there are

only 3 or 4 major ones. This means that the tools are more

expensive. It also means that they're lowering featured, and

less developed. On a major embedded project, at some point

you will almost always find a compiler bug of some sort.

Debugging tools are another issue. Since you can't always run

General programs on your embedded processor, you can't

always run a debugger on it. This makes fixing your program

difficult. Special hardware such as JTAG ports can overcome

this issue in part. However, if you stop on a breakpoint when

your system is controlling real world hardware, permanent

equipment damage can occur. As a result, people doing

embedded programming quickly become masters at using

serial IO channels and error message style debugging [3].

circuit board (PCB) of 30mm x 14mm x 1.5mm dimensions.

The PCB was etched in accordance with the receiver circuit

shown below with various integrated circuit (IC) pin hole

drilled. The microcontroller chip PIC16F877A, circuit

breakers and the relays were all inserted on the board to form

a complete receiver unit. The implementation of the system

involves two steps which are: Setting up the system and inter

facing with graphic user interface (i.e. application software).

The application software for the system has been developed by

using a high lever language C-programming debugger. The

debugger contains a high speed simulator and a target

debugger that let you simulate an entire PIC16F877A system

including on chip peripherals [4] [5].

The SI unit for magnetic field strength H is A/m. However,

if you wish to use units of T, either refers to magnetic flux

density B or magnetic field strength symbolized as 0H. Use

the center dot to separate compound units, e.g., Am2.

III. BLOCK DIAGRAM OF THE PROPOSED RESEARCH PAPER

The circuit was designed using electronic workbench

software. This software was used to design a sample for the

power supply which was incorporated on the receiver system.

The receiver sections were designed by this computer aid. In

designing the power supply, the software has a menu that

contains the various components of the circuit. One has to

identify which menu contains the component for the power

supplies were selected. The components that were selected

are: diodes (1n4001) capacitor (220F and 10F) and

regulator 7805. A step down transformer of 240/12V AC Was

also selected was also selected. These components were laid

out and their pins were joined appropriately with lines. These

lines are similar to the conductors on the printed circuit board

(PCB). The same procedure was followed in the design of the

receiver circuit. The receiver was constructed on printed

International Scholarly and Scientific Research & Innovation 7(12) 2013

1750

scholar.waset.org/1999.5/9997170

International Science Index, Electrical and Computer Engineering Vol:7, No:12, 2013 waset.org/Publication/9997170

World Academy of Science, Engineering and Technology

International Journal of Electrical, Computer, Energetic, Electronic and Communication Engineering Vol:7, No:12, 2013

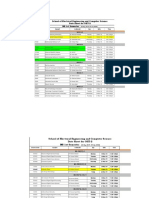

Figg. 1 Schematic diagram

Fig. 2 Comm

munication Systtem

IV. WOR

RKING PRINCIPLE

The system was

w tested byy connecting a GPRS modem and

t the PC. Thhe RS232 caable is conneected to

RS232 cable to

m

microcontroller

r PIC16F8777A through an interface MAX

2332Ic. The miccrocontroller PIC16F877A

A is connected

d to the

ciircuit breaker through a relaay. When the circuit

c

is pow

wered by

coonnecting it to

o 240 V AC suupply, the incoming AC vooltage is

reectified by briddge rectifier. The voltage iss then reducedd to 5V

byy a regulator which

w

serves as an input too the microconntroller.

Thhe system waas tested mannually by presssing a knob on the

sooftware to actiivate the circuuit breaker. Seecondary, the system

w tested remootely by sendiing an SMS message

was

m

to thee GPRS

orr modem thhrough the PC to RS232 cable to the

m

microcontroller

r PIC16F877A

A and it also worked.

w

Below

w is the

sccreen shot of the system coontrol Panel with

w circuit breakers

b

International Scholarly and Scientific Research & Innovation 7(12) 2013

turrned ON. Thuus the automattion of electriccal power Sm

martgrid

is designed and implementedd using GSM technology

t

[66]. This

briings out thee efficient w

way of powerr transmissioon and

disstribution in electrical Sm

martgrid thouggh it is carried out

usiing wirelesss mobile coommunication

n technologyy. AT

commands are used

u

to comm

municate the GSM

G

modem and

a the

miicrocontroller.. Cellular phoones have beeen invading all

a over

thee globe. Celluular phones ennable people to

o communicatte over

a wide area by

b using a nnetwork of radio

r

antennaas and

traansmitters arraanged in smaall geographiccal area calledd cells.

