Professional Documents

Culture Documents

Angulo Coronamiento

Uploaded by

Joel Pacheco DiazCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Angulo Coronamiento

Uploaded by

Joel Pacheco DiazCopyright:

Available Formats

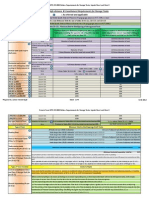

WELDED TANKS FOR OIL STORAGE

5-9

e) Except as specified for open-top tanks in 5.9, for tanks with frangible joints per 5.10.2.6, for self-supporting roofs in

5.10.5, and 5.10.6, and for tanks with the flanged roof-to-shell detail described in Item f below, tank shells shall be

supplied with top angles of not less than the following sizes:

Diametro del tanque

(D)

Tamao minimo del anguloa

(mm)

Tamao minimo del anguloa

(pulg.)

D 11 m, (D 35 ft)

50 50 5

2 2 3/16

11 m < D 18 m, (35 ft < D 60 ft)

50 50 6

2 2 1/4

D > 18 m, (D > 60 ft)

75 75 10

3 3 3/8

______________

Approximate equivalent sizes may be used to accommodate local availability of materials.

For fixed roof tanks equipped with full shell height insulation or jacketing, the horizontal leg of the top shell stiffener

shall project outward. For insulation system compatibility, the Purchaser shall specify if the horizontal leg is to be

larger than specified above.

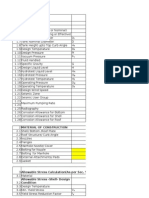

b) For tanks with a diameter less than or equal to 9 m (30 ft) and a supported cone roof (see 5.10.4), the top edge of

the shell may be flanged in lieu of installing a top angle. The bend radius and the width of the flanged edge shall

conform to the details of Figure 5.3a. This construction may be used for any tank with a self-supporting roof (see

5.10.5 and 5.10.6) if the total cross-sectional area of the junction fulfills the stated area requirements for the

construction of the top angle. No additional member, such as an angle or a bar, shall be added to the flanged roofto-shell detail.

5.2 Design Considerations

5.2.1 Loads

Loads are defined as follows.

a) Dead Load (DL): The weight of the tank or tank component, including any corrosion allowance unless otherwise

noted.

b) Design External Pressure (Pe): Shall not be less than 0.25 kPa (1 in. of water) except that External Pressure (Pe)

shall be considered as 0 kPa (0 in. of water) for tanks with circulation vents meeting Annex H requirements. Refer

to Annex V for external pressure greater than 0.25 kPa (1 in. of water). Design requirements for vacuum

exceeding this value and design requirements to resist flotation and external fluid pressure shall be a matter of

agreement between the Purchaser and the Manufacturer (see Annex V). Tanks that meet the requirements of this

standard may be subjected to a partial vacuum of 0.25 kPa (1 in. of water), without the need to provide any

additional supporting calculations.

c) Design Internal Pressure (Pi): Shall not exceed 18 kPa (2.5 lbf/in.2).

d) Hydrostatic Test (Ht): The load due to filling the tank with water to the design liquid level.

e) Internal Floating Roof Loads:

1) Dead load of internal floating roof (Df) including the weight of the flotation compartments, seal and all other

floating roof and attached components.

2) Internal floating roof uniform live load (Lf1) (0.6 kPa [12.5 lbf/ft2]) if no automatic drains are provided, (0.24 kPa

[5 lbf/f2]) if automatic drains are provided).

3) Internal floating roof point load (Lf2) of at least two men walking anywhere on the roof. One applied load of 2.2

kN [500 lbf] over 0.1 m2 [1 ft2] applied anywhere on the roof addresses two men walking.

4) Internal floating roof design external pressure (Pfe) of (0.24 kPa [5 lbf/ft2]) minimum.

f) Minimum Roof Live Load (Lr): 1.0 kPa (20 lb/ft2) on the horizontal projected area of the roof. The minimum roof

live load may alternatively be determined in accordance with ASCE 7, but shall not be less than 0.72 kPa (15 psf).

The minimum roof live load shall be reported to the Purchaser.

--```,,,``````,`,,,`,,,,,```,`,,-`-`,,`,,`,`,,`---

g) Seismic (E): Seismic loads determined in accordance with E.1 through E.6 (see Data Sheet, Line 8).

