Professional Documents

Culture Documents

PALL Gas Separation PDF

Uploaded by

paulpopOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

PALL Gas Separation PDF

Uploaded by

paulpopCopyright:

Available Formats

Fuels and Chemicals

1

1

Fuels and Chemicals

Founded

: 1946

By

: Dr. David B. Pall

HQ

: Long Island, New York (USA)

12.000 employees working in 30 countires

34 plants

Turnover:

Turnover: 2,4 billion USD in FY 2009

Fuels and Chemicals

Pall Experience

BASF

BAYER

BP

Chevron

DOW Chemical

Degussa

DSM

DuPont

Elf Atochem

Enichem

Exxon Chemical

Hoechst

Fuels and Chemicals

Projects executed with Gazprom:

1. Dovletabad GS-2, Turkmenistan

2. Daryalyk, Turkmenistan

3. Akpatlavuk, Turkmenistan

4. Dovletabad 3, Turkmenistan

5. Zapolarnoe, Russia

6. Alguy, Russia

7. Tyumentransgaz, Russia

8. Rusgasengineering, Russia

9. Tarkosalinskoye gas field, Russia

10. Surgut ZSK, Russia

11. Surgut ZSK 2, Russia

Sibur

Yaroslavl

TNK-BP

Petrom

Tyumen

LUKoil

Ceska Raf.

OMV

Latvijas Gas

MOL

Turkmengas

Gazprom

Fuels and Chemicals

Key Future Projects with Gazprom:

Bovanenkovo, Russia

GUS Bednodemianovskoye, Russia

Zapolyarnoye, Russia

Zapolyarnoye, Russia

Harvutinskoye, Russia

Kharasavey, Russia

South Stream, Russia-Bulgaria

Shtokman, Barents Sea

Teriberka, Russia

Leningradskoy, Kara Sea

Rusanovskoye, Kara Sea

Varandey-morey, Russia

Yoloton, Turkmenistan

Karachaganak, Kazakhstan

Fuels and Chemicals

Fuels and Chemicals

Fuels and Chemicals

Fuels and Chemicals

Fuels and Chemicals

Process Diagram

(pumping stations in the case of

LPG or condensates)

Fuels and Chemicals

Pall Liquid/Gas Coalescers

Fuels and Chemicals

Pall Coreless Profile Filter

Fuels and Chemicals

Daryalik Glycol Drying Station,

Turkmengaz/Turkmenistan

The biggest NG drying station of the world

Capacity: 60 billion Am/year

8 absorbers, 128 dia and 18 meters tall,

with 97 Pall Liquid/Gas Coalescers each

13

13

Fuels and Chemicals

Darjalyk Project,

construction site

Fuels and Chemicals

Fuels and Chemicals

Darjalyk Project,

construction site

Darjalyk Project,

construction site

Fuels and Chemicals

Gas transmission in the pipelines

Fuels and Chemicals

Russia:

12 Separators, 1400 mm

total 180 mln Nm3/day

Fuels and Chemicals

Latvijas Gas

Fuels and Chemicals

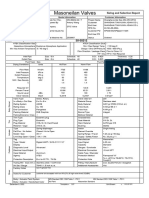

Fuel Gas Separators

Fuels and Chemicals

Turkmenistan

Syberia, Russia

Gas for dry seals - Russia

Fuels and Chemicals

Gazprom

pressure = 105 bar

flowrate = 1600 Nm3/h

Fuels and Chemicals

Purification of natural gas

with

Pall Liquid/Gas

Coalescer Technology

23

Fuels and Chemicals

Gas contaminated by particles and liquid

Fuels and Chemicals

Coalescence - removal of a fine dispersed liquid phase

into a bulk phase (either liquid or gas)

Liquid/Gas coalescers - removal of liquid AEROSOLS +

solids from gas

Coalescence principle :

MECHANICAL separation

based on ability of the

coalescer media to combine

the droplets, and to

separate them.

NO chemicals required

Life Sciences 39%

Fuels and Chemicals

Relative Performance

of Liquid/Gas separators

Type

Knock-out Drum

Cyclone separator

Vane Separator

Demister Pads

Pall Coalescers

Aerosol size removed

> 300 m

> 10 m

> 10 m

> 5 m

> .01 m

2000 Pall Europe Limited

Fuels and Chemicals

Pall Liquid/Gas Coalescers

Fuels and Chemicals

Configuration : VERTICALLY

Enables use of cartridge

drainage capabilities

outlet

Secures separation of both

phases : coalesced liquids and

purified gas flow in opposite

directions

stand

pipes

Smaller footprint vs. horizontal

configured coalescers

tubesheet

inlet

Fuels and Chemicals

Possible internals to reduce the size of

the coalescer (if liquid content in feed

gas is high):

