Professional Documents

Culture Documents

Cais17 PDF

Uploaded by

AhmedElSayedOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Cais17 PDF

Uploaded by

AhmedElSayedCopyright:

Available Formats

Health and Safety

Executive

Safety during emptying and cleaning of fryers

HSE information sheet

Catering Information Sheet No 17

Introduction

Whichever type of fryer is used, it is essential that:

This information sheet was produced by the Hospitality

and Catering Industry Liaison Forum, which has

members from trade and professional associations,

unions and enforcement authorities. Members

associations are free to reproduce and distribute this

guidance to catering establishments. The guidance is

issued by the Health and Safety Executive.

you make sure the fryer is well maintained and any

This sheet provides advice to employers in the catering

industry on safe emptying and cleaning of fryers. It

gives guidance on manual emptying and cleaning and

guidance on fryers with automated or semi-automated

filtering (using enclosed portable filtering units).

Automated and semi-automated filtering processes

avoid operators coming into contact with hot oil,

significantly reducing the risks. This enables filtering to

take place safely even while the oil is at normal cooking

temperature. Most automated or semi-automated

systems require an oil temperature of at least 100 C

for the filtering process to work effectively.

You should only carry out manual emptying and

filtering of fryers when the oil has been cooled to

40 C or below.

attachments used are suitable for their purpose, as

recommended by the manufacturer;

you have a procedure for reporting faults;

you clean up oil spillages immediately, and ensure

floor areas around equipment are completely clean

and dry to avoid slip risks;

you train staff in safe procedures for emptying and

cleaning;

you provide staff with suitable protective

equipment, where required by the risk

assessment, eg eye protection, heat-resistant

gloves, aprons.

When to empty and clean

Many catering establishments are closed overnight.

For fire safety and economy, switch off fat fryers

when unattended. Carry out oil filtering and cleaning

as a first task of the day rather than as part of the

closing-down procedure.

Hazards

The hazards in emptying and cleaning fryers include:

Key messages

Burns from hot oil can be very serious.

Oil takes only 6-7 minutes to heat up but can take

6-7 hours to cool down again.

What the law says

The Health and Safety at Work etc Act 1974 places a

duty on employers to ensure, so far as is reasonably

practicable, the health, safety and welfare of their

employees. This duty extends, amongst other things,

to providing and maintaining systems of work which

are, so far as is reasonably practicable, safe and

without risks to health. The Act also places a duty on

employees to take reasonable care of their own and

others health and safety.

fire;

burns from hot oil;

contact with hot surfaces;

fumes from boiling cleaning chemicals;

boiling chemicals overflowing;

eye injuries from splashes;

slips from oil spillage;

strains and sprains from lifting and moving

containers of oil.

If the catering service runs for 24 hours and the appliance

is required continuously, there are two safe options:

use more than one fryer and clean them in rotation;

use an automated filtering system or a semi-

automated portable filtering unit that removes the

hot oil directly from the fryer, filters the oil and holds

it safely.

1 of 3 pages

Health and Safety

Executive

Automated and semi-automated filtering

If the oil is too cold to drain easily, reheat it briefly

Automated filtering systems

An automated system consists of an inbuilt oil filtration

system. The oil is drained into an enclosed reservoir and

an electric pump circulates it through a filter system and

internal pipework back into the fryer. Since this process

is enclosed within the equipment, the operator does not

come into contact with hot oil, greatly reducing any risk.

Portable oil filtering units (semi-automated)

These units are not part of the fryer, but sit alongside

it. The operator attaches an extension pipe to the fryer

and the hot oil is drained into an enclosed container

within the portable unit. The oil is then filtered and

returned to the fryer.

If you have a fryer with automated oil draining

system or a portable oil filtering unit, refer to the

manufacturers guidelines for draining/filtering

temperatures and safe operational requirements.

These, together with your own risk assessment, will

determine the need for suitable protective equipment.

If there is still a risk from contact with hot surfaces or

oil splashing, you may need to provide staff with eye

protection, a protective apron and/or heat-resistant

gloves/gauntlets.

and agitate with the fryer basket (for no more than

one minute). Switch the appliance off and check

the temperature again before emptying.

Using a filter, run the oil into a suitable metal

holding or heat-resistant, hard, plastic container.

These containers will generally need carrying

handles and a cover or lid. Before moving, make

sure that the lid or cover is secure.

Make sure the container is empty and big enough

to take the volume of oil being drained at any time.

When you are draining large volumes of oil, it is

safer to drain off in smaller amounts. This avoids

overfilling the container and will reduce the chance

of spillages when you move it. Smaller amounts will

also be easier to carry.

