Professional Documents

Culture Documents

WPS Welding Procedure

Uploaded by

Danem HalasOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

WPS Welding Procedure

Uploaded by

Danem HalasCopyright:

Available Formats

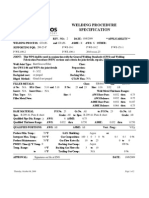

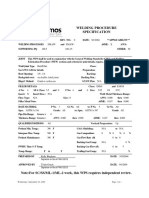

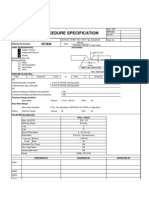

Welding Procedure Specification

1 of 2

http://eia-zirkw-p-ws1.lanl.gov/welding/RptWPS.aspx?ORG=N&ID=105

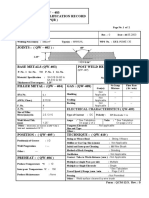

ELDING ROCEDURE

PECIFICATION

WPS: 5000-xxxx-HY80/HSLA100D1.1

REV. NO.: 0

WELDING PROCESS: SAW

SUPPORTING PQR:

DATE: 11/14/2011

CODE: AWS D1.1

**APPLICABILITY**

OTHER:

5000-HY80/HSLA100

JOINT: This WPS shall be used in conjunction with the General Welding Standards (GWS) and Welding Fabrication Procedure (WFP)

sections and criteria for joint details, repairs, NDE, inspection, etc.

Weld Joint Type:

Class: Full & Partial Penetration & Fillets

Butt

See GWS 1-06 and WFP's for joint details.

Root Opening:

N/A

Backgrind Root:

When required

Bkgrd Method:

Gouge, Chip, Grind

Preparation: Machined Bevel 37.5 with 0-1/8" land

Backing: Metal

Backing Mat.: Metal

GTAW Flux: N/A

FILLER METALS:

A No:

N/A

Insert:

N/A

Flux:

Backing Retainer: No

Class: Mill-100S-1

SFA Class: N/A and N/A

F No: N/A and N/A

Insert Type: N/A

Type: Mil800-H

Size: .045 1/16 3/32 1/8

Weld Metal Thickness Ranges:

Size: N/A

AWS Root Pass: .125 thru .250

Filler Material Note:

AWS Balance: .375 thru 99

ASME Root Pass: 0 thru 0

ASME Balance: 0 thru 0

BASE MATERIAL:

P No: N/A

Spec.: HY 80

Gr No.: N/A

Grade: N/A

to P No.: N/A

to Spec.: HSLA 100

Qualified Pipe Dia. Range: >=

AWS: 24

ASME: 0

Qualified Thickness Range:

AWS: 0.375 thru 99

ASME: 0 thru 0

QUALIFIED POSITIONS:

AWS: 1G

ASME: N/A

Preheat Min. Temp.:

200

Interpass Max. Temp.:

400 F

Preheat Maintenance:

200 F

PWHT: Time @ F Temp.:

Temperature Range:

N/A F to N/A F

GAS: Shielding: N/A

Grade: N/A

Vert. Prog.: N/A

or

Gas Composition: N/A / N/A / N/A %

Gas Flow Rate cfh: 0 to 0

Backing Gas/Comp: N/A

Gr No.: N/A

N/A

N/A / N/A / N/A %

0 to 0

N/A %

Backing Gas Flow cfh: 0

Trailing Gas/Comp: N/A

N/A %

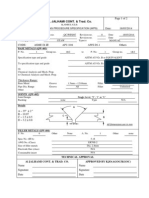

WELDING CHARACTERISTICS:

Current:

Tungsten Type: N/A

DCEN

Ranges:

Amps: 200

Tungsten Dia.: N/A

Volts: 18

Fuel Gas:

Pulsing Cycle: 0 to 0

Background Current: 0

Flame: N/A

N/A

Transfer Mode: N/A

Braze Temp F: N/A to N/A

WELDING TECHNIQUE:

For fabrication specific requirements such as fitup, cleaning, grinding, PWHT and inspection criteria, refer to

Volume 2, Welding Fabrication Procedures.