Byy using a roooming faciliity provided by cellular phone

prooviders, comm

munication could be effectiv

ve wherever you

y are

onn a globe. Teechnology caan explore more

m

benefit on the

utiilization of ceellular phones. The GPRS was

w able to reead the

daata sent by celll phone at a ffrequency of 900MH. The GPRS

usees packet swiitching methood to transferr data, which means

thaat data is sennt over the tiime, which has

h less traffiic. The

miicrocontroller PIC16F8777A is a low

l

power, high

performance CM

MOS 8-bit coomputer. It prrovides high-fflexible

ol applicationns. The

annd cost effecttive solution to the contro

above schematic diagram GS

SM Based Em

mbedded Systtem for

martgrid Monnitoring and Control Sy

ystem explain

ns the

Sm

intterfacing section of each ccomponent with

w micro conntroller

annd GSM moduule. [6]

The crystal oscillator

o

connnected to 13tth and 14th pins

p

of

miicro controller and Reggulated poweer supply iss also

connected to micro

m

controlleer and LEDs also conneccted to

nnected

miicro controllerr through resiistors and mottor driver con

to micro controlller.

1751

scholar.waset.org/1999.5/9997170

International Science Index, Electrical and Computer Engineering Vol:7, No:12, 2013 waset.org/Publication/9997170

World Academy of Science, Engineering and Technology

International Journal of Electrical, Computer, Energetic, Electronic and Communication Engineering Vol:7, No:12, 2013

Fig. 3 Screen shot of control Panel with circuit breakers turned ON

V. SCOPE OF THE RESEARCH

VI. RESULT

Our research paper GSM Based Embedded System for

Smartgrid Monitoring and Control System is mainly intended

to operate the devices like fans, lights, motors etc.., through a

GSM based mobile phone. The system has a GSM modem,

temperature, current, voltage sensors and the devices to be

operated through the switches like Relay which are interfaced

to the microcontroller. The micro controller is programmed in

such a way that if a particular fixed format of SMS is sent to

GSM modem from mobile phone, which is fed as input to the

microcontroller which operates the appropriate devices. A

return feedback message will be sent to the mobile from GSM

modem. The temperature at the place where devices are being

operated can be known. In future we can use this research

paper in several applications by adding additional components

to this research paper. This research paper can be extended by

using GPRS technology, which helps in sending the monitored

and controlled data to any place in the world. The temperature

controlling systems like coolant can also use in places where

temperature level should be maintained. By connecting

wireless camera in industries, factories etc. we can see the

entire equipment from our personal computer only by using

GPRS and GPS technology. The monitoring and controlling of

the devices can be done from the personal computer and we

can use to handle so many situations. By connecting

temperature Sensor, we can get the temperature of dangerous

zones in industries and we can use personal Computer itself

instead of sending human to there and facing problems at the

field. The temperature sensor will detect the temperature and it

gives information to the micro controller and micro controller

gives the information to the mobile phone from that we can

get the data at pc side.

The research paper designed such that the devices can be

monitored and also controlled from anywhere in the world

using GSM modem connected to mobile phone. The proposed

system which has been designed to monitor the transformers

essential parameters continuously monitors the parameters

throughout its operation. If the microcontroller recognizes any

increase in the level of voltage, current or temperature values

the unit has been made shutdown in order to prevent it from

further damages. The system not only controls the distribution

transformer in the Smartgrid by shutting it down, but also

displays the values throughout the process for users reference.

This claims that the proposed design of the system makes the

distribution transformer more robust against some key power

quality issues which makes the voltage, current or temperature

to peak. Hence the distribution is made more secure, reliable

and efficient by means of the proposed system.

