Professional Documents

Culture Documents

06 SEP674 RET670 Thermal Overload Protection

Uploaded by

طه محمدOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

06 SEP674 RET670 Thermal Overload Protection

Uploaded by

طه محمدCopyright:

Available Formats

Substation Automation Products

Transformer protection RET670

Thermal overload protection

1MRG019264

Chapter 06

Contents

ABB Group

September 10, 2015 | Slide 2

Application

Operating characteristics

Logical Diagram

Settings

Monitored data

Application thermal overload protection

Temporary overloading necessary in stressed

situations

Not possible to design the system to manage

all situations

Temporary overload not harmful

Hard decision for operator to disconnect the

transformer

Consequences of overload

Degrading in the quality of the transformer oil

Forced aging of insulation

Increase risk of internal faults

Hot spots within the transformer

ABB Group

September 10, 2015 | Slide 3

Chapter 06

Degrade paper insulation

Chapter 06

Thermal overload protection

Application

Based on measuring the true RMS

current

Uses the largest phase current to

calculate the heat content

Two time constants (i.e. ONAN or OFAF)

ABB Group

September 10, 2015 | Slide 4

Possibility to adjust the time constants at

high and/or low currents

Binary inputs to

select time constant

change reference settings

empty heat content

block the function

Chapter 06

Thermal overload protection

Application

49

Number of instances:

Customized: 0 6

Pre-configured:

Ith

TR PTTR

SMAI

SMAI

SMAI

49

Ith

TR PTTR

SMAI

ABB Group

September 10, 2015 | Slide 5

49

Ith

TR PTTR

Included: 1

Optional: < 1

Chapter 06

Operating characteristics

Thermal overload protection

The relative final temperature (heat

content) is expressed as:

Monitored data

Analog

I_MEASURE

Binary

I > ITrip Start

The actual temperature (heat content) is

calculated as:

HEATCON

if

> ALARM1 Alarm

> ALARM2 Alarm

> ITrip

Trip

(heating)

or:

HEATCON

if

ABB Group

September 10, 2015 | Slide 6

(cooling)

Chapter 06

Operating characteristics

Thermal overload protection

Present time to operation is calculated as:

Monitored data

Analog

Binary

TTRIP

If Start

If TTRIP < Warning WARNING

The time to lockout release is calculated

as:

TRESLO

ABB Group

September 10, 2015 | Slide 7

If Trip

Chapter 06

Operating characteristics

Thermal overload protection

Estimated time to trip

TTRIP

[%]

Tau 1

~ IBase 1

TripTemp

~ ITrip

~ IRef

Rated power

100 %

Alarm 2

Alarm 1

ResLo

ResetLockoutTemp

Estimated time to reset

TRESLO

ThetaInit

t[min ]

Current step

START/RESET

ABB Group

September 10, 2015 | Slide 8

WARNING

TRIP and

LOCKOUT

Chapter 06

Simplified Logical Diagram

Thermal overload protection

I-MEASURE

I3P

Cooling

Enmult

Reset

Final temp >

Trip Temp

START

Calc of heat

content

HEATCONT

Calc of final

temp

Management

of parameters

Actual Temp >

Alarm X Temp

ALARM1

ALARM2

Actual Temp >

Trip Temp

TRIP

Actual Temp <

Trip Temp

LOCKOUT

S

R

TTRIP

Calc time to trip

Calc time to

reset lockout

ABB Group

September 10, 2015 | Slide 9

WARNING

TRESLO

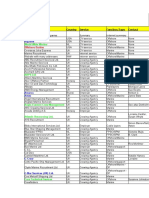

Thermal overload protection settings

Overview

Chapter 06

First instance of

TR PTTR

ABB Group

September 10, 2015 | Slide 10

Chapter 06

Thermal overload protection settings

General

General

Operation On/Off

Base current

Reference current

Factor for Ref current

Initial heat content

(at start and reset of

the function )