Copyright American Petroleum Institute

Provided by IHS under license with API

No reproduction or networking permitted without license from IHS

Licensee=Techint S.A./5938621100, User=Vanoli, Ariel

Not for Resale, 05/03/2013 13:46:43 MDT

You might also like

- 77 06 650 506reballotDocument7 pages77 06 650 506reballotVinicius GobboNo ratings yet

- NFPA 30 2008 Edition, Requirements For Storage Tanks, Liquids Class I and Class IIDocument4 pagesNFPA 30 2008 Edition, Requirements For Storage Tanks, Liquids Class I and Class IIzohaib_farooqNo ratings yet

- Basic API650-Training PDFDocument75 pagesBasic API650-Training PDFDivyesh PatelNo ratings yet

- Pages From (API 650-2003 Storage Tanks-Unprotected)Document1 pagePages From (API 650-2003 Storage Tanks-Unprotected)Vy NguyenNo ratings yet

- 650-728 Rev 4 Wind Girder Section ModulusDocument16 pages650-728 Rev 4 Wind Girder Section Modulusalilou2013No ratings yet

- Storage TanksDocument62 pagesStorage Tankstoychom2013No ratings yet

- Double Deck Floating RoofDocument16 pagesDouble Deck Floating RoofInamullah Khan100% (3)

- Requirements Concerning Gas Tankers: International Association of Classification SocietiesDocument31 pagesRequirements Concerning Gas Tankers: International Association of Classification SocietiescklconNo ratings yet

- Requirements Concerning Gas Tankers: International Association of Classification SocietiesDocument31 pagesRequirements Concerning Gas Tankers: International Association of Classification Societiesharikrishnanpd3327No ratings yet

- External Moisture Dec 2011Document38 pagesExternal Moisture Dec 2011TuroyNo ratings yet

- 500 Shell Design PDFDocument28 pages500 Shell Design PDFaliNo ratings yet

- API 650 Load CombinationsDocument10 pagesAPI 650 Load Combinationsศุภกฤต รักในหลวงNo ratings yet

- Design Criteria of Manholes PDFDocument5 pagesDesign Criteria of Manholes PDFshilpijain0504No ratings yet

- Code-compliant vessel design requirementsDocument90 pagesCode-compliant vessel design requirementsعصمت ضيف الله83% (12)

- XX X XXXX XX XXXX REV XX Civil Structural Design BasisDocument75 pagesXX X XXXX XX XXXX REV XX Civil Structural Design Basisg4goharNo ratings yet

- Natural Gas Storage TankDocument10 pagesNatural Gas Storage TankSurya Budi WidagdoNo ratings yet

- ChE 192 Handout 6a (Storage Tank)Document4 pagesChE 192 Handout 6a (Storage Tank)Aiza CabolesNo ratings yet

- Pub12 ReinforcedPlastic PDFDocument168 pagesPub12 ReinforcedPlastic PDFDarley NogueiraNo ratings yet

- Welded Steel Tank Project StandardsDocument7 pagesWelded Steel Tank Project StandardsYusufNo ratings yet

- Design of Pressure Vessel 1Document55 pagesDesign of Pressure Vessel 1Ezio3511No ratings yet

- Design Basis Rev 0 - Static EqptDocument57 pagesDesign Basis Rev 0 - Static Eqptdineshkumar1234100% (1)

- NFPA 22 (2003) Special RequirementsDocument4 pagesNFPA 22 (2003) Special RequirementsLeslie Scott67% (3)

- Design Calculation For Dirty Brackish Water Tank (129-0T2540)Document9 pagesDesign Calculation For Dirty Brackish Water Tank (129-0T2540)Dhakshina KNo ratings yet

- ATM Storage TankDocument10 pagesATM Storage TankSteve WanNo ratings yet

- Design Calculation (CST, Unit-10)Document12 pagesDesign Calculation (CST, Unit-10)kanishkmechenggNo ratings yet

- Design of Tanks For Storage of Oil and WaterDocument31 pagesDesign of Tanks For Storage of Oil and WaterUhong LaiNo ratings yet

- API 650 Storage Tank Design GuideDocument58 pagesAPI 650 Storage Tank Design GuideDwi HermawanNo ratings yet

- TanksDocument24 pagesTanksShaji Hakeem91% (23)

- PR VesselDocument10 pagesPR Vesselmayukhguhanita2010No ratings yet

- Notes Api650Document6 pagesNotes Api650MasoodMiyanNo ratings yet

- Storage Tank Calculation 3 PDF FreeDocument10 pagesStorage Tank Calculation 3 PDF Freealilou2013No ratings yet

- Mandatory Appendix 9Document2 pagesMandatory Appendix 9Asep DarojatNo ratings yet

- 100 Overview of Tank DesignDocument20 pages100 Overview of Tank Designkoparan35No ratings yet

- Geodesic Aluminum Dome & Cover Roof Specification API 650 Appendix GDocument6 pagesGeodesic Aluminum Dome & Cover Roof Specification API 650 Appendix GpassionNo ratings yet

- API-650 Design Procedure ExampleDocument21 pagesAPI-650 Design Procedure Examplegdwvcd92% (13)

- Scrubber DesignDocument5 pagesScrubber DesignchianhhoNo ratings yet

- Roof Live LoadsDocument7 pagesRoof Live LoadsY GangadharNo ratings yet

- Foundation Design Philosophy For Bullet VesselsDocument5 pagesFoundation Design Philosophy For Bullet Vesselsdicktracy11No ratings yet

