Professional Documents

Culture Documents

Job Hazard Analysis Rope Access

Uploaded by

Sean Kalu OnuohaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Job Hazard Analysis Rope Access

Uploaded by

Sean Kalu OnuohaCopyright:

Available Formats

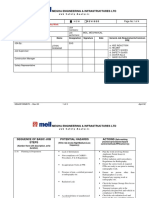

Rope-Access Work Plan and JHA

Page 1 of 5

Job Hazard Analysis (JHA) & Rope-Access Work Plan

Project Name

Date Prepared

Client/Host

Start Date

Location

Description

Host Facility

Manager

Host Facility Operator

Finish Date

Phone

email

Phone

email

Personnel

Position

Name

Sign only after reading

Contact phone/email

Training

Current

Emerg. Form

(on location)

Prepared by

Safety

Supervisor

Technician

Technician

Technician

Technician

other

other

other

Emergency Information

EMS Phone

Police Phone

Fire/Rescue

Team Phone

Company Contact

Name & Phone

Emergency

Where and how will EMS reach the worksite?

Access to Site

Communication:

Cell Phone (Check service on site

Y

N)

Radio (Channel:

Phone (Note phone number, location, special dialing, other contacts, etc)

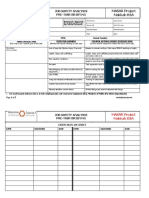

Rope-Access Work Plan and JHA

Page 2 of 5

Work Plan

Description of

Work

Standard practices outlined in Guidelines for Rope Access Work

Rope-access

Methods

Individual

Equipment

Helmet

Eye protection

Foot protection

Gloves

Protective clothing

Reflective Clothing

Respiratory protection

Hearing Protection

Harness

Connectors

Descender (ID)

Belay Device (Gri-Gri)

2 Backup Devices

Lanyards

Pulleys

headlamp

Group

Equipment

Team

Communication

Machinery

Lock-out/tag-out

Multi-tool

other

Ropes (length and quantity)

Rigging Straps

Connectors

Visual (Hand Signals)

Edge Protection

other

Verbal (unassisted)

Radio (Note Channel)

Do machinery, valves, or gates need to be locked-out?

Machinery Locked-out/Tagged out of service

Yes

No

Hold Order visually checked by RA Supervisor

Hold Order Number _________________________

RA Supervisor ____________________________

Equipment/Tool

Management

Other...(describe... attach additional pages if necessary)

Access Zone

Describe Access Zone and method to mark and secure entry

Hazard Zone

Describe hazard zone and method to mark and secure entry and to protect public or other workers

Standard anchors outlined in Guidelines

Anchors

Rescue and

Retrieval

Methods

Rescue Kit

First Aid Kit

other

Patient Packaging

Pulleys

Rope Grabs

Connectors

Spare Equipment

Rope-Access Work Plan and JHA

Page 3 of 5

Condition

Falling

Gravity-induced injury or death

Human Error

Rigging Errors

Communication

Difficulty

Loud ambient noise (traffic, machinery,

running water, wind, etc.)

Malfunctioning or dropped radios

Conditions change

Sharp/abrasive

Rope or anchor damage and/or failure

Abrasions or cuts to hands

Inadvertent contact with energized lines

Burns or electrocution from contact

Machinery

Injury from

Inadvertent operation of machinery

Injury sustained from machinery

Hazardous condition created (e.g.

release of water)

Hazards depend on tools used

Damage to rope-access or fall-protection

system

surfaces

Electrical Lines

Tools

Dropped Tools

Description of Hazards

Possible injury to personnel and public

Loss of important tools for work or

egress

Damage to structures or equipment

loose detritus

Possible injury to personnel and public

Damage to structures or equipment

Severed ropes

Rain/Wet

Conditions

Insulating qualities of wet clothing

decreases

Possible hypothermia (dangerously low

body temperature)

