Professional Documents

Culture Documents

Hydrogen Gas Dryer India

Uploaded by

tpplantOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Hydrogen Gas Dryer India

Uploaded by

tpplantCopyright:

Available Formats

Hydrogen Gas Dryer india Refrigerated Hydrogen Gas Dryer India Air Dryer

Send Enquiry

Page 1 of 2

Select Language

Contact Us

Corporate Info

Home

Customers

Product Profile

Approvals

Vendor Registration

Exhibitions

Photo Gallery

Product Search Select Product.

Hydrogen Gas Dryer

Mellcon Engineers offer quality Hydrogen Gas Dryers to ensure low humidity levels continuously inside the Generators in Power Plants. Manufactured from the premium quality raw

materials our Hydrogen Gas Dryers are highly durable and reliable. Hydrogen Gas Dryers provided by us are highly efficient, thus needs less energy and provides excellent

performance. Hydrogen Gas Dryer is easy to use and install.

Hydrogen Gas Dryer (Refrigerated type)(Moisture upto -20 Deg.C ADP)

Capacity 40Nm3/Hr to 60 Nm3/Hr

Op. Pressure 3.5 kg/cm2g to 7.0 Kg/cm2g

Operation

The system comprises two heat exchangers, the hydrogen shell and tube type called pre-cooler in which temperature of hydrogen reduces

around 25-30 (Deg C. ). The cooled hydrogen now enters the second heat exchanger named evaporator, further cooling upto 0-3 (Deg.C) is

accomplished in this hence the set dew point is adjustable. The cooling coil inside the evaporator have propelled through a refrigeration system

due to low temperature in the evaporator. The moisture in the hydrogen condences and converts in water form. The water is collected in a well

protected condensate collector and can be drained out when desired leaving the evaporator. Hydrogen again travels to pre-cooler where it has

dual function of cooling and outgoing leaving dry hydrogen again rises to a safe temperature Hydrogen of around 25-40 (Deg C.)

Application

Advantage

1. Hydrogen gas coolent treatment in power industry

1. Energy efficient

2. To maintain low humidity level inside the Generator.

2. Compact in size

Hydrogen Gas Dryer (Dessicant Type) (MOISTURE UPTO -80 Deg C. ADP)

The range of Hydrogen Gas Dryer from Mellcon is made in Delhi India For power generation industry. By studying hydrogen coolent problem in depth, our supply chain has been able

to develop a system that truly answers the needs of utility industry.

Each contaminant is removed effectively and efficiently so that the generator is exposed only to clean dry hydrogen.

The skid package offers the following equipment:

1. High quality pre-filter assembly with a super high efficiency coalesing pre- filter element.

2. A carbon steel carbon bed adsorber assembly to remove the remaining hydrocarbon vapours, providing for maximum dessicant bed

protection. Therefore the dessicant and other dryer components last longer and require less maintenance.

3. A dual chamber dessicant dryer ASME standard. This is internally heat reactivated unit with open loop regeneration

4. Cycle times are adjustable

5. Specialised valve systems are specially designed and manufactured for hydrogen dryer service.

6. Low watt density heaters are installed from the base of the vassels in the dessicant bed preventing direct contact between the heater and

dessicant thereby reducing premature dessicant damage and heater twisting.

7. Molecular sieve dessicant with superior adsorption capacity at low relative humidity levels present in hydrogen cooling system.

8. Pre-piped reduces leak prone connections.

9. The skid mounted package is easily installed into any existing hydrogen system.

Photo Gallery

Product Profile

Corporate Info

Exhibitions

Customers

Wanted Dealers / Distributors / Resellers

Approvals

Careers

B - 297, Okhla Industrial Area, Phase - I , New Delhi - 110020 , India

Phone : +91-11-26816103, 26811727, 26816530

Fax : +91-11-26816573

Mellcon Engineers pvt Ltd.

http://mellcon.com/hydrogen-gas-dryer.aspx

All Rights Reserved Mellcon Engineers Pvt Ltd.

