Professional Documents

Culture Documents

Dash Training Modules2

Uploaded by

dashCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Dash Training Modules2

Uploaded by

dashCopyright:

Available Formats

[Type text]

DASH INSPECTORATE P.LTD

P.

TRAINING COURSES A PROPOSAL

Head Office: VIP Road,

Opp. Bright School

Karelibaug,

Vadodara 390018

Phone: 0265 3952555

URL: www.dashinspectorate.com,

www.dashinspectorate.com

E-mail: dash@dashinspectorate.com

BRAINSTORM

I hated every minute of training, but I said, "Don't quit. Suffer now

and live the rest of your life as a champion."

Muhammad Ali

"You cannot teach a man anything. You can only help him discover

it within himself."

Galileo Galilei

"It is by teaching that we teach ourselves, by relating that we

observe, by affirming that we examine, by showing that we look, by

writing that we think, by pumping that we draw water into the well."

- Henri-Frederic

Frederic Amiel (1821-81),

(1821 81), Swiss philosopher, poet.

p

[Type text]

DASH INSPECTORATE P.LTD

P.

TRAINING COURSES A PROPOSAL

Head Office: VIP Road,

Opp. Bright School

Karelibaug,

Vadodara 390018

Phone: 0265 3952555

URL: www.dashinspectorate.com,

www.dashinspectorate.com

E-mail: dash@dashinspectorate.com

DASH TRAINING MOTTO

DASH INSPECTORATE IS COMMITED TO PROVIDE WORLD

CLASS METHODS

TECHNIQUE AND AIDS TO ENABLE/EXCEL , A TRAINING

CANDIDATE TO

SERVE THE REQUIRED /SPECIFIED/STATED /INSTRUCTIONS

TO BE

CARRIED OUT IN RESPECTIVE FIELD AREA INORDER TO

SERVE THE

SOCIETY AND THE TECHNICAL /ENGINEERING/WELDING

FERTINITY AND

ON TOP OF IT

A SOCIAL RESPONSIBILITY TO

HIMSELF

[Type text]

DASH INSPECTORATE P.LTD

P.

TRAINING COURSES A PROPOSAL

Head Office: VIP Road,

Opp. Bright School

Karelibaug,

Vadodara 390018

Phone: 0265 3952555

URL: www.dashinspectorate.com,

www.dashinspectorate.com

E-mail: dash@dashinspectorate.com

WELDERS

Welders Refresher Training and Qualification Test

DASH conducts Welders Qualification Test as per the requirement of our clients . The training is based on the

specific needs of the customers . Duration of the training programme depends upon the skill level of the welder .

After the Refresher Course the Welder

er may appear for qualification test as per requirement of various codes like

EN 287,ASME, IS, BS , DIN IBR etc.Any approval authority may witness these tests if specified by the

customers.

Certification of Welder / Fitter For Marine (Without Experience)

Welding Technology For Welders

Reclamation Welding Technology For Welders

Foundation Course On Oxy-Fuel

Fuel Gas Welding Process For Welding

Advanced Brazing Course

Foundation Course on Smaw for Beginners

Welding of Stainless Steel /Cast Iron/Hardfacing

Radiographic Quality Welding by Smaw

Pipe Welding by Shielded Metal arc Welding Process

Foundation Course on Ms/Ss by Gas Shielded Tungsten arc Welding (Gtaw)

Welding of Stainless Steel/Aluminium by Shielded Tungsten arc Welding

High Pressure Welding on Ms/Ss

Foundation Course for Welders Conversant with Smaw Process

Welding of Stainless Steel and Aluminium by Gmaw Process

Foundation Course on Gmaw Process (Mig/Mag) for Non Welders

Foundation Course for Submerged arc Welding Process

Foundation Course for Plasma arc Cutting

Foundation Course for Fitters

[Type text]

DASH INSPECTORATE P.LTD

P.

TRAINING COURSES A PROPOSAL

Head Office: VIP Road,

Opp. Bright School

Karelibaug,

Vadodara 390018

Phone: 0265 3952555

URL: www.dashinspectorate.com,

www.dashinspectorate.com

E-mail: dash@dashinspectorate.com

Certification of Welder / Fitter For Marine (Without Experience)

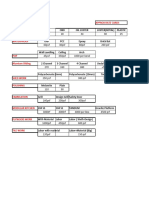

Course Content :

Schedule :

Installation of Welding M/C

DURATION

Operations of SMAW / GTAW / OFGW/MIG /

3 WEEKS (18 DAYS)

SAW Processes

Types of Joint and Welding Procedures

Classification of Electrodes

Welding Defects Causes and Remedies

This session will be based on 10% theoretical inputs and 90% practical inputs.