Wet surfaces can be slippery

Decreased friction on descent and ropegrab devices

Danger of stray current near improperly

insulated and grounded equipment

Decreased visibility

Insulating qualities of wet clothing

decreases

Possible hypothermia (dangerously low

body temperature) and frostbite

Loss of dexterity in extremities

Wet and icy surfaces are slippery

Decreased friction on descent and ropegrab devices

Danger of stray current around

improperly insulated and grounded

electrical equipment

Decreased visibility

Wet surfaces can be slippery

Potential for Drowning

or Materials

Rock fall or

Snow/Ice

Condition

Water

(working around/over

Description of Hazards

Control Measures

Always use appropriate fall-protection or rope-access

equipment when 6 feet from unprotected edge with a

fall potential of 6 feet or more

All personnel must be properly trained

Use 2-rope system when working line is primary

means of support

Use independent anchorages

Always do 4-point check: Ropes (including anchors),

Hardware, Harness, Helmet

Agree upon and use standardized communication

signals

Check communication system

Designate alternate communication system in case

conditions change or technical difficulties arise

Review hand signals (as appropriate)

Use proper edge protection and padding

Use re-direct or intermediate anchors as needed

Wear gloves and proper clothing

Examine lines that might be contacted by wind-blown

ropes

Get appropriate clearances

Follow lock-out/tag-out procedure

Get appropriate clearances

Follow lock-out/tag-out procedure

Confirm lock-out/tag-out

Follow all manufacturers instructions and keep all

protective guards in place

Separate suspension rope may be required for tools

greater than 10 kg

Clearly mark and barricade Hazard Zone

Helmets or hard hats must be worn in Hazard Zone

Keep a clean and orderly worksite

All tools and devices must be tethered or secured

Avoid working or standing below other workers

Careful scaling or clearing of slope prior to work

Loose materials or rock may need to be secured

(either temporarily or permanently)

Manage ropes carefully to avoid dislodging loose

materials

Stop work if conditions become dangerous

Wear proper footwear and clothing

Waterproof rain gear should be available

Be aware of slippery conditions

Electrical equipment must be adequately grounded

and equipped with GFCIs.

Stop work if conditions become dangerous

Wear proper footwear and clothing, including gloves

and hat

Waterproof rain gear should be available

Be aware of slippery conditions

Use appropriate rope access equipment for conditions

Electrical equipment must be adequately grounded

and equipped with GFCIs.

Hand warmers should be available in case of

emergency

Control Measures

Stop work if conditions become dangerous

Rescue boat shall be readily available if working

directly over water, especially if descent is a viable

Rope-Access Work Plan and JHA

Page 4 of 5

Condition

Falling

Gravity-induced injury or death

moving/standing

Trapped in current while tied off

(drowning hazard)

water)

Description of Hazards

Control Measures

Always use appropriate fall-protection or rope-access

equipment when 6 feet from unprotected edge with a

fall potential of 6 feet or more

All personnel must be properly trained

method of egress.

Fall protection or rope access equipment must not

allow worker to fall into water (especially moving water)

Personal flotation devices not required if proper fall

protection in place

Rope-Access Work Plan and JHA

Page 5 of 5

Condition

Falling

Gravity-induced injury or death

Description of Hazards

Sun/Heat

Possible dehydration, heat exhaustion or

heat stroke

Burns from tools, equipment, and

structural steel

Cold/Freezing

Temperatures

Wind

Lightning

Dimly lit or

night work

Dust

Chemical

exposure

Confined space

entry

High-noise area

Adhesives and first-aid supplies may be

degraded by heat

Possible hypothermia, frostbite, loss of

dexterity in extremities

Decrease in efficiency, adhesives and

first-aid supplies may not function

properly due to cold, water for drinking

and work may be frozen; slippery

surfaces

Possible increased cooling or

hypothermia risk, increased dehydration

risk in dry humidity

Decrease in efficiency, hindrance to

communications between team members

Danger of unsecured equipment or

material being blown into the access zone

Difficulty communicating

Possible electrocution due to lightning

strike, loss of consciousness or life

Rope-access equipment may provide a

pathway to the operative for electrical

strikes

Sharp or protruding objects (metal, nails,

bolts, etc.) may not be visible to moving

operatives, drowsiness of employees

Difficulty in breathing, possible allergic

reaction

Possible long-term exposure hazard

Difficulty in breathing, dizziness,

unconsciousness

Chemical burns to skin, eyes, internal

organs

Work areas may contain toxic gases or

insufficient oxygen levels for work.