International Scholarly and Scientific Research & Innovation 7(12) 2013

REFERENCES

[1]

[2]

[3]

[4]

[5]

[6]

1752

Embedded Automobile Engine Locking System, Using GSM

Technology, Jayanta Kumar Pany1 & R. N.Das Choudhury2

International Journal of Instrumentation, Control and Automation

(IJICA) ISSN : 2231-1890 Volume-1, Issue-2, 2011.

PIC Microcontroller Manual, Microchip Technology Inc. (2003), Page

no 3-41-49.

PIC Microcontroller and Embedded Systems, Mazidi, Muhammad Ali;

Mckinaly, Rolin D; Causey, Page no 99-112.

www.allaboutcircuits.com.

Microcontrollers Architecture, Programming, Interfacing and System

Design, Raj kamal, (2011), Page no 34-52[10] PCB Designe Tutorial.

Page no 17-25, David.L.Jones (2004)

GSM based Automated Embedded System for Monitoring and

Controlling of Substation, Amit Sachan, M.Tech. Thesis, Page no 7-9

June 2012.

scholar.waset.org/1999.5/9997170

You might also like

- Fundamentals of Information Systems PDFDocument164 pagesFundamentals of Information Systems PDFharshithaNo ratings yet

- Power Theft Detection EEDocument25 pagesPower Theft Detection EEGaurav sengarNo ratings yet

- 100 Cool Mainframe TipsDocument15 pages100 Cool Mainframe Tipskishore21kNo ratings yet

- Accident Alert and Vehicle Tracking System IJERTV9IS110129Document5 pagesAccident Alert and Vehicle Tracking System IJERTV9IS110129Tawan JimNo ratings yet

- Rotating Solar Inverter Project Using Microcontroller 50WDocument4 pagesRotating Solar Inverter Project Using Microcontroller 50Whamed raza0% (1)

- Energy Management in Smart Grids Using Embedded System & IOTDocument5 pagesEnergy Management in Smart Grids Using Embedded System & IOTEditor IJRITCCNo ratings yet

- Protection of Transmission Lines Using Gps Full ReportDocument28 pagesProtection of Transmission Lines Using Gps Full ReportRamya GajjarapuNo ratings yet

- Project Title:: Fingerprint Voting System For UniversityDocument8 pagesProject Title:: Fingerprint Voting System For UniversityMunshiNo ratings yet

- Health Monitoring GloveDocument7 pagesHealth Monitoring GloveYashNo ratings yet

- Energy Meter IotDocument73 pagesEnergy Meter IotManish NandurkarNo ratings yet

- Coin Detection Mobile ChargingDocument39 pagesCoin Detection Mobile ChargingAman GuptaNo ratings yet

- Final PPT of PLC GroupDocument36 pagesFinal PPT of PLC GroupRohit Deb0% (1)

- Real-Time Health Monitoring Using IoTDocument5 pagesReal-Time Health Monitoring Using IoTNesiga R 041No ratings yet

- Gourav Sharma - GSM Based Fuel Theft Detection, Overspeed Indicator Nad Temprature Alert System in Petroleum Transportation VehicleDocument19 pagesGourav Sharma - GSM Based Fuel Theft Detection, Overspeed Indicator Nad Temprature Alert System in Petroleum Transportation VehicleRaj MandloiNo ratings yet

- Automatic Railway Gate ControlDocument22 pagesAutomatic Railway Gate ControlsriramNo ratings yet

- Project Report FinalDocument60 pagesProject Report Finalaisha singhNo ratings yet

- Technical Specifications:: Over Speed & Unauthorized Vehicle Detection Using Ir Based Speed SensorsDocument3 pagesTechnical Specifications:: Over Speed & Unauthorized Vehicle Detection Using Ir Based Speed Sensorshamed razaNo ratings yet

- RF-ID Based Automatic Pesticide DosingDocument10 pagesRF-ID Based Automatic Pesticide DosingAbhishek HavgundeNo ratings yet

