Professional Documents

Culture Documents

04 Weld Joint Numbering

Uploaded by

Akhilesh KumarOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

04 Weld Joint Numbering

Uploaded by

Akhilesh KumarCopyright:

Available Formats

APPRO

VED

WORK PROCEDURE

FOR

WELD JOINT NUMBERING

PROJECT

: PAGUTHAN-NTPC JHANORE PIPELINE

PROJECT.

DOCUMENT NO

: JPL/GSPL/PNJPL/WP-08

CLIENT

: GUJARAT STATE PETRONET LTD.

CONSULTANT

: DORSCH CONSULT (INDIA) PVT. LTD.

TPIA

: BAXCOUNSCEL INSPECTION BUREAU

PVT. LTD.

CONTRACTOR

: JAIHIND PROJECTS LIMITED

JPL

DCIL

BIBPL

PREPARED BY

CHECKED &

APPROVED

BY

REVIEWED BY

GSPL

APPROVED

BY

NAME

DESIGNATION

SIGNATURE

DATE

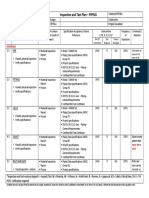

WELD JOINT NUMBERING

DOCUMENT NO.

JPL/GSPL/PNJPL

/WP/08

REV

00

Page 1 of 3

WORK PROCEDURE OF WELD JOINT NUMBERING

SCOPE

The scope covers numbering of weld joints for construction of natural gas pipeline from Paguthan to

NTPC - Jhanore.

METHOD

All joints to be welded shall be numbered as indicated below

MXX / TXX / A - C - E G

B-D-FH

PAGUTHAN

NTPC JHANORE

Flow Direction

Welders Number

Joint Number (Detail illustrated)

Chainage in KMS.

(Indicative only)

Where :

Joint Number shall start with prefix / suffix as indicated below :

KMXX

For joint welded as per Mainline Welding Procedure.

TXX

For joint welded as per Tie-in procedure.

M-XXRW, MXXA

Where cut outs are given, the first joint is identified by its original

joint no with prefix RE-WELD (RW). The other shall be

identifying by suffix A after the joint no.

MXXR, TXXR

where joint is repaired the suffix R shall be given after the

original joint no.

Where pipe ends are cut :

All pipe cutting including cut back, damaged bevel ends shall be reported and revised pipe numbers

allocated to each cut piece (Pup). The revision takes the form of a suffix A, B, C, etc. e.g. Pipe No:

2345 cut into three pups shall be denoted as 2345A, 2345B, and 2345C. The revised pipe nos shall be

transferred to pups before cutting and length should be recorded in presence of BIBPL/DCIL.

WELD JOINT NUMBERING

DOCUMENT NO.

JPL/GSPL/PNJPL

/WP/08

REV

00

Page 2 of 3

Illustration for Welder Numbers:

A -

C-

E -

NTPC JHANORE

B -

D-

F -

6 To 12 O Clock

PAGUTHAN. FLOW DIRECTION

12 To 6 O Clock

Root Hot Pass I Filler II Subsequent Passes

Where A, B, C, D, E, F, G & H are respective welder nos.

Clock position shall be visualized, with a person facing higher chainage and with its back towards

lower chainage.

All the numbers shall be written with yellow paint. Such paint shall be to the satisfaction of

TPIA/Dorsch/ GSPL at site.

For e.g. if joint no 30 is welded at chainage 60 by stringer welders with welder nos as (21, 26) (39,

42) and filler and capping by welders with welder nos (03, 06) and (09, 44) respectively, then the

joint shall be numbered as given below.

K60/M30/

21 39 03 09

26 42 06 44

JPL shall ensure that pipe weld numbering is recorded on respective inspection reports.

In case of any conflict between the requirements of this procedure and that of above referred

standards and specifications, then the requirements of DC/GSPL Specification shall govern, until and

unless specific intention is meant.

WELD JOINT NUMBERING

DOCUMENT NO.

