Professional Documents

Culture Documents

PR 4401

Uploaded by

AndreskoiraOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

PR 4401

Uploaded by

AndreskoiraCopyright:

Available Formats

LED DRIVER PR4401/PR4402

0.9V Boost Driver for White LEDs PR4401/4402

Requires Only One External Component

The PR4401 and PR4402 are single cell step-up converters for white LEDs operating from

a supply voltage of less than 0.9V. Only one external inductor is needed for operation of a

white LED. PR4401 is recommended for mean LED circuits of up to 20mA, PR4402 for up

to 40mA. This makes PR4401 and PR4402 ideal for use in low-cost or small-sized

applications such as LED flashlights or LCD backlighting for portable devices.

Features

Applications

minimum startup voltage 0.9V

200/250mA peak output current

only one external component required

battery deep discharge protection

Small-sized LED torches

LCD backlighting

LED indicator lights

The inductance L1 determines the LED

current:

Typical Application

L1

Vbat =1.2V or 1.5V

Vcc

White

LED

Vout

Gnd

PR4401/02

For output currents higher than 20mA an additional

blocking capacitor at Vcc is recommended.

Inductance L1

Mean current

for

22 H

11 mA

PR4401

14.7 H

14 mA

PR4401

10 H

22 mA

PR4401/4402

6.8 H *

32 mA *

PR4402

4.7 H *

40 mA *

PR4402

* PR4402 only

measured with inductor Murata type LQH32CN series

10-22H: one white LED

4.7-6.8H: two white LEDs in parallel

Pin Description

UIxx

Vcc

Vout

PIN Name

Gnd

PIN Function Description

Vcc

Supply voltage

Vout

Output voltage, LED connection

Gnd

Ground connection

top view

Topside marking: "UI" (PR4401) or "UJ" (PR4402) with a two-digit lot code

Package SOT23-3 or COB on request

PREMA Semiconductor GmbH 2006-2007

Page 1/12

Rev 0707

LED DRIVER PR4401/PR4402

Absolute Maximum Ratings

PR4401 and PR4402

Parameter

Min

Typ

Max

Units

VCC (no damage)

-0.3

Operating Temperature Range

-20

85

Storage Temperature Range

-55

150

Electrostatic Discharge (ESD) Protection

kV

Electrical Characteristics

Vcc=1.5V, Ta = 25C, 10-22H: one white LED / 4.7-6.8H: two white LEDs in parallel, unless otherwise noted.

Parameter

Conditions

Min

Typ

Max

Min

PR4401

Supply Voltage, min. operating

min. startup

max. operating

L1 = 10...22H

Supply Voltage, min. operating

min. startup

max. operating

L1 = 10...22H

LED Mean Current

measured with L1 type LQH32CN Murata

Switching Current at Vout

Ta = 25C

Ta = 0...60C

0.70

0.90

Vout = 0.4V

Units

0.80

0.95

0.70

0.90

0.80

0.95

V

V

V

0.80

1.00

0.90

1.05

V

V

V

1.90

0.80

1.00

0.90

1.05

1.90

1.90

12

15

23

---

12

15

23

32

40

200

Switching Frequency

Vcc > 950mV

Vcc = 600mV

Vcc = 400mV

4

50

10

Efficiency

mA

500

8

100

20

80

Vout

mA

mA

mA

mA

mA

250

500

Quiescent supply current

Max

PR4402

1.90

L1 = 22H

L1 = 14.7H

L1 = 10H

L1 = 6.8H

L1 = 4.7H

Typ

Vcc

kHz

10

80

15

mA

A

A

%

15

Block Diagram

Ref.

Comp.

Vout

Vcc

Control

Logic

Gnd

PREMA Semiconductor GmbH 2006-2007

Page 2/12

Rev 0707

LED DRIVER PR4401/PR4402

Typical Characteristics

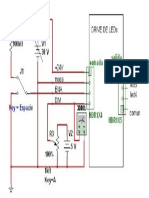

Test circuit

Measurement and Calculation of Efficiency

L1

0.5

or 1

Efficiency %=

Vcc

470nF

100

1

V inI in dt

T

0

Vout

Gnd

PR4401

1

V LEDI LED dt

T 0

0.5

or 1

Depending on test setup and measuring method, efficiency values can vary by approx. 5%, and peak

current values can vary by up to 20%, Accuracy of mean currents: 1mA.

