Professional Documents

Culture Documents

Sistema Embebido - Control Lazo Cerrado

Uploaded by

Danny AlejandroCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Sistema Embebido - Control Lazo Cerrado

Uploaded by

Danny AlejandroCopyright:

Available Formats

Available online at www.sciencedirect.

com

ScienceDirect

Procedia Technology 10 (2013) 840 848

1st International Conference on Computational Intelligence: Modeling Techniques and

Applications (CIMTA) 2013

Embedded System of DC Motor Closed Loop Speed Control based

on 8051 Microcontroller

Reetam Mondala,*,Arumay Mukhopadhyayb, Debdoot Basakc

a

Assistant Professor, Department of Electrical Engineering, JIS College of Engineering (Autonomous), Block-A, Kalyani, West Bengal, India

b,c

Pursuing B.Tech in Electrical Engineering, JIS College of Engineering (Autonomous), Block-A, Kalyani, West Bengal, India

Abstract

The objective of the present paper is designing 8051 Microcontroller based Embedded Closed Loop Speed Control System of

DC Motor to study the reaction of controlled variable to set-point changes. In this present scheme a tachogenerator has been used

as a speed sensor which generates a back emf corresponding to the speed attained by the DC Motor. This instantaneous value of

output voltage provided by the tachogenerator is then compared with the desired voltage corresponding to the desired speed. The

resulting error is used by the microcontroller to control the firing angle of the SCR for controlling the voltage applied to the DC

Motor which in turn adjusts directly the motor speed to attain the desired value. Thus a continuous closed loop speed control

system has been achieved. Proportional (P) Control Algorithm has been used in the present scheme. Experimental results have

been presented to study the reaction of process speed with respect to set-point changes. The system is of low cost and is suitable

for different industrial applications such as subway cars, trolley buses and battery operated vehicles.

2013

2013 The

TheAuthors.

Authors.Published

PublishedbybyElsevier

ElsevierLtd.

Ltd.

Selection

ofof

thethe

University

of Kalyani,

Department

of Computer

Science

& Engineering.

Selection and

andpeer-review

peer-reviewunder

underresponsibility

responsibility

University

of Kalyani,

Department

of Computer

Science

& Engineering

Keywords: Back-emf, DC Motor, Firing angle, Microcontroller, SCR, Set-point change, Speed Control, Tachogenerator.

1. Introduction

The speed of large electrical motors depends on many factors, including supply voltage level, load, and others. A

process control loop regulates this speed through direct change of operating voltage or current for a DC Motor. The

use of power electronic devices for control of these electric machines not only offers better performance with precise

* Reetam Mondal. Tel.: +919903804772; fax: +913322893944/5323.

E-mail address: reetammondal2008@gmail.com

2212-0173 2013 The Authors. Published by Elsevier Ltd.

Selection and peer-review under responsibility of the University of Kalyani, Department of Computer Science & Engineering

doi:10.1016/j.protcy.2013.12.429

Reetam Mondal et al. / Procedia Technology 10 (2013) 840 848

control and fast response but also provides quick maintenance and ease of implementation. In parallel with the

advancement in power electronics there has been great advances in microcontroller based process control systems as

well, due to its flexibility and versatility. Therefore they are widely used in industrial applications because they

provide variable speed characteristics. There are many methods of speed control which has been proposed in past

couple of years. Thadiappan Krisnan [1] has described and designed SCR based speed control unit for a separately

excited DC Motor. In the same year S.A.A.Farag [2] has performed experimental studies on variable speed DC

Shunt Motor driven by a single phase full-wave rectified power supply using SCRs. S.J.Jorna and Y.T.Chan [3]

designed a Microprocessor based DC Motor drive control using SCRs. Multiple operating modes of thyristor

converter has been studied using three phase fully controlled DC Motor motor drive system by Ahms Ula [4]. A

software based feed forward control system of DC Motor has been considered to calculate the load torque by

Tsuyoshi Hanamoto [5]. R.Abdolllah Khoei [6] has presented a closed loop speed control system using a Power

MOSFET and a microprocessor as its controller. Y.S.E Noor Ali, Samsal Bahari Mohd and S.M Bashi Hassan [7]

has investigated the MC68HC11E9 Microcontroller performance for DC Motor Speed control fed by DC chopper.