JPL/GSPL/PNJPL

/WP/08

REV

00

Page 3 of 3

You might also like

- Ag Test Package FormatDocument25 pagesAg Test Package FormatoparoystNo ratings yet

- Field Itp For Piping Work Samur Project Rev-5 (23 April 2013)Document28 pagesField Itp For Piping Work Samur Project Rev-5 (23 April 2013)Echik KiciNo ratings yet

- ITP - PipingDocument7 pagesITP - PipingRiaz Rasool100% (1)

- Pt-bm-g00-Dc-00101 Inspection and Test Plan For Piping Fabriction and ErectionDocument5 pagesPt-bm-g00-Dc-00101 Inspection and Test Plan For Piping Fabriction and Erectioneldobie3100% (1)

- PIPELINE WELD NUMBERING SYSTEMDocument9 pagesPIPELINE WELD NUMBERING SYSTEMgst ajah100% (2)

- WPS PQR FormatsDocument22 pagesWPS PQR Formatsmdharmaraj28No ratings yet

- ALN FP ESA MEC SPC 0001 - 92B2.1 General Welding, Fabrication and InspectionDocument31 pagesALN FP ESA MEC SPC 0001 - 92B2.1 General Welding, Fabrication and Inspectionahmed.njahNo ratings yet

- SA04C2-T-MET-AAG-00037 Hydrotest Method StatementDocument25 pagesSA04C2-T-MET-AAG-00037 Hydrotest Method StatementABAID ULLAH100% (2)

- Contractor Quality Control Plan For Storage Tank ErectionDocument2 pagesContractor Quality Control Plan For Storage Tank ErectionHamid Alilou100% (4)

- Hail Surface Facilities Eps Project Project No: 8598: Botl Torquing ReportDocument1 pageHail Surface Facilities Eps Project Project No: 8598: Botl Torquing ReportAnonymous AdofXEYAgENo ratings yet

- 003 ITP UG PipingDocument4 pages003 ITP UG Pipingrvsingh70100% (1)

- Test Pack Table of ContentsDocument1 pageTest Pack Table of ContentsRavindra S. JivaniNo ratings yet

- WPS - Smaw - 2Document6 pagesWPS - Smaw - 2Harkesh RajputNo ratings yet

- WPS Pipe 08'' SHD 40 SMAW REV02Document2 pagesWPS Pipe 08'' SHD 40 SMAW REV02Amine MaalejNo ratings yet

- Inspection and Test Plan Piping Works Main Deck, Service Platform, Module, EtcDocument3 pagesInspection and Test Plan Piping Works Main Deck, Service Platform, Module, Etcaditya kokoNo ratings yet

- 5 Material and Traceability RecordDocument6 pages5 Material and Traceability RecordEdha Ali100% (1)

- Inspection Test Plan PV Nozzle Modification/AlterationDocument4 pagesInspection Test Plan PV Nozzle Modification/AlterationMohd Shafuaaz KassimNo ratings yet

- Saudi Aramco welding reportDocument2 pagesSaudi Aramco welding reportsmdriyazbashaNo ratings yet

- How To Write A Welding Procedure Specification (WPS)Document5 pagesHow To Write A Welding Procedure Specification (WPS)Mohamed Atef100% (1)

- Indcon Projects Electrode Qualification Procedure IOCL Gas PipelineDocument11 pagesIndcon Projects Electrode Qualification Procedure IOCL Gas PipelineAkhilesh Kumar67% (3)

- Madina Group W.L.L. Procedure Qualification Record 152Document38 pagesMadina Group W.L.L. Procedure Qualification Record 152MAT-LIONNo ratings yet

- Procedure For Welding of PipingDocument16 pagesProcedure For Welding of PipingJohnson Raju100% (1)

- Daily Welding Progress ReportDocument1 pageDaily Welding Progress ReportManoj KumarNo ratings yet

- Liquid Penetrant Testing Report SummaryDocument1 pageLiquid Penetrant Testing Report SummaryAbdul NaveedNo ratings yet

- Asme Sec 9 - ADocument144 pagesAsme Sec 9 - Aروشان فاطمة روشانNo ratings yet

- How To Make Weld Map, Shop Weld Plan, WPS, PQR & WPQ For A Static Pressure Vessel (Part-3) Welding & NDTDocument5 pagesHow To Make Weld Map, Shop Weld Plan, WPS, PQR & WPQ For A Static Pressure Vessel (Part-3) Welding & NDTVKT TiwariNo ratings yet

- Npe SD Sqe Pip Ax4303 0009 Pad Leak TestDocument7 pagesNpe SD Sqe Pip Ax4303 0009 Pad Leak TestYulian Adhriansyah100% (1)