Measuring conditions for all diagrams, unless otherwise noted:

Ta = 25C

one LED connected (peak voltage 4.2...5.8V)

A LQH32CN from Murata has been used as reference inductor, the DC resistance is specified as 0.44

30% for 10 H (max current 300 mA), 0.71 30% for 22 H (max. current 250 mA) and 1.30 30% for a

47 H inductor (max. current 170 mA).

Oscilloscope Displays

PR4401; LED voltage (CH1) and LED current (CH2, over 0.5 Ohm resistor)

with L1 = 22 H

PREMA Semiconductor GmbH 2006-2007

Page 3/12

L1 = 10 H

Rev 0707

LED DRIVER PR4401/PR4402

PR4401 data

Efficiency vs. Supply Voltage

Mean Supply Current vs. Supply Voltage

100

120

90

110

Supply Current (mA)

80

Efficiency (%)

70

60

50

22 H

14,7 H

40

10 H

30

20

100

90

80

70

22 H

10 H

60

50

40

30

20

10

10

0

0

0,8

1,2

1,4

1,6

1,8

0,8

1,2

Supply Voltage (V)

1,4

1,6

1,8

Supply Voltage (V)

Mean LED Current vs. Supply Voltage

Peak LED Current vs. Supply Voltage

25

250

LED Peak Current (mA)

LED Mean Current (mA)

225

20

15

22 H

14.7 H

10

10 H

200

175

150

125

22 H

10 H

100

75

50

25

0

0,8

1,2

1,4

1,6

1,8

0,8

1,2

Supply Voltage (V)

1,4

1,6

1,8

Supply Voltage (V)

Startup Voltage vs. Temperature

Oscillation Frequency vs. Supply Voltage

1,1

800

0,9

Frequency (kHz)

Startup Voltage (V))

700

1

22 H

10 H

0,8

600

500

400

22 H

10 H

300

200

100

0

0,7

-20

-10

10

20

30

40

50

60

0,75

70

1,25

1,5

1,75

Supply Voltage (V)

Temperature (C)

Mean LED Current vs. Temp. @ L1=10H

Mean LED current (mA)

30

25

20

1.0V

1,25V

1,50V

1,75V

15

10

-20

-15

-10

-5

10

15

20

25

30

35

40

45

50

55

60

65

70

Temperature (C)

PREMA Semiconductor GmbH 2006-2007

Page 4/12

Rev 0707

LED DRIVER PR4401/PR4402

PR4402 data

Mean LED Current vs. Supply Voltage

40

LED Mean Current (mA)

35

30

25

20

22 H

10 H

6.8 H

4.7 H

15

10

5

0

0,8

1,2

1,4

1,6

1,8

Supply Voltage (V)

Efficiency vs. Supply Voltage

100

90

Efficiency (%)

80

70

60

50

22 H

10 H

6.8 H

4.7 H

40

30

20

10

0

0,8

1,2

1,4

1,6

1,8

Supply Voltage (V)

Peak LED Current vs. Supply Voltage

350

LED Peak Current (mA)

325

300

275

250

225

200

22 H

10 H

6.8 H

4.7 H

175

150

125

100

75

50

25

0

0,8

1,2

1,4

1,6

1,8

Supply Voltage (V)

PREMA Semiconductor GmbH 2006-2007

Page 5/12

Rev 0707

LED DRIVER PR4401/PR4402

Influence of the LED Forward Voltage

measured with 1 LED / 2 LEDs in parallel; Vcc = 1.5V

Circuit

LED Peak

LED Mean Current

Forward Voltage

Mean Supply

Current

Efficiency

10 H, 1 LED

5.8 V

20 mA

70 mA

77 %

10 H, 2 LEDs ||

4.6 V

24 mA

70 mA

80 %

22 H, 1 LED

4.2 V

13 mA

33 mA

82 %

22 H, 2 LEDs ||

3.5 V

14 mA

32 mA

82 %

Peak forward voltages above approx. 5V are often considered as an overload condition

and may lead to a lower LED efficiency.