Speed Control of DC Motor using DC Chopper has been investigated by Y.S.E Noor Ali, Samsal Bahari Mohd, S.M

Bashi Hassan[8]. Abu Zahrin Ahamad [9] has proposed a method to estimate the motor current to control the PWM

Voltage to maintain a constant speed of the DC Motor. H.Chin Choi [10] has presented experimental results of

solving speed and position control problems by using embedded controllers. A simplified approach of

Programmable Logic Controller (PLC) based speed control of DC Motor has been proposed by A.S.Z El Din [11].

Huan Guo-Shing Shing [12] has proposed a LABVIEW aided PID designed controller to monitor and control DC

Motor Speed. Hu Lingyan, Xueqiang Chan and Wu Helei [13] designed a closed loop system of motor speed control

where they adopted the algorithm of PWM to control the armature voltage and motor speed. A motorized golf bag

has been designed by Zhu Haishui [14] which has high efficiency and used a low cost DC Motor controller. Sliding

Mode Control (SMC) Technique was used by R.K Munje, M.R.Roda, E Kushare and Bansidhar [15] to control the

Speed of DC Motor. A conventional cascade speed control system has been realized by Liu Zhijun [16]. Radu Duma

[17] implemented a real time control algorithm for digital motor control using stellaris LM3S8962 microcontroller.

Different speed control techniques of DC Motor has been studied and compared by Rohit Gupta, Ruchika Lamba

and Subhransu Padhee [18]. Ziegler-Nichols tuning formula has been implemented for speed demand applications of

DC Motor by P.M.Meshram [19].

In the present investigation attempts have been made to design and develop AT89c51 Microcontroller based

embedded closed loop speed control system of DC Motor where Proportional (P) Control algorithm has been

implemented to control the firing angle of the SCR for controlling the voltage applied to the DC Motor. In this

design of Speed control system tachogenarator has been used as a speed sensor. The tachogenerator output voltage

after conversion into suitable form by the signal conditioning circuit designed is fed to the microcontroller which

then using suitable control software compares this measured speed signals with the reference or desired signal given

and generates an error. This error is used by the controller to trigger the SCR at an angle measured from the

reference provided by the Zero Crossing Detector (ZCD) circuit to achieve the required voltage across the Motor

terminals which maintains the process speed at desired value.

2. Methodology and Block Diagram

In the proposed design shown in Fig.1. a DC motor of 12 Volt, 1000 rpm, Zero Crossing Detector (ZCD) for zero

reference and a Tachogenerator as a Speed sensor has been used. This system describes the design and

implementation of the AT89c51 Microcontroller based closed loop DC Motor Speed Control System that controls

the speed of a DC motor through Optically Coupled Half Controlled SCR bridge rectifier used as a Motor Driver

circuit. The tachogenerator used gives a back emf in the range of 0 - 10 Volt corresponding to the speed attained by

the DC Motor. This output voltage of the tachogenerator is then given as input to the signal conditioning circuit

which converts the output voltage from 0-10Volt to 0 5 Volt. This analog value of voltage obtained after signal

conditioning is fed to ADC converter which gives the corresponding digital values. The controller unit will sense

this digital data of output voltage of the tachogenerator and will compare with the desired level of voltage

corresponding to the set-point speed. The error obtained is reduced by Proportional (P) Control Algorithm during

which the controller continuously sends triggering pulses through the opto-coupler circuit to the SCRs of the Motor

841

842

Reetam Mondal et al. / Procedia Technology 10 (2013) 840 848

Driver Circuit which controls the voltage applied and hence the speed of the DC motor. Then the error signal

is updated and the cycle is thus repeated. Thus the desired speed is attained.

Fig.1.Block Diagram of Closed Loop DC Motor Speed Control System

3. Hardware Implementation and Discussions

The detailed hardware circuit of Closed Loop Speed Control system described above consists of Speed

Measurement and Monitoring circuit using tachogenerator as a speed sensor, Analog Signal Conditioning Circuit,

Analog-to-Digital (ADC) converter, Zero Crossing Detector (ZCD) circuit, optically coupled Motor Driver circuit

using MCT-2E and interfacing of AT89c51 Microcontroller with the hardware circuit.

3.1. Regulated Power Supply Circuit Designed

Most of the electrical domestic appliances feature microcontroller unit, mechanical relay, or solid state SCR

switches and several loads such as single phase motors, lamps, valves, etc. They are either powered directly via a

regulated power supply or a switch mode power supply (SMPS). A regulated power supply is one that controls the

output voltage or current to a specific value. The controlled value of voltage is held nearly constant despite

variations in either load current or the voltage supplied by the power supply's energy source. They are more

efficient, consume less power and are more compact and weigh less.