- Substation Protection Devices ExplainedDocument24 pagesSubstation Protection Devices ExplainedAshish AgarwalNo ratings yet

- GSM Based Power Grid Monitoring SystemDocument41 pagesGSM Based Power Grid Monitoring SystemPreetham SurepallyNo ratings yet

- A Review On IOT Based Power Theft Detection and Control SystemsDocument36 pagesA Review On IOT Based Power Theft Detection and Control SystemsKaveri D SNo ratings yet

- Electric Lineman Safety System using One Time Passwords (OTPDocument63 pagesElectric Lineman Safety System using One Time Passwords (OTPSiva KumarNo ratings yet

- IoT Based Hydroponic Monitoring SystemDocument9 pagesIoT Based Hydroponic Monitoring SystemUrmatan MarvinNo ratings yet

- Patient Monitoring System Using GSM For Hospitals and Old Age HomesDocument5 pagesPatient Monitoring System Using GSM For Hospitals and Old Age Homesvgmanjunatha100% (1)

- Vehicle Starting System Using Fingerprint SensorDocument18 pagesVehicle Starting System Using Fingerprint SensorVIKASH SINGHNo ratings yet

- Crop Yield Prediction Using ML Algorithms: A Mini Project Report OnDocument9 pagesCrop Yield Prediction Using ML Algorithms: A Mini Project Report OnMd Talha KhanNo ratings yet

- Final PPT (Autosaved)Document34 pagesFinal PPT (Autosaved)KARTHIK.K 18BEC023No ratings yet

- ReportDocument38 pagesReportvaishnaviNo ratings yet

- Automatic Staircase LightningDocument23 pagesAutomatic Staircase LightningAniket Pawar100% (3)

- Unit 1Document41 pagesUnit 1Sarthak Singh ChandelNo ratings yet

- GSM Based Automatic Energy MeterDocument80 pagesGSM Based Automatic Energy MeterKhalid BenaribaNo ratings yet

- Power Theft Detection SystemDocument5 pagesPower Theft Detection SystemVivek KumarNo ratings yet

- Home Based Security Control System Using Raspberry Pi and GSMDocument6 pagesHome Based Security Control System Using Raspberry Pi and GSMAlan SagarNo ratings yet

- Artificial Intelligence in Power SystemsDocument6 pagesArtificial Intelligence in Power SystemsVIVA-TECH IJRINo ratings yet

- Iot Base Heart Beat Monitoring System PDFDocument43 pagesIot Base Heart Beat Monitoring System PDFRohit AdnaikNo ratings yet

- Project PPT 1Document11 pagesProject PPT 1Mahesh ShendeNo ratings yet

- Smart Notice BoardDocument42 pagesSmart Notice BoardDhiraj BhattNo ratings yet

- Iot Assignment - 1: Manhole Detection and Monitoring SystemDocument5 pagesIot Assignment - 1: Manhole Detection and Monitoring Systemj abhishekNo ratings yet

- Iot Based Health Monitoring SystemDocument13 pagesIot Based Health Monitoring SystemSamuelNo ratings yet

- Applications of Artificial Intelligence in Power SystemsDocument15 pagesApplications of Artificial Intelligence in Power Systemsraul_bsuNo ratings yet

- Camera Based Trafic ControlDocument83 pagesCamera Based Trafic ControldaNo ratings yet

- Alcohol Detection and Security System for Automobiles Using Embedded TechnologyDocument8 pagesAlcohol Detection and Security System for Automobiles Using Embedded TechnologyBhavik DoshiNo ratings yet

- Air Quality Monitoring System using IoTDocument43 pagesAir Quality Monitoring System using IoTakashlogicNo ratings yet

- Monitoring System in IoTDocument11 pagesMonitoring System in IoTJoao DuqueNo ratings yet

- 3 IEEE Tranction 2014Document9 pages3 IEEE Tranction 2014Lokanath TripathyNo ratings yet

- Solar Charge ControllerDocument11 pagesSolar Charge Controllerayirp89No ratings yet