Space may have restricted entry/exit

making access difficult,

Permanent or temporary damage to

hearing

Difficult Communications

High-noise levels may mask warning

buzzers or other alert sounds

Possible injury or incapacitation of

personnel depending on severity of bite or

venom

Vehicular

Possible impact or crushing injury

Traffic

Bird & Animal

Possible inhalation of disease carried by

feces

Insect or animal

bites or stings

Feces

Control Measures

Always use appropriate fall-protection or rope-access

equipment when 6 feet from unprotected edge with a

fall potential of 6 feet or more

All personnel must be properly trained

Stop work if conditions become dangerous

Ample water and/or electrolytes must be on hand for

workers

Schedule proper breaks and work in morning or

evening to avoid peak temperatures

Wear gloves and proper clothing to protect hands from

hot surfaces

Use and frequently re-apply adequate sunscreen

Stop work if conditions become dangerous

Wear proper footwear and clothing, including gloves

and hat

Warm liquids should be available to workers

Stop work if conditions become dangerous

Wear proper footwear and clothing, including gloves

and hat

Secure loose materials at work site

Be wary of wind developing slack in ropes where they

may be blown in to areas making retrieval difficult

Stop work when lightning threatens

Provide adequate lighting: area lighting and/or headand hand-lamps

Provide spare batteries, light sources, and bulbs

Provide adequate engineering controls

Provide PPE where engineering controls not possible

or impractical

Workers must have MSDS on site for all chemicals

used in work

Proper PPE and engineering controls must be in place

Respirators must be the correct type for the exposure

Follow confined space procedures

Toxic rescue plan required and in force prior to entry

Hearing protection required, in extremely loud

environments (+120 dBA), multiple types of protection

may be necessary.

Agree on hand signals before work starts

Workers may be equipped with sound-isolating

hearing protection for radios.

Careful access into areas where spiders, snakes,

scorpions, or other creatures may reside.

Use of gloves at all times, equip first aid kit with

medical supplies appropriate for bites and stings.

Careful demarcation of access and hazard zones, Use

flags, signs, flag persons, lighting as needed

Provide high-visibility clothing for personnel

Workers may need to wear protective gloves or

respirators.

Rope-Access Work Plan and JHA

Page 6 of 5

Post-Job Debrief

Date/Time

Completed

Safety

Considerations

Anchorages Used

/ Special

Techniques

Near Miss or

Accidents

Debrief Prepared

by:

Were adequate safety measures taken to insure the safety of personnel and public? Note any

additional safety measure taken or recommended.

Describe the anchorage set-up used and any special techniques used

Describe any near misses or accidents. If none, write none. Attach additional pages if necessary.

You might also like

- SOP For Working at HeightDocument19 pagesSOP For Working at HeightShreedhar94% (18)

- QP Painting JSADocument6 pagesQP Painting JSAMohammed Mujahid100% (2)

- Rope Access Inspection GuidebookDocument44 pagesRope Access Inspection GuidebookShaik Mohamed100% (2)

- Working at Heights Rescue ProcedureDocument6 pagesWorking at Heights Rescue ProcedureBea Mok0% (1)

- Safety Harness Inspection ChecklistDocument1 pageSafety Harness Inspection Checklistshaheer100% (7)

- Safe Working at HeightsDocument27 pagesSafe Working at Heightscosty_mcv100% (7)

- Electric Hand Drill Risk AssessmentDocument4 pagesElectric Hand Drill Risk AssessmentTariq AkhtarNo ratings yet

- Manual Tig Welding (RRC) - Job ProcedureDocument3 pagesManual Tig Welding (RRC) - Job Proceduretitto84886100% (1)