Welding Technology For Welders

Course Content :

Welding Processes

Basic Welding Metallurgy

Weldability of metals-Ferrous

Ferrous & Non-Ferrous

Non

Weld Defects-their

their cause & remedies

Classification & Coding of welding electrodes

WPS & PQR

Weld distortion stress & control

Welding Consumables

Safety in welding

Schedule :

CODE

COMMENCING

DASH/WW/1 1ST MONDAY OF

EVERY MONTH

DURATION

1 WEEK

This session will be based on 70% theoretical inputs and 30% practical inputs.

Reclamation Welding Technology For Welders

Course Content :

Welding Process

Basic Welding Metallurgy

Welding Consumables

Weldability of metals-Ferrous

Ferrous & Non-Ferrous

Non

Weld defects Causes

Causes and Remedies

Weld distortion, stress and control

Wear Factors and weld surfacing

Schedule :

CODE

COMMENCING

DASH/WW/2 3RD WEDNESDAY OF

EVERY MONTH

This session will be based on 40% theoretical inputs and 60% practical inputs.

DURATION

3 DAYS

[Type text]

DASH INSPECTORATE P.LTD

P.

TRAINING COURSES A PROPOSAL

Head Office: VIP Road,

Opp. Bright School

Karelibaug,

Vadodara 390018

Phone: 0265 3952555

URL: www.dashinspectorate.com,

www.dashinspectorate.com

E-mail: dash@dashinspectorate.com

Foundation Course On Oxy-Fuel

Fuel Gas Welding Process For Welding

Course Content :

Schedule :

Equipment & accessories

CODE

COMMENCING

Selection of consumable

DASH/OF/1 EVERY MONDAY

Joint preparation & procedure

Welding defects their causes and remedies

Safety precautions

DURATION

3 WEEKS

This session will be based on 10% theoretical inputs and 90% practical inputs.

Advanced Brazing Course

Course Content :

Schedule :

Brazing processes

CODE

COMMENCING

Process Characteristics

DASH/OF/2 1ST MONDAY OF

Brazing on different metals and metal

EVERY MONTH

combinations

Different types of Brazing alloys and their uses

Brazing Fluxes

Behavior of brazing joints under different service

conditions

AWS & IS specifications

DURATION

2 WEEK

This session will be based on 10% theoretical inputs and 90% practical inputs.

Foundation Course on Smaw for Beginners

Course Content :

SMAW process Equipment & accessories

Welding consumables

Welding technique

Weld joints ,weld symbols

Welding defects,causes and remedies

Hardfacing Procedure

Cutting by SMAW process

Safety in welding

Schedule :

CODE

COMMENCING DURATION FEES

DASH/SM/1 EVERY

MONDAY

This session will be based on 10% theoretical inputs and 90% practical inputs.

5 WEEKS

TBA

[Type text]

DASH INSPECTORATE P.LTD

P.

TRAINING COURSES A PROPOSAL

Head Office: VIP Road,

Opp. Bright School

Karelibaug,

Vadodara 390018

Phone: 0265 3952555

URL: www.dashinspectorate.com,

www.dashinspectorate.com

E-mail: dash@dashinspectorate.com

Welding of Stainless Steel /Cast Iron/Hardfacing

Course Content :

Schedule :

Weldability of SS

CODE

COMMENCING DURATION FEES

Weldability of Cast Iron

DASH/SM/2 EVERY

1 WEEK

TBA

Welding electrodes for SS Welding

MONDAY

Welding electrodes for CI Welding

Gas welding Consumables for CI Welding

Hardfacing by SMAW and OFW Processes

Various Wear factors and Compatible Hardfacing

alloys

This session will be based on 10% theoretical inputs and 90% practical inputs.

Radiographic Quality Welding by Smaw

Course Content :

Schedule :

SMAW process and process advantages

CODE

SMAW Consumables : Rutile Coated Vs. L H

DASH/SM/3

Electrodes

Classification and coding of electrodes AWS &

IS

Welding Technique

Welding defects and their remedies

Welding Stress : Distortion and its control

Destructive & non destructive testing

Weld design & symbol

COMMENCING

DURATION FEES

1ST MONDAY

OF EVERY

MONTH

2 WEEKS

TBA

This session will be based on 20% theoretical inputs and 80% practical inputs.