29-12-2015

Hydrogen Gas Dryer india Refrigerated Hydrogen Gas Dryer India Air Dryer

Page 2 of 2

http://mellcon.com/hydrogen-gas-dryer.aspx

29-12-2015

You might also like

- Ind Bharat Energy (Utkal) LTD (English)Document11 pagesInd Bharat Energy (Utkal) LTD (English)Prateek DubeyNo ratings yet

- Heat Required in Kcal For Unit Generation of ElectricityDocument18 pagesHeat Required in Kcal For Unit Generation of ElectricityAyan ChattarajNo ratings yet

- NTPC/SMPP Operation Department REV:0.00 Area-Tg TDBFP Isolation & Normalization Procedure UNIT-1/2 Date: 27.07.2010Document5 pagesNTPC/SMPP Operation Department REV:0.00 Area-Tg TDBFP Isolation & Normalization Procedure UNIT-1/2 Date: 27.07.2010Balaji AllupatiNo ratings yet

- Role of Maintenance in Boiler Energy ConservationDocument125 pagesRole of Maintenance in Boiler Energy ConservationkkannanmtpsNo ratings yet

- Boiler Light-Up PrerequisitesDocument3 pagesBoiler Light-Up PrerequisitesmallavscNo ratings yet

- This Bhel ProjectDocument51 pagesThis Bhel ProjectRaj_005No ratings yet

- Training ReportPDF PDFDocument42 pagesTraining ReportPDF PDFAman RajNo ratings yet

- TG Referal DatapediaDocument20 pagesTG Referal Datapediajp mishraNo ratings yet

- 115 Flexibility Report WEBDocument116 pages115 Flexibility Report WEBThanasate PrasongsookNo ratings yet

- Presentation ON Cerc Discussion Paper On Terms & Conditions of Tariff Applicable FROM 01.04.2004Document74 pagesPresentation ON Cerc Discussion Paper On Terms & Conditions of Tariff Applicable FROM 01.04.2004Mohit MalikNo ratings yet

- CW, CWR & CWX Pumps Installation, Operation and Maintenance ManualDocument20 pagesCW, CWR & CWX Pumps Installation, Operation and Maintenance ManualNadeemNo ratings yet

- 2nd Control of BoilerDocument14 pages2nd Control of BoilerMuanifNo ratings yet

- Mill ProjectDocument5 pagesMill ProjectChaitanya Dev SadaphalNo ratings yet

- BOE QuestionsDocument4 pagesBOE QuestionsParameswararao BillaNo ratings yet

- Super Critical Salient FeaturesDocument16 pagesSuper Critical Salient Featureshanumehrotra100% (1)

- Energy Performance Assessment of Boiler at P.S.S.K. LTDDocument12 pagesEnergy Performance Assessment of Boiler at P.S.S.K. LTDPajooheshNo ratings yet

- Overview of NTPC PDFDocument40 pagesOverview of NTPC PDFRahul KediaNo ratings yet

- B. Prestart Checks of Boiler LightupDocument14 pagesB. Prestart Checks of Boiler LightupPrudhvi RajNo ratings yet

- Super Critical Power PlantDocument27 pagesSuper Critical Power PlantPrabir Kumar PatiNo ratings yet

- NTPC (National Thermal Power Corporation) Sipat Mechanical Vocational Training Report 4-Haxxo24 I IDocument44 pagesNTPC (National Thermal Power Corporation) Sipat Mechanical Vocational Training Report 4-Haxxo24 I Ihaxxo24No ratings yet

- NTPC Training ReportDocument49 pagesNTPC Training Reportpusd_90100% (1)

- Boiler OperationDocument14 pagesBoiler OperationjmayurrNo ratings yet

- Cold Startup Procedure 250 MWDocument7 pagesCold Startup Procedure 250 MWPrudhvi RajNo ratings yet

- Fuel Cells Article in ISOFT by Inderraj GulatiDocument6 pagesFuel Cells Article in ISOFT by Inderraj GulatiInderraj_Gulati100% (1)

- ENERGY AUDIT REVEALS POTENTIAL TO INCREASE OUTPUT AT R-INFRA POWER PLANTDocument84 pagesENERGY AUDIT REVEALS POTENTIAL TO INCREASE OUTPUT AT R-INFRA POWER PLANTLakshmi NarayanNo ratings yet

- 2 HP WTR Hdr-Seal Trough FlushingDocument10 pages2 HP WTR Hdr-Seal Trough Flushingsekhar_ntpcNo ratings yet

