Professional Documents

Culture Documents

G540 REV8 Manual PDF

Uploaded by

Remus PopescuOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

G540 REV8 Manual PDF

Uploaded by

Remus PopescuCopyright:

Available Formats

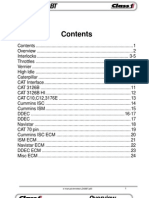

G540 User Manual

Date Modified: March 5, 2012

Page 1 of 10

G540 4-AXIS STEP MOTOR CONTROL

REVISION: 8

__________________________________________________________________________________

DIMENSIONS

PHYSICAL AND ELECTRICAL RATINGS

Supply Voltage

Motor Current

Power Dissipation

Short Circuit Trip

Temperature

Humidity

Motor Inductance

Input Frequency

Step Pulse 0 Time

Step Pulse 1 Time

Direction Setup

(Before step rising edge)

Direction Setup

(Hold after pulse rising edge)

Signal Voltage

Weight

Charge Pump Frequency

Date Modified: March 5, 2012

Minimum

Maximum

Units

18

0

1

14

0

0

1

0

2

1

200

50

3.5

13

VDC

A

W

A

C

%

mH

kHz

uS

uS

nS

70

95

30

200

200

3.3

8.8

10

nS

5

VDC

oz.

kHz

Page 2 of 10

G540 4-AXIS STEP MOTOR CONTROL

REVISION: 8

__________________________________________________________________________________

Thank you for choosing to purchase the G540 4-Axis Drive System. If you are dissatisfied with it for any reason at all within

two weeks of its purchase date, you may return it for a full refund provided it is cosmetically unmarred and undamaged

electrically in any way. Geckodrive Inc. fully warranties the G540 against workmanship defects for 1 year after its purchase

date.

PLEASE READ FIRST BEFORE USING THE G540

Before beginning, be sure to have a suitable step motor, a DC power supply suitable for the motor and a current set resistor.

The motors rated phase current must be between 0 Amps and 3.5 Amps. Using a motor with a higher current rating will cause

a proportional loss in torque, meaning a 5A motor will get 3.5/5 (70%) of its maximum torque. The power supply voltage must

be determined by the inductance equation listed later or be between 4 times and 20 times the motors rated voltage. The

current set resistor may be a 1/4 Watt, 5% part. Finally have a STEP and DIRECTION pulse source available.

STEP 1: CONNECT POWER

Connect your power supply positive to TERMINAL 11 and negative to TERMINAL 12. The power supply voltage is determined

by multiplying the square root of the motors inductance by 32, as in the example below for a 2mH rated motor:

32 * (2) = 45VDC

Be sure that your power supply is turned OFF when connecting or disconnecting it from the G540. Failure to do so may result

in physical damage to the connectors.

CAUTION! Never put a switch on the DC side of the power supply! This will damage, if not destroy, your drive due to a current

inrush when the switch is first thrown.

CAUTION! Power supply voltage in excess of 50 VDC will damage the G540.

Turn the power supply on and make sure that a red LED comes on. Once you have verified that the drive lights up turn your

power supply off before continuing.

STEP 2: INSERT E-STOP OR JUMPER

The G540 is designed to fault unless there is a normally closed switch (functionally identical to a jumper wire) between

TERMINAL 10 and TERMINAL 12 on the 12-PIN TERMINAL BLOCK. Without TERMINAL 10 shorted to ground the G540 will

remain disengaged to the motors and will not respond to commands. The red LED will be illuminated if there is no jumper

connecting these two terminals.

STEP 3: DISABLE CHARGE PUMP

The G540 has a switch allowing you to disable the charge pump feature, which makes it possible to verify the G540 works

without having to have your DB25 cable plugged in. The switch is located near the 12-PIN TERMINAL STRIP on the top of the

drive. Flip the switch to DISABLE and apply power to the G540; you should have a green LED lit indicating that setup is

successful thus far.

STEP 4: CONNECT MOTORS

Wire your motors to the included DB9 solder cup and secure the backshell connectors. If your motors are rated below 3.5A

you must use a current set resistor across PIN 1 and PIN 5. The resistor is calculated by taking the current in amps and

Date Modified: March 5, 2012

Page 3 of 10

G540 4-AXIS STEP MOTOR CONTROL

REVISION: 8

__________________________________________________________________________________

multiplying by 1000. If your motor is rated at 2.8A per phase you will have to use a 2.8K 5% 1/4W resistor. If your motor is rated

at 3.5A or above you can safely not use a current set resistor; however, your G540 will not go into current standby mode which

will result in increased motor heating.