Application Notes

Selection of PR4401 and PR4402

The circuit type should be selected according to the required LED current.

PR4401 is best operated with inductors between 10 and 22H.

PR4402 is best operated with inductors between 4.7 and 10H.

Using lower inductances may lead to erratic behaviour, especially at low supply voltages

and should be avoided.

Operating with higher inductances is possible and will lead to lower supply and LED

current.

However the quiecient current which is independent of the inductance will lead to a lower

overall efficiency. Since PR4402 has about twice the quiescient current of PR4401, it is

not recommended for small LED currents.

LED compatibility

It must be considered that the peak current through the LED is a factor of up to 7 higher

than the mean current. LED lifetime may be affected if operated outside the range

specified by the LED vendor.

Since the emission spectrum of white LEDs usually depends on the current, the light color

may shift to blueish white. High peak currents may also saturate the LED and reduce the

light efficiency of the LED.

If the rated LED peak current is exceeded, it is recommended to use a smoothing

capacitor and diode to provide a continuous output current (see below). With most

standard LEDs, this will improve the overall performance with inductors of 10H and less,

or mean output currents of 23mA and more.

Note that with especially with the higher currents of PR4402 the current rating of most

standard LEDs is exceeded, and more powerful or multiple LEDs must be used.

Inductor compatibility

While the series resistance of the coil has a small impact on the LED current, it is

important that the saturation current is higher than the maximum peak current over the

supply voltage range. Inductors optimized for DC-DC converters are mostly suitable.

PREMA Semiconductor GmbH 2006-2007

Page 6/12

Rev 0707

LED DRIVER PR4401/PR4402

Connection from Battery

Due to high peak currents, it is important to connect the PR4401/PR4402 to the battery

with short, low resistance wires, to achieve the best performance. A voltage drop along the

wire affects LED current, efficiency and minimum startup and operating voltage.

This is most critical for applications with low inductivity and high current.

In cases where a longer wire from the battery cannot be avoided, a capacitor should be

placed close to the Vcc and Gnd pin of PR4401. Typically capacitors between 220nF and

1F are used.

With PR4402 operated at higher currents, a blocking capacitor is usually necessary even

if wires or board layout are optimized.

Using Different Battery Types

The input voltage must be 1.90V at maximum. At higher voltages the circuit may not

trigger and start up correctly. Therefore operation with one Alkaline, NiCd, or NiMH cell

(AA or AAA type) is recommended.

Alkaline button cells can also be used for supply. However, since high peak currents are

drawn from the battery, button cells are recommended only with inductors of 22H or

more, depending on the battery type. A capacitor at the supply pins of PR4401 may also

improve performance with button cells.

Lithium batteries are not suitable due to their higher voltage.

Approximate battery lifetime:

Battery

Battery Lifetime, typical

Battery Lifetime, typical

L1= 22H, LED mean current 12mA

L1= 10H, LED mean current 23mA

AA (Mignon, LR 6/AM-3)

55 h

27 h

AAA (Micro, LR 03/AM-4)

22 h

8h

Conditions: one white LED connected, measured with single 1.5V TDK Alkaline battery.

Battery lifetime depends on battery capacity and operating conditions. Therefore the times

indicated here can only give a rough indication of achievable times.

Connecting several LEDs in parallel

When several LEDs are connected in parallel, it is necessary to match the forward voltage

of these LEDs, to achieve a uniform brightness. The total current of all LEDs together

corresponds approximately to the mean output current for operation with one LED.

Vbat =1.2V or 1.5V

L1=10H

Vcc

Vout

Gnd

PR4401

PREMA Semiconductor GmbH 2006-2007

Page 7/12

Matching

White

LEDs

Rev 0707

LED DRIVER PR4401/PR4402

Operation of LED with smoothed current (rectifier)

With a diode (preferably a Schottky diode) and a smoothing capacitor the voltage at the

LED can be buffered if necessary. The capacitance must be small enough so that the

voltage at the capacitor will exceed a voltage of 2.5V in the first cycle, otherwise the circuit

may not start up. In most cases, values between 100nF and 1F are appropriate.