Fig.2.Circuit Diagram for Power supply designed

Using voltage regulators

Fig.3. Modified 50/60 Hz Zero Crossing

Detector Circuit Designed

Therefore, in the present investigation a regulated power supply shown in Fig.2. has been designed using full-wave

centre tap rectifier circuit with 12-0-12V, 500mA centre-tap step-down transformer, diodes, 1000F, 63V

843

Reetam Mondal et al. / Procedia Technology 10 (2013) 840 848

electrolytic capacitor and LM 7812, LM 7805 and LM 7912 voltage regulators from where output voltages of

+12V,+5V and -12V respectively are distributed to various units of the system components as required for their

respective operations.

3.2. Modified Zero Crossing Detector (ZCD) Circuit Designed

A Zero Crossing Detector (ZCD) literally detects the transition of the a.c signal waveform from positive to

negative and vice-versa, ideally providing a narrow pulse that coincides exactly with the zero voltage condition.

This will be required by the microcontroller to generate a triggering pulse to the SCRs with some delay from the

zero crossing of the a.c signal. In this present work as shown in Fig.3. a 4.5-0-4.5 Volt, 500mA centre-tap

transformer is used with two diodes and two n-p-n transistors with suitable resistors are used to obtain the outputs of

the ZCD circuit from the collector terminals which are connected to +5V supply. Outputs are obtained from output

terminal 1 and output terminal 2 respectively of the modified Zero Crossing Detector (ZCD) circuit designed.

3.3. DC Motor

Essentially, a DC motor consists of a stator, a rotor and commutator. The stator is the housing of the motor and

contains magnets and the rotor is the rotating part of the motor, which is called the armature, contains conductors

placed in the armature slots through which current flows. The control of speed of these DC Motors can be achieved

by variation of the applied voltage amplitude. This can be achieved by SCR bridge circuit. By variation of the

SCRs firing angle the amplitude of the DC voltage and current of the armature conductors, and hence the speed can

be varied.

3.4. DC Tachogenerator (Speed Sensor)

Tachogenarator is a transducer that converts speed of rotation directly into an electrical signal. They are

commonly used for speed control of rotating equipments. The tachogenerator is coupled with the DC motor.

Tachogenerator gives an output voltage according to the speed attained by the DC motor. The amount of output

voltage (e0) generated by the tachogenerator is given by,

e0=[ npnc 10-8/ (60npp) ] Volt

(1)

where, np= Number of poles,nc= Number of Conductors in the armature, p=flux per pole, npp=parallel brush

between positive and negative brushes, =rpm to be measured.

3.5. Sensor Analog Signal Conditioning Circuit Designed

For successful process control, the parameter to be controlled should be sensed by a suitable sensor, converted

into a signal which will truly represent the parameter and present it to the controller for further action. Signal

conditioning using passive circuits are extensively used for many years. As microcontroller can not recognize

voltage beyond 5 Volt, so it is necessary to convert the voltage signal into 0-5Volt range. In this present research

work we have designed a Sensor analog signal conditioning circuit shown in Fig.4. that converts 0-12Volt output

signal of the tachogenerator into 0-5Volt for each variation in the process variable (speed of the DC Motor).

Fig.4. Sensor Signal Conditioning Circuit Designed

3.6. Optically Coupled Motor Driver Circuit interfaced with 8051 Microcontroller

An opto-isolator, also called an opto-coupler or a photo coupler, is an electronic device designed to transfer

844

Reetam Mondal et al. / Procedia Technology 10 (2013) 840 848

electrical signals by utilizing light waves to provide coupling with electrical isolation between its input and output.

The main purpose of an opto-isolator is to prevent high voltages or rapidly changing voltages on one side of the

circuit from damaging components or distorting transmissions on the other side or low voltage side. In this

investigation opto-coupler MCT-2E has been used which protects the microcontroller which requires low voltage

from over voltage damaging and also prevents the motor to run in the reverse direction.