- Costs and Results of Hydrogen Drying and PurificationDocument3 pagesCosts and Results of Hydrogen Drying and PurificationMarco BuraniNo ratings yet

- 1200 MW Coal Plant PerformanceDocument20 pages1200 MW Coal Plant Performancemaknu2827 Jain100% (1)

- TPP Steel PlantDocument25 pagesTPP Steel PlantPRASANTHNo ratings yet

- Lakshmi Narain NTPC Aux Power Consumption ReductionDocument14 pagesLakshmi Narain NTPC Aux Power Consumption Reductionmoorthymtps_54120305No ratings yet

- Ennore Thermal Power StationDocument14 pagesEnnore Thermal Power StationRajesh Kumar100% (2)

- GENERator Auxilary System MonitoringDocument10 pagesGENERator Auxilary System MonitoringdhirendracommonNo ratings yet

- 22a.boilers and Thermic Fluid HeatersDocument54 pages22a.boilers and Thermic Fluid Heatersprasi1010100% (1)

- NTPC Vindhyachal ReportDocument13 pagesNTPC Vindhyachal Reportblackswan_07No ratings yet

- Boiler Ga, Specification & Line Up For Light Up: by Rahul R MungaleDocument11 pagesBoiler Ga, Specification & Line Up For Light Up: by Rahul R MungaleMukesh Kumar VaishnavNo ratings yet

- Advanced Cycles JIPTDocument26 pagesAdvanced Cycles JIPTjp mishraNo ratings yet

- Final YearDocument51 pagesFinal YearAnand Kumar0% (1)

- Boiler Fundamental & Water Circulation SystemDocument30 pagesBoiler Fundamental & Water Circulation SystemSamNo ratings yet

- Fuel Oil SystemDocument14 pagesFuel Oil SystemNageswar MakalaNo ratings yet

- Diagnostic Tools and Control Parameters For Refinery HeatersDocument7 pagesDiagnostic Tools and Control Parameters For Refinery HeaterskrishnaNo ratings yet

- Condensate Extraction Pump: GeneralDocument5 pagesCondensate Extraction Pump: GeneralAnonymous DKv8vpNo ratings yet

- Bhel Pipe Color Code-Aa10630 1Document7 pagesBhel Pipe Color Code-Aa10630 1Vamsikrishna LakamsaniNo ratings yet

- Basic Principles of Steam Turbine1Document141 pagesBasic Principles of Steam Turbine1Durga Prasad PadhyNo ratings yet

- APHDocument3 pagesAPHMallinatha PNNo ratings yet

- Turbovisory SystemDocument2 pagesTurbovisory SystemLily Sharma100% (1)

- Black Out Is Land OperationDocument41 pagesBlack Out Is Land Operationstubborn002No ratings yet

- 6.6 KV Switchgear Charging & IsolationDocument12 pages6.6 KV Switchgear Charging & IsolationSreekanthMylavarapuNo ratings yet

- Captive Power PlantDocument26 pagesCaptive Power PlantAshish ThakurNo ratings yet

- Suratgarh Super Thermal Power Station: Full ReportDocument2 pagesSuratgarh Super Thermal Power Station: Full ReportVivek SharmaNo ratings yet

- Eskom 2017 Q2 Final Draft Report To ShareholderDocument132 pagesEskom 2017 Q2 Final Draft Report To ShareholderChris YellandNo ratings yet

- HP Heaters Operation During Start Up of UnitDocument1 pageHP Heaters Operation During Start Up of UnitMuhammad luqman100% (1)

- Doc-2 Training Material On Coal Fired Thermal Power PlantsDocument21 pagesDoc-2 Training Material On Coal Fired Thermal Power PlantsSharan100% (2)

- B-Asic of Super Critical Boiler (660mw)Document48 pagesB-Asic of Super Critical Boiler (660mw)Arvind Shukla100% (1)

- Hydrogen Dew Point MonitoringDocument0 pagesHydrogen Dew Point Monitoringbauskarm1No ratings yet

- USCG ME Exam - Steam KnowledgeDocument112 pagesUSCG ME Exam - Steam KnowledgeMark Anthony SisonNo ratings yet