Due to different load characteristics, output current and efficiency are typically higher than

without capacitor, especially in the high-current range.

L1

Vbat =1.2V or 1.5V

S

Vcc

White

LED

Vout

Gnd

PR4401/02

Recommended configuration for higher LEDs currents

While for lower LED currents it is possible to operate PR4401 with the minimum number

of components, it is recommended to provide both rectifier circuit a the output and buffer

capacitor at the input at high LED currents, to achieve the best performance.

L1

Vbat =1.2V or 1.5V

S

Vcc

Vout

White

LED

Gnd

PR4401/02

Whether the extra components are necessary or not depends largely on the performance

of the components used, most importantly the peak current of the LED, the internal

resistance of the battery and the resistance of the battery cables. If by adding the extra

components the mean LED current increases significantly, it is usually advisable to add

them permanently to achieve a high efficiency.

As a rule of thumb, with a 22H inductor the extra components will usually not increase

the current significantly, while for inductors below 10H they will usually improve the

performance noticeably.

Buffer capacitor and rectifier circuit are independent measures. For powerful LEDs, or two

or more LEDs in parallel at the output, the rectifier may not be necessary, but the buffer

capacitor will still prevent high voltage drops along the supply wire.

For the buffer capacitor, values between 220nF and 1F are common.

PREMA Semiconductor GmbH 2006-2007

Page 8/12

Rev 0707

LED DRIVER PR4401/PR4402

Connecting two LEDs in series

It is possible to operate PR4401 and PR4402 with two LEDs in series at the output.

However, while the peak output current is nearly independent of the output load, the mean

output current with two LEDs in series is reduced to half the current with one LED. In

addition, at high output voltages the efficiency drops significantly, depending on operating

conditions, and current pulses become shorter and sharper.

Therefore, although possible and useful in some cases, this operation mode is not

recommended for general applications and not specified further.

Using red, green or yellow LEDs

Although PR4401/PR4402 is optimized for operation with white or blue LEDs, it will usually

also work with red, green or yellow LEDs, with the following restrictions:

a) The LED must build up a sufficient forward voltage to trigger PR4401/PR4402. Due to

the internal resistance of the LED, this condition is usually met. However, no guarantee

can be assumed for proper operation under all conditions, and you need to qualify the

system yourself

b) Due to the different forward voltage level and internal resistance of colored LEDs, the

timing is different, and mean currents are mostly lower than for white LEDs. Also other

parameters may deviate from this data sheet.

PREMA Semiconductor GmbH 2006-2007

Page 9/12

Rev 0707

LED DRIVER PR4401/PR4402

Sample Board Layouts

Flashlight board with AAA battery holder

Size: 77.5 mm x 14 mm

PREMA Semiconductor GmbH 2006-2007

Page 10/12

Rev 0707

LED DRIVER PR4401/PR4402

Available Packages

Typical Dimensions

B = 0.40 mm D = 2.92 mm

E = 1.30 mm H = 2.37 mm

e1 = 1.92 mm

PR4401/PR4402 SOT23 package in tape and reel

Packing unit: 3000 ICs per reel (reel diameter 7" / 178mm)

Delivery in die form on request

All parts delivered comply with RoHS. Finish is pure tin.

PREMA Semiconductor GmbH 2006-2007

Page 11/12

Rev 0707

LED DRIVER PR4401/PR4402

Disclaimer

Information provided by PREMA is believed to be accurate and correct. However, no responsibility is assumed by PREMA for its use,

nor for any infringements of patents or other rights of third parties which may result from its use. PREMA reserves the right at any time

without notice to change circuitry and specifications.

Life Support Policy

PREMA Semiconductors products are not authorized for use as critical components in life support devices or systems without the

express written approval of PREMA Semiconductor. As used herein:

1. Life support devices or systems are devices or systems which, (a) are intended for surgical implant into the body, or (b) support or

sustain life, and whose failure to perform when properly used in accordance with instructions for use provided in the labeling, can be

reasonably expected to result in a significant injury to the user.