Place the container in a safe place where it cannot

be contaminated with chemicals, water or foreign

bodies. Place the container on top of a drip tray to

avoid any floor contamination.

Do not dispose of waste oil down the drain

disposal must comply with environmental

legislation.

Clean up any spillages immediately.

Make sure floor areas around equipment are

completely clean and dry to avoid slip risks (see

also Preventing slips and trips in kitchens and food

service).

Other precautions

Manual oil filtering

This involves the operator draining the oil from the

fryer, through a filter, into a suitable metal holding or

heat-resistant, hard, plastic container and manually

lifting it back into the fryer (fryer oil is often supplied in

hard, plastic, rigid containers). Serious accidents have

occurred where oil that has not sufficiently cooled has

been drained back into an empty plastic container and

the base of the container has given way.

To drain oil safely and in the correct sequence, follow

these guidelines:

Make sure the design of the drain-off tap prevents it

being turned on accidentally:

mark clearly on it that the tap should not be

touched;

place warning signs near the tap;

if possible, remove the tap handle when the fryer is

switched on.

Cleaning procedure

This section applies to all types of fryers:

Turn off the appliance and the power supply at the

Turn off the appliance, and the power supply at the

wall socket for electric appliances, and the on/off

control for gas appliances.

Allow the oil to cool, ideally for at least six hours,

and check the temperature, using a suitable probe

thermometer before draining. Do not drain if the

temperature is above 40 C.

Follow the manufacturers instructions and use the

correct equipment (eg a detachable spout for the

type of fryer you are emptying), making sure to bring

any equipment you need to the fryer before you start.

Depending on the type of fryer, drain the oil by drain

valve, removable spout, lifting container or by tilting.

wall socket for electric appliances and the on/off

control for gas appliances.

Wear suitable protective equipment, including eye

protection (if appropriate).

Check that other activities will not be put at risk by

the cleaning activity.

Check that the oil has been thoroughly drained and

that there are no spillages that may cause slipping.

Remove loose debris from the internal surfaces.

Thoroughly wash all internal and external surfaces

with suitable cleaning chemicals and check for any

leaks.

2 of 3 pages

Health and Safety

Executive

For stubborn residues, fill the fryer with your

recommended cleaning agents and leave or

simmer according to instructions.

Do not leave the fryer unattended or allow it to

boil as this may cause it to cascade liquid onto

the floor, causing additional scalding and slipping

hazards.

Drain the appliance and rinse thoroughly with

plenty of water.

Dry all internal surfaces and make sure there is no

water left in the fryer.

Check the drain valve is closed and working

properly, then refill and switch on as required.

When refilling the fryer with oil, the oil container

may be too large or heavy for one member of staff.

Where possible, use smaller containers.

Do not overfill the fryer. Follow the manufacturers

guidelines.

Clean up any spillages immediately.

Make sure floor areas around the equipment are

completely clean and dry to avoid slip risks.

Training

Further information

Preventing slips annd trips in kitchens and food

service Catering Information Sheet CASI6(rev2)

HSEBooks 2012 www.hse.gov.uk/pubns/cais6.htm

HSE has produced a suite of Catering Information

Sheets and other guidance for the catering and

hospitality industry. These are available on the HSE

website at www.hse.gov.uk/catering/index.htm.

There is also helpful advice in Health and safety made

simple: The basics for your business www.hse.gov.

uk/simple-health-safety/index.htm.

For more information about health and safety, or

to report inconsistencies or inaccuracies in this

guidance, visit www.hse.gov.uk/. You can view

HSE guidance online and order priced publications

from the website. HSE priced publications are also

available from bookshops.

This document contains notes on good practice

which are not compulsory but which you may

find helpful in considering what you need to do.

This section applies to all types of fryers:

Make sure only staff trained in the safe use of the

cleaning chemicals and cleaning procedures for

the fryer do this task.

Train staff in reporting procedures, if they find the

equipment is faulty, or if they have experienced any

practical difficulties with cleaning the fryer in their

specific work environment.

Make staff aware of the reasons for using suitable

protective equipment, ie gloves, eye protection.

Complete risk assessments for hazardous

chemicals and make staff aware of the correct

procedures for using cleaning chemicals.

Make safety data sheets available to staff.

A short, written procedure can act as a reminder to

staff for both draining and cleaning operations.

Published by the Health and Safety Executive

This document is available at: www.hse.gov.uk/pubns/

cais17.htm.

Crown copyright If you wish to reuse this

information visit www.hse.gov.uk/copyright.htm for

details. First published 07/12.