At this point you should have holding torque on the motors and a green LED lit. If you do not then the motor is wired

incorrectly or is damaged.

STEP 5: CONNECT DB25 CABLE

If you have holding torque and a green LED you can plug in your DB25 straight through cable to the G540 and your computer.

Use the pinout on page 7 to set up your programs output pins or load the G540 XML configuration file from the G540 product

page on the Geckodrive website.

Your step pulse width must be at least 2uS wide and the pulse polarity for the step and direction signals are ACTIVE HIGH.

STEP 6: TEST FUNCTIONS

After you configure your CNC program it is time to test the G540 for functionality. You should be able to move all axes at this

time.

STEP 7: ADJUST TRIMPOT

The G540 is composed of four individual G250 motor controls, each of which has a designated pin outputting the smoothness

adjust trimpot to the G540 motherboard. In your CNC program set the axis being adjusted to move at 2 revolutions per second

and use a screwdriver to turn the trimpot in the ADJUST hole on the top of the drive. The trimpot has 270 degrees of motion

and will have an audible sweet spot when it is in proper position. This position will change with each motor so be sure to

readjust if you change motors.

STEP 8: OPTIONAL CONNECTIONS

The following connections are completely optional and are not required to make the G540 operate.

INPUTS: The G540 has four general purpose inputs called INPUT 1, INPUT 2, INPUT 3 and INPUT 4 on the MAIN

TERMINAL BLOCK. They are at POSITION 1, POSITION 2, POSITION 3 and POSITION 4 respectively on the terminal

block. These inputs may be used as limit switches or for any other purpose. SPST switches can be used with these

inputs. One end of the switch goes to the input, the other end of the switch goes to ground (POSITION 12).

OUTPUTS: The G540 has two general purpose outputs called OUTPUT 1 and OUTPUT 2 on the MAIN TERMINAL

BLOCK. They are at POSITION 5 and POSITION 6 respectively on the terminal block. These outputs may be used to

drive relay coils or for any other purpose. The outputs are rated at 1A and 50VDC maximum. Connect one end of the

load to the output and connect the other end of the load to a positive DC voltage. This voltage may be the G540

power supply or it may be a separate power supply having a different voltage.

ANALOG OUTPUT: This is a 0V to +10V opto-isolated analog output intended for use with VFD drives. VFD OUT goes

to 0VDC while the G540 is disabled. Connect VFD GND, VFD OUT and VFD +10V to the VFD drive inputs. Make sure the

VFD drive positive voltage does not exceed +12VDC. Do not short VFD OUT to any other terminal. Do not reverse

polarity to VFD GND and VFD +10V or the G540 may be damaged.

Date Modified: March 5, 2012

Page 4 of 10

G540 4-AXIS STEP MOTOR CONTROL

REVISION: 8

__________________________________________________________________________________

CHARGE PUMP: The G540 is equipped with a charge pump (watchdog timer) that disables the drive without a 10 kHz

signal on pin 16 of the DB25 port. You can enable this by reversing what was done in STEP 3 and making sure that

your parallel port is set to EPP mode. To do this, go into BIOS and set your parallel port to either EPP or

Send/Receive; most parallel cards are set to ECP or Send Only by default.

DISCLAIMER

CERTAIN APPLICATIONS USING POWER PRODUCTS MAY INVOLVE POTENTIAL RISKS OF DEATH, PERSONAL INJURY OR SEVERE

DAMAGE TO PROPERTY. GECKODRIVE INC. PRODUCTS ARE NOT DESIGNED, AUTHORIZED OR WARRANTED TO BE SUITABLE FOR

USE IN LIFE-SUPPORT DEVICES OR OTHER CRITICAL APPLICATIONS. INCLUSION OF GECKODRIVE INC. PRODUCTS IN SUCH

APPLICATIONS IS UNDERSTOOD TO BE FULLY AT THE PURCHASERS OWN RISK

In order to minimize risks associated with the purchasers application, adequate design and operating safeguards must be

provided by the purchaser to minimize inherent or procedural hazards. GECKODRIVE INC. assumes no liability for applications

assistance or the purchasers product design. GECKODRIVE INC. does not warrant or represent that any license, either express

or implied, is granted under any patent right, copyright or other intellectual property right of GECKODRIVE INC.