Technique:

Machine

Cleaning Method: Chip/grind/file/wire brush

11/16/2011 3:06 PM

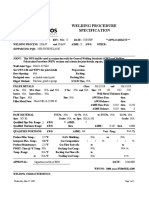

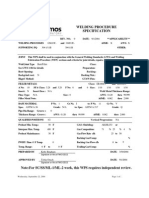

Welding Procedure Specification

2 of 2

http://eia-zirkw-p-ws1.lanl.gov/welding/RptWPS.aspx?ORG=N&ID=105

Single or Multi Pass:

Multi

Stringer or Weave Bead (S/W): S or N/A

GMAW Gun Angle:

0 to 0

No Pass > 1/2":

N/A

Oscillation: N/A

Forehand or Backhand for GMAW: N/A

GMAW/FCAW Tube to Work Distance (in): N/A

Maximum K/J Heat Input: 62000 KJ/in

Travel Speed:

Gas Cup Size: N/A

PROCEDURE QUALIFIED FOR:

Charpy "V" Notch:

Comments:

Weld

Layer

1

Nil-Ductile Transition Temperature: No

No

Dynamic Tear: No

No comments.

Manual

Process

Filler Metals

Size

Amp Range

SAW

Mill-100S-1

Volt Range

Travel/ipm

Nozzle

Angle

0 to 0

.045

200 to 240

18 to 22

2.3 to 3.0

1/16

345 to 390

24 to 28

8 to 12

3/32

340 to 600

26 to 34

9 to 12

1/8

350 to 600

26 to 34

9 to 12

Other

REM. * Weld layers are representative only - actual number pf passes and layer sequence may vary.

ML-1/2 projects or jobs must determine if the supporting documentation for this WPS complies with quality requirements of the project/job.

Use of LANL Welding Procedures and Welder Qualifications for non-LANL work shall be at the sole risk and responsibility of the Subcontractor, and

the Subcontractor shall indemnify and save LANL and the Government harmless from any and all claims, demands, actions or causes of action, and

for any expense or loss by the reason of Subcontractor's and their employees posession and use of LANL procedures and qualifications.

APPROVAL:

Signatures on file at ES-DE

DATE: 11/16/2011

11/16/2011 3:06 PM

You might also like

- Aluminim WPSDocument2 pagesAluminim WPSKarthikeyan ShanmugavelNo ratings yet

- Welding Procedure SpecificationDocument2 pagesWelding Procedure SpecificationSAKDA MAPRADITKULNo ratings yet

- WPS Sa 517Document2 pagesWPS Sa 517DHANANNJAI SINGH -No ratings yet

- 1000 XXXX HY80 HSLA100Document2 pages1000 XXXX HY80 HSLA100srb metallurgNo ratings yet

- WPS ExampleDocument2 pagesWPS ExampleMarcio Jr.No ratings yet

- WPS for GTAW Welding of Aluminum Butt JointsDocument2 pagesWPS for GTAW Welding of Aluminum Butt Jointsmahmoud_allam3No ratings yet

- Welding Procedure for Stainless Steel PipesDocument2 pagesWelding Procedure for Stainless Steel Pipes模具工程系鄭德彥No ratings yet

- WPS for Welding HY80 SteelDocument2 pagesWPS for Welding HY80 Steelsrb metallurgNo ratings yet

- Aluminium WPSDocument2 pagesAluminium WPSAnonymous yCpjZF1rF100% (1)

- Welding Procedure SpecificationDocument2 pagesWelding Procedure SpecificationFrancisco HoyosNo ratings yet

- CD Welding ProcDocument2 pagesCD Welding ProcAnonymous yCpjZF1rFNo ratings yet

- Engineering Standards Manual - Welding Standards M Anual - Volume 3 Welding Procedure SpecificationsDocument3 pagesEngineering Standards Manual - Welding Standards M Anual - Volume 3 Welding Procedure Specificationslaz_k50% (2)