Trip pulse length

ABB Group

September 10, 2015 | Slide 11

Chapter 06

Thermal overload protection settings

Time constant 1

Cooling input low

Base current 1

Time constant 1

Rescaling of Tc if I >

Rescaling percentage

Rescaling of Tc if I <

Rescaling percentage

ABB Group

September 10, 2015 | Slide 12

Chapter 06

Thermal overload protection settings

Time constant 2

Cooling input high

Base current 2

Time constant 2

Rescaling of tc if I >

Rescaling percentage

Rescaling of tc if I <

Rescaling percentage

ABB Group

September 10, 2015 | Slide 13

Chapter 06

Thermal overload protection settings

Trip and supervision

Trip and supervision

Steady state trip level

Alarm 1 level warning

Alarm 2 level warning

Lockout reset level

Warning time to trip

ABB Group

September 10, 2015 | Slide 14

Chapter 06

Monitored data

Thermal overload protection

ABB Group

September 10, 2015 | Slide 15

Test/Functions status/Current

protection/ThermalOverload2Time

Const (PTTR,49)

TRIP

START

ALARM1

ALARM2

LOCKOUT

WARNING

Chapter 06

Monitored data

Thermal overload protection

Test/Functions status/Current

protection/ThermalOverload2TimeConst

(PTTR,49)

I-MEASURE Measured current (% of

rated current)

HEATCONT Heat content of the

transformer (%)

TTRIP Estimated time to trip (min)

TRESLO Estimated time to reset (min)

TTRIPCAL Time status to trip

0: Not active

1: Long time

2: Active

TRESCAL Time status to reset

ABB Group

September 10, 2015 | Slide 16

0, 1 or 2

Chapter 06

ABB

SA-TGroup

Training

September 10, 2015 | Slide 17

You might also like

- 03 SEP674 RET670 Differential ProtectionDocument21 pages03 SEP674 RET670 Differential Protectionطه محمدNo ratings yet

- 7SK80 Protection of Medium-Power Motors A1 PDFDocument11 pages7SK80 Protection of Medium-Power Motors A1 PDFpothirajNo ratings yet

- Transformer Protection RET670: Exercise 4 - Differential Protection Negative Sequence FeatureDocument17 pagesTransformer Protection RET670: Exercise 4 - Differential Protection Negative Sequence FeatureRobert MihayoNo ratings yet

- 06 Sep-603b Ref Ret 670 PDFDocument13 pages06 Sep-603b Ref Ret 670 PDFm khNo ratings yet

- 3 - 7UT6 Transf. Settings - enDocument16 pages3 - 7UT6 Transf. Settings - enrajeshNo ratings yet

- 07 SEP674 RET670 Overexcitation Protection PDFDocument17 pages07 SEP674 RET670 Overexcitation Protection PDFarunmozhiNo ratings yet

- 07 SEP674 RET670 Overexcitation ProtectionDocument17 pages07 SEP674 RET670 Overexcitation Protectionطه محمد100% (1)

- 5-Line DifferentialDocument52 pages5-Line DifferentialmubarakkirkoNo ratings yet

- Line Differential Protection - HeddingDocument69 pagesLine Differential Protection - HeddingIgnacio Lucas Avila ManganoNo ratings yet

- P633 Test Tools Farhad Rev 01Document5 pagesP633 Test Tools Farhad Rev 01Neelakandan MasilamaniNo ratings yet

- Transformer Protection RET670: Exercise 3 - Differential Protection Open CT and OLTC AdjustmentDocument22 pagesTransformer Protection RET670: Exercise 3 - Differential Protection Open CT and OLTC AdjustmentRobert MihayoNo ratings yet

- APN-076 - Inrush Restraint For 7UT6 PDFDocument11 pagesAPN-076 - Inrush Restraint For 7UT6 PDFWaskito AjiNo ratings yet

- 05 SEP-603B Diff Protection RET 670Document46 pages05 SEP-603B Diff Protection RET 670m khNo ratings yet

- 3 REB500 Transverse CurrentsDocument7 pages3 REB500 Transverse CurrentsRetratosDeMiVidaNo ratings yet