MANUAL CHANGE LOG

DATE

CHANGES MADE

3/1/2012

3/5/2012

New manual format published

G540 Revision 8 released

Date Modified: March 5, 2012

Page 5 of 10

G540 4-AXIS STEP MOTOR CONTROL

REVISION: 8

__________________________________________________________________________________

TROUBLESHOOTING

Generally speaking, there are only a few reasons why the G540 will not function as expected. The most common are listed

below.

PROBLEM: G540 UNRESPONSIVE (RED LED LIT CONSTANTLY)

SOLUTION: This is the most common fault and can be caused by several problems. First, double check that a jumper

wire or normally closed switch is present between PIN 10 and PIN 12 on the 12 POSITION TERMINAL BLOCK. Next, turn the

CHARGE PUMP SWITCH to the OFF position; if the green LED comes on then there is a problem with your CNC program not

putting out a charge pump signal on PIN 16. If those do not work, check the motor for holding torque; if you do not have

holding torque move on to the next section.

PROBLEM: NO MOTOR HOLDING TORQUE

SOLUTION: Verify that your motor is connected to the G540 with the DB9 connector and that it is wired as it says in

the motors datasheet. Check the LED indicators to verify that power is being applied to the G540. Lastly, make sure that you

have an appropriately sized current set resistor. If there is not one present or it is grossly undersized you may have burned out

your motor and it could be shorted internally.

PROBLEM: NO LEDS LIT

SOLUTION: Verify that the power supply is plugged in correctly to the 12-PIN TERMINAL BLOCK. If it is and power is

applied with no LEDs being lit up, you have most likely had the fuse blow open. To check the fuse you must first remove the

cover. The fuse is located by the 12-PIN TERMINAL BLOCK on the underside of the motherboard; you can pull the motherboard

off of the G250 drives to access it. Next, use an ohmmeter to check for continuity on the fuse, which looks like a green 1/4W

resistor. If the fuse it destroyed you may contact Geckodrive for replacement fuses or order spares online with part number

F2318-ND from www.digikey.com.

PROBLEM: INPUTS OR OUTPUTS NOT WORKING

SOLUTION: This problem is most often caused by a problem with the parallel port or the parallel cable. Use an

ohmmeter to verify that your cable is a straight through cable and not a crossover or a printer cable. Next, go into BIOS and

make sure that your parallel port is set to EPP or Send/Receive mode. If your parallel port is on your motherboard and is not a

PCI card then the problem could be that it is incapable of EPP operation. Use a PCI parallel card and see if the problem persists.

PROBLEM: G540 GETS HOT

SOLUTION: The G540, being a stepper drive, is meant to get warm. While operating at its maximums the G540 can get

up to 70C (158F) comfortably; heatsinking is mandatory if the temperature gets above that range. On the Geckodrive website is

a document titled G540 Heatsink Experiment that discusses issues of overheating. If the G540 is in a control cabinet or an

area with limited airflow it is required to put an intake and exhaust fan in the enclosure. Please read the cited document if you

have further questions.

IMPORTANT!

If your drive will not come out of fault or is not acting normally, please return it for a free evaluation. A return form can be

found at www.geckodrive.com under the Support tab at the top. All repairs and evaluations are performed free of charge and

include return shipping.

Date Modified: March 5, 2012

Page 6 of 10

G540 4-AXIS STEP MOTOR CONTROL

REVISION: 8

__________________________________________________________________________________

DB 25 PINOUT

DB9 PINOUT

Pin Number

Minimum

Pin Number

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

OUTPUT 2

X-AXIS STEP

X-AXIS DIRECTION

Y-AXIS STEP

Y-AXIS DIRECTION

Z-AXIS STEP

Z-AXIS DIRECTION

A-AXIS STEP

A-AXIS DIRECTION

INPUT 1

INPUT 2

INPUT 3

INPUT 4

VFD PWM (50 Hz)

FAULT (input to PC)

CHARGE PUMP (>10 kHz)