Fig.5.Interfacing between 8051 microcontroller and DC Motor Driver Circuit

As shown in Fig.5. Half controlled bridge rectifier DC Motor driver circuit with a flywheel diode D3 has been

used. Flywheel diode (D3) is used to eliminate negative spikes in the output voltage and prevent reversal of load

voltage, improves power factor angle and better load performance. Here we have used phase controlled technique,

the basic principle of which is to control the point of time at which the SCRs are allowed to conduct during each

cycle. That is at the instant SCR starts conducting, at that particular point of time control action should start. So at

the point of control SCRs are to be turned ON. This can be achieved by application of Gate signal through the Optocoupler MCT-2E with the help of the Microcontroller at any angle with respect to the applied voltage. This angle

is called the firing angle or delay angle. It should be ensured though the SCR is forward biased it should not be

allowed to conduct until it is triggered.

4. Software Implementation of the Control Unit

According to the general design requirement, hardware circuit, principle of the system, the character of the

hardware connection, each module chip, the function requirement, as well as the improvement of program

readability, transferability and convenient debugging the software design shown in Fig.6. has been modularized.

In this design of closed loop speed control system KEIL Vision 4 Software has been used as the C Compiler. The

KEIL Vision Debugger accurately simulates on-chip peripherals of the 8051 microcontroller.

1

INPUT PORT AND OUTPUT

PORT INITIALIZATION

GET THE ZCD

OUTPUT

ADJUST THE DELAY FOR

THE FIRING PULSE TO

MINIMIZE THE ERROR

SET THE DESIRED VALUE

CALCULATE THE

FIRING ANGLE FOR

REDUCING THE

ERROR

IS

ERROR = 0

?

START

READ THE SPEED ATTAINED

CALCULATE THE

ERROR

Y

2

STOP MODIFYING THE

FIRING ANGLE

Fig.6. Software Flow diagram for the Control Unit.

N

3

Reetam Mondal et al. / Procedia Technology 10 (2013) 840 848

5. Experimental Results and Discussions

In the first step of experimentation, calibration of the DC Motor with and without speed sensor has been done by

varying the voltage across the Motor terminals by varying resistance of potentiometer and recording the process

speed.

5.1. Open Loop Speed Variation of DC Motor with input Voltage (without Speed Sensor)

The input voltage of the DC Motor was varied from 0 12 Volt by using a 10K multi-turn Potentiometer(POT)

for which an open loop speed variation from 150 rpm to 800rpm has been obtained. The open loop variation of

Speed with applied voltage without speed sensor has been shown in Fig.7. This variation of Speed with the

applied voltage will be required later for firing of the SCRs with the microcontroller. The SCRs will be

fired at this voltage levels instead of using a potentiometer to get the required Speed.

Fig.7. Open Loop Speed Variation with applied voltage

Fig.8. Percentage Error Curve

without Speed Sensor

By examining the curve of Fig.7. it is observed that it is almost linear. This leads to the development of linear

approximation of speed attained with applied input voltage by plotting a linear trend line equation and comparing it

with the curve obtained. Thus linear calculated values or true values of motor speed are obtained. The error

percentage is calculated from the measured value and the true values of speed. From the percentage error curve in

Fig.8. it is observed that the percentage error lies between 6%.

5.2. Open Loop Speed Variation of DC Motor with input Voltage (with Speed Sensor)

Fig.9. Open Loop Speed Variation with applied voltage

Fig.10. Percentage Error Curve

(with Speed Sensor)

Fig.9. represents variation of DC Motor Speed with applied voltage with speed sensor. Here the tachogenerator used

as a Speed Sensor is coupled as a load with the shaft of the DC Motor whose speed is to be controlled. While

performing the previous experimentation of open loop speed variation without speed sensor, we have observed that

845

846

Reetam Mondal et al. / Procedia Technology 10 (2013) 840 848

there were large fluctuations of Speed with the variation of applied voltage without the load. But here the deviation

of the curve from the trendline equation is very small which means variation of measured value of motor speed

compared with the calculated true value is also almost linear. The error percentage is calculated from the

measured value and true value of attained Speed. From the percentage error curve in Fig.10. it is observed that

the percentage error lies between 5%.

5.3. Variation of Tachogenerator (Speed Sensor) Output Voltage with Speed attained by DC Motor

Fig.11. represents variation of DC Motor Speed with the tachogenerator (Speed Sensor) output voltage. The

speed variation was obtained from 200 rpm to 600 rpm. The tachogenerator generates a back emf in the range of 010 volt corresponding to each speed attained by the DC Motor. This analog value of voltage is fed to the signal

conditioning circuit which converts it in the range of 0-5 Volt to be fed to the Microcontroller unit.

