Professional Documents

Culture Documents

Multilevel Car Parking

Uploaded by

RajatSharmaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Multilevel Car Parking

Uploaded by

RajatSharmaCopyright:

Available Formats

International Journal of Emerging Technology and Advanced Engineering

Website: www.ijetae.com (ISSN 2250-2459, ISO 9001:2008 Certified Journal, Volume 5, Issue 4, April 2015)

Vertical Car Parking A Prototype

Sawankumar G. Narone1, Swapnil S. Chabukswar2, Shriharh A. Valyal3, Ravikant B. Hirapure4,

Prof. V. R. Solapure5

1,2,3,4

Final Year, Department of Mechanical Engineering, N B Navale Sinhgad College of Engineering, Solapur, Maharashtra,

India

5

Assitant Prof., Department of Mechanical Engineering, N B Navale Sinhgad College of Engineering, Solapur, Maharashtra,

India

Abstract - This project deals with manufacture of a

Prototype of Vertical Car Parking System. This system has

been implemented to reduce the excess use of land space

which is already very scarce in metro cities. Different types of

vehicle parking are applied worldwide namely Multi-level

Automated Car Parking, Automated Car Parking System,

and Rotary Parking System. The present project work is

aimed to develop a scale down working model of a car parking

system for parking cars within a large parking area. The

chain and sprocket mechanism is used for driving the parking

platform. This total prototype is powered by a D.C motor.

When the car comes on the ramp the switch will be activated

and the bucket comes to carry the vehicle. When the switch

will be operated by the operator, sprockets starts to rotate and

the new space will be adjusted for new vehicle. Planners,

developers, architects are finding out solutions to tackle this

problem of parking, so we took this opportunity to bring the

technology of automated parking to where it is needed.

II.

The automated parking management system has existed

for a long time, but is only now finding mass demand for

the efficient and effective parking solution. The demand for

parking is constantly increasing while the space for large

parking lots is decreasing. As a result, automated parking

management systems have filled the void by parking more

cars in less space and improving profitability, safety,

environment considerations and all related expenses. With

this in mind, knowing the background of the parking

garage can be an interesting topic.

The automated parking system was actually first

developed in 1925 by Max Miller in New York City. The

designs original purpose was simple to lift a vehicle off the

ground, such as in the case of a stalled or broken down car

on a street. It was never used.

It was not until 1941, as cars crowded cities that the first

attempt to vertically park cars was attempted. O.A. Light

created a device that allowed three cars to park vertically,

three on each side for a total capacity of six. A year later,

E.W. Austin invented the automated garage. His invention

became the leader in automated parking during the 40s, 50s

and 60s. These systems were called Bowsers, Pigeon Holes

and Roto Parks.

Throughout these years, developments and design

changes were made to continually improve the automated

car park. In 1964, Eric Jaulmes invented what is most

similar to the automated parking management systems of

today. His system had a valet drive the car into an elevator.

The elevator would then take the car to a predetermined

spot and the valet would park the car in that space. Then on

the return down, if it had been requested, the valet would

stop at another spot to get a car to be returned. At the same

time, the three former systems were revitalized to remove

the valet altogether allowing the lift to tip the car into place

and the opposite on retrieval.

Keywords - automated parking, mechanism prototype,

space scarce, vehicle.

I.

B ACKGROUND

INTRODUCTION

The first question we are facing when we explaining the

project is, When your project is about parking system

which involves some type of lifting mechanism then why

dont you build a multilevel parking system? So we would

like to introduce our project answering that question

showing different types of parking as of now which are

widely used and the reasons why we had to make this

choice from them, in the field of technology everyday a

new technique is launched. It has its own characteristics

due to which we have to adopt it. Today is the world of

new technology which we have to take in practice.

These advanced automatic parking systems are

extraordinarily well designed, tested and constructed. They

are being used worldwide in totally automated locations,

where speed and reliability is critical. The advantages are

clear. The systems are scalable and adapt to virtually any

architectural foot print. They hold as many as twice any

vehicles as similarly sized conventional garages. Whats

more they are fast, efficient and environmentally sound.

199

International Journal of Emerging Technology and Advanced Engineering

Website: www.ijetae.com (ISSN 2250-2459, ISO 9001:2008 Certified Journal, Volume 5, Issue 4, April 2015)

III.