- Ug PipingDocument1 pageUg PipingVinoth KumarNo ratings yet

- QC FORMDocument3 pagesQC FORMRicardo LourençoNo ratings yet

- ConocoPhillips Welding Procedure SpecificationDocument18 pagesConocoPhillips Welding Procedure SpecificationAgus Budiono100% (5)

- Form Welding Summary and Material Traceability Record - Piping TuhupDocument6 pagesForm Welding Summary and Material Traceability Record - Piping TuhupYuwantoniAlNo ratings yet

- Storage Tank Hydrostatic Test Quality Control and Inspection Report FormDocument1 pageStorage Tank Hydrostatic Test Quality Control and Inspection Report FormsugiantobarusNo ratings yet

- QCF326 Bolt Torque ReportDocument1 pageQCF326 Bolt Torque Reportminhnn0% (1)

- Inspection and Test Plan For Steel StrucDocument6 pagesInspection and Test Plan For Steel Strucwawan gunawan100% (1)

- Weld Repair Procedure Rev0Document2 pagesWeld Repair Procedure Rev0aszliza100% (1)

- Piping Fabrication ProcedureDocument11 pagesPiping Fabrication ProcedureMohammed Elsaid Yousef Harhera100% (2)

- Hydrotesting of PipelineDocument14 pagesHydrotesting of PipelineJWC Sales & Services :100% (1)

- Qa&qc-Log-04 PQR Log Sheet With CSD CommentsDocument2 pagesQa&qc-Log-04 PQR Log Sheet With CSD CommentsasiqNo ratings yet

- Carbon Steel Pipe Weld Repair ProcedureDocument4 pagesCarbon Steel Pipe Weld Repair ProcedureSc Tan100% (2)

- Dobhi Durgapur Haldia Pipeline Project (Part - A) : Welding Procedure Specification For Station PipingDocument3 pagesDobhi Durgapur Haldia Pipeline Project (Part - A) : Welding Procedure Specification For Station PipingBiswajit DeyNo ratings yet

- Installation Checklist Adhesive BondingDocument1 pageInstallation Checklist Adhesive BondingGogulu KumarNo ratings yet

- Wps For Smaw06-001 (Pipe 6g CS)Document10 pagesWps For Smaw06-001 (Pipe 6g CS)walitedisonNo ratings yet

- B2020-TDC-VF-009 Vessel Fabrication R0Document5 pagesB2020-TDC-VF-009 Vessel Fabrication R0Ramalingam PrabhakaranNo ratings yet

- Itp For InsulationDocument14 pagesItp For InsulationHytham El-NoubyNo ratings yet

- 06 Fire Water Piping Welding ProcedureDocument10 pages06 Fire Water Piping Welding ProcedureAkhilesh Kumar100% (1)

- Rotating Itp 1Document4 pagesRotating Itp 1abdul aziz100% (1)

- Inspection Procedure For ContractDocument24 pagesInspection Procedure For ContractVijaya PatilNo ratings yet

- 1.13 Inspection & Test PlansDocument1 page1.13 Inspection & Test Plansabimanyubawono100% (2)

- Thickness Qualification Range For PQR and WPQDocument5 pagesThickness Qualification Range For PQR and WPQOuled BladiNo ratings yet

- Elding Rocedure Pecification: 7200-HDPE Butt WeldDocument2 pagesElding Rocedure Pecification: 7200-HDPE Butt Weldsamer8saifNo ratings yet

- ITP - OF - Structural Work FOR PARADEEPDocument4 pagesITP - OF - Structural Work FOR PARADEEPRajeev KumarNo ratings yet

- Material Inspection Report: Project Name Date InspDocument22 pagesMaterial Inspection Report: Project Name Date InspRafiqKuNo ratings yet

- Visual Inspection ReportDocument2 pagesVisual Inspection ReportAlfian ImaduddinNo ratings yet

- Leak Test Valve ReportDocument2 pagesLeak Test Valve Reportadnansh1No ratings yet

- Method Statement: Pt. Duta Graha Indah TBK Welding Procedure (Preparation)Document4 pagesMethod Statement: Pt. Duta Graha Indah TBK Welding Procedure (Preparation)Nigin Parambath50% (2)

- Summit Meghnaghat II power plant fire system inspectionDocument4 pagesSummit Meghnaghat II power plant fire system inspectionMahmud AlamNo ratings yet

- Technics Offshore Engineering Pte LTD: Fitup Inspection ReportDocument3 pagesTechnics Offshore Engineering Pte LTD: Fitup Inspection ReportHanuman RaoNo ratings yet