- JHA Stacks EDG Substation r0 14 August 2017 EdittedDocument5 pagesJHA Stacks EDG Substation r0 14 August 2017 EdittedJeniffer Ong100% (1)

- Grinding Equipment Risk AssessmentDocument3 pagesGrinding Equipment Risk Assessmentdroffilcz270% (1)

- Jsa Grinding W Angle GrinderDocument2 pagesJsa Grinding W Angle GrinderMichael Angelo SanteNo ratings yet

- Al - Osais Contracting Company Haradh Area Power Reliability EnhancementDocument3 pagesAl - Osais Contracting Company Haradh Area Power Reliability EnhancementREHAN IQBAL100% (3)

- Industrial Rope Access MethodDocument38 pagesIndustrial Rope Access MethodUllas Krishnan0% (1)

- Rope Access-Method Statement RoughDocument22 pagesRope Access-Method Statement RoughSean Kalu Onuoha80% (5)

- Working at Height Is One of The Hazardous OccupationsDocument6 pagesWorking at Height Is One of The Hazardous OccupationsHemaNo ratings yet

- Jsa-Jha For Using of Hand ToolsDocument2 pagesJsa-Jha For Using of Hand ToolsKamran Khan50% (2)

- Risk Assessment for Window Cleaning by Rope AccessDocument11 pagesRisk Assessment for Window Cleaning by Rope AccessADIL FAZALNo ratings yet

- DM-PHSD-P7-A-TG - (Guidelines For Rope Access Work) English PDFDocument11 pagesDM-PHSD-P7-A-TG - (Guidelines For Rope Access Work) English PDFdemie figueroaNo ratings yet

- Jsa For Piping and Erection RevisedDocument1 pageJsa For Piping and Erection RevisedDr AnwarNo ratings yet

- JSA UT TestDocument1 pageJSA UT TestIksan Adityo MulyoNo ratings yet

- Working at Heights Rescue ProcedureDocument4 pagesWorking at Heights Rescue ProcedureAizat Hanem100% (1)

- Boom Lift PDFDocument2 pagesBoom Lift PDFcityofdarwingisNo ratings yet

- Heights Safe Working atDocument7 pagesHeights Safe Working atHendrias Ari SujarwoNo ratings yet

- Deathtrap Dungeon 3Document87 pagesDeathtrap Dungeon 3hdjhsjhd50% (2)

- Job Safety Analysis - Rope AccessDocument2 pagesJob Safety Analysis - Rope AccessMathavaraj Dharmaraj75% (4)

- Jsa FormDocument3 pagesJsa Formmiaicarba100% (1)

- Print and Embroidery Business Plan (Full)Document23 pagesPrint and Embroidery Business Plan (Full)Tahsin Morshed80% (5)

- Construction SafetyDocument48 pagesConstruction SafetyZain Sani Butt83% (6)

- JHA Scaffolding ErectionDocument12 pagesJHA Scaffolding ErectionChayank TiwariNo ratings yet

- Ladder Safety SOPDocument3 pagesLadder Safety SOPBoiler ScrubberNo ratings yet

- JSA For Rope Access Services (24-Sep-14)Document8 pagesJSA For Rope Access Services (24-Sep-14)TomasPavlovic100% (1)

- JSA FormDocument6 pagesJSA FormAjeesh CochinNo ratings yet

- Jsa For RadiographyDocument3 pagesJsa For Radiographyjithin shankarNo ratings yet

- Upgrade Fire Detection SystemDocument3 pagesUpgrade Fire Detection SystemPaul Sodipo100% (1)

- JHA For Tie-In at PCR14-02Document7 pagesJHA For Tie-In at PCR14-02Francis Enriquez TanNo ratings yet

- Chinese New Year Festival Traditions & CelebrationsDocument9 pagesChinese New Year Festival Traditions & CelebrationsJudy Ann Magaling LptNo ratings yet

- JSA Welding Confined SpaceDocument2 pagesJSA Welding Confined Spacegkmlal100% (4)

- Rope Access Rescue PlanDocument4 pagesRope Access Rescue Planpatvindewr89% (9)