P RESENT P ARKING SOLUTIONS

a. Integrated Car Parking Solution

Customize application suitable for various types of

landscapes and buildings Structures available below the

ground. Ease control by soft touch on the operation panel

screen. When a vehicle stops in front of the entrance,

automatically door opens and trolley transfers the vehicle

to parking cell. Misleading of this solution is it should be

undergrounded. By this investment increases and lot much

space utilization is to be made.

Figure 2.Automated Car Parking

c. Multi-Level Parking

A multi-level car parking is essentially a building with

number of floors or layers for the cars to be parked. The

different levels are accessed through interior or exterior

ramps. An automated car parking has mechanized lifts

which transport the car to the different levels. Therefore,

these car parks need less building volume and less ground

space and thus save on the cost of the building. It also does

away the need for employing too many personal to monitor

the place. In an automated car parking, the cars are left at

the entrance and are further transported inside the building

by robot trolley. Similarly, they are retrieved by the trolley

and placed at the exit for the owner to drive away.

Figure 1 Integrated Car Parking Solution

b. Automated Car Parking

The driver will pull the car onto a computer- controlled

pallet, turn it off, and get out. The pallet is then lowered

into the abyss of parking spaces, much like a freight

elevator for cars, except it can also move sideways, not just

up and down. There's an array of laser sensors that let the

system know if the car doesn't fit on the pallet (although it's

big enough to fit a mid-sized SUV),. The system retrieves

the car when the driver returns, although this might take

some time and creative manoeuvring. Cars are parked two

deep in some spots, so a specially tailored software system

has to figure out the logistics of shuffling the various

vehicles around as needed to retrieve a specific car. And for

those, like me, who find it difficult to turn their vehicle

around after pulling out of a space, there's an underground

turntable that turns the car around before it is lifted to the

surface, so the car is facing out into the driveway, ready to

go. Backing out of garages or parking spaces is one of the

most common causes of accidents.

Figure 3. Multi-Level Parking

200

International Journal of Emerging Technology and Advanced Engineering

Website: www.ijetae.com (ISSN 2250-2459, ISO 9001:2008 Certified Journal, Volume 5, Issue 4, April 2015)

IV.

VERTICAL C AR P ARKING A P ROTOTYPE

You are able to keep track of the entire structure and

spend virtually no time driving the car in the parking you.

You simply drop off the car at the entrance and pick up on

your way out. Aside from the comfort that the automation

brings you can also save space through incorporating the

park lift system as well. Through this we are able to utilize

the vertical space in a parking lot that is usually wasted.

You are also able to customize each stack parker so that

you can fit different sized cars in each of the different slots.

It would be meaningless to have all stack parkers adjusted

to the height of a SUV when you can have different sets

where you can park 2 SUVs or 3 regular sedans

Unique Characteristics

The space for parking 3 cars can hold more than 9

cars.

It adopts rotating for mechanism so as to minimize the

vibration and noise.

Flexible operation.

No caretaker is needed, key pressing operation.

High safety, complete inspecting device

Stable and reliable

It is simple to operate with the driver parking and

leaving the vehicle in the system at the ground level. Once

the driver leaves the incorporated safety zone the vehicle is

automatically parked by the system rotating to lift the

parked car away from the bottom central position. This

leaves an empty parking space available at the ground level

for the next car to be parked on. The parked car is easily

retrieved by pushing the button for the relevant position

number the car is parked on. This causes the required car to

rotate down to ground level ready for the driver to enter the

safety zone and reverse the car out of the system. Except

vertical car parking system all other systems use a large

ground area, vertical car parking system is developed to

utilize maximum vertical area in the available minimum

ground area. It is quite successful when installed in busy

areas which are well established and are suffering with

shortage of area for parking. Although the construction of

this system seems to be easy, it will be par from

understanding without the knowledge of materials, chains,

sprockets, bearings, and machining operations, kinematic

and dynamic mechanisms

Imagine the time that automatic smart parking systems

would save you. Every time you enter your office building

you have to find a parking space and spend time walking in

and out of the lot as well. Imagine how much time it is

costing you. Even if you just spend 5 minutes a day to park

that translates to you spending more than a whole day just

parking every year. If you calculate the time you spend

walking in and out of the parking lot, searching for space

and such it will be easily more than the above amount. A

fully automated system mimics a futuristic assembly line

structure where the cars are moved to an empty platform.

The platform under the car moves to a designated spot and

all the other platforms are arranged so that no cars are

stuck.