- BHEL Submits Transformer DrawingsDocument3 pagesBHEL Submits Transformer Drawingssuleman247No ratings yet

- CRS - of - PS - For - CDP - Rev 01Document3 pagesCRS - of - PS - For - CDP - Rev 01Harish GundaNo ratings yet

- Daily Log Sheet BAPL III Dated 01-06-2019Document2 pagesDaily Log Sheet BAPL III Dated 01-06-2019shahroz alamNo ratings yet

- Api 571Document8 pagesApi 571Akhilesh KumarNo ratings yet

- PlasteringDocument56 pagesPlasteringAkhilesh KumarNo ratings yet

- PaintingDocument6 pagesPaintingAkhilesh KumarNo ratings yet

- Brick MasonaryDocument80 pagesBrick MasonaryAkhilesh KumarNo ratings yet

- Roof Waterproofing ProcedureDocument5 pagesRoof Waterproofing ProcedureAkhilesh KumarNo ratings yet

- Project:Panipat-Jallandhar LPG Pipeline Project. Owner:I.O.C.L. Conntractor: M/s Indcon Projects & Equipment LTDDocument14 pagesProject:Panipat-Jallandhar LPG Pipeline Project. Owner:I.O.C.L. Conntractor: M/s Indcon Projects & Equipment LTDAkhilesh KumarNo ratings yet

- FlooringDocument10 pagesFlooringAkhilesh KumarNo ratings yet

- Chainlink FencingDocument56 pagesChainlink FencingAkhilesh KumarNo ratings yet

- False CeilingDocument48 pagesFalse CeilingAkhilesh KumarNo ratings yet

- Project:Panipat-Jallandhar LPG Pipeline Project. Owner:I.O.C.L. Conntractor: M/s Indcon Projects & Equipment LTDDocument16 pagesProject:Panipat-Jallandhar LPG Pipeline Project. Owner:I.O.C.L. Conntractor: M/s Indcon Projects & Equipment LTDAkhilesh KumarNo ratings yet

- ConcretingDocument28 pagesConcretingAkhilesh KumarNo ratings yet

- Back FillingDocument70 pagesBack FillingAkhilesh KumarNo ratings yet

- Procedure For Road WorkDocument5 pagesProcedure For Road WorkAkhilesh KumarNo ratings yet

- 12 Form WorkDocument7 pages12 Form WorkAkhilesh KumarNo ratings yet

- Anti TermiteDocument30 pagesAnti TermiteAkhilesh KumarNo ratings yet

- Procedure For Area Grading and Development WorksDocument3 pagesProcedure For Area Grading and Development WorksAkhilesh KumarNo ratings yet

- 15 ConcretingDocument22 pages15 ConcretingAkhilesh KumarNo ratings yet

- 11-Backfiling at Station NoDocument7 pages11-Backfiling at Station NoAkhilesh KumarNo ratings yet

- Flooring Procedure and Inspection PlanDocument4 pagesFlooring Procedure and Inspection PlanAkhilesh Kumar0% (1)

- Roof Waterproofing ProcedureDocument4 pagesRoof Waterproofing ProcedureAkhilesh KumarNo ratings yet

- Procedure For RCCDocument3 pagesProcedure For RCCAkhilesh KumarNo ratings yet

- 06-Earthwork in ExcavationDocument7 pages06-Earthwork in ExcavationAkhilesh KumarNo ratings yet

- Procedure For PVC DoorsDocument3 pagesProcedure For PVC DoorsAkhilesh KumarNo ratings yet

- Barbed Wire Fencing ProcedureDocument3 pagesBarbed Wire Fencing ProcedureAkhilesh KumarNo ratings yet

- Procedure For Plumbing Sanitary WorkDocument5 pagesProcedure For Plumbing Sanitary WorkAkhilesh Kumar100% (1)

- Procedure For Aluminum Door Window and VentilatorsDocument3 pagesProcedure For Aluminum Door Window and VentilatorsAkhilesh KumarNo ratings yet

- Procedure For Horticulture WorksDocument4 pagesProcedure For Horticulture WorksAkhilesh KumarNo ratings yet

- Materials Concrete Mix TestingDocument5 pagesMaterials Concrete Mix TestingAkhilesh KumarNo ratings yet

- Procedure For Antitermite TreatmentDocument4 pagesProcedure For Antitermite TreatmentAkhilesh KumarNo ratings yet