- WPS Gtaw) - 47Document2 pagesWPS Gtaw) - 47Dharmendra BhardwajNo ratings yet

- WPS for FCAW Welding of SteelDocument2 pagesWPS for FCAW Welding of SteelHamid MansouriNo ratings yet

- PQR-WPS-WPQR XXX Rev 0Document6 pagesPQR-WPS-WPQR XXX Rev 0Brett Gosselin100% (1)

- Welding Procedure SpecificationDocument2 pagesWelding Procedure SpecificationWaranya Musika100% (1)

- Elding Rocedure Pecification: 7200-HDPE Butt WeldDocument2 pagesElding Rocedure Pecification: 7200-HDPE Butt Weldsamer8saifNo ratings yet

- Welding Procedure Specification NO. 1-7-1: National Certified Pipe Welding BureauDocument5 pagesWelding Procedure Specification NO. 1-7-1: National Certified Pipe Welding BureauTharakeshNo ratings yet

- WPS-PQR For Split TeeDocument9 pagesWPS-PQR For Split TeemaheshmalaichamyNo ratings yet

- Welding Procedure SpecificationDocument2 pagesWelding Procedure SpecificationFrancisco HoyosNo ratings yet

- Wps p91 - BhelDocument2 pagesWps p91 - BhelAshish Gupta100% (4)

- GWAW Welding SpecificationDocument2 pagesGWAW Welding SpecificationSaurabh GuptaNo ratings yet

- API-1000-11 Rev 0Document3 pagesAPI-1000-11 Rev 0Mahesh MishraNo ratings yet

- Welding Procedure Specification (WPS)Document0 pagesWelding Procedure Specification (WPS)Oscar Iván Duque DíazNo ratings yet

- WPS Sitelca S002Document2 pagesWPS Sitelca S002Jose Antonio GomezNo ratings yet

- WPS - 012Document11 pagesWPS - 012MAT-LIONNo ratings yet

- WPS GTAW Stainless SteelDocument4 pagesWPS GTAW Stainless SteelAnand NarayananNo ratings yet

- NORTH CAROLINA DEPARTMENT OF TRANSPORTATION ARMOR ANGLE FIELD SPLICE WELDING PROCEDURE SPECIFICATIONDocument3 pagesNORTH CAROLINA DEPARTMENT OF TRANSPORTATION ARMOR ANGLE FIELD SPLICE WELDING PROCEDURE SPECIFICATIONans44155No ratings yet

- Wps SawDocument2 pagesWps Sawdevendrasingh2021100% (6)

- WPS SampleDocument6 pagesWPS SampleAshishNo ratings yet

- WELDING PROCEDURE SPECIFICATION FOR TIE-IN WORKSDocument6 pagesWELDING PROCEDURE SPECIFICATION FOR TIE-IN WORKSAshishNo ratings yet

- WPS For Different Materail by BhelDocument176 pagesWPS For Different Materail by Bhelsaisssms911691% (46)

- Welder Cirt TotalDocument78 pagesWelder Cirt TotalNguyễn ChâuNo ratings yet

- Superduplex Welding Procedure Specification (WPSDocument4 pagesSuperduplex Welding Procedure Specification (WPSClaudia Mms100% (3)

- WPS 01 WQT PDFDocument1 pageWPS 01 WQT PDFkiki270977No ratings yet

- GTAW Welding Procedure Specification for Aluminum Butt JointsDocument7 pagesGTAW Welding Procedure Specification for Aluminum Butt JointsJose MoralesNo ratings yet

- WPS FormatDocument2 pagesWPS FormatAmit SarkarNo ratings yet

- Wps Sp14 Reva PDFDocument9 pagesWps Sp14 Reva PDFravi00098No ratings yet

- Audco India Limited Welding Procedure Specification: LAB-005R1Document3 pagesAudco India Limited Welding Procedure Specification: LAB-005R1sudeep_singh1No ratings yet