Figure 4. Vertical car parking A prototype

201

International Journal of Emerging Technology and Advanced Engineering

Website: www.ijetae.com (ISSN 2250-2459, ISO 9001:2008 Certified Journal, Volume 5, Issue 4, April 2015)

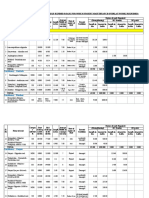

V.

STEPS T O COMPLETE T HE PROJECT

VI.

C ALCULATIONS & MODELLING

PHASE 1

a. Market survey

During this period detail market survey has been done to

learn available parking systems and their utility also their

literatures of different types of parking systems and its

difference between have been observed.

b. Problems in existing systems

The problems regarding the existing system have been

found such as, Complicated programming, High budgets,

Unfeasible design, high end robots, etc.

c. Conceptual Design.

Taking problem statement from above and studying the

fundamental engineering concepts various concepts

regarding modern parking system are prepared and

amongst those best concepts design has been selected for

further phases.

Figure 5. Model Assembly

PHASE 2

a. Calculated value of shaft diameter

By using Power Equation, P = 0.0462 KW

By using Average Velocity Equation,

a. Modelling in CATIA.

Putting the ideas on the modelling software for

visualisation of the prototype and making it more and more

compatible so that there will be less complexity in

designing

V = 1.532 * 10-6 m/s

By using Maximum Bending Moment Equation,

Ma = 121.61 * 103 N.mm

b. Material Selection and Procurement

In this phase material selection is done and also its

procurement as per need the dimensions are taken from

CATIA model.

By using Maximum Shear Stress Theory Equation,

Te = 129.37 N.m

max = 195.23 N/mm2

From above equations, shaft diameter,

c. Fabrication

This phase includes fabrication of prototype in the

workshop from the procured material and preparing the

Prototype model from the software model.

D = 14.53mm 15 mm

By using Maximum Principle Stress Theory Equation,

Me = 125.49 * 103 N.mm

d. Assembly & Testing

This phase include Assembly of all the sub parts, also

the arrangement of the motor and its wiring is done, all

finishing operations like grinding, trimming, painting is

done here.

Testing phase includes testing of the Prototype model

under real environment.

bmax. = 378.746 N/mm2

D = 14.57 mm 15mm

b. Chain design

No. of links, Ln = 106 Links

Length of chain, L = 1358.8 mm 1360 mm

202

International Journal of Emerging Technology and Advanced Engineering

Website: www.ijetae.com (ISSN 2250-2459, ISO 9001:2008 Certified Journal, Volume 5, Issue 4, April 2015)

c. Design of spokes

Maximum Bending Moment, M = 15858.36 N.mm

2. It can be fully automated by integrating it with a panel

board, such that whenever a particular number is

called on the panel board, the respective platform

should appear at the ground level.

3. This calling can also be made more secured by

providing each platform a specific password, so that

only whenever a particular password is typed the

platform is retrieved.

b = 96585.86 N/mm2

Spoke Diameter, D = 2 mm

VII.

OBSERVATIONS

After completion of manufacturing all the parts were

gathered to assemble the whole prototype. Accordingly it

has assembled but after assembling it was observed that

there were misalignments in the chain.

So it was checked for misalignment thoroughly and the

output came was a bit loosening of one of the chain. The

corrective actions were taken and the prototype ran without

misalignment.

After eliminating this misalignment it was found that 3

buckets were not in the proper motions due to presence of

taper in the acrylic sheet .To eliminate this taper once again

drilling of sheets are carried out. After drilling it worked

properly.

Even though corrective actions were taken there were

little bit vibrations in buckets and founded that it was

vibrating only when the buckets were with negligible

weight and at designed load conditions they were not

vibrating at all.

In this way the prototype ran successfully.

VIII.

REFERENCES

Text References

[1]

S S RATTAN, Theory of Machines, 4th Edition, Mcgraw Hill

Education (India) Private Limited

[2] R. K. Jain, Production Technology, 17th Edition, Khanna

Publications Private Limited

[3] V B Bhandari, Design of Machine Element, Mcgraw Hill Education

(India) Private Limited

[4] R. K. Rajput, Strength Of Meterials, S. Chand

[5] M. Wada K.S. Yoon,H. Hashimoto, Development Of Advanced

Parking Assistance System, IEEE Transactions On Industrial

Electronics, Vol. 50, Pp. 4-17, February 2003.