- False Ceiling Proc.Document4 pagesFalse Ceiling Proc.Akhilesh KumarNo ratings yet

- Great Gatsby Study NotesDocument69 pagesGreat Gatsby Study NotesLara Westwood100% (2)

- Matrix Algebra by A.S.HadiDocument4 pagesMatrix Algebra by A.S.HadiHevantBhojaram0% (1)

- 89HPES24T3G2 Hardware Design Guide: NotesDocument10 pages89HPES24T3G2 Hardware Design Guide: NotesDavidNo ratings yet

- 7H17-28 Clearances and Wear Limits PDFDocument3 pages7H17-28 Clearances and Wear Limits PDFDimitris K100% (1)

- 1 SM PDFDocument14 pages1 SM PDFSiti HamsyiahNo ratings yet

- Solution Guide For PpeDocument45 pagesSolution Guide For PpeTrek Apostol57% (7)

- Akshay 71 Seminar ReportDocument22 pagesAkshay 71 Seminar ReportSanket Yadav25% (4)

- MSC Syllabus AllDocument13 pagesMSC Syllabus AllOmSilence2651No ratings yet

- Wyoming County Fair (2022)Document20 pagesWyoming County Fair (2022)Watertown Daily TimesNo ratings yet

- Production Management Midterm ReviewDocument21 pagesProduction Management Midterm Reviewielsiu21184No ratings yet

- Australian 9 Grade Physics Lesson 1Document32 pagesAustralian 9 Grade Physics Lesson 1binoyrajcrNo ratings yet

- 11 F.Y.B.Sc - Chemistry PDFDocument22 pages11 F.Y.B.Sc - Chemistry PDFmalini PatilNo ratings yet

- Dokumen - Tips - Astm A535 9 Percent NickelDocument5 pagesDokumen - Tips - Astm A535 9 Percent NickelJeovanne CabralNo ratings yet

- JCB 532-120 PDFDocument4 pagesJCB 532-120 PDFSyazrur Syazmir0% (1)

- MACRO XII Subhash Dey All Chapters PPTs (Teaching Made Easier)Document2,231 pagesMACRO XII Subhash Dey All Chapters PPTs (Teaching Made Easier)Vatsal HarkarNo ratings yet

- Collab#2 (Edited)Document14 pagesCollab#2 (Edited)Yani BatoctoyNo ratings yet

- DG350 ManualDocument17 pagesDG350 ManualCareergamingNo ratings yet

- B.pharm Course Handbook 2017 18Document74 pagesB.pharm Course Handbook 2017 18Md RaquibNo ratings yet

- Ghost Events in Optical Time - NewDocument3 pagesGhost Events in Optical Time - NewsekutunetNo ratings yet

- Introducing Inspira's: Managed Noc & Itoc ServicesDocument2 pagesIntroducing Inspira's: Managed Noc & Itoc ServicesmahimaNo ratings yet

- Vapour Bar Exchange IMFL PackageDocument4 pagesVapour Bar Exchange IMFL PackageNishank AgarwalNo ratings yet

- Biology Practical NotebookDocument38 pagesBiology Practical Notebookabdulmalik saniNo ratings yet

- L4004N - 0920 - Nilfisk - Robotic-brochure-Liberty SC60Document12 pagesL4004N - 0920 - Nilfisk - Robotic-brochure-Liberty SC60Lucianderson Marques FerreiraNo ratings yet

- Stepan Pol BC 180Document2 pagesStepan Pol BC 180Parag RautNo ratings yet

- Inkontinensia Urin: Dr. Adhi Permana, SPPDDocument35 pagesInkontinensia Urin: Dr. Adhi Permana, SPPDTiara KhairinaNo ratings yet

- Baby NamesDocument9 pagesBaby Namesppremamca_617705407No ratings yet

- Self-Balancing Two-Wheeler Using GyroscopeDocument33 pagesSelf-Balancing Two-Wheeler Using Gyroscopemilan mottaNo ratings yet

- AAA Variable Spring Hangers CatalogDocument31 pagesAAA Variable Spring Hangers CatalogNopparut0% (1)

- Mar For M: I MMQ SeriesDocument28 pagesMar For M: I MMQ SeriesIpal Febri NartaNo ratings yet

- Kathleen Langreo Notes FB (Feb6)Document27 pagesKathleen Langreo Notes FB (Feb6)Kaycee Ayo100% (4)