Fig.11.Variation Tachogenerator Output Voltage with Speed Attained by DC Motor

It is observed from Fig.11. that the variation of the tachogenerator (Speed Sensor) output voltage with the Speed of

the DC Motor compared with the linear trendline equation is almost linear.

5.4. Variation of Signal Conditioning Output with Tachogenerator (Speed Sensor) Output Voltage

The input given to the 8051 Microcontroller should vary with in 0 to 5 volts. The AT89c51 Microcontroller used

cannot recognize analog voltage beyond 5Volt. Therefore, the tachogenerator output voltage is given as input to the

Signal Conditioning circuit designed as shown in Fig.4. which converts the output voltage of the tachogenerator

from 0-10Volt to 0-5 Volt.

Fig.12. Variation of Signal conditioning output with

Fig.13. Percentage Error Curve

Tachogenerator Output Voltage

The variation of the output voltage after signal conditioning with respect to the change in tachogenerator output

voltage is shown in Fig.12. The percentage error curve in Fig.13. shows that the percentage error calculated after

comparing the measured values with the true values obtained from linear trendline equation, lies between -0.4% to 0.8%.

Reetam Mondal et al. / Procedia Technology 10 (2013) 840 848

847

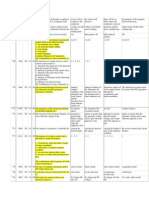

5.5. Digital Signal Conditioning using Analog to Digital Converter (ADC)

The signal conditioning circuit output which is an analog voltage is now converted to its equivalent

digital form using ADC as shown in Table.1. This digital output is given as input to the microcontroller

unit used.

Table.2. Open Loop Voltage and Speed Variation with

Table.1. ADC Digital Output corresponding to the

change in firing angle

Output of the Signal conditioning circuit

Input Binary Delay

Firing

Voltage

Speed

Signal Conditioning

ADC Digital

Combination

angle

from

Attained

Output (Volt)

Output

(Degree) Driver

(rpm)

2.69

01110001

Circuit

3.54

10010001

(Volt)

3.97

10100011

0

0

0x1E

40.75

11.25

588

4.56

10111100

0

1

0x3E

82.01

9.76

496

1

0

0x5E 126.16

7.68

382

1

1

0x7E 174.90

6.62

224

5.6. Variation of Open Loop Voltage with Firing Angle

Table.2. represents the Open Loop Voltage and Speed Variation with change in firing angle of the SCRs from

40.75 to 174.90. This variation has been achieved through C program using AT89C51 Microcontroller. For

different binary combinations of input given to the Microcontroller, the Microcontroller triggers the SCRs with

different delays given in the look-up table written in the C program. It is observed that with the decrease in the firing

angle, the open loop voltage across the load in the driver circuit increases and vice-versa. Thus, Speed of the DC

Motor also increases.

5.7. Closed Loop Speed Control of DC Motor

Table.3. shows that with the increase in set-point Speed in Closed Loop Speed Control System the Speed

Attained by the DC Motor increases proportionally by multiplying the error between the set point and the Speed

attained, with a proportional constant repeatedly until the error is reduced to zero. Thus, Proportional(P)

Control of Speed is obtained with some offset error.

Table.3. Speed attained for a given Set-point Speed

Set-point

Speed attained

Percentage Error

speed (RPM)

(RPM)

(%)

372

390

1.980902

460

484

-2.71335

567

603

1.071955

Fig.14. Set-point Speed Vs Speed Attained Curve

Fig.15. Percentage Error Curve

848

Reetam Mondal et al. / Procedia Technology 10 (2013) 840 848

It is observed from Fig.14. that the variation of Process Speed attained with Set-point Speed is almost linear. The

error percentage is calculated from the measured value and the true value of process Speed attained. It is observed

from Fig.15. that the error percentage calculated from linearity of closed loop speed control system using 8051

Microcontroller is reduced nearly to 2 % compared to 6% of open loop speed control system achieved

previously using potentiometer by varying its resistance and thus the DC Motor terminal voltage.