[6] J. Pohl1, M. Sethsson, P. Degerman, And J Larsson, A SemiAutomated Parallel Parking System For Passenger Cars, Proc.

Imeche Vol. 220 Part D: J. Automobile Engineering, 2006, Pp. 53.

[7] Papacostas, C.S. and Prevedouros, P.D., Transportation Engineering

and Planning, 2nd Edition, Prentice Hall, Englewood Cliffs, New

Jersey, 1993.

[8] M.O. Reza, M.F. Ismail, A.A. Rokoni, M.A.R. Sarkar, Smart

Parking System with Image Processing Facility, I.J. Intelligent

Systems and Applications, Vol. 3, pp. 41-47, 2012.

[9] E. S. Kardoss, K. Baliant, I. Wahl, Design of a Semi Aautonomous

Park Assist System, Proceedings of The European Control

Conference,2009, pp. 497-516.

[10] Bong, D.B.L. K. C. Ting, N. Rajaee, 2006. Car-Park Occupancy

Information System. Third Real-Time Technology and applications

symposium, RENTAS 2006, Serdang, Selangor, December 2006

[11] Lu, R., Lin, X., Zhu, H., Shen, X.: SPARK: A New VANET-Based

Smart Parking Scheme for Large Parking Lots, In INFOCOM

(2009)1413-1421

CONCLUSIONS

Vertical Car Parking model has been designed; all the

parts in it were manufactured and assembled and

tested successfully.

Analysis of the model has been done and developed

with the scaling of 1:9 for life size model Such as

SUVs like Fortuner.

As the life cycle model involves proper design and

advanced methods are to be used to meet the

requirements of the customers.

IX.

Web References

[1]

[2]

FUTURE SCOPE

[3]

1. The platforms can also be equipped with safety

sensors guiding the movement of vehicles in the

platforms.

203

http://www.parkingsystemsolutions.com/rotary/Dated 15/11/2014

http://www.tksmy.com/activities_parking_system.html

Dated

17/11/2014

http://twistedphysics.typepad.com/cocktail_party_physics/2007/12/w

here-to-park-i.html Dated 23/11/2014

You might also like

- Project Management - The DisciplineDocument27 pagesProject Management - The DisciplineanilaNo ratings yet

- H S S X S S HDocument4 pagesH S S X S S HahmadskhanNo ratings yet

- Market Research On 3G ServicesDocument30 pagesMarket Research On 3G ServicesV Satya DeepakNo ratings yet

- MRO Product Range From Project Sales Corp, IndiaDocument43 pagesMRO Product Range From Project Sales Corp, IndiaProject Sales CorpNo ratings yet

- Build a Simple Photosensor Using an LDRDocument6 pagesBuild a Simple Photosensor Using an LDRShubham Marwade0% (1)

- Analyze Financial Health with Key MetricsDocument12 pagesAnalyze Financial Health with Key Metricsayushi kapoorNo ratings yet

- Driverless CARDocument16 pagesDriverless CARAbhimanyu Singh BhatiNo ratings yet

- Car ParkingDocument58 pagesCar ParkingSuraj WadeNo ratings yet

- Computer Architecture - SnARM ProjectDocument8 pagesComputer Architecture - SnARM ProjectProject Symphony Collection100% (2)

- Operations Research Project PresentationDocument10 pagesOperations Research Project PresentationSarabjeet SinghNo ratings yet

- MArketingDocument40 pagesMArketingolsenNo ratings yet

- Project ARGUS - Third Newsletter (English)Document9 pagesProject ARGUS - Third Newsletter (English)Project ARGUSNo ratings yet

- Car Rental Management SystemDocument7 pagesCar Rental Management SystemTania NNo ratings yet

- A Report On Protection, Maintanence, Operation and Analysing The Transformer and Generator Based On Their PerformanceDocument3 pagesA Report On Protection, Maintanence, Operation and Analysing The Transformer and Generator Based On Their PerformanceSwetha ReddyNo ratings yet

- Solar Car Vehicle DesignDocument224 pagesSolar Car Vehicle Designsheraaz8775% (4)

- SMART PARKING SYSTEM USING INTERNET of THINGS (IoT)Document4 pagesSMART PARKING SYSTEM USING INTERNET of THINGS (IoT)GRD Journals100% (2)

- Hybrid Vehicles Aims and Objectives (38Document29 pagesHybrid Vehicles Aims and Objectives (38Muhammad FahadNo ratings yet