- Requirements Concerning Gas Tankers: International Association of Classification SocietiesDocument36 pagesRequirements Concerning Gas Tankers: International Association of Classification Societiesantopaul2No ratings yet

- 650-680 Rev 4 - Hydrostatic Test ExemptionsDocument3 pages650-680 Rev 4 - Hydrostatic Test ExemptionspediNo ratings yet

- Roof Drainage PDFDocument68 pagesRoof Drainage PDFFrancisco BonillaNo ratings yet

- Concrete Tanks Design NotesDocument14 pagesConcrete Tanks Design NotesJulían Darío Medina100% (5)

- Storage Tanks CalculationsDocument21 pagesStorage Tanks Calculationsjimallen21288% (25)

- A Practical Guide to Piping and Valves for the Oil and Gas IndustryFrom EverandA Practical Guide to Piping and Valves for the Oil and Gas IndustryRating: 5 out of 5 stars5/5 (3)

- Small Unmanned Fixed-wing Aircraft Design: A Practical ApproachFrom EverandSmall Unmanned Fixed-wing Aircraft Design: A Practical ApproachNo ratings yet

- A Guide to Ship Repair Estimates in Man-hoursFrom EverandA Guide to Ship Repair Estimates in Man-hoursRating: 4.5 out of 5 stars4.5/5 (5)

- Emulsions and Oil Treating Equipment: Selection, Sizing and TroubleshootingFrom EverandEmulsions and Oil Treating Equipment: Selection, Sizing and TroubleshootingRating: 5 out of 5 stars5/5 (3)

- The Fabrication of Materials: Materials TechnologyFrom EverandThe Fabrication of Materials: Materials TechnologyRating: 5 out of 5 stars5/5 (1)

- Durability Design of Concrete Structures: Phenomena, Modeling, and PracticeFrom EverandDurability Design of Concrete Structures: Phenomena, Modeling, and PracticeNo ratings yet

- Sewage Disposal Works: Their Design and ConstructionFrom EverandSewage Disposal Works: Their Design and ConstructionNo ratings yet

- Goodyear GA-28A/B Convoy Fighter: The Naval VTOL Turboprop Tailsitter Project of 1950From EverandGoodyear GA-28A/B Convoy Fighter: The Naval VTOL Turboprop Tailsitter Project of 1950Rating: 4 out of 5 stars4/5 (2)

- Aisc PerfilesDocument26 pagesAisc Perfilesapi-2672311278% (9)

- 000 Indice APIDocument6 pages000 Indice APIJoel Pacheco DiazNo ratings yet

- AISC Shapes Database v14.1Document20 pagesAISC Shapes Database v14.1Joel Pacheco DiazNo ratings yet

- Sistema Hidraulico de La PrimariaDocument1 pageSistema Hidraulico de La PrimariaJoel Pacheco DiazNo ratings yet

- Optimize crusher performance with the right liner selectionDocument42 pagesOptimize crusher performance with the right liner selectionJoel Pacheco Diaz100% (1)

- 110P0320427 ADocument1 page110P0320427 AJoel Pacheco DiazNo ratings yet

- Quality Cost AnalysisDocument5 pagesQuality Cost Analysisapi-3805571No ratings yet

- Guía de Ventilación de TanquesDocument31 pagesGuía de Ventilación de TanquesMulkururNo ratings yet

- Reviewed For Information OnlyDocument1 pageReviewed For Information OnlyJoel Pacheco DiazNo ratings yet

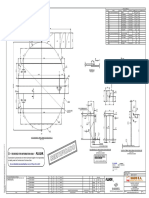

- Dimensions in Millimeters: 5-68 Api S 650Document1 pageDimensions in Millimeters: 5-68 Api S 650Joel Pacheco DiazNo ratings yet

- Radiografia 3Document1 pageRadiografia 3Joel Pacheco DiazNo ratings yet

- A240Document11 pagesA240Joel Pacheco DiazNo ratings yet

- Angulo CoronamientoDocument1 pageAngulo CoronamientoJoel Pacheco DiazNo ratings yet

- Dimensions in Millimeters: 5-68 Api S 650Document1 pageDimensions in Millimeters: 5-68 Api S 650Joel Pacheco DiazNo ratings yet

- Nozzles Anexo S Api 650Document1 pageNozzles Anexo S Api 650Joel Pacheco DiazNo ratings yet

- Steel Joint Bars, Low, Medium, and High Carbon (Non-Heat-Treated)Document3 pagesSteel Joint Bars, Low, Medium, and High Carbon (Non-Heat-Treated)mulong83No ratings yet