- Finger Print Based Electronic Voting MachineDocument4 pagesFinger Print Based Electronic Voting Machinesagarsm2No ratings yet

- Cognitive RadioDocument33 pagesCognitive RadioJanardhan Reddy TNo ratings yet

- Inverter ProjectDocument15 pagesInverter Projectchiranjeet chandraNo ratings yet

- Design and Implementation of Water Bill Control System Based GSMDocument5 pagesDesign and Implementation of Water Bill Control System Based GSMPeter MulengaNo ratings yet

- Design and Implementation of an Intelligent Animal Intrusion Detection System Using IoTDocument17 pagesDesign and Implementation of an Intelligent Animal Intrusion Detection System Using IoTYash ChNo ratings yet

- Automatic Control of Water Supply Street Light and Garbage System For Making Village SmartDocument4 pagesAutomatic Control of Water Supply Street Light and Garbage System For Making Village SmartInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Driver'S Drowsiness Detection System: Bachelor of Technology in Computer Science and Engineering byDocument18 pagesDriver'S Drowsiness Detection System: Bachelor of Technology in Computer Science and Engineering byShanker Yadav0% (1)

- IOT Based Social Distancing and Monitoring Robot For QueueDocument8 pagesIOT Based Social Distancing and Monitoring Robot For QueueIJRASETPublicationsNo ratings yet

- Time Base Circuits Generate Linear Voltages and CurrentsDocument12 pagesTime Base Circuits Generate Linear Voltages and CurrentsRakib RashidNo ratings yet

- Vegetable Tracing Using IOTDocument64 pagesVegetable Tracing Using IOTSampath TNo ratings yet

- Human Robot InteractionDocument30 pagesHuman Robot InteractionUmasree A K100% (1)

- Mini Project Report: A Dissertation Submitted in Partial Fulfilment of The Requirements For The Award of Degree ofDocument38 pagesMini Project Report: A Dissertation Submitted in Partial Fulfilment of The Requirements For The Award of Degree ofS R I K A N T HNo ratings yet

- Smart Chair SystemDocument10 pagesSmart Chair SystemyashNo ratings yet

- Grid Sub Station Parameters Monitoring System by GSMDocument4 pagesGrid Sub Station Parameters Monitoring System by GSMmohdshujaatNo ratings yet

- GSM Based Distribution Transformer Monitoring and Controlling System Ijariie1748Document3 pagesGSM Based Distribution Transformer Monitoring and Controlling System Ijariie1748Velu SamyNo ratings yet

- PBC Regulator ModelDocument1 pagePBC Regulator ModelMukuro RokudoNo ratings yet

- Distribution Grid Transformers Monitoring Using GSM With Forced Cooling Control SystemDocument3 pagesDistribution Grid Transformers Monitoring Using GSM With Forced Cooling Control SystemMukuro RokudoNo ratings yet

- IITAW '08. International Symposium On, Shanghai, 2008, PPDocument1 pageIITAW '08. International Symposium On, Shanghai, 2008, PPMukuro RokudoNo ratings yet

- Med Yale EduDocument236 pagesMed Yale EduMukuro Rokudo100% (1)

- Ac Motor Control Theory (Constant V-F and Vector PWM With DSP Tms320)Document131 pagesAc Motor Control Theory (Constant V-F and Vector PWM With DSP Tms320)roxi50No ratings yet

- Distribution Grid Transformers Monitoring Using GSM With Forced Cooling Control SystemDocument3 pagesDistribution Grid Transformers Monitoring Using GSM With Forced Cooling Control SystemMukuro RokudoNo ratings yet

- Electronics - Ijece - Anti-Theft Home Security System.....Document6 pagesElectronics - Ijece - Anti-Theft Home Security System.....iaset123No ratings yet

- Ac Motor Control Theory (Constant V-F and Vector PWM With DSP Tms320)Document131 pagesAc Motor Control Theory (Constant V-F and Vector PWM With DSP Tms320)roxi50No ratings yet

- TM800 User GuideDocument266 pagesTM800 User Guidegeoagr2003No ratings yet

- Multiple Standby Config Changes2Document3 pagesMultiple Standby Config Changes2kapoor22No ratings yet