- Project Report Work On Direct-To-Home Satellite Broadcasting - Kumar DeepakDocument37 pagesProject Report Work On Direct-To-Home Satellite Broadcasting - Kumar DeepakKumar Deepak100% (2)

- Pestal AnalysisDocument9 pagesPestal AnalysisPriyesh PandeyNo ratings yet

- Robotic CarDocument27 pagesRobotic CarJESTIN JAISONNo ratings yet

- EmpilhadoresDocument3 pagesEmpilhadoresMOZAMBiCARNo ratings yet

- Indian Snacks MarketDocument2 pagesIndian Snacks MarketShub SidhuNo ratings yet

- Java Media Player ReportDocument25 pagesJava Media Player ReportSourav SharmaNo ratings yet

- Fuel Economy of Road VehiclesDocument50 pagesFuel Economy of Road VehiclesdressfeetNo ratings yet

- Signals AnalysisDocument6 pagesSignals AnalysisAnonymous G0oZQaNo ratings yet

- PEL Operations Management ProjectDocument20 pagesPEL Operations Management Projecthamzaa mazharNo ratings yet

- Furniture Management System: BachelorDocument66 pagesFurniture Management System: BachelorjissmathewNo ratings yet

- Road Detection PaperDocument14 pagesRoad Detection Papersaeb2saebNo ratings yet

- Project ReportDocument10 pagesProject ReportMugesh LeokingNo ratings yet

- Car DashboardDocument17 pagesCar DashboardHadee SaberNo ratings yet

- The Heat Transfer Through Jacket: Introduction To API Process Simulation, Example 1Document4 pagesThe Heat Transfer Through Jacket: Introduction To API Process Simulation, Example 1Tamer Abd ElrasoulNo ratings yet

- Cluster AnalysisDocument47 pagesCluster AnalysisAmber GuptaNo ratings yet

- ProjectDocument6 pagesProjectAli RazaNo ratings yet

- Smart ParkingDocument9 pagesSmart ParkingSandeep DhimanNo ratings yet

- Rao & Naidu Engineering College: Topic: Embedded Systems SUB: Automation of CarsDocument9 pagesRao & Naidu Engineering College: Topic: Embedded Systems SUB: Automation of Carsapi-19799369100% (1)

- EirGrid's Guide to Scheduling and Dispatch ProcessesDocument10 pagesEirGrid's Guide to Scheduling and Dispatch ProcessesmsalmanishaqNo ratings yet

- Hybrid Electric VehicleDocument27 pagesHybrid Electric VehicleKuldeep Singh BrarNo ratings yet

- Impact of FDI policy changes on India's petroleum retail sectorDocument9 pagesImpact of FDI policy changes on India's petroleum retail sectorAdith A KumarNo ratings yet

- An IoT Based School Zone Vehicle Monitoring System With Automatic Vehicle Speed Control and Alert SystemDocument17 pagesAn IoT Based School Zone Vehicle Monitoring System With Automatic Vehicle Speed Control and Alert SystemM NAVYANo ratings yet

- Baudrate GeneratorDocument88 pagesBaudrate GeneratorT.snehaNo ratings yet

- Speed Limit Chapter 1Document21 pagesSpeed Limit Chapter 1kalu chimdiNo ratings yet

- Cost Behavior and Cost-Volume RelationshipsDocument97 pagesCost Behavior and Cost-Volume RelationshipsUtsav DubeyNo ratings yet

- Intelligent Traffic Light Control SystemDocument18 pagesIntelligent Traffic Light Control Systemrockeysuseelan100% (1)

- OS PresentationDocument25 pagesOS PresentationAbs BravoNo ratings yet

- Car EvaluationDocument33 pagesCar Evaluationbrayan0428No ratings yet

- Petrol Pump Management SystemDocument6 pagesPetrol Pump Management SystemShekhar Imvu50% (2)

- Seminar Report ManasDocument19 pagesSeminar Report ManasAbhay Gupta100% (1)

- "Programmable Logic Controller": Degree of Bachelor of TechnologyDocument42 pages"Programmable Logic Controller": Degree of Bachelor of TechnologyVikas VermaNo ratings yet

- Working of Single Plate ClutchDocument1 pageWorking of Single Plate ClutchBikash Das50% (2)

- Hypercar ReportDocument24 pagesHypercar Reportdevhx67% (6)

- ProjectDocument57 pagesProjectMohammed Rashid0% (1)