6. Conclusion

A method of designing a Single phase half-controlled SCR based bridge rectifier circuit used as a DC Motor

driver has been presented with which the speed of DC motor has been successfully controlled by using 8051

microcontroller. Other processors such as 8085 and 8086 Microprocessors could also be used but the system

designer has to add peripherals such as Memory, I/O ports and timers externally to make them functional compared

to 8051 Microcontrollers. Thus 8051 Microcontrollers are ideal for these embedded control applications in which

cost and space are critical. Speed of high rating 220V,8A,1400 rpm DC Motors can also be controlled using

rheostats of 500,2A instead of using potentiometer (POT) by varying the armature voltage as it has been done here

for 12 Volt,1000 rpm DC Motor. But it is observed that speed control using Microcontrollers as digital controller is

more accurate and versatile than any other analog controllers. Both the circuit design and the control algorithm of

the continuous digital controller have been studied. The effectiveness of the design method has been well verified by

experimental results. The percentage error of closed loop speed control system lies approximately between 2%

which has been reduced from 6% obtained in open loop speed control system. Thus, the result shows that the

Microcontroller is a reliable and highly flexible instrument to control the DC Motor with more accuracy and

precision. An offset error has been obtained in the present work which can be eliminated by using PI control

algorithm which provides the future scope of work. The controller implemented has reduced the total hardware

complexity and thus is more convenient and easy to implement.

References

[1]

[2]

[3]

[4]

[5]

[6]

[7]

[8]

[9]

[10]

[11]

[12]

[13]

[14]

[15]

[16]

[17]

[18]

[19]

[20]

Thadiappan Krisnan, A Fast-Response DC Motor Speed Control System,IEEE Transactions on Industry Applications, Vol-IA-10, Issue5, 1974, pp.643-651.

S.A.A Farag, Studies on an SCR Controlled Variable Speed DC Shunt Motor, IEEE Transactions on Power Apparatus and Systems, VolPAS-93, Issue-3,1974, pp.785-792.

S.J Jorna, Y.T. Chan, Microprocessor Control of Position or Speed of an SCR DC Motor Drive, IEEE Transactions on Industrial

Electronics and Control Instrumentation, Vol.27, Issue-3, 1980, pp.228-234.

AHMS Ula, Design and demonstration of a microcomputer controller for an industrial sized DC motor, IEEE Transactions on Energy

Conversion, Vol.3, Issue-1, 1988, pp.102-110.

Tsuyoshi Hanamoto, Speed Control Method of DC Drive System with Speed Observer, International Conference on Industrial

Electronics, Control and Instrumentation, IECON 1991, Vol.1, pp. 613-618.

R. Abdolllah Khoei, Microprocessor based closed-loop speed control system for DC motor using power MOSFET, Proceedings of the

Third IEEE International Conference on Electronics, Circuits, and Systems, ICECS 1996, Vol.2,1996,pp.1247-1250.

Y.S.E Noor Ali, Samsal Bahari Mohd, S.M Bashi Hassan, Microcontroller performance for DC motor speed control system, Power

Engineering Conference, PECon 2003, pp.104-109.

S.B.M Moor, M.Senan.Bashi, M.K Hasan, Microcontroller based adjustable closed-loop dc motor speed control, Proceedings of

Student Conference on Research and Development, SCORED 2003, pp. 59-63.

Abu Zaharin, A study on the DC motor speed control by using back-EMF voltage, Asian Conference on Sensors, 2003, pp.359-364.

H Chiu Choi, Applications of embedded controllers in speed and position controls, International Conference on Industrial Electronics

and Control Applications,ICIECA 2005, pp. 6-7.

A.S.Z El Din, PLC-Based Speed Control of DC Motor, CES/IEEE 5th International Power Electronics and Motion Control Conference,

IPEMC 2006, Vol.2, pp.1-6.

Huan Guo-Shing Shing,PC-based PID speed control in DC motor, International Conference on Audio, Language and Image Processing,

ICALIP 2008 , pp.400-407.

Hu Lingyan, Xueqiang Chan, Wu Helei, Embedded System of DC Motor Speed Control based on ARM, IEEE International Colloquium

on Computing, Communication, Control and Management, ISECS 2008, pp.123-126.

Zhu Haishui, Design on a DC Motor Speed Control, International Conference Intelligent Computation Technology and Automation

(ICICTA), 2010, Vol.2, pp.59-63.

R.K Munje, M.R.Roda, E Kushare & Bansidhar, Speed control of DC motor using PI and SMC, Conference Proceedings (IPEC), 2010,

pp. 943-950.