- Dec 09Document35 pagesDec 09Krishnan SanthanarajNo ratings yet

- Mapping MDocument39 pagesMapping MRajneesh VachaspatiNo ratings yet

- GEK 116682 7FA9FA Cooling and Sealing Air System PDFDocument14 pagesGEK 116682 7FA9FA Cooling and Sealing Air System PDFZaki nouiNo ratings yet

- Jindal Hydrogen Gas DryerDocument2 pagesJindal Hydrogen Gas DryerLakshmi Narayan100% (2)

- Eone Generator Gas Dryer (GGD Ii) Justification and Specification InfoDocument6 pagesEone Generator Gas Dryer (GGD Ii) Justification and Specification InfoAmal ChinthakaNo ratings yet

- అతీంద్రియ రహస్యాలు - బ్లావట్స్కీDocument162 pagesఅతీంద్రియ రహస్యాలు - బ్లావట్స్కీtpplant100% (2)

- Successful Negotiation Skills Process PDFDocument12 pagesSuccessful Negotiation Skills Process PDFtpplantNo ratings yet

- BAT007 - Fuel Cell V Batteries WP - 0814 PDFDocument18 pagesBAT007 - Fuel Cell V Batteries WP - 0814 PDFLong NguyenNo ratings yet

- GST Data CollectedDocument11 pagesGST Data CollectedtpplantNo ratings yet

- Presentation On GST: (Goods and Services Tax)Document11 pagesPresentation On GST: (Goods and Services Tax)tpplantNo ratings yet

- TQM Awards: Leading International Quality AwardsDocument2 pagesTQM Awards: Leading International Quality AwardstpplantNo ratings yet

- Aviation Phonetic Alphabet GuideDocument2 pagesAviation Phonetic Alphabet GuideJohnnyNo ratings yet

- GST-Concept and StatusDocument52 pagesGST-Concept and StatusPramod NayakNo ratings yet

- SEN301previousexamquestions PDFDocument22 pagesSEN301previousexamquestions PDFM MohanNo ratings yet

- Elements and Types of Contracts in India and UAE TaxationDocument8 pagesElements and Types of Contracts in India and UAE TaxationtpplantNo ratings yet

- Boeing PPT LinksDocument1 pageBoeing PPT LinkstpplantNo ratings yet

- S.No Name Place of Incorporation: EXHIBIT (21) - List of Company SubsidiariesDocument12 pagesS.No Name Place of Incorporation: EXHIBIT (21) - List of Company SubsidiariestpplantNo ratings yet

- HRSG StartupDocument19 pagesHRSG Startuptpplant100% (1)

- Sop 01-Turbine Cold StartupDocument12 pagesSop 01-Turbine Cold Startuptpplant100% (1)

- 2014 05 Turbine Generator PKG EreDocument8 pages2014 05 Turbine Generator PKG EretpplantNo ratings yet

- h2 Purity and LoadDocument4 pagesh2 Purity and LoadtpplantNo ratings yet

- Top Tools For CalligraphersDocument2 pagesTop Tools For CalligrapherstpplantNo ratings yet

- Nitrogen Plant Operation Manual With DrawingDocument29 pagesNitrogen Plant Operation Manual With Drawingtpplant100% (3)

- Purification of Drinking Water-MethodsDocument9 pagesPurification of Drinking Water-MethodstpplantNo ratings yet

- Appnotes Differential Expansion TSIDocument6 pagesAppnotes Differential Expansion TSItpplantNo ratings yet

- 2013 02 Working of Gas TurbineDocument3 pages2013 02 Working of Gas TurbinetpplantNo ratings yet

- Wiki Wobbe IndexDocument2 pagesWiki Wobbe IndextpplantNo ratings yet

- PDF 2015 02 05 20150205b 001102006.jpgDocument1 pagePDF 2015 02 05 20150205b 001102006.jpgtpplantNo ratings yet

- Wiki Wobbe IndexDocument2 pagesWiki Wobbe IndextpplantNo ratings yet

- Common Names of ChemicalsDocument6 pagesCommon Names of ChemicalstpplantNo ratings yet

- Thermodynamics of 1911 Pea BDocument3 pagesThermodynamics of 1911 Pea BtpplantNo ratings yet

- Boiler CalculationsDocument16 pagesBoiler CalculationsBilly Moerdani100% (1)

- Methods of Analysis of Coal in India.Document9 pagesMethods of Analysis of Coal in India.jpsniraNo ratings yet