CAIS17(rev3)

07/12

3 of 3 pages

You might also like

- Industry Guide To Good Hygiene Practice (1997) - Chadwick CourtDocument103 pagesIndustry Guide To Good Hygiene Practice (1997) - Chadwick CourtAHmm YeAhNo ratings yet

- Code of Construction Safety Practice ARABIC-3 PDFDocument107 pagesCode of Construction Safety Practice ARABIC-3 PDFAhmedElSayedNo ratings yet

- Presentation PAS223 PDFDocument17 pagesPresentation PAS223 PDFAhmedElSayedNo ratings yet

- PartIIoctober2011 PDFDocument33 pagesPartIIoctober2011 PDFAhmedElSayedNo ratings yet

- Esquema de CertificacionDocument13 pagesEsquema de CertificacionMichael FoxNo ratings yet

- Presentation Mark Overland Cargill PDFDocument9 pagesPresentation Mark Overland Cargill PDFAhmedElSayedNo ratings yet

- Presentation Marc Cwikowski Coca Cola PDFDocument11 pagesPresentation Marc Cwikowski Coca Cola PDFAhmedElSayedNo ratings yet

- FSSC 22000: Foundation For Food Safety CertificationDocument14 pagesFSSC 22000: Foundation For Food Safety CertificationAhmedElSayedNo ratings yet

- Presentation ITC PDFDocument21 pagesPresentation ITC PDFAhmedElSayedNo ratings yet

- Presentation GFSI BenchmarkingFSSC PDFDocument29 pagesPresentation GFSI BenchmarkingFSSC PDFAhmedElSayedNo ratings yet

- Presentation Audit Integrity Programme PDFDocument9 pagesPresentation Audit Integrity Programme PDFAhmedElSayedNo ratings yet

- FSSC 22000: Foundation For Food Safety CertificationDocument4 pagesFSSC 22000: Foundation For Food Safety CertificationlaswawariasNo ratings yet

- CXG 024eDocument2 pagesCXG 024egolojoskaliNo ratings yet

- Brochurefssc22000 enDocument6 pagesBrochurefssc22000 enSantoso Jokowaluyo100% (1)

- F SSC 22000 Changes OktoberDocument73 pagesF SSC 22000 Changes OktoberMonching AdecerNo ratings yet

- Catering Quality Assurance Programme PDFDocument44 pagesCatering Quality Assurance Programme PDFAhmedElSayedNo ratings yet

- Cases HD 2011 Including Answers PDFDocument11 pagesCases HD 2011 Including Answers PDFAhmedElSayedNo ratings yet

- Attendance Overview HD 2011 Final PDFDocument2 pagesAttendance Overview HD 2011 Final PDFAhmedElSayedNo ratings yet

- Catering Quality Assurance Programme PDFDocument11 pagesCatering Quality Assurance Programme PDFAhmedElSayed100% (1)

- Halal Presentation-Ramadan Elsayyad PDFDocument39 pagesHalal Presentation-Ramadan Elsayyad PDFAhmedElSayedNo ratings yet

- Ohio Layout PDFDocument2 pagesOhio Layout PDFAhmedElSayedNo ratings yet

- Standard Is at Ion For HALAL Food (SIRIM)Document18 pagesStandard Is at Ion For HALAL Food (SIRIM)Adia RejNo ratings yet

- Quality Assurance Food Facility DesignDocument5 pagesQuality Assurance Food Facility DesignSiti Salwani binti Ab RahimNo ratings yet

- Catering Unit PDFDocument4 pagesCatering Unit PDFAhmedElSayedNo ratings yet

- Hosp Safe Design Com KitchenDocument97 pagesHosp Safe Design Com KitchenRedheartkidNo ratings yet

- Food Safety PDFDocument96 pagesFood Safety PDFmmammerNo ratings yet

- Catering PDFDocument9 pagesCatering PDFAhmedElSayedNo ratings yet

- Catering Guidance Overall PDFDocument210 pagesCatering Guidance Overall PDFAhmedElSayedNo ratings yet

- Industry Guide To Good Hygiene Practice (1997) - Chadwick CourtDocument103 pagesIndustry Guide To Good Hygiene Practice (1997) - Chadwick CourtAHmm YeAhNo ratings yet

- Industry Guide To Good Hygiene Practice (1997) - Chadwick CourtDocument103 pagesIndustry Guide To Good Hygiene Practice (1997) - Chadwick CourtAHmm YeAhNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5783)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Influence of Work Environment On Employee Engagement of Local Government Unit in Municipality of Candelaria ZambalesDocument15 pagesThe Influence of Work Environment On Employee Engagement of Local Government Unit in Municipality of Candelaria ZambalesInternational Journal of Arts, Humanities and Social Studies (IJAHSS)No ratings yet