- Welding Procedure Specification Joint Venture: Azzawiya Control System Modernization ProjectDocument4 pagesWelding Procedure Specification Joint Venture: Azzawiya Control System Modernization ProjectwentropremNo ratings yet

- 0.1C#PAOLO) Sample PQR-35 For Mock Up Exam 19032016 @PCDocument2 pages0.1C#PAOLO) Sample PQR-35 For Mock Up Exam 19032016 @PCAshish PatelNo ratings yet

- Welding Procedure Specification (WPS) As Per Asme Sec. Ix: Project Contractor Inspection WorkDocument10 pagesWelding Procedure Specification (WPS) As Per Asme Sec. Ix: Project Contractor Inspection Workvijayshelke100% (1)

- WPS GTAW pipe welding procedureDocument2 pagesWPS GTAW pipe welding procedureRichard PeriyanayagamNo ratings yet

- Welding Procedure Specification (WPS) : Code: API Std. 1104 and ASME B31.4/B31.8 M.P.C.C 002Document2 pagesWelding Procedure Specification (WPS) : Code: API Std. 1104 and ASME B31.4/B31.8 M.P.C.C 002shervinyNo ratings yet

- PQR B7A SingleDocument3 pagesPQR B7A SingleNabeel Adeeb AlshareNo ratings yet

- PQR Gmaw3gDocument4 pagesPQR Gmaw3gdevendrasingh2021100% (3)

- (P22) Nsc-1020-Tr-0102-5a.5a-Wps-04-NewDocument4 pages(P22) Nsc-1020-Tr-0102-5a.5a-Wps-04-NewBIIS QAQC Babu SivaNo ratings yet

- Engineering Standards Manual - Welding Standards Manual - Volume 3 Welding Procedure SpecificationsDocument3 pagesEngineering Standards Manual - Welding Standards Manual - Volume 3 Welding Procedure SpecificationsjacquesmayolNo ratings yet

- 03 WPS CS 1Document3 pages03 WPS CS 1mohammadNo ratings yet

- Offshore Electrical Engineering ManualFrom EverandOffshore Electrical Engineering ManualRating: 4 out of 5 stars4/5 (9)

- Principles of Welding: Processes, Physics, Chemistry, and MetallurgyFrom EverandPrinciples of Welding: Processes, Physics, Chemistry, and MetallurgyRating: 4 out of 5 stars4/5 (1)

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- Welding the Inconel 718 Superalloy: Reduction of Micro-segregation and Laves PhasesFrom EverandWelding the Inconel 718 Superalloy: Reduction of Micro-segregation and Laves PhasesNo ratings yet

- Applied Process Design for Chemical and Petrochemical Plants: Volume 1From EverandApplied Process Design for Chemical and Petrochemical Plants: Volume 1Rating: 3.5 out of 5 stars3.5/5 (3)

- Pipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsFrom EverandPipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsRating: 4.5 out of 5 stars4.5/5 (10)

- Transistor Electronics: Use of Semiconductor Components in Switching OperationsFrom EverandTransistor Electronics: Use of Semiconductor Components in Switching OperationsRating: 1 out of 5 stars1/5 (1)

- Fluid Analysis for Mobile Equipment: Condition Monitoring and MaintenanceFrom EverandFluid Analysis for Mobile Equipment: Condition Monitoring and MaintenanceNo ratings yet

- Consignation HTDocument6 pagesConsignation HTDanem HalasNo ratings yet

- TWI CSWIP 3.1 Wis 5 Welding Inspection: World Centre For Materials Joining TechnologyDocument26 pagesTWI CSWIP 3.1 Wis 5 Welding Inspection: World Centre For Materials Joining TechnologyDanem HalasNo ratings yet

- Chapter 13 - Designing For Quality: PTTE 434 Jim Wixson - InstructorDocument72 pagesChapter 13 - Designing For Quality: PTTE 434 Jim Wixson - InstructorPrabhat SharmaNo ratings yet

