Professional Documents

Culture Documents

Experiment On Semi-Circular Arch

Uploaded by

Nurul NadhirahOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Experiment On Semi-Circular Arch

Uploaded by

Nurul NadhirahCopyright:

Available Formats

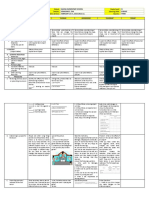

TITLE : EXPERIMENT ON SEMI-CIRCULAR ARCH

1.1 INTRODUCTION

The main advantage of an arch has over a beam, is that it can carry a much larger load. History arches

wee important because they could be constructed using small, easy carry blocks of brick or stone rather

than using massive, monolithic stone beam or lentil. Romans used the semi-circular arch in bridges,

aqueducts and in large-scale architecture. In most cases they did not use mortar, relying simply on the

precision of their stone finish. When an arch is loaded by gravity forces, the pressure acts downward on

the arch and has the effect of compressing it together instead of pulling it apart.

In this laboratory activity students will be exposed to the apparatus and the procedures to carry out

experiment on two-hinged and three-hinged arches.

1.2 OBJECTIVE

The objective of the experiment is:

To determine the relationship between applied load and the horizontal thrust at the supports

of a two-hinged and a three-hinged arches.

To explore the relationship between the loads and the horizontal reaction force in threepinned arch.

To determine the horizontal thrust in a three hinged arch for a given system of loads

experimentally and verify the same with calculated values.

1.3 THEORETICAL BACKGROUND

Arches have a diverse range of applications in bridges, arched dams and in industrial, commercial and

recreational buildings.

An arch is supported by abutments. The heels and crown are the lowest and highest points of the arch,

respectively; supports may be rolled, pinned, or fixed. Horizontal distance between two heels is span

L, a vertical distance between heels line and crown is rise r.

(Source: Theory of Arched Structures by Igor A. Karnovsky)

Three-hinged semi-circular arch

1.4 PROBLEM STATEMENT

to determine the relationship between applied load and the horizontal thrust at the supports of a threehinged arches.

2

2.1 APPARATUS

I.

Support frame

II.

Three hinge arch assembly

III.

A simple support

IV.

A roller support

V.

A set of weights

2.2 PROCEDURE

i. The load cell was connected to the digital indicator

ii. The indicator was switched on. For stability of the reading the indicator must be switch on 10

minutes before taking readings.

iii. The load hanger was placed at the location where the load is to be applied.

iv. The indicator reading was noted. If it is not zero press the tare button.

v. A load was placed on the load hanger.

vi. The indicator reading was recorded. This represents the horizontal reaction of the pinned support.

vii. The load on the load hanger was increased and the horizontal reaction was recorded.

viii.Step 7 was repeated for another 4 load increments.

ix. The result was tabulated.

x. The experiment was repeated to get another set of readings.

You might also like

- Exc Cat #20 312Document2 pagesExc Cat #20 312Washington Santamaria100% (1)

- PM TB Solutions C05Document6 pagesPM TB Solutions C05Vishwajeet Ujhoodha82% (11)

- Most Essential Learning CompetenciesDocument8 pagesMost Essential Learning CompetenciesKaterina TagleNo ratings yet

- Lab Report On Waren GirderDocument12 pagesLab Report On Waren GirderSamuel Ogeda Otieno100% (2)

- Impact of A Jet Lab ReportDocument3 pagesImpact of A Jet Lab ReportSaiful IslamNo ratings yet

- Arihant NTA CUET UG 2022 Section 2 Domain (Science)Document445 pagesArihant NTA CUET UG 2022 Section 2 Domain (Science)Hp100% (2)

- CBSE Class 9 Physics Worksheet - Force and Laws of MotionDocument4 pagesCBSE Class 9 Physics Worksheet - Force and Laws of Motionravi chandranNo ratings yet

- CVE 230. Lab Report 4 (Torsion Testing) .Document4 pagesCVE 230. Lab Report 4 (Torsion Testing) .Juan Villa100% (1)

- N Detailed Modelling PDFDocument32 pagesN Detailed Modelling PDFhussain100% (1)

- Basic Theory of Structures: The Commonwealth and International Library: Mechanical Engineering DivisionFrom EverandBasic Theory of Structures: The Commonwealth and International Library: Mechanical Engineering DivisionRating: 4 out of 5 stars4/5 (4)

- Project On Ac Generator and DC GeneratorDocument17 pagesProject On Ac Generator and DC GeneratorAshutosh Rastogi50% (12)

- Span Deflection (Double Integration Method)Document14 pagesSpan Deflection (Double Integration Method)Ikhwan Z.88% (8)

- Lab 5-Force in A Statically Determinate Cantilever Truss UTHMDocument15 pagesLab 5-Force in A Statically Determinate Cantilever Truss UTHMMoly Muliyani75% (8)