Pipe Welding by Shielded Metal arc Welding Process

Course Content :

Schedule :

Welding processes for pipe welding

CODE

COMMENCING

Welding consumables for pipe welding

DASH/SM/4 EVERY

Welding standards and codes for pipe welding

MONDAY

Joint preparations for pipe welding

Welding techniques on different positions

DURATION FEES

4 WEEKS

TBA

[Type text]

DASH INSPECTORATE P.LTD

P.

TRAINING COURSES A PROPOSAL

Head Office: VIP Road,

Opp. Bright School

Karelibaug,

Vadodara 390018

Phone: 0265 3952555

URL: www.dashinspectorate.com,

www.dashinspectorate.com

E-mail: dash@dashinspectorate.com

Welding defects causes & remedies

Weld tests for Radiographic welding

Safety in welding

This session will be based on 10% theoretical inputs and 90% practical inputs.

Foundation Course on Ms/Ss by Gas Shielded Tungsten arc Welding (Gtaw)

Course Content :

Schedule :

GTAW Process & accessories

CODE

COMMENCING

Selection of holders / nozzles Tungsten

DASH/GT/1 EVERY MONDAY

electrodes & shielding gases

Welding techniques

Welding defects and their causes and remedies

Selection of filler metals

Safety precaution

DURATION

2 WEEKS

This session will be based on 10% theoretical inputs and 90% practical inputs.

Welding of Stainless Steel/Aluminium by Shielded Tungsten arc Welding

Course Content :

Schedule :

GTAW Process characteristics & its advantages

CODE

COMMENCING

Power sources, equipment & their properties

DASH/GT/2 1ST MONDAY OF

Shielding gases and their properties

EVERY MONTH

Selection of filler metals

Choice of non-consumable

consumable electrode & electrode

holder

Joint design & welding techniques

Physical & chemical properties of SS & AL

DURATION

1 WEEK

This session will be based on 20% theoretical inputs and 80% practical inputs.

High Pressure Welding on Ms/Ss

Course Content :

Schedule :

GTAW Process characteristics, its advantages & CODE

limitations

Power sources, equipment & accessories

COMMENCING

DURATION

[Type text]

DASH INSPECTORATE P.LTD

P.

TRAINING COURSES A PROPOSAL

Head Office: VIP Road,

Opp. Bright School

Karelibaug,

Vadodara 390018

Phone: 0265 3952555

URL: www.dashinspectorate.com,

www.dashinspectorate.com

E-mail: dash@dashinspectorate.com

Shielding gasses and their properties

Non consumable electrodes & filler metals

Weldability of MS & SS

Joint design & welding techniques

DASH/GT/3 EVERY MONDAY

4 WEEKS

This session will be based on 10% theoretical inputs and 90% practical inputs.

Foundation Course for Welders Conversant with Smaw Process

Course Content :

Schedule :

GMAW Process

CODE

COMMENCING

Equipment & Accessories

DASH/GM/1 EVERY MONDAY

Modes of metal transfer and industrial

application

Selection of welding consumables

Weld defects - their causes & remedies

Welding Safety

DURATION

2 WEEKS

This session will be based on 10% theoretical inputs and 90% practical inputs.

Welding of Stainless Steel and Aluminium by Gmaw Process

Course Content :

Schedule :

Physiochemical properties of Aluminum and

CODE

COMMENCING

Stainless Steel

DASH/GM/2 EVERY MONDAY

Process characteristics, advantages and

limitations

Shielding gases and their effects

Welding techniques in various positions

Important Process parameters and their effects

Filler alloys for SS and Al and their codes

DURATION

1 WEEK

This session will be based on 20% theoretical inputs and 80% practical inputs.

Foundation Course on Gmaw Process (Mig/Mag) for Non Welders

Course Content :

Schedule :

Basics of SMAW & GMAW process

CODE

COMMENCING

Important welding variables of each process and

DURATION

[Type text]

DASH INSPECTORATE P.LTD

P.

TRAINING COURSES A PROPOSAL

Head Office: VIP Road,

Opp. Bright School

Karelibaug,

Vadodara 390018

Phone: 0265 3952555

URL: www.dashinspectorate.com,

www.dashinspectorate.com

E-mail: dash@dashinspectorate.com

their effects on welding

Welding techniques of each process in different

positions

Welding Consumables

Effect of shielding gases on GMAW of Carbon

steel

GMAW Steel filler wires and their codes

GMAW process characteristics

GMAW process advantages

Current/voltage relation in different shielding

gases and their effects on metal transfer modes

in GMAW process

DASH/GM/3 1ST MONDAY

OFEVERY MONTH

4 WEEKS

This session will be based on 20% theoretical nputs and 80% practical inputs.