- Final Report IntershipDocument23 pagesFinal Report IntershipShivam BajpaiNo ratings yet

- Agile ManufacturingDocument17 pagesAgile ManufacturingSushil Kr ChaurasiaNo ratings yet

- Technology in Transport: Mumbai Area Traffic Control SystemDocument30 pagesTechnology in Transport: Mumbai Area Traffic Control SystemAvaniShahNo ratings yet

- Guidelines For Summer Project ReportDocument5 pagesGuidelines For Summer Project ReportCHIRAG ABROLNo ratings yet

- Toll Plaza Management Case Study NHAIDocument4 pagesToll Plaza Management Case Study NHAIKenden Tshering0% (1)

- Vertical Car ParkingDocument5 pagesVertical Car ParkingTanvi Khurana0% (1)

- Introduction To Multistage Car Parking SystemDocument4 pagesIntroduction To Multistage Car Parking SystemInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- Multilevel Car ParkingDocument16 pagesMultilevel Car ParkingsagarNo ratings yet

- Heat Pump Rates 9-11-2021Document1 pageHeat Pump Rates 9-11-2021RajatSharmaNo ratings yet

- EnergyDocument20 pagesEnergyapi-286291732No ratings yet

- LBT India Ramsar SitesDocument13 pagesLBT India Ramsar SitesRajatSharmaNo ratings yet

- List 44 PNP Courses Result On 26th October 2021Document1 pageList 44 PNP Courses Result On 26th October 2021RajatSharmaNo ratings yet

- Otec PDFDocument7 pagesOtec PDFMUKESHMURALI_ATLNo ratings yet

- Technical FormulaesDocument3 pagesTechnical FormulaesRajatSharmaNo ratings yet

- HPU student higher education destinationsDocument2 pagesHPU student higher education destinationsRajatSharmaNo ratings yet

- Himachal Pradesh Public Service CommissionDocument3 pagesHimachal Pradesh Public Service CommissionRajatSharmaNo ratings yet

- 7.TopUniversityDetails 3DDocument2 pages7.TopUniversityDetails 3DRajatSharmaNo ratings yet

- Mohit PandeyDocument4 pagesMohit PandeyRajatSharmaNo ratings yet

- 3 Final Select GraduateDocument7 pages3 Final Select GraduateRajatSharmaNo ratings yet

- Main Report RF RobotDocument23 pagesMain Report RF RobotRajatSharmaNo ratings yet

- Institute Name India Rankings 2017 ID Discipline: Format - IiDocument1 pageInstitute Name India Rankings 2017 ID Discipline: Format - IiRajatSharmaNo ratings yet

- Computer Questions Capsule For IBPS PO Clerk ExamsDocument25 pagesComputer Questions Capsule For IBPS PO Clerk ExamsRajatSharmaNo ratings yet

- SoniDocument1 pageSoniRajatSharmaNo ratings yet

- Strength of Materials by S K MondalDocument429 pagesStrength of Materials by S K MondalSaajal Sharma88% (26)

- R&AC Lecture 1Document19 pagesR&AC Lecture 1jojovaliaveetilNo ratings yet

- Lec6Rainfall and Run-Off Measurements and Plotting of Various Curves Forestimating Power PlantsDocument24 pagesLec6Rainfall and Run-Off Measurements and Plotting of Various Curves Forestimating Power PlantsRajatSharmaNo ratings yet

- RF Based Wireless RobotDocument26 pagesRF Based Wireless RobotRajatSharmaNo ratings yet

- LM Raclab PDFDocument38 pagesLM Raclab PDFRajatSharmaNo ratings yet

- Junior Associates Clerical Cadre Hindi (Final) 06.04.16Document5 pagesJunior Associates Clerical Cadre Hindi (Final) 06.04.16rajesh971No ratings yet

- RF Based Wireless RobotDocument26 pagesRF Based Wireless RobotRajatSharmaNo ratings yet

- Line Follower RobotDocument30 pagesLine Follower RobotRajatSharmaNo ratings yet

- Line Follower RobotDocument30 pagesLine Follower RobotRajatSharmaNo ratings yet

- Erosion of Mild SteelDocument18 pagesErosion of Mild SteelRajatSharmaNo ratings yet

- Solution To Traffic AccidentDocument2 pagesSolution To Traffic AccidentPham Thi Nhung QP3145No ratings yet

- Exam Presentation Master Plan A3Document1 pageExam Presentation Master Plan A3Joris KatkeviciusNo ratings yet