- Ut Proceduregeneral 141118232235 Conversion Gate02Document24 pagesUt Proceduregeneral 141118232235 Conversion Gate02Danem HalasNo ratings yet

- Everything You Need to Know About Stainless Steel Welding Procedure SpecificationDocument6 pagesEverything You Need to Know About Stainless Steel Welding Procedure SpecificationDanem HalasNo ratings yet

- CV Ait KoufiDocument3 pagesCV Ait KoufiDanem HalasNo ratings yet

- Crane SafetyDocument12 pagesCrane SafetymytheeNo ratings yet

- Construction IssuesDocument50 pagesConstruction IssuesDanem HalasNo ratings yet

- A 6 - A 6m - 02 QtytmdiDocument63 pagesA 6 - A 6m - 02 QtytmdiDanem HalasNo ratings yet

- A 6 - A 6m - 02 QtytmdiDocument63 pagesA 6 - A 6m - 02 QtytmdiDanem HalasNo ratings yet

- Carbon Steel Girder Rails of Plain, Grooved, and Guard TypesDocument3 pagesCarbon Steel Girder Rails of Plain, Grooved, and Guard TypesDanem HalasNo ratings yet

- 13 L1 L2 Reactor DesignDocument48 pages13 L1 L2 Reactor DesignStan LouisNo ratings yet

- WPS PQR Checklist 2014Document2 pagesWPS PQR Checklist 2014Sebastian Rajesh100% (1)

- Part2 Notice 1Document21 pagesPart2 Notice 1Danem Halas100% (1)

- Inspection & Test Plans 1 of 50Document49 pagesInspection & Test Plans 1 of 50jok1974No ratings yet

- Welding Procedure Specification NO. 8-32-1: National Certified Pipe Welding BureauDocument7 pagesWelding Procedure Specification NO. 8-32-1: National Certified Pipe Welding BureauDanem HalasNo ratings yet

- WPQRDocument27 pagesWPQRJayaram MVNo ratings yet

- WSS Welding Handbook 2013 Full Lowres PDFDocument552 pagesWSS Welding Handbook 2013 Full Lowres PDFsridharchowdary3490% (1)

- 254-SmoDocument12 pages254-SmoDanem Halas100% (1)

- En Metalwork Gas Tungsten Arc WeldingDocument48 pagesEn Metalwork Gas Tungsten Arc WeldingadammzjinNo ratings yet

- MT Training SpecifiqueDocument4 pagesMT Training SpecifiqueDanem HalasNo ratings yet

- Duplex 2101Document6 pagesDuplex 2101Anonymous AlhzFE9EVNNo ratings yet

- WPS PQR Checklist 2014Document2 pagesWPS PQR Checklist 2014Sebastian Rajesh100% (1)

- Office: Printout Sample - ASME WPSDocument2 pagesOffice: Printout Sample - ASME WPSDanem HalasNo ratings yet

- WeldingofStainlesssSteelandotherJoiningMethods 9002Document0 pagesWeldingofStainlesssSteelandotherJoiningMethods 9002jvs11021102No ratings yet

- WPS GTAW Stainless SteelDocument2 pagesWPS GTAW Stainless SteelSrinivasan Muruganantham84% (31)

- WLD 290 Submerged Arc WeldingDocument52 pagesWLD 290 Submerged Arc WeldingDanem HalasNo ratings yet

- Clad PQRDocument5 pagesClad PQRRinshadNo ratings yet

- 8a Codes and Q & CDocument35 pages8a Codes and Q & CDanem HalasNo ratings yet

- Office: Printout Sample - ASME WPSDocument2 pagesOffice: Printout Sample - ASME WPSDanem HalasNo ratings yet

- Spot WeldDocument8 pagesSpot Weld0502raviNo ratings yet

- Software Gives Welders Tools to Achieve Quality and ProductivityDocument4 pagesSoftware Gives Welders Tools to Achieve Quality and ProductivityHerd ImanNo ratings yet