Liu Zhijun, PWM speed control system of DC motor, International Conference Electronic and Mechanical Engineering and Information

Technology (EMEIT),2011,Vol-3, pp.1301-1303.

Radu Duma, Embedded control of electrical motors, 16th International Conference System Theory, Control and Computing (ICSTCC),

2012 , pp.1-6.

Rohit Gupta, Ruchika Lamba, Subhransu Padhee, Thyristor Based Speed Control Technique of DC Motor: A Compatitive Study,

International Journal of Scientific and Research Publication, Vol-2, Isssue-6, June 2006, pp.1-6.

P.M. Meshram, Tuning of PID controller using Ziegler-Nichols method for speed control of DC motor, International Conference on

Advances in Engineering Science and Management ICAESM 2012, pp.117-122.

Muhammad H. Rashid, Power Electronics Circuits, Devices and Applications, Prentice Hall, 3rd Edition.

You might also like

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- LM7833/LM7847 1A Positive Voltage Regulator GuideDocument6 pagesLM7833/LM7847 1A Positive Voltage Regulator GuideDanny AlejandroNo ratings yet

- 5 Fuente de Voltaje y Freq Variable Con PWMDocument9 pages5 Fuente de Voltaje y Freq Variable Con PWMDanny AlejandroNo ratings yet

- Norma IEEE (Referencias)Document9 pagesNorma IEEE (Referencias)Danny AlejandroNo ratings yet

- Sirena Mini HornDocument1 pageSirena Mini HornDanny AlejandroNo ratings yet

- 4 Sistema Fotovoltaico Con MicroDocument13 pages4 Sistema Fotovoltaico Con MicroDanny AlejandroNo ratings yet

- Monitorizacion Del Aire Usando Micro y Red de SensoresDocument5 pagesMonitorizacion Del Aire Usando Micro y Red de SensoresDanny AlejandroNo ratings yet

- Aplicador de Herbicida Con MicroDocument6 pagesAplicador de Herbicida Con MicroDanny AlejandroNo ratings yet

- Electronica A-03 PDFDocument1 pageElectronica A-03 PDFDanny AlejandroNo ratings yet

- nrf24 TutorialDocument16 pagesnrf24 TutorialBruno MelandriNo ratings yet

- PWM 1Document9 pagesPWM 1Vaibhav PatilNo ratings yet

- Low-Cost Microcontroller-Based Hover Control Design of A QuadcopterDocument7 pagesLow-Cost Microcontroller-Based Hover Control Design of A QuadcopterDanny AlejandroNo ratings yet

- System Architecture For Wireless Sensor NetworksDocument196 pagesSystem Architecture For Wireless Sensor NetworksSurenderMalan100% (1)

- Photovoltaic Maximum Power Point Tracking Control System j17Document9 pagesPhotovoltaic Maximum Power Point Tracking Control System j17Tiago RamosNo ratings yet

- Aplicador de Herbicida Con MicroDocument6 pagesAplicador de Herbicida Con MicroDanny AlejandroNo ratings yet

- 6 Sistema de Manejo de Energia Con Micro para Energias RenovablesDocument9 pages6 Sistema de Manejo de Energia Con Micro para Energias RenovablesDanny AlejandroNo ratings yet

- 3 Oscilador Caotico Con PicDocument6 pages3 Oscilador Caotico Con PicDanny AlejandroNo ratings yet

- Wireless Sensor Systems Security Implications For The Industrial Environment FuhrDocument136 pagesWireless Sensor Systems Security Implications For The Industrial Environment FuhrDanny AlejandroNo ratings yet

- Ficha Tecnica de Espuma 3% Fluoroproteinica Buckeye UlDocument2 pagesFicha Tecnica de Espuma 3% Fluoroproteinica Buckeye UlDanny AlejandroNo ratings yet

- System Architecture For Wireless Sensor NetworksDocument196 pagesSystem Architecture For Wireless Sensor NetworksSurenderMalan100% (1)

- FM 200型錄Document10 pagesFM 200型錄Danny AlejandroNo ratings yet

- 1 Control Motor Pap Con MicroDocument5 pages1 Control Motor Pap Con MicroDanny AlejandroNo ratings yet

- 1 Control Motor Pap Con MicroDocument5 pages1 Control Motor Pap Con MicroDanny AlejandroNo ratings yet