- Haskell FunctionalDocument22 pagesHaskell FunctionaldfjhNo ratings yet

- (Type The Document Title) : Ekalavya Model Residential SchoolDocument2 pages(Type The Document Title) : Ekalavya Model Residential SchoolSatyapriya PangiNo ratings yet

- NCS Appliance Configuration GuideDocument1,628 pagesNCS Appliance Configuration GuideFernando BolivarNo ratings yet

- ALL LCD - LED Service Menu Code - Kazmi ElecomDocument21 pagesALL LCD - LED Service Menu Code - Kazmi ElecomOscarGonzalezNo ratings yet

- Incremental Migration (IMIG) : Before You Begin 1Document7 pagesIncremental Migration (IMIG) : Before You Begin 1jaleelpeace9157No ratings yet

- FEDERAL GOVERNMENT COLLEGE DATA PROCESSINGDocument5 pagesFEDERAL GOVERNMENT COLLEGE DATA PROCESSINGEmmanuel AremuNo ratings yet

- PHP Star Rating System With JavaScript - PhppotDocument5 pagesPHP Star Rating System With JavaScript - PhppotAsmaNo ratings yet

- Abbott Alinity Ci FactSheetDocument1 pageAbbott Alinity Ci FactSheetLi RongNo ratings yet

- The MATLAB Online Desktop: Functional DifferencesDocument4 pagesThe MATLAB Online Desktop: Functional DifferencesMarilene LobatoNo ratings yet

- Chapter 4. File OperationsDocument49 pagesChapter 4. File OperationsTeshale SiyumNo ratings yet

- PL SQL Chapter 2Document32 pagesPL SQL Chapter 2designwebargentinaNo ratings yet

- Mork ResumeDocument2 pagesMork ResumeAdam ReedNo ratings yet

- Archmodels Vol 120Document11 pagesArchmodels Vol 120gombestralalaNo ratings yet

- ALPHA Brochure enDocument5 pagesALPHA Brochure enMuhamad ivan abrorNo ratings yet

- How To Solve It by Computer - R G Dromey PDFDocument463 pagesHow To Solve It by Computer - R G Dromey PDFVersha Rustagi90% (20)

- AMAG-5013 DataSheet ProfessionalV9 202210Document2 pagesAMAG-5013 DataSheet ProfessionalV9 202210Tri LifeNo ratings yet

- ACTIII Quick User GuideDocument20 pagesACTIII Quick User GuideCésarNo ratings yet

- JAVA MCQ (Answers) - 2Document7 pagesJAVA MCQ (Answers) - 2Sri SriNo ratings yet

- System Programming Lab: LEX: Lexical Analyser GeneratorDocument33 pagesSystem Programming Lab: LEX: Lexical Analyser GeneratorDivya D GowdaNo ratings yet

- Discover a public domain book scanned by GoogleDocument265 pagesDiscover a public domain book scanned by GoogleBhat NaieemNo ratings yet

- Excel Document Tutorial For BeginnersDocument2 pagesExcel Document Tutorial For BeginnersSehar KhanNo ratings yet

- KONE TranSys DX-brochure SOC 21 2 Tcm238-98197Document8 pagesKONE TranSys DX-brochure SOC 21 2 Tcm238-98197Bill GetsNo ratings yet

- Information and Communication Technology: Pearson Edexcel International GCSEDocument24 pagesInformation and Communication Technology: Pearson Edexcel International GCSEEric TTLNo ratings yet

- RH033Document1 pageRH033Suman RagiNo ratings yet

- Online: An Initiative of Ministry of Electronics & Information Technology (Meity), Government of IndiaDocument1 pageOnline: An Initiative of Ministry of Electronics & Information Technology (Meity), Government of IndiaTHE KNOWLEDGE BOOKSNo ratings yet

- Fiche SPIDERVIEW 4 MultilinguaDocument8 pagesFiche SPIDERVIEW 4 Multilinguaکوروش بزرگNo ratings yet