- Well Cementation: SynopsisDocument18 pagesWell Cementation: SynopsisHolger PinzonNo ratings yet

- Computer Mcqs1'Document34 pagesComputer Mcqs1'Imran SheikhNo ratings yet

- Power System Harmonics Causes and Effects PDFDocument8 pagesPower System Harmonics Causes and Effects PDFRamon DrakeNo ratings yet

- Capsule technology overviewDocument5 pagesCapsule technology overviewKazi Nafis UllahNo ratings yet

- CN398 - Dual ESSP Interface To Both Smart Payout and HopperDocument1 pageCN398 - Dual ESSP Interface To Both Smart Payout and HopperAymen CheffiNo ratings yet

- LCA Training PackageDocument57 pagesLCA Training PackageSilvia PolliniNo ratings yet

- Perfect Gas Law Lab ReportDocument9 pagesPerfect Gas Law Lab ReportTan Zu Kuan50% (2)

- Plotting OctaveDocument13 pagesPlotting OctaveJhonatan AriasNo ratings yet

- PACSystemsRX3i CS GFA559G (2010)Document4 pagesPACSystemsRX3i CS GFA559G (2010)Omar Alfredo Del CastilloNo ratings yet

- Loading ArmDocument6 pagesLoading ArmSardar ShahnawazNo ratings yet

- Ramsey Hobby 2 KDocument40 pagesRamsey Hobby 2 Kjsmith20No ratings yet

- MPR TMN NetworkingDocument91 pagesMPR TMN Networkingkazi_hoque5729No ratings yet

- Mahindra&mahindraDocument95 pagesMahindra&mahindraAshik R GowdaNo ratings yet

- Biotech. Facility DesignDocument17 pagesBiotech. Facility Designابُوالبَتُول ڈاکٹر صفدر علی قادری رضوی100% (1)

- Communications201509 DLDocument132 pagesCommunications201509 DLleecomNo ratings yet

- Addis Ababa Science and Technolog1 (Autorecovered) (Autorecovered)Document70 pagesAddis Ababa Science and Technolog1 (Autorecovered) (Autorecovered)penihaniNo ratings yet

- Restricting TECO revoking after order settlementDocument4 pagesRestricting TECO revoking after order settlementMayank MevchaNo ratings yet

- 14EEMME00 - Darshna RamawatDocument31 pages14EEMME00 - Darshna Ramawatdatshna ramawatNo ratings yet

- UDN6118ADocument8 pagesUDN6118AkizonzNo ratings yet

- Dam Break AnalysisDocument18 pagesDam Break AnalysisBushra UmerNo ratings yet

- Model 3260 Constant Speed Mixer ManualDocument31 pagesModel 3260 Constant Speed Mixer ManualNi MaNo ratings yet

- Paper tube adhesive composition increases strengthDocument4 pagesPaper tube adhesive composition increases strengthProduction SHVPMNo ratings yet

- Effectof Cyclic Loadingsonthe Shear StrengthandDocument14 pagesEffectof Cyclic Loadingsonthe Shear StrengthandAbel MulugetaNo ratings yet

- 750 Programming 102010Document83 pages750 Programming 102010Ehsan Rohani100% (1)

- Felsic 105 Tfrs v4Document12 pagesFelsic 105 Tfrs v4mohammad reza aghatiNo ratings yet

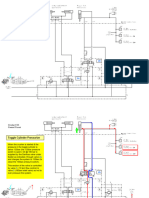

- Toggle Ram - CSS Ram Valve SetupDocument6 pagesToggle Ram - CSS Ram Valve Setupsassine khouryNo ratings yet

- GSR 10-8-2 Li Professional Manual 129196Document169 pagesGSR 10-8-2 Li Professional Manual 129196madmatskNo ratings yet

- Presented by Intramantra Global Solution PVT LTD, IndoreDocument14 pagesPresented by Intramantra Global Solution PVT LTD, IndoreDeepak RathoreNo ratings yet

- Queensferry Crossing PresentationDocument7 pagesQueensferry Crossing PresentationGregor MackenzieNo ratings yet

- Conservation of Momentum Worksheet PDFDocument8 pagesConservation of Momentum Worksheet PDFChristopher John Inamac Gayta (Chris)No ratings yet