- bc458 PDFDocument7 pagesbc458 PDFKristy BarrettNo ratings yet

- bc458 PDFDocument7 pagesbc458 PDFKristy BarrettNo ratings yet

- AN857 BLDC Motor Control Made Easy (Microchip)Document48 pagesAN857 BLDC Motor Control Made Easy (Microchip)Carlos Iván RuedaNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Use of TurbinesDocument13 pagesUse of TurbinescanscotNo ratings yet

- Dfig de 1.5-3.6 MW AbbDocument4 pagesDfig de 1.5-3.6 MW AbbIvan Contrreras QuispeNo ratings yet

- Pulse Motor Free Energy Generator For Electric Car Charging SystemDocument5 pagesPulse Motor Free Energy Generator For Electric Car Charging Systemرشيد بن صغيرNo ratings yet

- Electrical Machine Drives: Dr. Arsalan ArifDocument6 pagesElectrical Machine Drives: Dr. Arsalan ArifFaraz AhmadNo ratings yet

- 7um62 Machine Protection Automation Device Medium To High Power Siprotec PDFDocument30 pages7um62 Machine Protection Automation Device Medium To High Power Siprotec PDFjose machadoNo ratings yet

- Ee6401 IqDocument6 pagesEe6401 IqK.Swetha PriyadharshiniNo ratings yet

- Ijeet2014 PDFDocument12 pagesIjeet2014 PDFSuparna DebNo ratings yet

- Electromagnetism WorksheetsDocument13 pagesElectromagnetism WorksheetsSer Louis Fetilo FabunanNo ratings yet

- Grounding & Ground Fault Protection of Multiple Generator InstallationsDocument22 pagesGrounding & Ground Fault Protection of Multiple Generator InstallationssparkCE100% (1)

- Standby Diesel Generator Set GuideDocument46 pagesStandby Diesel Generator Set GuideSeindahNyaNo ratings yet

- Atg Ats PanelsDocument9 pagesAtg Ats PanelszainahmedscribdNo ratings yet

- Lab 2 - DC Generator SimulinkDocument6 pagesLab 2 - DC Generator Simulinkaishah atikahNo ratings yet

- EC2259 Lab Manual for Electrical Engineering and Control SystemsDocument83 pagesEC2259 Lab Manual for Electrical Engineering and Control Systemssudheerreddy115100% (1)

- ZJ70DBS Drilling Rig Electrical Drive and Control System User ManualDocument58 pagesZJ70DBS Drilling Rig Electrical Drive and Control System User ManualYugandhar Yugu100% (2)

- Important Text Book Based QuestionsDocument52 pagesImportant Text Book Based QuestionsSonamm YangkiiNo ratings yet

- Industrial Training Report (MAHAGENCO)Document69 pagesIndustrial Training Report (MAHAGENCO)Girish MadaviNo ratings yet

- DC Generator TheoryDocument8 pagesDC Generator TheoryDeep Chowdhury100% (1)

- PPT-5 - Wind Energy - Unit-3Document25 pagesPPT-5 - Wind Energy - Unit-3avinashNo ratings yet

- MIG0600MS Instruction ManualDocument32 pagesMIG0600MS Instruction ManualNitish BhajeNo ratings yet

- MP 128 4aDocument2 pagesMP 128 4aRichel GenabeNo ratings yet

- Technical Data Overview for MCA Plus SystemDocument427 pagesTechnical Data Overview for MCA Plus SystemChris Valdez DrumsNo ratings yet

- Broadcrown PresentationDocument27 pagesBroadcrown PresentationVicki AvolaNo ratings yet

- 021Document1 page021sollyy1971No ratings yet

- Generic Test & Acceptance ChecklistDocument24 pagesGeneric Test & Acceptance ChecklistM Kashif JunaidNo ratings yet

- Comparison of Static and Rotary UPS: White Paper 92Document15 pagesComparison of Static and Rotary UPS: White Paper 92Juan AriguelNo ratings yet

- Hybris IEPS 2022 GuideDocument63 pagesHybris IEPS 2022 Guideedi2805No ratings yet

- HW3-Renewable Energy System EE 733-WindDocument7 pagesHW3-Renewable Energy System EE 733-WindBreaker heartNo ratings yet

- Pse Problems Group AssignmentDocument14 pagesPse Problems Group AssignmentSajid KhanNo ratings yet

- Assignment-I (Power System Stability and Control EE16103)Document2 pagesAssignment-I (Power System Stability and Control EE16103)Prasenjit Dey50% (2)