- D006Document3 pagesD006Ruddy EspejoNo ratings yet

- A002 Carbon Steel Girder Rails of Plain, Grooved, and Guard TypesDocument3 pagesA002 Carbon Steel Girder Rails of Plain, Grooved, and Guard TypesDaniel Alonso Flores MezaNo ratings yet

- TC Series 2 Cycle EnginesDocument43 pagesTC Series 2 Cycle EngineseverthgNo ratings yet

- LHV of FuelDocument33 pagesLHV of FuelSeptian HardiNo ratings yet

- Service Manual: Downloaded From Manuals Search EngineDocument118 pagesService Manual: Downloaded From Manuals Search EngineMickeyNo ratings yet

- BusDocument30 pagesBussham100% (8)

- Our Innovative Breakthrough Vessel:: Strength and DepthDocument20 pagesOur Innovative Breakthrough Vessel:: Strength and DepthKenneth TanNo ratings yet

- Alfa Laval Fuel Oil Filter PDFDocument4 pagesAlfa Laval Fuel Oil Filter PDFarifsanNo ratings yet

- 34-SAMSS-119 Bi-Directional Meter Prover PDFDocument15 pages34-SAMSS-119 Bi-Directional Meter Prover PDFfraihafraihaNo ratings yet

- 08 EfaDocument19 pages08 EfabountymaniNo ratings yet

- Company Presentation: 80+ Years of Marine, Naval and Industrial PumpsDocument46 pagesCompany Presentation: 80+ Years of Marine, Naval and Industrial PumpsMinh Hoàng Nguyễn HữuNo ratings yet

- Sanitary Fitures: Res - Dev./Main Bld./M/Page 1Document9 pagesSanitary Fitures: Res - Dev./Main Bld./M/Page 1hakmarconsultantsNo ratings yet

- Manutencao Hyster H40 70FT, Maintenance Hyster H40 70FTDocument115 pagesManutencao Hyster H40 70FT, Maintenance Hyster H40 70FTJorge Vasconcelos63% (8)

- Reciprocating EnginesDocument3 pagesReciprocating EnginesHarish Reddy Singamala100% (1)

- Positive Displacement Motor: Downhole Tool Converts Fluid Power to Drive Drill BitDocument4 pagesPositive Displacement Motor: Downhole Tool Converts Fluid Power to Drive Drill BitPopa AdrianNo ratings yet

- Rathore Et AlDocument7 pagesRathore Et AlIqra SarfrazNo ratings yet

- All Systems - ALCO LocoDocument56 pagesAll Systems - ALCO Locochandu mohamedNo ratings yet

- Bomag BW55E User Manual PDFDocument61 pagesBomag BW55E User Manual PDFchristodoulos charalambous50% (2)

- Exhaust System Layout and ComponentsDocument42 pagesExhaust System Layout and ComponentsMiguel Ángel RodríguezNo ratings yet

- Fire Safety TBT EssentialsDocument15 pagesFire Safety TBT Essentialsbilo1984No ratings yet

- 'Docslide - Us - General Catalogue MZT Pumpi PDFDocument24 pages'Docslide - Us - General Catalogue MZT Pumpi PDFIvkraNo ratings yet

- Audi Maintenance Schedule Model Year 2011Document1 pageAudi Maintenance Schedule Model Year 2011api-247506078No ratings yet

- 500 kVA EDG Innova DieselDocument5 pages500 kVA EDG Innova DieselRitaban222No ratings yet

- 4G63 ManualDocument34 pages4G63 Manualfrinliwigo100% (4)

- Basic Fire Fighting TrainingDocument52 pagesBasic Fire Fighting TrainingFarrukh AhmedNo ratings yet

- (L006) H Om Us Es (10 2017)Document204 pages(L006) H Om Us Es (10 2017)ruben100% (1)

- Audit Proses Rule of Thumb Pabrik: Rendemen CPO 20-22% Rendemen Kernel 4-5% Kandungan FFA 2%Document4 pagesAudit Proses Rule of Thumb Pabrik: Rendemen CPO 20-22% Rendemen Kernel 4-5% Kandungan FFA 2%Evans Azka FNo ratings yet

- Active Heating and CoolingDocument16 pagesActive Heating and Coolinga_j_sanyal2590% (1)

- W-Hme - Hrx537c5-Hy, HZ - 00X39VH7 V060Document140 pagesW-Hme - Hrx537c5-Hy, HZ - 00X39VH7 V060Fabien MassenetNo ratings yet

- D.7 Oil Compressibility: Vasquez and Beggs' CorrelationDocument10 pagesD.7 Oil Compressibility: Vasquez and Beggs' Correlationسحر سلامتیانNo ratings yet

- PSM 8Document5 pagesPSM 8Salvatore MirandaNo ratings yet

- CM4 DS2015 v1.3mmDocument2 pagesCM4 DS2015 v1.3mmmarcusNo ratings yet