OUTPUT 1

GND

GND

GND

GND

GND

GND

GND

GND

1

2

3

4

5

6

7

8

9

Minimum

CURRENT SET RESISTOR

N/C

N/C

N/C

CURRENT SET RESISTOR

PHASE B MOTOR WIRE

PHASE /B MOTOR WIRE

PHASE A MOTOR WIRE

PHASE /A MOTOR WIRE

MAIN TERMINAL BLOCK PINOUT

MAIN TERMINAL BLOCK PINOUT

Pin Number

Minimum

1

2

3

4

5

6

7

8

9

10

11

12

INPUT 1 (DB25 PIN 10)

INPUT 2 (DB25 PIN 11)

INPUT 3 (DB25 PIN 12)

INPUT 4 (DB25 PIN 13)

OUTPUT 1 (DB25 PIN 17)

OUTPUT 2 (DB25 PIN 1)

VFD GROUND

VFD OUTPUT

VFD +10VDC

DISABLE INPUT (E-STOP)

SUPPLY +18 50VDC

POWER SUPPLY GND

IMPORTANT WIRING NOTES

1.) Always verify that your DB25 cable is a straight through cable, not a crossover. This can be done by using an

ohmmeter to test continuity between all pins.

2.) Do not allow the current set resistor to touch pins 2, 3, or 4 on the DB9 cable. This will set off a FAULT condition in the

G540.

3.) Do not use wire plugs for the main terminal block. Only put stranded wire with a gauge range of 14 24 to make

proper contact and not stress any terminals.

4.) The only required connections for the G540 to run are a power supply and a normally closed emergency stop. If you

get a fault at any time that will not clear, you can safely disconnect all wires but these and get a green LED with the

charge pump turned off.

Date Modified: March 5, 2012

Page 7 of 10

G540 4-AXIS STEP MOTOR CONTROL

REVISION: 8

__________________________________________________________________________________

Sample Wiring Diagram

Date Modified: March 5, 2012

Page 8 of 10

G540 4-AXIS STEP MOTOR CONTROL

REVISION: 8

__________________________________________________________________________________

G540 CUTOUT DIAGRAM

Date Modified: March 5, 2012

Page 9 of 10

G540 4-AXIS STEP MOTOR CONTROL

REVISION: 8

__________________________________________________________________________________

This drawing is to scale. Use it as a guide for panel mounting your G540.

Date Modified: March 5, 2012

Page 10 of 10

You might also like

- G540 REV8 ManualDocument10 pagesG540 REV8 ManualJoseph Michael MirasoleNo ratings yet

- G540 Manual Rev8Document10 pagesG540 Manual Rev8andienNo ratings yet

- G320X REV-10 Manual FormattedDocument7 pagesG320X REV-10 Manual FormattedNghia Nguyen TrongNo ratings yet

- CV7300 Instruction Manual 11-05Document132 pagesCV7300 Instruction Manual 11-05boomdenNo ratings yet

- Yaskawa TM.J7.01Document96 pagesYaskawa TM.J7.01Salvador CrisantosNo ratings yet

- Njr2-D Series Soft Starter: Instruction ManualDocument21 pagesNjr2-D Series Soft Starter: Instruction ManualNguyen Van ChungNo ratings yet

- MD30B Motor Driver User's ManualDocument15 pagesMD30B Motor Driver User's ManualMinh Trí KnightNo ratings yet

- Throttle Information Reference Guide PDFDocument24 pagesThrottle Information Reference Guide PDFJohn Rivera100% (1)

- 4 Phase ULN2003 Stepper Motor Driver PCB: A B C D V+Document3 pages4 Phase ULN2003 Stepper Motor Driver PCB: A B C D V+ZadidNo ratings yet

- ULN2003 Stepper Motor Drivers PDFDocument3 pagesULN2003 Stepper Motor Drivers PDFJuan CamiloNo ratings yet

- Automotive Applications: ProductsDocument5 pagesAutomotive Applications: ProductsSebastian BelmonttNo ratings yet

- Soft Starters SSW04 Technical Data GuideDocument8 pagesSoft Starters SSW04 Technical Data GuideAlberto Hern JimNo ratings yet

- M800 OEM WRX78 Installation DocumentDocument10 pagesM800 OEM WRX78 Installation DocumentRaheel FaroukNo ratings yet

- s1000 Voltage RegulatorDocument36 pagess1000 Voltage RegulatorAnonymous 7PtTlrNo ratings yet