- P54x en CommissioningDocument126 pagesP54x en CommissioningChandra Dwi SaputraNo ratings yet

- RET 670 3windingDocument4 pagesRET 670 3windingm khNo ratings yet

- 03 SEP671 REL670 Exercise 2 Distance Protection Operate TimesDocument10 pages03 SEP671 REL670 Exercise 2 Distance Protection Operate TimesMarcos Casanova LopezNo ratings yet

- Omicron PTL: Omicron PTL ABB RET670 V1.2 Transformer PTT User ManualDocument7 pagesOmicron PTL: Omicron PTL ABB RET670 V1.2 Transformer PTT User Manualmohammed yousifNo ratings yet

- Micom P40 Agile: Ge Grid SolutionsDocument868 pagesMicom P40 Agile: Ge Grid SolutionsNOVASKY De Paula e CarvalhoNo ratings yet

- 10 Ex 01 - Distance Prot Function Characteristic Radial FeedDocument48 pages10 Ex 01 - Distance Prot Function Characteristic Radial FeedahmedNo ratings yet

- Commissioning Test Report-Transformer Protection Relay Ret670Document6 pagesCommissioning Test Report-Transformer Protection Relay Ret670Venkatesan ElumalaiNo ratings yet

- Technical Instruction ABB RED670Document10 pagesTechnical Instruction ABB RED670Iqball ArdiyanNo ratings yet

- Example Settings For Applying The SEL-487B To A Six-Breaker BusDocument24 pagesExample Settings For Applying The SEL-487B To A Six-Breaker Busu2andresNo ratings yet

- REF 615 Protection Applications - Part - 1Document97 pagesREF 615 Protection Applications - Part - 1burkinafasogluNo ratings yet

- SIP5-APN-016 Distance Protection With Tele-Protection On An OHL Feeder enDocument32 pagesSIP5-APN-016 Distance Protection With Tele-Protection On An OHL Feeder enKhajaBurhanNo ratings yet

- p632 Testing Procedure of Tranformer Diffrential Protection PDFDocument14 pagesp632 Testing Procedure of Tranformer Diffrential Protection PDFJawad AmjadNo ratings yet

- 22 - 5 - 7UT6 Low Imp. REF - enDocument26 pages22 - 5 - 7UT6 Low Imp. REF - enMohammedSaadaniHassaniNo ratings yet

- 06 - Disturbance Recording and Handling PDFDocument62 pages06 - Disturbance Recording and Handling PDFAnonymous fM2c6BNo ratings yet

- Problem With LDCM Module of RED670Document4 pagesProblem With LDCM Module of RED670Sellappan MuthusamyNo ratings yet

- Slope Calculation of Line Diff Relay P543Document5 pagesSlope Calculation of Line Diff Relay P543Abhishek RajputNo ratings yet

- High Impedance Restricted Earth Fault Protection: Answers For EnergyDocument40 pagesHigh Impedance Restricted Earth Fault Protection: Answers For EnergyWildan erik77No ratings yet

- 3 REB500 Transverse CurrentsDocument6 pages3 REB500 Transverse CurrentsRK KNo ratings yet

- 07 SEP-602A - Fuse FailureDocument10 pages07 SEP-602A - Fuse Failuredenysenko1982No ratings yet

- Power System Protection Power System Stability: Substation Automation ProductsDocument15 pagesPower System Protection Power System Stability: Substation Automation ProductsRobert Mihayo100% (1)

- MiCOM P125Document3 pagesMiCOM P125Md NadeemNo ratings yet

- Schneider MiCOM P343 B1 Generator PTT User Manual ENUDocument7 pagesSchneider MiCOM P343 B1 Generator PTT User Manual ENUkarim_ouakliNo ratings yet

- Autoreclosing: Protection Application HandbookDocument38 pagesAutoreclosing: Protection Application Handbooksandy02477No ratings yet

- 7UT613 63xDocument514 pages7UT613 63xdenisseNo ratings yet

- ERPC Protection Philosophy PDFDocument7 pagesERPC Protection Philosophy PDFSai Mani Dattu DhulipallaNo ratings yet