Demister pad

Gas

distributor

Fuels and Chemicals

Coalescer

cartridges

Pre-separation

device

Back to presentation outline

Adaptor of

coalescer

cartridge

Examples of coalescers equipped

with a pre-separation stage:

Fuels and Chemicals

cartridges

Horizontally configured coalescers do not perform well

Very aggressively sized

Two-stage separator : overall efficiency

is the one of the downstream vane pack

or demister pad

often undersized

Vane pack or

demister pad

IN

OUT

Fuels and Chemicals

The target to clean natural gas

equipment protection

-

compressors

valves

instruments

process protection like

glycol tower

Minimise the maintance cost

Fuels and Chemicals

Contamination in natural gas

Sand

Ironoxide / Ironsulfide

Water (liquid)

- salt dissolved

- Hydrogensufide (dissolved)

Hydrocarbon (liquid / solid)

Fuels and Chemicals

Origin and size of liquid

aerosols in gas

PALL LG removal

Demister removal

Fuels and Chemicals

The product

Coalescer

Drainage

medium

medium

Fuels and Chemicals

The product

Fuels and Chemicals

SepraSol Plus

(High Capacity)

Liquidloading > 010.000 ppmw

< 0.01 ppm Aerosolconcentration

cleanside

99.7 % Particle

removal

> 0.3um

Length

100 cm

Diameter

15 cm

Fuels and Chemicals

SepraSol

Liquidloading 0- 1.000 ppmw

< 0.003 ppm Aerosolconcentration cleanside

99.99 % Particle removal

> 0.3um

Length

75 cm

Diameter

7 cm

Fuels and Chemicals

Test field equipment

5

6

INLET

OUTLET

Fuels and Chemicals

The end of a areosol journey:

so called Pall SepraSol Plus

Fuels and Chemicals

Installation and Maintenance

Low maintenance costs

Automatic drains ( if needed)

Long life of Coalescers (> 1 year)

Fewer cartridges

Unlike conventional separators, efficiency is

not affected by reduced gas flow

Assemblies are manufactured to the safety

demands and specifications of individual

applications, natural gas plants/hydrogen

plants/ ammonia plants/ refineries..

Fuels and Chemicals

PMG Wierzchowice,

Wierzchowice, Poland

Underground Gas storage

Fuels and Chemicals

Application I

Solid and liquid separation at the

inlet before checking point

2 x 260 000 Nm3/h

3,9 8,4 Mpa

Requirments

Liquids > 1 mic 98,60 %

Solids > 1 mic 98,90

2 x 11 x CS 604 LGH 13 / Dn 900

Fuels and Chemicals

Application II

Oil removal after compressors

4 x 130 000 Nm3/h

6,5 19,5 Mpa

Requirments

Liquids > 3 mic 99,00 %

Solids > 5 mic 98,00 %

4 x 5 x CS 604 LGH 13 / Dn 700

Fuels and Chemicals

Application III

Glycol removal after dryer

/turboexpander protection/

2 x 300 000 Nm3/h

6,5 12,5 Mpa

Requirments

Liquids > 1 mic 98,60 %

Solids > 1 mic 98,90 %

2 x 11 x CS 604 LGH 13 / Dn 900

Fuels and Chemicals

PALL

Aplication II

Aplication I

Aplication III

inlet

water

separation unit

From

transit

pipe

Gas network

Well head

Underground Gas Storage PMG Wierzchowice II

Gas drying glycol injection

Fuels and Chemicals

3 x CS604 LGH13

Dn 600 mm

Fuels and Chemicals

Typical layout

Fuels and Chemicals

PALL

Fuels and Chemicals

ULTIPLEAT HIGH FLOW

Pleated Construction

Flow In to Out

Filtration Media :

- Polypropylene

- Glass Fibre

Length : 20 to 60 ins

Filtration ratings :

1.2 m to 100 m

Housing Vertical or Horizontal

Fuels and Chemicals

Housing Cut-Away

Black Powder

Fuels and Chemicals

No definition - Catch-all term

which describes a material that collects in gas

piping and creates wear and reduce efficiency in

compressors, clogs instrumentation and valves and

leads to flow losses in long pipe lines

From chemical point of view primarily: iron and sulphur in different

molecular combinations (iron sulfides) + iron oxides + mill scale,

flush rust from hydrotest water

Measuring orifice,

coated with black powder

(Gazprom, compression station)