Foundation Course for Submerged arc Welding Process

Course Content :

Schedule :

Process Definition

CODE

COMMENCING

Process Characteristics

DASH/SA/1 2ND MONDAY OF

Process Equipment

EVERY MONTH

Process Advantages and Limitations

Flux Types

Welding wires & their codes

The importance of edge preparations of MS

plates and their alignments

Effect of changes of important process

parameters on welding

Weld defects and their causes

DURATION

1 WEEK

This session will be based on 20% theoretical inputs and 80% practical inputs.

Foundation Course for Plasma arc Cutting

Course Content :

Process Equipment

Process Advantage

Mechanism of plasma jet formation and the

design of plasma cutting torch

Schedule :

CODE

COMMENCING

DASH/PA/1 3RD MONDAY OF

EVERY MONTH

DURATION

1 WEEKS

[Type text]

DASH INSPECTORATE P.LTD

P.

TRAINING COURSES A PROPOSAL

Head Office: VIP Road,

Opp. Bright School

Karelibaug,

Vadodara 390018

Phone: 0265 3952555

URL: www.dashinspectorate.com,

www.dashinspectorate.com

E-mail: dash@dashinspectorate.com

Importance of Shielding & Plasma gas

Plasma Arc cutting technique

Faulty technique and their effects

This session will be based on 10% theoretical inputs and 90% practical inputs.

Pipe Welding by GTAW & SMAW (6G position - up Hill) Process

8 Weeks

Pipe Welding by GTAW & SMAW (6G position - up Hill) Process

16 Weeks

Welding Technology for Fresh Engineers (DASH

(

CERTFICATION)

40 Hours

Welding Technology for Engineers (DASH

DASH CERTFICATION)

ADVANCE LEVEL

40 Hours

40 Hours

OTHER TRAINING SERVICES

ISO 9000 ,ISO 14000, OHSAS 18000, BSI

27001, BSI 22001, CE, WCM, SIX SIGMA,

TQM

Lead auditor and internal auditor course. ISO 9000, ISO 14000

OHSAS Awareness programme for Engineers and managers.

Welding inspector course (CWI)Certified

Welding Inspector

Certified welding inspector course based on DASH written

practice, ASME SEC IX Latest edition and

d AWS QC1

[Type text]

DASH INSPECTORATE P.LTD

P.

TRAINING COURSES A PROPOSAL

Head Office: VIP Road,

Opp. Bright School

Karelibaug,

Vadodara 390018

Phone: 0265 3952555

URL: www.dashinspectorate.com,

www.dashinspectorate.com

E-mail: dash@dashinspectorate.com

NACE CORROSION COURSES

NACE CIP1,CIP2,PEER,CP ETC

ASNT NDT Level II ,I in VT, ET, MT, PT,

RT, UTNDT Awareness programme for

Engineers and Managers.

Certified courses as per SNT-TC-IA

IA latest guidelines Visual Testing,

Eddy current testing, Magnetic particle testing, Radiographic

testing, Penetrant testing, Helium leak testing, Ultrasonic testing

Special Preparatory courses

AWS (CWI,ASNT NDT Level III, API 510, 653, 570

Pipeline inspection

Gas, Water, Crude transmission based on ASME/API standards.

Line Pipe manufacturing

(Saw pipes (Longitudinal and Spiral ), ERW & Seamless pipes

Coating inspection in pipe and other

equipment

Coated pipe inspection (PE, coal Tar, concrete, FBE in coating

mills). Tank, structure and equipment coating inspection @

AWWA, NACE, BS, ISO, ASME, API , DIN

Inspection engineer course

Material inspection like pipes, plates, valves, fittings, electrodes,

electrodes

equipments, pipes etc.

Shutdown and in-service inspection of

Refineries.

Inspection of Heat exchangers, condensers, boilers, column,

pressure vessel, piping, heater, storage tanks, coolers

Statuary requirement awareness course

CCE, SMPV, BR, Petroleum /pollution, factory act and state and

central Government rules.