- Principles of Differential Protection Technology: Power Transmission and DistributionDocument19 pagesPrinciples of Differential Protection Technology: Power Transmission and DistributionDinesh Pitchaivel100% (1)

- Communication Scheme PUTTDocument8 pagesCommunication Scheme PUTTCesar Gabriel Berdejo RiveraNo ratings yet

- Application Manual Line Differential Protection RED670 Version 2.2 IECDocument996 pagesApplication Manual Line Differential Protection RED670 Version 2.2 IECJavier Valencia MurilloNo ratings yet

- Protection Directional OC & EFDocument54 pagesProtection Directional OC & EFbrijalNo ratings yet

- Setting Sheet of 7UM622 For 25MW GPRDocument16 pagesSetting Sheet of 7UM622 For 25MW GPRSrini100% (1)

- General Line ProtectionDocument104 pagesGeneral Line ProtectionPrasenjit Dutta100% (1)

- 07a Backup OCEF Relay - Tech. Data Check List CompletedDocument6 pages07a Backup OCEF Relay - Tech. Data Check List CompletedAnupam0103No ratings yet

- Rej525 Tob 751205enc PDFDocument12 pagesRej525 Tob 751205enc PDFJayam KondanNo ratings yet

- Ziv Oc Ef RelayDocument10 pagesZiv Oc Ef RelayAnonymous QRER3bsNr100% (1)

- 1MRK508019-BEN A en Fuse Supervisory Relays RXBA 4 RXETB 1 PDFDocument6 pages1MRK508019-BEN A en Fuse Supervisory Relays RXBA 4 RXETB 1 PDFUmanshu PandeyNo ratings yet

- Line Differential Protection Scheme Modelling (PDF Library)Document6 pagesLine Differential Protection Scheme Modelling (PDF Library)Nirmal RajaNo ratings yet

- CSC 326 ManualDocument86 pagesCSC 326 ManualSushant KadavNo ratings yet

- Test Procedure 7sj61Document7 pagesTest Procedure 7sj61Anoss Olier100% (1)

- This Is The Test Procedure For Siemens 7UT61 RelayDocument4 pagesThis Is The Test Procedure For Siemens 7UT61 RelayNassar Abdulrahiman100% (2)

- Calculation of Stabilizing Resistor in High Impedance Differential Protection - Electrical ConceptsDocument13 pagesCalculation of Stabilizing Resistor in High Impedance Differential Protection - Electrical ConceptsABHINAV SAURAVNo ratings yet

- Transformer Protection RET670: Exercise 2 - Differential Protection Stability and Pick-Up TestDocument18 pagesTransformer Protection RET670: Exercise 2 - Differential Protection Stability and Pick-Up TestRobert MihayoNo ratings yet

- 33.DUOBIAS-M Relay TestingDocument75 pages33.DUOBIAS-M Relay TestingTerezkaM100% (2)

- 70.00.00023 28-NOV-2022 28-NOV-2022 Open A320-200N, A321-200N, A321-200NX 80-00 Iae LLC Update With EIU S4.4Document9 pages70.00.00023 28-NOV-2022 28-NOV-2022 Open A320-200N, A321-200N, A321-200NX 80-00 Iae LLC Update With EIU S4.4jivomirNo ratings yet

- Sliding Pressure OperationDocument29 pagesSliding Pressure OperationvesridharNo ratings yet

- Protección de MotorDocument17 pagesProtección de MotoryesrojasNo ratings yet

- SYS600 - Installation and AdministrationDocument160 pagesSYS600 - Installation and Administrationطه محمدNo ratings yet

- Essentials DP Bus and Read Write Parameter de v4 76Document40 pagesEssentials DP Bus and Read Write Parameter de v4 76Ben PhanNo ratings yet

- SINAMICS DriveDocument61 pagesSINAMICS Driveطه محمدNo ratings yet

- WiringDocument20 pagesWiringطه محمدNo ratings yet

- A2 Ket Vocabulary List PDFDocument33 pagesA2 Ket Vocabulary List PDFAdriana BialisNo ratings yet