- Industrial Rope AccessDocument166 pagesIndustrial Rope Accessrevers0100% (3)

- Risk Assessment Magnetic Particle InspectionDocument4 pagesRisk Assessment Magnetic Particle InspectionSanjeev Nair75% (4)

- Confined Space ProcedureDocument16 pagesConfined Space ProcedureRey Gaballo Jr67% (3)

- Work Height ProcedureDocument7 pagesWork Height ProcedureardodotNo ratings yet

- 031 Procedure Rigging Slinging and LiftingDocument18 pages031 Procedure Rigging Slinging and LiftingMohamed Hadjkacem100% (2)

- Crash (Film Script)Document52 pagesCrash (Film Script)Maite GuelermanNo ratings yet

- Rope Access Guide Book Vertical SpecialistDocument23 pagesRope Access Guide Book Vertical Specialistpkannan100% (1)

- Method Statement For RadiographyDocument10 pagesMethod Statement For RadiographySanjeev Nair100% (1)

- Task Risk Assessment WeldingDocument3 pagesTask Risk Assessment WeldingBabar Manzoor GhauriNo ratings yet

- Surface Pattern Design GuideDocument30 pagesSurface Pattern Design GuideEster Cellucci97% (30)

- Guide Suspended Swing Stage ScaffoldsDocument14 pagesGuide Suspended Swing Stage Scaffoldsahmed rafeeq100% (1)

- Job Safety Analysis Pre-Task Briefing: MASAR Project Makkah KSADocument2 pagesJob Safety Analysis Pre-Task Briefing: MASAR Project Makkah KSAmahammed saleem100% (2)

- 052 Sand BlastingDocument2 pages052 Sand Blastingwilson mantilla100% (1)

- Excavation JSADocument4 pagesExcavation JSASalah Abd EldayemNo ratings yet

- Industrial Rope Access CleaningDocument22 pagesIndustrial Rope Access CleaningAli SadiqinNo ratings yet

- Jsa For Ut TestDocument2 pagesJsa For Ut Testnasar_mahsood50% (2)

- Title: Hot Work Procedure: Occupational Health and Safety Act 2004 Occupational Health and Safety Regulations 2007Document5 pagesTitle: Hot Work Procedure: Occupational Health and Safety Act 2004 Occupational Health and Safety Regulations 2007Adeyinka MichealNo ratings yet

- Working at Height ProcedureDocument6 pagesWorking at Height ProcedureBabar Manzoor GhauriNo ratings yet

- Safe Lifting Operations ProcedureDocument7 pagesSafe Lifting Operations ProcedureJoozza MandaNo ratings yet

- Job Safety Analysis Sheet: FacilityDocument1 pageJob Safety Analysis Sheet: Facilitywahyu nugrohoNo ratings yet

- Sample BQDocument10 pagesSample BQmohdshahrircheabdul100% (1)

- TATA Power Scaffold Safety StandardDocument7 pagesTATA Power Scaffold Safety StandardDSG100% (1)

- Rope Access TechniqueDocument14 pagesRope Access TechniqueSai FujiwaraNo ratings yet

- Tower Climbing and Rigging Risk AssessmentDocument7 pagesTower Climbing and Rigging Risk Assessmentnevily wilbardNo ratings yet

- Detailed Lesson Plan in Dressmaking TailDocument7 pagesDetailed Lesson Plan in Dressmaking TailCherry Mae Cornelio100% (4)

- Sword Art Online 8 - Early and Latev2Document393 pagesSword Art Online 8 - Early and Latev2ccKalluto100% (2)

- Daily JSADocument4 pagesDaily JSAumn_mlkNo ratings yet

- 10 Questions For Electrical SafetyDocument2 pages10 Questions For Electrical Safetydilesh50% (2)

- Angle Grinder SOPDocument2 pagesAngle Grinder SOPFord Katim50% (2)

- Job Hazard Analysis (Jha) : Contractor: Date: Doc. No. & Rev. No.: 00Document6 pagesJob Hazard Analysis (Jha) : Contractor: Date: Doc. No. & Rev. No.: 00poovazhaganNo ratings yet