QA /QC INSPECTOR 3 MONTHS DIPLOMA COURSE

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5784)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Irganox® 1010 Sds en SGDocument10 pagesIrganox® 1010 Sds en SGPrototypeNo ratings yet

- Dow Corning - Fabricating With XIAMETER® High Consistency Silicone Rubber PDFDocument50 pagesDow Corning - Fabricating With XIAMETER® High Consistency Silicone Rubber PDFLin NiuNo ratings yet

- 16 ACC Issues and ConcernsDocument11 pages16 ACC Issues and ConcernsShivakumarNo ratings yet

- Studies On Degradation of Synthetic Polymer Nylon 6 by FungusDocument8 pagesStudies On Degradation of Synthetic Polymer Nylon 6 by FungusTiten PinastiNo ratings yet

- Air Pollution: by Bibhabasu MohantyDocument54 pagesAir Pollution: by Bibhabasu MohantyJaned PerwiraNo ratings yet

- THE THE: Notes Meter Factor ForDocument19 pagesTHE THE: Notes Meter Factor Forjgarcia388No ratings yet

- Antibacterial Surfaces For Biomedical DevicesDocument15 pagesAntibacterial Surfaces For Biomedical DevicesClever Ricardo ChinagliaNo ratings yet

- NF A49-711 Steel Tubes External Polypropylene CoatingDocument40 pagesNF A49-711 Steel Tubes External Polypropylene CoatingDARYONO sudaryonoNo ratings yet

- History of Heat Pumps - Swiss Contributions and International MilestonesDocument114 pagesHistory of Heat Pumps - Swiss Contributions and International MilestonesAndreeaIrinaNo ratings yet

- SPC F1 IS Unit 2 Water - TeacherEdDocument29 pagesSPC F1 IS Unit 2 Water - TeacherEdFor BackupNo ratings yet

- Applications of Isotopes C11!3!01&C11!3!02Document12 pagesApplications of Isotopes C11!3!01&C11!3!02Olivia M OliverNo ratings yet

- DPP 20220411175616686155Document52 pagesDPP 20220411175616686155Ronit NigamNo ratings yet

- Philips NMR and MRIDocument98 pagesPhilips NMR and MRItsram90No ratings yet

- Hemoglobin Oxidation-Reduction BiochemistryDocument5 pagesHemoglobin Oxidation-Reduction BiochemistryYasmine AzzackiyahNo ratings yet

- Rate CardDocument6 pagesRate CardRavi SrivastavaNo ratings yet

- Spent Coffee Grounds Heat Coffee RoastingDocument15 pagesSpent Coffee Grounds Heat Coffee RoastingMJundiNo ratings yet

- Unit Iv Photochemistry and Spectroscopy: Part A 1. Define PhotochemistryDocument18 pagesUnit Iv Photochemistry and Spectroscopy: Part A 1. Define PhotochemistryKrithigasri MurugesanNo ratings yet

- Novenco Cnd-Cnf-Cat-Gb-Mu15467-0317Document20 pagesNovenco Cnd-Cnf-Cat-Gb-Mu15467-0317budayaNo ratings yet

- Quick Coupling Products Distribution: Catalogue 3800-DS/UKDocument68 pagesQuick Coupling Products Distribution: Catalogue 3800-DS/UKhoussem houssemNo ratings yet

- Disassembly & Assembly Instructions Multistage Centrifugal PumpsDocument28 pagesDisassembly & Assembly Instructions Multistage Centrifugal Pumpsjalw88100% (1)

- Fishing in Drilling OperationsDocument19 pagesFishing in Drilling Operationsmts1234100% (1)

- Bollhoff HeliCoil Plus ImperialDocument48 pagesBollhoff HeliCoil Plus ImperialAce Industrial SuppliesNo ratings yet

- CIL of Preg Robbing GS POXed Slurry For GOLD 100 (FINAL)Document11 pagesCIL of Preg Robbing GS POXed Slurry For GOLD 100 (FINAL)Edgar Barrios JNo ratings yet

- Advantage and Disadvantage of Using Nanoparticles in AgricultureDocument13 pagesAdvantage and Disadvantage of Using Nanoparticles in AgricultureAmjadRashidNo ratings yet

- Int Esws at Y9 Workbook Answers TTPPDocument37 pagesInt Esws at Y9 Workbook Answers TTPPChrystal GraceNo ratings yet

- Nu 5100 5100eg HalfDocument19 pagesNu 5100 5100eg HalfCristian AedoNo ratings yet

- Isolation of Genomic DNA From Plant TissuesDocument4 pagesIsolation of Genomic DNA From Plant TissuesMahathir Mohmed100% (9)

- Rohm & Haas Amberlite IRN 150 LDocument2 pagesRohm & Haas Amberlite IRN 150 LMuhammad ImranNo ratings yet

- Hydrogen Fuel CellDocument27 pagesHydrogen Fuel CellVikash Mohanty100% (12)

- 2009 - Turner, J. W. - Death of A Child From Topical DiphenhydramineDocument2 pages2009 - Turner, J. W. - Death of A Child From Topical DiphenhydramineMaria KandelaNo ratings yet