- PDF Function Block To Control MM4 Via Profibus-DP en V3Document11 pagesPDF Function Block To Control MM4 Via Profibus-DP en V3طه محمدNo ratings yet

- Ket Vocabulary ListDocument33 pagesKet Vocabulary Listطه محمدNo ratings yet

- 25b - List of Additional Resources - r1Document1 page25b - List of Additional Resources - r1طه محمدNo ratings yet

- E 251 ContentDocument34 pagesE 251 Contentطه محمدNo ratings yet

- 1MRK504115-UEN D en Installation Commissioning Manual RET670 1.2 PDFDocument266 pages1MRK504115-UEN D en Installation Commissioning Manual RET670 1.2 PDFطه محمدNo ratings yet

- FiperDocument91 pagesFiperطه محمدNo ratings yet

- Sinamics-G Querverkehr Leit-Folgeantrieb v1-1 enDocument47 pagesSinamics-G Querverkehr Leit-Folgeantrieb v1-1 enطه محمدNo ratings yet

- 16 Data Exchange With MM440 PDFDocument16 pages16 Data Exchange With MM440 PDFFirzaNo ratings yet

- 13 - Directional Element Application and Evaluation - r7Document51 pages13 - Directional Element Application and Evaluation - r7طه محمدNo ratings yet

- Understanding and Testing The ABB RED670 Distanc-Line Differential RelayDocument0 pagesUnderstanding and Testing The ABB RED670 Distanc-Line Differential RelayAlly Raxa100% (3)

- ABB TransformersDocument213 pagesABB Transformersajeez86100% (1)

- Application Setting Philosophy: A Philosophy For Distance Element Fault Detector SettingsDocument2 pagesApplication Setting Philosophy: A Philosophy For Distance Element Fault Detector Settingsطه محمدNo ratings yet

- Module 1Document20 pagesModule 1Taha MohammedNo ratings yet

- D4 - Application - of - Overreaching - Distance - Relays PDFDocument49 pagesD4 - Application - of - Overreaching - Distance - Relays PDFRavinder SharmaNo ratings yet

- P544&6 en TM M PDFDocument924 pagesP544&6 en TM M PDFطه محمدNo ratings yet

- E 293 ContentDocument34 pagesE 293 Contentطه محمدNo ratings yet

- Power Systems - Basic Concepts and Applications - Part Ii: Pdhonline Course E105 (12 PDH)Document27 pagesPower Systems - Basic Concepts and Applications - Part Ii: Pdhonline Course E105 (12 PDH)koti_sreedharNo ratings yet

- P543 Diff CalculatorDocument2 pagesP543 Diff Calculatorطه محمدNo ratings yet

- Ret 670 ABBDocument12 pagesRet 670 ABBطه محمد100% (1)

- Sa2009 001608 en Rel670 CT Calculation ExampleDocument7 pagesSa2009 001608 en Rel670 CT Calculation Exampleطه محمدNo ratings yet

- TransformerProtection by Hands On Relay SchoolsDocument63 pagesTransformerProtection by Hands On Relay SchoolshiteshkelaNo ratings yet

- P544&6 en TM M PDFDocument924 pagesP544&6 en TM M PDFطه محمدNo ratings yet

- 5005E en Power Transformer ProtectionDocument20 pages5005E en Power Transformer ProtectionLuis LopezNo ratings yet

- TransformerProtection by Hands On Relay SchoolsDocument63 pagesTransformerProtection by Hands On Relay SchoolshiteshkelaNo ratings yet

- 17b Transformer Class Exercise Solution r13Document10 pages17b Transformer Class Exercise Solution r13طه محمدNo ratings yet

- List of All Entrance Exams A Student Can Appear After Passing 12th in IndiaDocument2 pagesList of All Entrance Exams A Student Can Appear After Passing 12th in IndiaDeepak Gupta100% (1)