- Goals and plans for conducting intensive training seminars globallyDocument3 pagesGoals and plans for conducting intensive training seminars globallyAmna Khan YousafzaiNo ratings yet

- Why Men Earn More SummaryDocument4 pagesWhy Men Earn More SummaryAlDobkoNo ratings yet

- Revised Problems and Prospects of Street Vendors in Dapitan City FinalDocument90 pagesRevised Problems and Prospects of Street Vendors in Dapitan City FinalCarlo DugeniaNo ratings yet

- Organo GramDocument9 pagesOrgano GramProtap RoyNo ratings yet

- Adkar ModelDocument6 pagesAdkar ModelDRUVA KIRANNo ratings yet

- Functions of HRMDocument9 pagesFunctions of HRMMahnoor AslamNo ratings yet

- Why Firms Cluster: Labor Pooling and Economies of ScaleDocument5 pagesWhy Firms Cluster: Labor Pooling and Economies of ScaleMoayed Mohamed100% (1)

- Work Life Balance Thesis StatementDocument6 pagesWork Life Balance Thesis Statementmellisahedeensiouxfalls100% (2)

- Work-Life Balance: Achieving EquilibriumDocument54 pagesWork-Life Balance: Achieving EquilibriumMany_Maryy22No ratings yet

- Vietnam Employment Law SummaryDocument8 pagesVietnam Employment Law Summaryjohnmurray1215670No ratings yet

- SoortyDocument18 pagesSoortyNabeel AhmedNo ratings yet

- HR Policy Manual SummaryDocument142 pagesHR Policy Manual SummaryAhmed RazaNo ratings yet

- 03072020205523VCNo.16 2020forAGM JGM DGM (Projects) Ahmedabad NHMC, LothalDocument16 pages03072020205523VCNo.16 2020forAGM JGM DGM (Projects) Ahmedabad NHMC, Lothalnp1101992No ratings yet

- Greene v. United States, 376 U.S. 149 (1964)Document14 pagesGreene v. United States, 376 U.S. 149 (1964)Scribd Government DocsNo ratings yet

- 360 Degree AppraiselDocument57 pages360 Degree Appraiseldibyendu_mondalNo ratings yet

- Prevalence of Work Related Musculoskeletal Disorders and Risk Factors Amongst Nurses of Buea and Tiko Health Districts, South West Region, CameroonDocument8 pagesPrevalence of Work Related Musculoskeletal Disorders and Risk Factors Amongst Nurses of Buea and Tiko Health Districts, South West Region, CameroonEditor IJTSRDNo ratings yet

- American Style Resume GuidelinesDocument3 pagesAmerican Style Resume GuidelinesJames GordonNo ratings yet

- The International Labour Organization and The Quest For Social Justice, 1919-2009Document288 pagesThe International Labour Organization and The Quest For Social Justice, 1919-2009Edgar Ruiz100% (1)

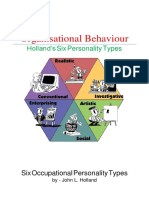

- Organisational Behaviour: Holland's Six Personality TypesDocument5 pagesOrganisational Behaviour: Holland's Six Personality TypesKarina PoNo ratings yet

- G.R. No. L-20451 - R.F. Sugay & Co., Inc. v. ReyesDocument4 pagesG.R. No. L-20451 - R.F. Sugay & Co., Inc. v. ReyesLolersNo ratings yet

- Neri V NLRCDocument3 pagesNeri V NLRCMikaela Denise PazNo ratings yet

- 12 HR Practices in SBI 2016 PDFDocument9 pages12 HR Practices in SBI 2016 PDFPrateek DadhichNo ratings yet

- Industrial/Organizational Psychology - Chapters 9Document6 pagesIndustrial/Organizational Psychology - Chapters 9Myca Katrina CantaneroNo ratings yet

- Authority, Responsibility, DelegationDocument8 pagesAuthority, Responsibility, DelegationCollins OtienoNo ratings yet

- CMPF Act 1948Document17 pagesCMPF Act 1948Sandeep PatidarNo ratings yet

- Samantha Carter ResumeDocument3 pagesSamantha Carter Resumeapi-346880300No ratings yet

- Rise of Nationalism in Europe: Key Events and IdeasDocument5 pagesRise of Nationalism in Europe: Key Events and IdeasREAL GAUTATA83% (12)

- State and Social Transformation in NepalDocument18 pagesState and Social Transformation in NepalSilviu Petre100% (2)

- PERSONAL HISTORY STATEMENTDocument7 pagesPERSONAL HISTORY STATEMENTJoshuaLavegaAbrina100% (2)