2. A critical component is any component of a life support device or system whose failure to perform can be reasonably expected to

cause the failure of the life support device or system, or to affect its safety or effectiveness.

PREMA Semiconductor GmbH

Robert-Bosch-Str. 6

55129 Mainz Germany

Phone: +49-6131-5062-0

Fax: +49-6131-5062-220

Email: prema@prema.com Web site: www.prema.com

PREMA Semiconductor GmbH 2006-2007

Page 12/12

Rev 0707

You might also like

- Eup3484dir1 C47740Document11 pagesEup3484dir1 C47740AndreskoiraNo ratings yet

- Probador de Driver LEDDocument1 pageProbador de Driver LEDAndreskoiraNo ratings yet

- Power Inverter KIP072I12 01 - 34006268 - IC OZ9926Document3 pagesPower Inverter KIP072I12 01 - 34006268 - IC OZ9926Andreskoira100% (1)

- CX LMN75Document71 pagesCX LMN75AndreskoiraNo ratings yet

- Product Profile: SCR, 12 A, 15ma, 650 V, SOT78Document11 pagesProduct Profile: SCR, 12 A, 15ma, 650 V, SOT78Christian Moreno AlvarezNo ratings yet

- MP1470Document16 pagesMP1470AndreskoiraNo ratings yet

- Chassis TX91SADocument1 pageChassis TX91SAAndreskoiraNo ratings yet

- BDP 2900Document18 pagesBDP 2900Andreskoira100% (1)

- Panasonic DVD Home Theater - Sa-Pt 250 EeDocument126 pagesPanasonic DVD Home Theater - Sa-Pt 250 Eecosaceaion100% (2)

- Aiwa cx81 xs81 PDFDocument32 pagesAiwa cx81 xs81 PDFAndreskoiraNo ratings yet

- If Signal Processing (Super Pll-Ii Vif + Sif) Circuit For Tvs and VcrsDocument18 pagesIf Signal Processing (Super Pll-Ii Vif + Sif) Circuit For Tvs and VcrsAndreskoiraNo ratings yet

- BGH BP4201S RemotoDocument1 pageBGH BP4201S RemotoAndreskoiraNo ratings yet

- 9619 Hisense LTDN32K316AM LTDN32K310WAM Chassis MSD1328 Ver 1.0 2012.07 Televisor LCD Manual de ServicioDocument48 pages9619 Hisense LTDN32K316AM LTDN32K310WAM Chassis MSD1328 Ver 1.0 2012.07 Televisor LCD Manual de ServicioAndreskoiraNo ratings yet

- Audioton T3602RM T5103RM T5104RM Condor T3602RM T5103RM T510 PDFDocument5 pagesAudioton T3602RM T5103RM T5104RM Condor T3602RM T5103RM T510 PDFAndreskoiraNo ratings yet

- Visit ChipDocs Site for InfoDocument36 pagesVisit ChipDocs Site for InfoAndreskoiraNo ratings yet

- TK6A65D Datasheet en 20131101Document6 pagesTK6A65D Datasheet en 20131101AndreskoiraNo ratings yet

- An Tda937x Ps v1.0 (E)Document141 pagesAn Tda937x Ps v1.0 (E)AndreskoiraNo ratings yet

- Datasheet - HK An5410 7334491Document3 pagesDatasheet - HK An5410 7334491AndreskoiraNo ratings yet

- Data Sheet Dioda PenyearahDocument3 pagesData Sheet Dioda PenyearahHeri SantosoNo ratings yet

- Data Sheet Dioda PenyearahDocument3 pagesData Sheet Dioda PenyearahHeri SantosoNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5783)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Afu 08504 - International Capital Bdgeting - Tutorial QuestionsDocument4 pagesAfu 08504 - International Capital Bdgeting - Tutorial QuestionsHashim SaidNo ratings yet

- Janome DC6030 Sewing Machine Instruction ManualDocument56 pagesJanome DC6030 Sewing Machine Instruction ManualiliiexpugnansNo ratings yet

- ME6404 Thermal EngineeringDocument18 pagesME6404 Thermal EngineeringAnonymous mRBbdopMKfNo ratings yet