Fuels and Chemicals

Pipeline Contaminants: Results from Field

Studies

Case #1: Middle East, Sour Gas Export Lines

PSD: 50+% of particles smaller than 5 microns

Mostly comprised between 3-5m

Site 1

13m

12%

<5m <10

m

64% 83%

<15 <25

m

m

94% 100%

Site 2

9%

49%

85%

71%

99%

Measurement of contamination

In transmission pipelines

Fuels and Chemicals

Black Powder (in gas or liquid)

Sampling device

Isokinetic sampling

probe

Fuels and Chemicals

Black Powder

Erosion Damage on 12-Inch Control Valve Body (left) and Trim cage (right)

Fuels and Chemicals

Black Powder

Fuels and Chemicals

Fuels and Chemicals

Black Powder

Black Powder

Erosion Damage on 12-Inch Control Valve Body (left) and Trim cage (right)

Fuels and Chemicals

Black Powder

(Approx. cost of this 42 inspection pig ~ $500K)

Fuels and Chemicals

Black Powder

Fuels and Chemicals

Pall Coreless Profile Filter

Fuels and Chemicals

Catched

by Pall

Coreless

in Saudi

Arabia

Fuels and Chemicals

Black Powder

More information about

Black Powder:

www.pall.com

Fuels and Chemicals

The end.

Thank you for listening.

,Pall and SepraSol are trade marks of Pall

Corporation

Indicates that it is registered in the USA

Filtration,Separation,Solutions is a service mark of Pall

Corporation

You might also like

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Churchill PDFDocument8 pagesChurchill PDFpaulpopNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Intermolecular ForcesDocument60 pagesIntermolecular ForcesBernard D. Fajardo Jr.75% (4)

- PALL L-G Coalescers PDFDocument16 pagesPALL L-G Coalescers PDFpaulpopNo ratings yet

- Clayton - I&O Manual - E Series Steam Generator&Fluid Heater - R16600PDocument118 pagesClayton - I&O Manual - E Series Steam Generator&Fluid Heater - R16600PMus TioNo ratings yet

- Line Sizing Calculation 1Document9 pagesLine Sizing Calculation 1SAMUEL UDOHNo ratings yet

- API Plans FlowserveDocument56 pagesAPI Plans Flowservewwast72100% (5)

- Open Vessel Level Calculation GuideDocument11 pagesOpen Vessel Level Calculation GuideAnurag GuptaNo ratings yet

- Steam From Cavitation PDFDocument4 pagesSteam From Cavitation PDFNiculae George RazvanNo ratings yet

- Vulcan PU General Data PDFDocument15 pagesVulcan PU General Data PDFpaulpopNo ratings yet

- Vulcan PU General Data PDFDocument15 pagesVulcan PU General Data PDFpaulpopNo ratings yet

- Vulcan PU General Data PDFDocument15 pagesVulcan PU General Data PDFpaulpopNo ratings yet

- Steam Generator Fluid Heater &: E-SeriesDocument128 pagesSteam Generator Fluid Heater &: E-SeriespaulpopNo ratings yet

- Your Single Worldwide Source For Steam TechnologyDocument12 pagesYour Single Worldwide Source For Steam TechnologypaulpopNo ratings yet

- Steam Generator Presentation ESC Pony Boilers ESC-Pony BoilersDocument38 pagesSteam Generator Presentation ESC Pony Boilers ESC-Pony BoilerspaulpopNo ratings yet

- Catalog API PDFDocument6 pagesCatalog API PDFpaulpopNo ratings yet

- Catalog API PDFDocument6 pagesCatalog API PDFpaulpopNo ratings yet

- Catalog API PDFDocument6 pagesCatalog API PDFpaulpopNo ratings yet

- Catalog API PDFDocument6 pagesCatalog API PDFpaulpopNo ratings yet

- PDFDocument114 pagesPDFpaulpopNo ratings yet

- Catalog API PDFDocument6 pagesCatalog API PDFpaulpopNo ratings yet

- Type HD Hard / Soft ClipDocument2 pagesType HD Hard / Soft ClippaulpopNo ratings yet

- Yukon Rubber FlooringDocument2 pagesYukon Rubber FlooringpaulpopNo ratings yet

- Catalog API PDFDocument6 pagesCatalog API PDFpaulpopNo ratings yet

- Manual006 PDFDocument51 pagesManual006 PDFpaulpopNo ratings yet

- Clayton Trumpas PristatymasDocument16 pagesClayton Trumpas PristatymaspaulpopNo ratings yet

- Vulcan 1Document18 pagesVulcan 1paulpopNo ratings yet

- Yukon Rig Mats BrochureDocument2 pagesYukon Rig Mats BrochurepaulpopNo ratings yet