- European Traffic Signs PDFDocument2 pagesEuropean Traffic Signs PDFDahndray0% (1)

- Road Transport Year Book InsightsDocument144 pagesRoad Transport Year Book Insightssravan kumar garaNo ratings yet

- JD BUSH (РТИ)Document338 pagesJD BUSH (РТИ)Сергей Водяницкий100% (1)

- A Guide To The Design of at Grade Intersections PDFDocument84 pagesA Guide To The Design of at Grade Intersections PDFLuis Artiaga Ben100% (2)

- New Vanlink Driver AgreementDocument3 pagesNew Vanlink Driver AgreementShekhar SumanNo ratings yet

- Mandatory Sign: No EntryDocument4 pagesMandatory Sign: No EntryNarayan HariNo ratings yet

- MRT3 History and OperationsDocument12 pagesMRT3 History and OperationsRosell CortezNo ratings yet

- Public Awareness Campaign ManualDocument29 pagesPublic Awareness Campaign ManualPadma ShahiNo ratings yet

- Essay. in Many Large Cities Some People Waste Hours of Their Time Every Day Because of Traffic Congestion On The RoadDocument2 pagesEssay. in Many Large Cities Some People Waste Hours of Their Time Every Day Because of Traffic Congestion On The RoadЭлина МаркинаNo ratings yet

- Lecture 10 Pavement DesignDocument17 pagesLecture 10 Pavement Designceanil100% (2)

- Rescue ManualDocument72 pagesRescue ManualleruaitesNo ratings yet

- Internship Report On ITC LogisticsDocument17 pagesInternship Report On ITC LogisticsSajjad Ahmed Noor71% (7)

- Florida Traffic Crash Report ManualDocument67 pagesFlorida Traffic Crash Report ManualRabie AlzifiteNo ratings yet

- AshokDocument27 pagesAshoksudheeNo ratings yet

- Division Wise List of BM & BC Roads (DLP Expired Roads For Which Urgent Maintenance/Overlay Works Required)Document56 pagesDivision Wise List of BM & BC Roads (DLP Expired Roads For Which Urgent Maintenance/Overlay Works Required)insafaNo ratings yet

- Seminar Course CVQ301: Bicycle LaneDocument25 pagesSeminar Course CVQ301: Bicycle LaneKhushiBairwaNo ratings yet

- NHAI Projects Awarded Appointed Date Not Declared as on 29.02-2024Document17 pagesNHAI Projects Awarded Appointed Date Not Declared as on 29.02-2024GaneshBuilder .BatalalabNo ratings yet

- 2014-6-2 PCED South Hill Coalition Proposed Elements MatrixDocument2 pages2014-6-2 PCED South Hill Coalition Proposed Elements MatrixSpokane City CouncilNo ratings yet

- ShuttleBD RawDocument8 pagesShuttleBD RawYo HoneyNo ratings yet

- Vwa Traffic MGT ChecklistDocument1 pageVwa Traffic MGT ChecklistAnonymous ANmMebffKRNo ratings yet

- A-Revised-Method-For-The-Determination-Of-Passenger Car Equvalent - 1980 - Transportation-Research-PDocument6 pagesA-Revised-Method-For-The-Determination-Of-Passenger Car Equvalent - 1980 - Transportation-Research-Pfood diariesssNo ratings yet

- CSE312-Topic 1-Introduction 2022 Part 1-3Document36 pagesCSE312-Topic 1-Introduction 2022 Part 1-3iloveminjuNo ratings yet

- Standards 2014 05 27 Final rfr7 PDFDocument284 pagesStandards 2014 05 27 Final rfr7 PDFStephanieNo ratings yet

- Labsheet Signalized Intersection Capacity and LOSDocument36 pagesLabsheet Signalized Intersection Capacity and LOSKhairus BakarNo ratings yet

- 11th Street Bridge Winter Newsletter 2011-12-02Document4 pages11th Street Bridge Winter Newsletter 2011-12-02AnacostiaWaterfrontNo ratings yet

- List of Road AccidentsDocument28 pagesList of Road AccidentsmkumNo ratings yet

- OD-HSE-013 Safety IndicatorsDocument1 pageOD-HSE-013 Safety IndicatorsMohamed Ali BoumarafNo ratings yet

- Parent-Teen Driving ContractDocument2 pagesParent-Teen Driving Contractapi-344172875No ratings yet