- Lab 1 - Impact of JetDocument7 pagesLab 1 - Impact of JetMichael York100% (1)

- BROAD CRESTED WEIR LABORATORY EXPERIMENTDocument12 pagesBROAD CRESTED WEIR LABORATORY EXPERIMENTSyafiq Roslan75% (4)

- Pin-Jointed Truss LabreportDocument4 pagesPin-Jointed Truss LabreportFatin Afiqah40% (5)

- Nonconvergence in Caesar in Caesar IIDocument11 pagesNonconvergence in Caesar in Caesar IIviv0102No ratings yet

- Equilibrium of A BeamDocument5 pagesEquilibrium of A Beamawe_em50% (4)

- Shear Force in A BeamDocument16 pagesShear Force in A BeamIkhwan Z.100% (7)

- Impact of Jet Lab ReportDocument7 pagesImpact of Jet Lab ReportMohamad Hilmy HaririeNo ratings yet

- Bending Moment in A BeamDocument8 pagesBending Moment in A BeamLim Ksoon100% (1)

- Buckling Lab ReportDocument16 pagesBuckling Lab ReportYu Wan100% (5)

- A Point Load Moving Across Two Pinned Arch Intro N ExplainationDocument3 pagesA Point Load Moving Across Two Pinned Arch Intro N ExplainationarunNo ratings yet

- Lab Report 1 - Two and Three Hinged ArchesDocument19 pagesLab Report 1 - Two and Three Hinged ArchesNurshahadah Shahrunnizam100% (3)

- StrutsDocument7 pagesStrutsBatrisyialya RusliNo ratings yet

- Structure Lab-Three Hinge Arc (Example Lab Report)Document13 pagesStructure Lab-Three Hinge Arc (Example Lab Report)NabilZaed0% (2)

- Lab Report Structual Analysis ArchDocument4 pagesLab Report Structual Analysis ArchChoo Fu-KiatNo ratings yet

- Lab Report Indeterminate BeamDocument9 pagesLab Report Indeterminate BeamFatin Samsudin60% (5)

- Impact of Water JetDocument12 pagesImpact of Water JetIqbal Buddy100% (1)

- Lab Report Instability of StrutDocument13 pagesLab Report Instability of StrutepolNo ratings yet

- Three Pinned Arches Lab Report AnalysisDocument6 pagesThree Pinned Arches Lab Report Analysismarina zamriNo ratings yet

- Lab Experiment 1: Buckling of ColumnsDocument14 pagesLab Experiment 1: Buckling of Columnsabhishek kumarNo ratings yet

- Lab-2 TrussDocument4 pagesLab-2 TrussBrian WongNo ratings yet

- Cables and Arches: Version 2 CE IIT, KharagpurDocument19 pagesCables and Arches: Version 2 CE IIT, Kharagpursatyakam87453950% (2)

- LAB 1 - PARTICLE DENSITY & MOISTURE CONTENT (Level 1)Document6 pagesLAB 1 - PARTICLE DENSITY & MOISTURE CONTENT (Level 1)Muhd MuqhreyNo ratings yet

- (COMPLETE) Ring Ball and Penetration Test PDFDocument10 pages(COMPLETE) Ring Ball and Penetration Test PDFAthirah DinataNo ratings yet

- Structure CableDocument7 pagesStructure CableEriey ZuhairiNo ratings yet

- Cable Suspension Experiment ReportDocument4 pagesCable Suspension Experiment ReportShiv Kumar Meena0% (1)

- Lab 1 Flow Through A Venturi MeterDocument5 pagesLab 1 Flow Through A Venturi MeterAfwan IrfanNo ratings yet

- Engineering Mechanics Truss Forces Lab ReportDocument8 pagesEngineering Mechanics Truss Forces Lab ReportzaimNo ratings yet

- EXPERIMENTAL BEAMSDocument10 pagesEXPERIMENTAL BEAMSNurul NadhirahNo ratings yet

- Group 3 (Seksyen4)Document15 pagesGroup 3 (Seksyen4)alnzNo ratings yet

- Report Moment Influence LinesDocument25 pagesReport Moment Influence LinesUtaya Kumar Veelmurugan100% (1)

- Torsion Experiment ReportDocument14 pagesTorsion Experiment ReportNbl KlfNo ratings yet

- Lab Soil UctDocument3 pagesLab Soil UctSyed Zulfaizzuan AljufriNo ratings yet

- Introduction Impact JetDocument4 pagesIntroduction Impact JetIniaan SaminathanNo ratings yet

- SEO Flow Weirs Lab ReportDocument20 pagesSEO Flow Weirs Lab ReportGua HantuNo ratings yet

- Two Hinged Parabolic ArchDocument10 pagesTwo Hinged Parabolic ArchHans Izairi100% (1)