- Catalogo LufkinDocument64 pagesCatalogo LufkinJesus BcNo ratings yet

- UP Verticala Tip LRPDocument32 pagesUP Verticala Tip LRPpaulpopNo ratings yet

- Confind Pumping UnitsDocument4 pagesConfind Pumping UnitspaulpopNo ratings yet

- OF110029 R02 - LHL Brochure Low ResDocument2 pagesOF110029 R02 - LHL Brochure Low RespaulpopNo ratings yet

- MegaDeck Specifications Long Version Sep2011 PDFDocument12 pagesMegaDeck Specifications Long Version Sep2011 PDFpaulpopNo ratings yet

- MegaDeck Field Manual PDFDocument16 pagesMegaDeck Field Manual PDFpaulpopNo ratings yet

- Fluid MechanicsDocument53 pagesFluid MechanicsNIHAR NAIKNo ratings yet

- Outgassing of Vacuum materials-IIDocument15 pagesOutgassing of Vacuum materials-IIAbhik BhattacharyaNo ratings yet

- 10.1.1.476.6482 Tesis de DR Carlos Oropeza VasquezDocument132 pages10.1.1.476.6482 Tesis de DR Carlos Oropeza VasquezAnonymous AtAGVssJNo ratings yet

- Assignment 2Document2 pagesAssignment 2Pallav AgrawalNo ratings yet

- Thermo Tables PDFDocument12 pagesThermo Tables PDFEmma WidhiNo ratings yet

- Vacuum Evaporators Mateo Torres.Document11 pagesVacuum Evaporators Mateo Torres.Jakson Mateo Torres GuerraNo ratings yet

- DR Andres Ayuela FernandezDocument17 pagesDR Andres Ayuela FernandezjovmicicNo ratings yet

- Diffuser (Thermodynamics) - Wikipedia PDFDocument9 pagesDiffuser (Thermodynamics) - Wikipedia PDFvarshaNo ratings yet

- ME Laboratory 1 Experiment No. 1Document7 pagesME Laboratory 1 Experiment No. 1Aaron Choco De GuzmanNo ratings yet

- Chemistry Final Exam Study GuideDocument9 pagesChemistry Final Exam Study GuideJosh MorganNo ratings yet

- Introduction PostedDocument64 pagesIntroduction PostedPyarsingh MeenaNo ratings yet

- T.D, 2 Marks & Notes For Units 1,2,3Document54 pagesT.D, 2 Marks & Notes For Units 1,2,3ABHIROOP KNo ratings yet

- MN-89242-22-7 SpecDocument6 pagesMN-89242-22-7 Specrenhat parulian sitorusNo ratings yet

- Retrograde Gas Condensate ReservoirsDocument10 pagesRetrograde Gas Condensate ReservoirsLuchito Canteen SNo ratings yet

- The Kinetics of Nitrogen Absorption by Arc-Melted Fe-C-Mn-Type Filler MetalsDocument8 pagesThe Kinetics of Nitrogen Absorption by Arc-Melted Fe-C-Mn-Type Filler MetalstazzorroNo ratings yet

- PhysicsDocument4 pagesPhysicsDexter the DoubledmintNo ratings yet

- FPM Piezo Lecture1Document61 pagesFPM Piezo Lecture1Aastha JoshiNo ratings yet

- HUNG-THU, DIEP (Eds.) - FRUSTRATED SPIN SYSTEMS (2ND EDITION) - WSPC - World Scientific Publishing Company (2013) PDFDocument638 pagesHUNG-THU, DIEP (Eds.) - FRUSTRATED SPIN SYSTEMS (2ND EDITION) - WSPC - World Scientific Publishing Company (2013) PDFEvelyn TrianaNo ratings yet

- Determining Vacuum Chamber Gaseous Environment Using A Cold FingerDocument5 pagesDetermining Vacuum Chamber Gaseous Environment Using A Cold FingerTuan AnhNo ratings yet

- Corona A. Cabanilla National High School: Direction: Choose The Letter of The Correct AnswerDocument6 pagesCorona A. Cabanilla National High School: Direction: Choose The Letter of The Correct Answerrain sagotNo ratings yet

- Preliminary Design of Indian Test Blanket Module For ITERDocument4 pagesPreliminary Design of Indian Test Blanket Module For ITERTanaji KambleNo ratings yet

- Chemical Bonding and Molecular StructureDocument20 pagesChemical Bonding and Molecular StructureEdwin KAzeNo ratings yet

- Ta 274 273Document9 pagesTa 274 273adamNo ratings yet

- MCE 244 Course OutlineDocument1 pageMCE 244 Course OutlineKaren DavisNo ratings yet