- G3612Document12 pagesG3612Victor NunezNo ratings yet

- 5110UL EngDocument2 pages5110UL EngAhmed Elsayed Abdel GhanyNo ratings yet

- FC102 FallasalarmasDocument192 pagesFC102 Fallasalarmasingvic1No ratings yet

- Mitsubishi D700 VFD Installation Guide V1.0.2Document23 pagesMitsubishi D700 VFD Installation Guide V1.0.2Raghavendran BabujiNo ratings yet

- Driver DFC MotorDocument24 pagesDriver DFC Motorda.dientuhnNo ratings yet

- F900got Connection 2 of 6Document78 pagesF900got Connection 2 of 6chaubinhkhang110686No ratings yet

- Emko ATS10 Eng Short v00 PDFDocument6 pagesEmko ATS10 Eng Short v00 PDFCarmen Serbanoiu33% (3)

- Gen Auto XMDocument47 pagesGen Auto XMCameron Ledingham100% (1)

- Codigo 0070-02 de D6N AkmDocument5 pagesCodigo 0070-02 de D6N AkmMiguel LopezNo ratings yet

- Greatork ActuatorDocument58 pagesGreatork ActuatorgrandherameshNo ratings yet

- An-5073 - Active Miller Clamp Technology - FairchildDocument3 pagesAn-5073 - Active Miller Clamp Technology - FairchildchandooNo ratings yet

- Itc 06h1101eDocument34 pagesItc 06h1101essuthaaNo ratings yet

- MSD50DDocument43 pagesMSD50DGessybell UrbinaNo ratings yet

- Gecko Drive g340 - 815e28e418 PDFDocument7 pagesGecko Drive g340 - 815e28e418 PDFRemus PopescuNo ratings yet

- Datasheet - M542H Stepper Motor DriverDocument10 pagesDatasheet - M542H Stepper Motor DriversthollanderNo ratings yet

- Warning: Canstart™ 9641/9642Document4 pagesWarning: Canstart™ 9641/9642montoya2333No ratings yet

- Generator 307 USERDocument54 pagesGenerator 307 USERLiviu PopaNo ratings yet

- Viper 100Document8 pagesViper 100SeanNo ratings yet

- Easy Gen 1500Document13 pagesEasy Gen 1500subhashsomaNo ratings yet

- ACS550 U1 Quick Start GuideDocument2 pagesACS550 U1 Quick Start GuideIvonne Mayela DiazNo ratings yet

- LS SV IG5A Easy Start GuideDocument16 pagesLS SV IG5A Easy Start GuidePhong Nguyen100% (2)

- Manual de Servicio de Inversora V270Document2 pagesManual de Servicio de Inversora V270Taz Juan GNo ratings yet

- DKG 705 User ManualDocument58 pagesDKG 705 User ManualMarioEnriqueAlcocerÁvila100% (1)

- G 1 MG52A202 PDFDocument192 pagesG 1 MG52A202 PDFCaspar HeerkensNo ratings yet

- Diagrama Electrico de Transmcion 160HDocument4 pagesDiagrama Electrico de Transmcion 160HJuan CarlosNo ratings yet

- Deep Sea Electronics PLC: Model 520 Automatic Start ModuleDocument2 pagesDeep Sea Electronics PLC: Model 520 Automatic Start ModuleLuis Francisco Calderon EspinozaNo ratings yet

- EGS002 Manual en PDFDocument6 pagesEGS002 Manual en PDFValerică Hizanu67% (6)

- Parker SSD Drives 650 Series Quick Start GuideDocument2 pagesParker SSD Drives 650 Series Quick Start Guideeng_karamazabNo ratings yet

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1Rating: 2.5 out of 5 stars2.5/5 (3)

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2No ratings yet

- PLC Programming from Novice to Professional: Learn PLC Programming with Training VideosFrom EverandPLC Programming from Novice to Professional: Learn PLC Programming with Training VideosRating: 5 out of 5 stars5/5 (1)

- Analog Circuit Design: A Tutorial Guide to Applications and SolutionsFrom EverandAnalog Circuit Design: A Tutorial Guide to Applications and SolutionsRating: 3.5 out of 5 stars3.5/5 (6)

- Diesel Engine Care and Repair: A Captain's Quick GuideFrom EverandDiesel Engine Care and Repair: A Captain's Quick GuideRating: 5 out of 5 stars5/5 (1)