- Structure Lab-Three Hinge ArcDocument13 pagesStructure Lab-Three Hinge ArcFendi Roon100% (1)

- Space Frame ReportDocument14 pagesSpace Frame ReportAsmawiayob100% (1)

- Lab 3 TorsionDocument8 pagesLab 3 TorsionFarid NajandNo ratings yet

- Heron's Fountain Physics ProjectDocument12 pagesHeron's Fountain Physics ProjectsandsphilipNo ratings yet

- Experiment Center Pressure Lab ReportDocument9 pagesExperiment Center Pressure Lab ReportAyong Anis100% (4)

- Full As Contoh Member AkashahDocument29 pagesFull As Contoh Member AkashahWayen Bulat100% (1)

- Lab ReportDocument16 pagesLab Reportabe97No ratings yet

- Lab 2 Determing Fluid Velocity and Discharge Coefficient-Converted NewwwDocument11 pagesLab 2 Determing Fluid Velocity and Discharge Coefficient-Converted Newwwkashvin rajNo ratings yet

- Truss ReportDocument20 pagesTruss ReportSyuhaidah Zul Hadi100% (2)

- Centre of Hidrostatic PressureDocument16 pagesCentre of Hidrostatic PressureVanithaa Ponnaiah0% (1)

- TrussDocument12 pagesTrussAmirullah Adnan100% (1)

- OpenChannel Flow Lab ReportDocument8 pagesOpenChannel Flow Lab ReportNur SalwaniNo ratings yet

- PEC2215B1 Madam Hafizah Binti Muhamad Azlan: Ces511 - Structural Engineering Laboratory Lab Experiment: Torsion (Co2:Po5)Document8 pagesPEC2215B1 Madam Hafizah Binti Muhamad Azlan: Ces511 - Structural Engineering Laboratory Lab Experiment: Torsion (Co2:Po5)elhammeNo ratings yet

- Moment Influence Line ReportDocument13 pagesMoment Influence Line Reporthaziq khairudin33% (3)

- Experiment 3 (Bending Moments in Beam)Document13 pagesExperiment 3 (Bending Moments in Beam)Shafiq MahadiNo ratings yet

- Shear Force Bending Moment Test ReportDocument5 pagesShear Force Bending Moment Test ReportZahed AbdAzizNo ratings yet

- Experiment On Semi Circular ArchDocument3 pagesExperiment On Semi Circular ArchMukhriz Mansor50% (2)

- Load Cells: Types, How It Works, Applications, & Advantages: What Is A Load Cell?Document27 pagesLoad Cells: Types, How It Works, Applications, & Advantages: What Is A Load Cell?Portland GeoNo ratings yet

- ABSTRACTDocument4 pagesABSTRACTAiman MaqsoodNo ratings yet

- Civil Engineering Lab 2: Faculty of Engineering and Built EnvironmentDocument7 pagesCivil Engineering Lab 2: Faculty of Engineering and Built EnvironmentAdel MoflhiNo ratings yet

- Test Method RC 31701 Surface Texture by Sand PatchDocument3 pagesTest Method RC 31701 Surface Texture by Sand PatchSanjeevKambleNo ratings yet

- Topic 1 Introduction of Park2020 PDFDocument45 pagesTopic 1 Introduction of Park2020 PDFNurul NadhirahNo ratings yet

- Sand PatchDocument1 pageSand PatchNurul NadhirahNo ratings yet

- Meeting FormDocument1 pageMeeting FormNurul NadhirahNo ratings yet

- Course Highway Engineering Course Code ECG354 Level of Openness 0Document6 pagesCourse Highway Engineering Course Code ECG354 Level of Openness 0Nurul NadhirahNo ratings yet

- CONCLUSION Spot SpeedDocument1 pageCONCLUSION Spot SpeedNurul NadhirahNo ratings yet

- Running SpeedDocument3 pagesRunning SpeedNurul NadhirahNo ratings yet

- Title Skid ResistanceDocument2 pagesTitle Skid ResistanceNurul NadhirahNo ratings yet

- Fixed End MomentsDocument1 pageFixed End MomentsHarold DeanNo ratings yet

- Bitumen Penetration Test Sample Penetration Value, PV (DMM) 1 2 3 4 5 Average A (60/70) B (80/100)Document3 pagesBitumen Penetration Test Sample Penetration Value, PV (DMM) 1 2 3 4 5 Average A (60/70) B (80/100)Nurul NadhirahNo ratings yet

- Lab ManganeseDocument3 pagesLab ManganeseNurul NadhirahNo ratings yet

- Spot Speed Study Reveals Drivers Exceed 35 Mph LimitDocument12 pagesSpot Speed Study Reveals Drivers Exceed 35 Mph Limitazrulamri1980yahoocom0% (1)

- Format of Lab ReportDocument2 pagesFormat of Lab ReportNurul NadhirahNo ratings yet