- Senior Design Engineer - Mechanical Vacancy AdvertDocument1 pageSenior Design Engineer - Mechanical Vacancy AdvertSean Kalu OnuohaNo ratings yet

- Senior Design Engineer - Mechanical Vacancy AdvertDocument1 pageSenior Design Engineer - Mechanical Vacancy AdvertSean Kalu OnuohaNo ratings yet

- Technical Assistant SOP and DutiesDocument1 pageTechnical Assistant SOP and DutiesSean Kalu OnuohaNo ratings yet

- W1S2-Evolution of The Global Transportation System - MDP - DesbloqueadoDocument4 pagesW1S2-Evolution of The Global Transportation System - MDP - DesbloqueadoJesus Enrique Figueroa GilNo ratings yet

- InTrayExercise PDFDocument33 pagesInTrayExercise PDFSean Kalu OnuohaNo ratings yet

- Flow Assurance Quiz#4 Flashcards - Quizlet PDFDocument4 pagesFlow Assurance Quiz#4 Flashcards - Quizlet PDFSean Kalu OnuohaNo ratings yet

- NOV - Powerstroke Drilling JarDocument2 pagesNOV - Powerstroke Drilling JarpendexxNo ratings yet

- IPS Past Question 2004Document105 pagesIPS Past Question 2004Sean Kalu Onuoha100% (1)

- One of The Largest Drilling Contracts in The World Outsourced To HalliburtonDocument4 pagesOne of The Largest Drilling Contracts in The World Outsourced To HalliburtonSean Kalu OnuohaNo ratings yet

- NOV - Powerstroke Drilling JarDocument2 pagesNOV - Powerstroke Drilling JarpendexxNo ratings yet

- Bahar MartonosiDocument10 pagesBahar MartonosiNah CaliNo ratings yet

- Bahar MartonosiDocument10 pagesBahar MartonosiNah CaliNo ratings yet

- Flow Assurance Quiz#4 Flashcards - Quizlet PDFDocument4 pagesFlow Assurance Quiz#4 Flashcards - Quizlet PDFSean Kalu OnuohaNo ratings yet

- Flow Assurance Quiz#4 Flashcards - Quizlet PDFDocument4 pagesFlow Assurance Quiz#4 Flashcards - Quizlet PDFSean Kalu OnuohaNo ratings yet

- W3V18 - EP Conclusion - Handout PDFDocument4 pagesW3V18 - EP Conclusion - Handout PDFSean Kalu OnuohaNo ratings yet

- W3V17 - Offshore - HandoutDocument4 pagesW3V17 - Offshore - HandoutSean Kalu OnuohaNo ratings yet

- Oilg and Gass MOOC (IFP) W3V16 - Process - HandoutDocument5 pagesOilg and Gass MOOC (IFP) W3V16 - Process - HandoutRebekah PetersonNo ratings yet

- DocumentDocument11 pagesDocumentSean Kalu OnuohaNo ratings yet

- W3V13 Drilling V2016 HandoutDocument6 pagesW3V13 Drilling V2016 HandoutSean Kalu OnuohaNo ratings yet

- Deadlines International Master - 2016Document1 pageDeadlines International Master - 2016Sean Kalu OnuohaNo ratings yet

- W2V11 - Production Mechanisms - Handout PDFDocument12 pagesW2V11 - Production Mechanisms - Handout PDFannisamuliahati100% (1)

- W2V12 Reservoir Simulation V2016 Handout V2Document9 pagesW2V12 Reservoir Simulation V2016 Handout V2Sean Kalu OnuohaNo ratings yet

- W2V11 - Production Mechanisms - Handout PDFDocument12 pagesW2V11 - Production Mechanisms - Handout PDFannisamuliahati100% (1)

- Date Time Topic Room Speaker: Grounds (PPS) Schedule of Monthly Safety MeetingsDocument1 pageDate Time Topic Room Speaker: Grounds (PPS) Schedule of Monthly Safety MeetingsSean Kalu OnuohaNo ratings yet