- Boiler Welding ElectrodesDocument24 pagesBoiler Welding Electrodesjohnknight000No ratings yet

- Filler Metal - Bestseller - Engl - NT - BohlerDocument29 pagesFiller Metal - Bestseller - Engl - NT - BohlerMaher BmdNo ratings yet

- PSC vs Composite Girder: Cost comparisonDocument3 pagesPSC vs Composite Girder: Cost comparisonamitkuknaNo ratings yet

- Mahalaxmi Quality Plan For FabricationDocument1 pageMahalaxmi Quality Plan For FabricationAnonymous RXXdbl36ANo ratings yet

- Design Guide Galvanized Steel StructuresDocument28 pagesDesign Guide Galvanized Steel StructuresLuis MundacaNo ratings yet

- AISI 1022 Steel, Heat Treated, Quenched From Pot, 13.7 MM RoundDocument2 pagesAISI 1022 Steel, Heat Treated, Quenched From Pot, 13.7 MM RoundygfrostNo ratings yet

- A641 PDFDocument5 pagesA641 PDFandresNo ratings yet

- Viking PumpDocument36 pagesViking PumpSakir Zak100% (2)

- CR StandardsDocument6 pagesCR Standardsalpha_beta48No ratings yet

- PDF - 1.3505 - DIN - EN - Steel Material Sheet - SteelShopDocument1 pagePDF - 1.3505 - DIN - EN - Steel Material Sheet - SteelShopMuslim N FNo ratings yet

- ICEF2010-35139: New Approaches On Material Design For High-Performance 2-Stroke Engine BearingsDocument6 pagesICEF2010-35139: New Approaches On Material Design For High-Performance 2-Stroke Engine BearingsFLangNo ratings yet

- 316L SS CrucibleDocument2 pages316L SS CrucibleARUNKANNANNo ratings yet

- Welder Job Description For ResumeDocument5 pagesWelder Job Description For Resumef5dthdcd100% (2)

- CH 13 JjcbdaiuDocument9 pagesCH 13 JjcbdaiuDaya AhmadNo ratings yet

- Hot Rod - Technical Paper Rod Mill Processes - NDT - 1099 - E PDFDocument11 pagesHot Rod - Technical Paper Rod Mill Processes - NDT - 1099 - E PDFradinasrNo ratings yet

- FOB Chute Bin Write UpDocument3 pagesFOB Chute Bin Write UpJulio Wacas BangguiyaoNo ratings yet

- ASTM's Steel Standards GuideDocument63 pagesASTM's Steel Standards GuideNagarjun ReddyNo ratings yet

- Dodge Et Al., 2014Document7 pagesDodge Et Al., 2014Luan CaetanoNo ratings yet

- Welding MCQ Module for Mechanical EngineeringDocument14 pagesWelding MCQ Module for Mechanical Engineeringanil100% (1)

- Model B: Thermostatic Control ValvesDocument13 pagesModel B: Thermostatic Control ValvesRei_budNo ratings yet

- L5-Materials To ProductsDocument30 pagesL5-Materials To ProductsDramil ThakkarNo ratings yet

- Ce 355 - Policy and ScheduleDocument2 pagesCe 355 - Policy and SchedulecpufreakzNo ratings yet

- WPRK Pack Preparation PDFDocument42 pagesWPRK Pack Preparation PDFYusufNo ratings yet

- Resistance Welding: Introduction and Recent Developments: S. Tripathy & Ajitav SahooDocument6 pagesResistance Welding: Introduction and Recent Developments: S. Tripathy & Ajitav SahooTJPRC PublicationsNo ratings yet

- NPQS A1-40 Metal Cladding GuideDocument29 pagesNPQS A1-40 Metal Cladding GuideJacky Tiong100% (1)

- RDT 99005Document96 pagesRDT 99005Hashem EL-MaRimeyNo ratings yet

- A-A-59326a (1) AcoplamentoDocument15 pagesA-A-59326a (1) AcoplamentogilsonNo ratings yet