- GemDocument23 pagesGemMukesh KumarNo ratings yet

- 2.changing Challenges For The Operations - Engineering Managers-1Document34 pages2.changing Challenges For The Operations - Engineering Managers-1b00199916No ratings yet

- Glass Defect CompleteDocument99 pagesGlass Defect CompleteHimanshu Vaid67% (3)

- FM 5-102 - CountermobilityDocument220 pagesFM 5-102 - CountermobilitySurvivIt100% (2)

- Códigos de Fallas de Problemas Específicos de PEUGEOTDocument8 pagesCódigos de Fallas de Problemas Específicos de PEUGEOTJesus GarciaNo ratings yet

- Week 03 Network Concepts and Network Media PDFDocument63 pagesWeek 03 Network Concepts and Network Media PDFikonNo ratings yet

- Fire Hydrant - WikipediaDocument9 pagesFire Hydrant - WikipediaVaibhav SawantNo ratings yet

- Good Practices and Innovations in Public Governance United Nations Public Service Awards Winners, 2012-2013Document254 pagesGood Practices and Innovations in Public Governance United Nations Public Service Awards Winners, 2012-2013Adriana Alberti UN100% (1)

- File Handling in C PDFDocument86 pagesFile Handling in C PDFDeepak ShakyaNo ratings yet

- Drainage Service GuidelinesDocument15 pagesDrainage Service GuidelinesMarllon LobatoNo ratings yet

- Resume - Abishek AntonyDocument4 pagesResume - Abishek AntonyabishekantonyNo ratings yet

- Flame Arrester Installation and Maintenance Instructions ForDocument3 pagesFlame Arrester Installation and Maintenance Instructions Forhk168No ratings yet

- Mechanics Guidelines 23 Div ST Fair ExhibitDocument8 pagesMechanics Guidelines 23 Div ST Fair ExhibitMarilyn GarciaNo ratings yet

- B0193AV P IA Series Integrated Control Configurator PDFDocument136 pagesB0193AV P IA Series Integrated Control Configurator PDFJuan Rivera50% (2)

- Datasheet Borne SiemensDocument3 pagesDatasheet Borne Siemenslorentz franklinNo ratings yet

- B+V-Manual - Drill Pipe Elevator, Hydraulic Op. VES-CL 250 For TYPE T REV 005-03-APRIL-2008Document67 pagesB+V-Manual - Drill Pipe Elevator, Hydraulic Op. VES-CL 250 For TYPE T REV 005-03-APRIL-2008lucas ronaldo coronel mendozaNo ratings yet

- MemoDocument12 pagesMemoGaurav GoelNo ratings yet

- Company Name Country Service Function/Type Contact: RigzoneDocument4 pagesCompany Name Country Service Function/Type Contact: RigzonekokabawaNo ratings yet

- P-L-N-Statistik 2011Document104 pagesP-L-N-Statistik 2011Ahmad AfandiNo ratings yet

- 9-4130 - Loose Stepper MotorDocument2 pages9-4130 - Loose Stepper MotorarasNo ratings yet

- 032 Wire Rope Sling 76.5 TonDocument4 pages032 Wire Rope Sling 76.5 TonHario PramuditoNo ratings yet

- MANANANGGALDocument3 pagesMANANANGGALJeminah PauneNo ratings yet

- Apache Derby DatabaseDocument4 pagesApache Derby DatabaseJohn KrcmarikNo ratings yet

- Hydrograph - Analysis - 2 Hydro PDFDocument68 pagesHydrograph - Analysis - 2 Hydro PDFNurul QurratuNo ratings yet

- Stone MasonaryDocument23 pagesStone MasonarypurvaNo ratings yet

- Summer Practice Report Format For CeDocument8 pagesSummer Practice Report Format For CesohrabNo ratings yet

- Ina201 Industrial Network ArchitectureDocument2 pagesIna201 Industrial Network ArchitectureFranNo ratings yet

- Alignment On Sundyne Compor PumpDocument23 pagesAlignment On Sundyne Compor PumpBen Sijhi100% (1)

- Business ListingDocument16 pagesBusiness ListingSarika YadavNo ratings yet