- Radio Shack TRS-80 Expansion Interface: Operator's Manual: Catalog Numbers: 26-1140, 26-1141, 26-1142From EverandRadio Shack TRS-80 Expansion Interface: Operator's Manual: Catalog Numbers: 26-1140, 26-1141, 26-1142No ratings yet

- Thomson Electrac HD Linear Actuator Motion Control per CAN BusFrom EverandThomson Electrac HD Linear Actuator Motion Control per CAN BusNo ratings yet

- Engineering Service Revenues World Summary: Market Values & Financials by CountryFrom EverandEngineering Service Revenues World Summary: Market Values & Financials by CountryNo ratings yet

- Ball Plate FinalDocument13 pagesBall Plate FinalHeath CollinsNo ratings yet

- Modeling and Control of Ball and Beam System Using Model Based and Non-Model Based Control ApproachesDocument22 pagesModeling and Control of Ball and Beam System Using Model Based and Non-Model Based Control ApproachesAbolfazl_mohebbiNo ratings yet

- Commparison Between Different MethodsDocument6 pagesCommparison Between Different MethodsRemus PopescuNo ratings yet

- ESO Based LQR Controller For Ball and Beam System PDFDocument4 pagesESO Based LQR Controller For Ball and Beam System PDFRemus PopescuNo ratings yet

- Parts List: (RX-5020VBK) (RX-5022VSL)Document19 pagesParts List: (RX-5020VBK) (RX-5022VSL)Remus PopescuNo ratings yet

- HAKKO 936 - Schematic: Rendered By: Tom Hammond - NØSS 26 MAR 2011 v1.7Document6 pagesHAKKO 936 - Schematic: Rendered By: Tom Hammond - NØSS 26 MAR 2011 v1.7Gak TahuNo ratings yet

- PZ6 A3 S N6 Wi Om VZK3Document161 pagesPZ6 A3 S N6 Wi Om VZK3SamSimonNo ratings yet

- Service Manual: RX-5020VBK RX-5022VSLDocument57 pagesService Manual: RX-5020VBK RX-5022VSLRemus PopescuNo ratings yet

- Bosch Alpha 2 PDFDocument20 pagesBosch Alpha 2 PDFRemus Popescu100% (1)

- Alpha1-2 User Manual PDFDocument88 pagesAlpha1-2 User Manual PDFRemus PopescuNo ratings yet

- Gecko Drive g340 - 815e28e418 PDFDocument7 pagesGecko Drive g340 - 815e28e418 PDFRemus PopescuNo ratings yet

- Gelcelcharger Diagram PDFDocument6 pagesGelcelcharger Diagram PDFRemus PopescuNo ratings yet

- Cimkc 1 - Comp PDFDocument1 pageCimkc 1 - Comp PDFRemus PopescuNo ratings yet

- Ultrafast Soft Recovery Rectifier Diode: Product Benefits Product Features Product ApplicationsDocument4 pagesUltrafast Soft Recovery Rectifier Diode: Product Benefits Product Features Product ApplicationsRemus PopescuNo ratings yet

- Tecnoweld Monster 170 Awelco 5680Document1 pageTecnoweld Monster 170 Awelco 5680ValiBardaNo ratings yet

- Acs756sca 050b PFF TDocument10 pagesAcs756sca 050b PFF TRemus PopescuNo ratings yet

- Samsung J 1045avw Explded View Parts ListDocument6 pagesSamsung J 1045avw Explded View Parts ListRemus PopescuNo ratings yet

- Service Guide: Colour TelevisionDocument43 pagesService Guide: Colour TelevisiontiganiadaNo ratings yet

- Genius SW HF5.1 - 5000Document6 pagesGenius SW HF5.1 - 5000sorintvrNo ratings yet

- Akai Ctg1401e SCHDocument1 pageAkai Ctg1401e SCHRemus PopescuNo ratings yet

- Samsung J 1045avw Explded View Parts ListDocument6 pagesSamsung J 1045avw Explded View Parts ListRemus PopescuNo ratings yet

- LG 19LG3000 19LG3010英文维修手册Document92 pagesLG 19LG3000 19LG3010英文维修手册Remus PopescuNo ratings yet

- ATX Power Supply Modification Symmetric 2X30V DC DC Converter Circuit sg3525 - Electronics Projects Circuits PDFDocument1 pageATX Power Supply Modification Symmetric 2X30V DC DC Converter Circuit sg3525 - Electronics Projects Circuits PDFStefan CorneaNo ratings yet