- Quiz-Travel - Beginner (A1)Document4 pagesQuiz-Travel - Beginner (A1)Carlos Alberto Rodriguez LazoNo ratings yet

- School Quality Improvement System PowerpointDocument95 pagesSchool Quality Improvement System PowerpointLong Beach PostNo ratings yet

- Imaging Approach in Acute Abdomen: DR - Parvathy S NairDocument44 pagesImaging Approach in Acute Abdomen: DR - Parvathy S Nairabidin9No ratings yet

- Variable Speed Pump Efficiency Calculation For Fluid Flow Systems With and Without Static HeadDocument10 pagesVariable Speed Pump Efficiency Calculation For Fluid Flow Systems With and Without Static HeadVũ Tuệ MinhNo ratings yet

- IP68 Rating ExplainedDocument12 pagesIP68 Rating ExplainedAdhi ErlanggaNo ratings yet

- Socially Responsible CompaniesDocument2 pagesSocially Responsible CompaniesItzman SánchezNo ratings yet

- Bluetooth Home Automation Using ArduinoDocument25 pagesBluetooth Home Automation Using ArduinoRabiNo ratings yet

- WhatsoldDocument141 pagesWhatsoldLuciana KarajalloNo ratings yet

- Identifying The TopicDocument2 pagesIdentifying The TopicrioNo ratings yet

- Electrosteel Castings Limited (ECL) - Technology That CaresDocument4 pagesElectrosteel Castings Limited (ECL) - Technology That CaresUjjawal PrakashNo ratings yet

- Empowerment Technology Reviewer: First SemesterDocument5 pagesEmpowerment Technology Reviewer: First SemesterNinayD.MatubisNo ratings yet

- Time Table For Winter 2023 Theory ExaminationDocument1 pageTime Table For Winter 2023 Theory ExaminationSushant kakadeNo ratings yet

- ASTM D256-10 - Standard Test Methods For Determining The Izod Pendulum Impact Resistance of PlasticsDocument20 pagesASTM D256-10 - Standard Test Methods For Determining The Izod Pendulum Impact Resistance of PlasticsEng. Emílio DechenNo ratings yet

- USA V BRACKLEY Jan6th Criminal ComplaintDocument11 pagesUSA V BRACKLEY Jan6th Criminal ComplaintFile 411No ratings yet

- Suband Coding in MatlabDocument5 pagesSuband Coding in MatlabZoro Roronoa0% (1)

- IntroductionDocument34 pagesIntroductionmarranNo ratings yet

- ROM Flashing Tutorial For MTK Chipset PhonesDocument5 pagesROM Flashing Tutorial For MTK Chipset PhonesAriel RodriguezNo ratings yet

- SQL Server 2008 Failover ClusteringDocument176 pagesSQL Server 2008 Failover ClusteringbiplobusaNo ratings yet

- Individual Sports Prelim ExamDocument13 pagesIndividual Sports Prelim ExamTommy MarcelinoNo ratings yet

- MMW FinalsDocument4 pagesMMW FinalsAsh LiwanagNo ratings yet

- Brain, Behavior, and Immunity: Alok Kumar, David J. LoaneDocument11 pagesBrain, Behavior, and Immunity: Alok Kumar, David J. LoaneRinaldy TejaNo ratings yet

- Mechanics of Deformable BodiesDocument21 pagesMechanics of Deformable BodiesVarun. hrNo ratings yet

- Land Measurement in PunjabDocument3 pagesLand Measurement in PunjabJunaid Iqbal33% (3)

- Key ssl101 Academic Skills For University Success ssl101cDocument196 pagesKey ssl101 Academic Skills For University Success ssl101cHùng NguyễnNo ratings yet

- HistoryDocument144 pagesHistoryranju.lakkidiNo ratings yet

- 5505 SW 138th CT, Miami, FL 33175 ZillowDocument1 page5505 SW 138th CT, Miami, FL 33175 Zillowlisalinda29398378No ratings yet

- Single-Phase Induction Generators PDFDocument11 pagesSingle-Phase Induction Generators PDFalokinxx100% (1)