- Uniform Building By-Laws 1984Document7 pagesUniform Building By-Laws 1984oioian0% (4)

- Uniform Building By-Laws 1984Document7 pagesUniform Building By-Laws 1984oioian0% (4)

- Paper 3 - BombaDocument86 pagesPaper 3 - BombamachaNo ratings yet

- Field Density Test by Sand Replacement MethodDocument5 pagesField Density Test by Sand Replacement Methodngo_truong7820041757100% (1)

- Cable ExpDocument2 pagesCable ExpNurul NadhirahNo ratings yet

- Engg Mech Lab Me-213-FDocument36 pagesEngg Mech Lab Me-213-FLutfan LubaibNo ratings yet

- EXP9Document8 pagesEXP9NguyenThanhdungNo ratings yet

- BridgeDocument30 pagesBridgeNurul NadhirahNo ratings yet

- Field Density Test by Sand Replacement MethodDocument5 pagesField Density Test by Sand Replacement Methodngo_truong7820041757100% (1)

- EXPERIMENTAL BEAMSDocument10 pagesEXPERIMENTAL BEAMSNurul NadhirahNo ratings yet

- EXP9Document8 pagesEXP9NguyenThanhdungNo ratings yet

- Deflection of BeamDocument6 pagesDeflection of BeamNurul Nadhirah50% (2)

- Field Density Test by Sand Replacement MethodDocument5 pagesField Density Test by Sand Replacement Methodngo_truong7820041757100% (1)

- Antenna Antenna Equivalent CircuitDocument5 pagesAntenna Antenna Equivalent CircuitThorn De LeonNo ratings yet

- FiltersDocument3 pagesFilterspraneeth kuchimanchiNo ratings yet

- Elpro 23bpt GBDocument6 pagesElpro 23bpt GBTerryAdamsNo ratings yet

- Tissue Adaptation To Physical Stress: A Proposed "Physical Stress Theory" To Guide Physical Therapist Practice, Education, and ResearchDocument21 pagesTissue Adaptation To Physical Stress: A Proposed "Physical Stress Theory" To Guide Physical Therapist Practice, Education, and ResearchGavin Cao100% (1)

- Understanding Apparent Power, Real Power and Reactive PowerDocument2 pagesUnderstanding Apparent Power, Real Power and Reactive PowerMohamed ShareefNo ratings yet

- DC Machine CommutationDocument55 pagesDC Machine CommutationARSLAN FALAKNo ratings yet

- Electric Circuit & MachinesDocument2 pagesElectric Circuit & MachinesAnil MarsaniNo ratings yet

- Fluid Mechanics Chapter 6Document34 pagesFluid Mechanics Chapter 6Ricky Mak100% (1)

- Lorentz Force Sigmometry: A Contactless Method For Electrical Conductivity MeasurementsDocument8 pagesLorentz Force Sigmometry: A Contactless Method For Electrical Conductivity MeasurementsAnnisa Syahida KhakimNo ratings yet

- Eee3352 L1Document37 pagesEee3352 L1Desmond CheweNo ratings yet

- HYDAC PTK Bell HousingDocument4 pagesHYDAC PTK Bell HousingpeterNo ratings yet

- SVL Testing GuideDocument7 pagesSVL Testing GuideNagaraj RamNo ratings yet

- Stability control model for huge surface excavatorDocument10 pagesStability control model for huge surface excavatorJoseph JoseNo ratings yet

- PEC 2017 Supplement 1-2019Document2 pagesPEC 2017 Supplement 1-2019Noel RazaNo ratings yet

- Abb Disconnector Gw54 1yva000105 Reva enDocument8 pagesAbb Disconnector Gw54 1yva000105 Reva enerkamlakar2234No ratings yet

- Earth Resistance Calculations and Soil Resistivity MeasurementsDocument27 pagesEarth Resistance Calculations and Soil Resistivity MeasurementsAnonymous FmtXlUVyMGNo ratings yet

- Balloon Powered Race Cars-1Document8 pagesBalloon Powered Race Cars-1Angelica CamilonNo ratings yet

- Isl 98604Document28 pagesIsl 98604divubi2004No ratings yet

- Jhonna Marie Nikole P. Sumando - Introduction To Elastic Potential Energy, Work and Hooke's LawDocument4 pagesJhonna Marie Nikole P. Sumando - Introduction To Elastic Potential Energy, Work and Hooke's LawNikole SumandoNo ratings yet

- DLL - SCIENCE 4 - Q3 - WEEK 1 Explain The Effects of Force@edumaymay@lauramosDocument7 pagesDLL - SCIENCE 4 - Q3 - WEEK 1 Explain The Effects of Force@edumaymay@lauramosjeraldine endenoNo ratings yet

- IES Assignment: Unit-1Document53 pagesIES Assignment: Unit-1ruchikaNo ratings yet