- Flexpoint T1/E1: Key FeaturesDocument3 pagesFlexpoint T1/E1: Key FeaturesIan JaredNo ratings yet

- Price List Accessories CCTV: Contact Us at (021) 6000777, 0818810105 (PIN BB MEDUSA)Document1 pagePrice List Accessories CCTV: Contact Us at (021) 6000777, 0818810105 (PIN BB MEDUSA)biar berkahNo ratings yet

- Besam Assa AbloyDocument2 pagesBesam Assa Abloyjuan camilo EscuderoNo ratings yet

- Wekomp E-Catalogue PDFDocument12 pagesWekomp E-Catalogue PDFAbdallah HashamNo ratings yet

- Light Industrial grade underwater ROV for professional and enterprise customersDocument18 pagesLight Industrial grade underwater ROV for professional and enterprise customersdidraceNo ratings yet

- Cu de Luminaria OD-3648CSDocument3 pagesCu de Luminaria OD-3648CSMari Tere GutierrezNo ratings yet

- Programmable V/I/Hz Transducer Setup GuideDocument32 pagesProgrammable V/I/Hz Transducer Setup GuideRanjit Sahoo0% (1)

- Eee PVSC 33Document7 pagesEee PVSC 33Serapio TrabucoNo ratings yet

- PfeifferTC110ElectronicDriveUnit PDFDocument29 pagesPfeifferTC110ElectronicDriveUnit PDFFinsensius PeniNo ratings yet

- Netsure 531 A31 DatasheetDocument2 pagesNetsure 531 A31 DatasheetCharmer JiaNo ratings yet

- IC901 Manual 9IS42073 Rel.04 03 GBDocument4 pagesIC901 Manual 9IS42073 Rel.04 03 GBalbaniancityalbaniatNo ratings yet

- TH TouchWin ManualDocument70 pagesTH TouchWin ManualRahmad Misin100% (1)

- Date GE Tag Description LearningDocument3 pagesDate GE Tag Description LearningVictor BiacoloNo ratings yet

- 1300 Edi Full Aug 2006 First Part (Shrunk+)Document84 pages1300 Edi Full Aug 2006 First Part (Shrunk+)Gustavo Vargas100% (24)

- EEE Lab EquipmentsDocument12 pagesEEE Lab Equipments1balamanianNo ratings yet

- IPC-PT/MV11 Series HW ManualDocument37 pagesIPC-PT/MV11 Series HW ManualAlexa BearNo ratings yet

- S8209a e PDFDocument27 pagesS8209a e PDFkarkeraNo ratings yet

- APEX3000 High Density Universal Edge QAM Data SheetDocument3 pagesAPEX3000 High Density Universal Edge QAM Data SheetHugo FedulloNo ratings yet

- An 98080Document58 pagesAn 98080MohamedElsawiNo ratings yet

- Operation System Euipo Ultrasonic CalibrationDocument55 pagesOperation System Euipo Ultrasonic CalibrationFernandoiNo ratings yet

- XL 2020 ManualDocument44 pagesXL 2020 ManualSoma GhoshNo ratings yet

- Becker RA3502 - IODocument28 pagesBecker RA3502 - IOBill MonkNo ratings yet

- Patient Monitoring System Using Pic16f877Document82 pagesPatient Monitoring System Using Pic16f877Gautam Talukdar100% (1)

- Industrial Catalogue-2021Document18 pagesIndustrial Catalogue-2021Carlos SatoNo ratings yet

- L11831-01 Instruction Manual Ver.2.0.0Document48 pagesL11831-01 Instruction Manual Ver.2.0.0tao zhangNo ratings yet

- RC100C Led35s 840 Psu W30L120Document2 pagesRC100C Led35s 840 Psu W30L120Post Venta 1No ratings yet

- Fx2n-2ad User's GuideDocument0 pagesFx2n-2ad User's GuideMohamed AbdouNo ratings yet

- RCB600 :: ROAL Living EnergyDocument10 pagesRCB600 :: ROAL Living EnergyroalscribdNo ratings yet

- Art 708-A, Art 710-A, Art 712-A, Art 722-A, Art 715-A, Art 725-ADocument12 pagesArt 708-A, Art 710-A, Art 712-A, Art 722-A, Art 715-A, Art 725-AtoutiwaiNo ratings yet