- W2V10 Reservoir Engineering V2016 Handout v2Document10 pagesW2V10 Reservoir Engineering V2016 Handout v2SaraCaballeroNo ratings yet

- CBN CircularDocument2 pagesCBN CircularSean Kalu OnuohaNo ratings yet

- W2V12 Reservoir Simulation V2016 Handout V2Document9 pagesW2V12 Reservoir Simulation V2016 Handout V2Sean Kalu OnuohaNo ratings yet

- Drilling - Introduction: Subjects Being TreatedDocument23 pagesDrilling - Introduction: Subjects Being Treatedamramazon88No ratings yet

- SHELL Compression Project Vanguard Newspaper PDFDocument2 pagesSHELL Compression Project Vanguard Newspaper PDFSean Kalu OnuohaNo ratings yet

- CBN Circular PDFDocument2 pagesCBN Circular PDFSean Kalu OnuohaNo ratings yet

- Thesis TopicDocument20 pagesThesis Topicjme_pescasioNo ratings yet

- Indian Apparel Industry FundamentalsDocument101 pagesIndian Apparel Industry FundamentalsRitika SharmaNo ratings yet

- Comparative and Superlative TestDocument1 pageComparative and Superlative TestLuis Fernando Cuartas100% (1)

- The Verb Get: Get Become, Arrive, Receive, Obtain, UnderstandDocument5 pagesThe Verb Get: Get Become, Arrive, Receive, Obtain, UnderstandSusanaNo ratings yet

- TLC Ocean Ave - ReviceDocument1 pageTLC Ocean Ave - Revicelaurajawor0No ratings yet

- New Society 7th Edition Brym Test BankDocument36 pagesNew Society 7th Edition Brym Test Bankrattingbivial7ac1gr100% (24)

- Folkdance Final BookDocument134 pagesFolkdance Final BookMendoza, Yasmin Ahmir A.No ratings yet

- A Level English Literature Transition PackDocument37 pagesA Level English Literature Transition PackArryNo ratings yet

- Istory Evisited: Julian Nott Reprises His Flight Over The Plains of NazcaDocument4 pagesIstory Evisited: Julian Nott Reprises His Flight Over The Plains of NazcacostpopNo ratings yet

- Globalink Research Intern Handbook 2020Document18 pagesGlobalink Research Intern Handbook 2020Sankalp DixitNo ratings yet

- Do Not Open This Booklet Until Told To Do So: Question Booklet Series: - Question Booklet No.Document7 pagesDo Not Open This Booklet Until Told To Do So: Question Booklet Series: - Question Booklet No.Yash AgarwalNo ratings yet

- World Textile Fibers: Freedonia Industry Study #1525Document16 pagesWorld Textile Fibers: Freedonia Industry Study #1525NGUYEN MINH HUYNo ratings yet

- Micro TeachingDocument3 pagesMicro TeachingRoevi MarquezNo ratings yet

- English MorphologyDocument26 pagesEnglish Morphologyxalba14No ratings yet

- New Lyocell Fibers for Absorbent NonwovensDocument3 pagesNew Lyocell Fibers for Absorbent Nonwovensimran24No ratings yet

- The Emperor's New ClothesDocument3 pagesThe Emperor's New ClothesEdwin LojánNo ratings yet

- Saudi Royal Guard protects royal familyDocument2 pagesSaudi Royal Guard protects royal familyJean-pierre Negre100% (1)

- Ankita DEY: Career ObjectiveDocument3 pagesAnkita DEY: Career ObjectiveHRD CORP CONSULTANCYNo ratings yet

- Classified: Your Local MarketplaceDocument3 pagesClassified: Your Local MarketplaceDigital MediaNo ratings yet

- Hoodies or Altar BoysDocument2 pagesHoodies or Altar BoysJaneen GattyNo ratings yet

- Feasibility Spna Beauty ParlourDocument14 pagesFeasibility Spna Beauty Parlourapi-1966585240% (1)

- Plant FibreDocument5 pagesPlant FibreNur Hafizah MukhtarNo ratings yet