Professional Documents

Culture Documents

Lindapter

Uploaded by

Bryan PittmanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Lindapter

Uploaded by

Bryan PittmanCopyright:

Available Formats

Lindapter Fixing

Product Guide

BAPP

Group of Companies

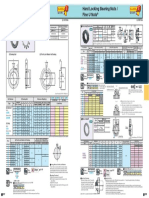

Steelwork Fixings Type A

Nose

Recess

Type A

Malleable iron, bright zinc plated / hot dip galvanised

Clamping Area K

Skirt

Tail

Steelwork clamp with recessed top to hold the bolt head captive whilst

the nut is tightened. The skirt prevents the clamp rotating during

installation. Suitable for flanges up to 8.

The clamp is installed correctly when the area K grips the flange.

The tail must be chosen to suit the thickness of the flange being gripped.

For full specification data and typical application examples,

please refer to the Lindapter Design Guide available

free of charge from BAPP. For Higher loads the Type AF should

be used on page 4.

T

V

X

Product

Code

Order example: A16 medium HDG

Bolt 8.8

Z

Safe Working Loads

(5:1 Factor of Safety)

Tensile / 1 Bolt

Frictional / 2 Bolts

kN

kN

1.0

-

Torque

Nm

6

Y

mm

16

X

mm

8

Dimensions

Tail Length V

short medium long

mm

mm

mm

4

-

T

mm

4

Width

mm

20

A08

M8

A10

M10

1.5

20

20

11

26

A12

M12

5.8

0.7

69

26

13

4.5

9.5

29

A16

M16

7.3

1.5

147

30

16

5.5

11

36

A20

M20

14.7

285

36

19

10

12.5

10

46

A24

M24

19.7

4.5

491

48

25

12

16

12

55

Stockists of Industrial Fasteners, Engineering

Supplies and Health & Safety Products

BAPP

Group of Companies

Steelwork Fixings Type B

Type B

Malleable iron, bright zinc plated / hot dip galvanised

Nose

Flat Top

T

V

Y

Clamping

Area K

Skirt

Tail

Steelwork clamp with flat top which allows the bolt head or

nut to be rotated. Suitable for use with all bolts, studs, tie

rods and J-bolts, and flanges up to 8.

The clamp is installed correctly when the area K grips the

flange. The tail must be chosen to suit the thickness of the

flange being gripped. For Higher loads the Type AF should

be used on page 4.

Product

Code

Order example: B16 medium HDG

Bolt 8.8

Z

Safe Working Loads

(5:1 Factor of Safety)

Tensile / 1 Bolt

Frictional / 2 Bolts

kN

kN

1.0

-

Torque

Nm

6

Y

mm

16

X

mm

8

Dimensions

Tail Length V

short medium long

mm

mm

mm

4

-

T

mm

8

Width

mm

20

B08

M8

B10

M10

1.5

20

20

11

10

26

B12

M12

5.8

0.7

69

26

13

4.5

9.5

12

29

B16

M16

7.3

1.5

147

30

16

5.5

11

16

36

B20

M20

14.7

285

36

19

10

12.5

20

46

B24

M24

19.7

4.5

491

48

25

12

16

24

55

Stockists of Industrial Fasteners, Engineering

Supplies and Health & Safety Products

BAPP

Group of Companies

Steelwork Fixings Type LR

Type LR

max Y

min Y

min X

max X

Malleable iron, bright zinc plated / hot dip galvanised

min T

max T

max V

min V

Saddle

Slot

Nose

Self adjusting clamp for various flange thicknesses and slopes up

to 15. The leg of the saddle prevents the clamp rotating during

installation. The LR tail spans slotted holes. For thicker flanges

packings P1 long and P2 long are available.

Order example: LR10 BZP

Safe Working Loads

(5:1 Factor of Safety)

Tensile / 1 Bolt

Frictional / 2 Bolts

kN

kN

1.5

-

Product

Code

Bolt 8.8

Z

LR10

M10

LR12

M12

5.8

LR16

M16

7.3

LR20

M20

LR24

M24

Leg

Clip

Tail

Torque

Nm

20

Clamping Range

V

mm

3 - 10

Y

mm

21 - 24

Dimensions

X

T

Width with Saddle

mm

mm

mm

24 - 26

21 - 24

33

0.7

69

3 - 12

26 - 29

25 - 31

25 - 29

1.5

147

3 - 16

30 - 35

34 - 37

30 - 36

46

14.7

285

3 - 20

42 - 49

46 - 51

41 - 48

57

19.7

4.5

491

3 - 24

47 - 57

52 - 58

44 - 54

76

Stockists of Industrial Fasteners, Engineering

Supplies and Health & Safety Products

39

BAPP

Group of Companies

Steelwork Fixings Type AF

Type AF

SG iron, hot dip galvanised

Without washer: For bolt grade 8.8

With washer inverted Type AFW

for bolt grade 10.9 with larger hexagons

(M12 - M20)

With washer Type AFW

Flat Top

Recess

Nose

Skirt

Tail

Typical Applications

High friction clamp with recessed top to hold bolt head captive whilst

the nut is tightened. Can be combined with type CF. The skirt prevents

the clamp rotating during installation. The tail of the AF spans across

slotted holes. For flanges up to 10. Washer type AFW available

(see illustration).

T

V

Y

1)

2)

3)

4)

Frictional Load figures are based on Type AF and Location plates in hot dip galvanised finish

Shot blast and painted steelwork

3.2:1 factor of safety

For HR or HV bolts (hot dip galvanised and lubricated) please refer to manufacturers

recommendation for torque figures.

Order example: AF12 short

Bolt

Safe Working Loads

(5:1)

Factor of Safety (2:1)

Tensile / 1 Bolt

Frictional1) / 2 Bolts

Painted Steelwork2)

Galv. Steelwork

kN

kN

kN

8.5

3.4

3.9

Dimensions

Tail Length V

T

short medium Type AF Type AF with AFW Width

mm mm

mm

mm

mm

5

12.5

17

22

39

Product

Code

Grade

AF12

M12

8.8

AF16

M16

8.8

16.0

8.0

AF20

M20

8.8

26.3

13.0

AF24

M24

8.8

40.0

24.0

AF12

M12

10.94)

10.0

AF16

M16

10.94)

19.5

AF20

M20

10.94)

30.0

20.0

25.0

647

40

39

10

18

25

31

56

AF24

M24

10.94)

62.53)

28.0

35.0

1000

48

60

15

30

32

42

82

Torque

Nm

90

Y

mm

29

X

mm

27

10.0

240

35

37

15

22

27

49

16.0

470

40

39

10

18

25

31

56

30.0

800

48

60

15

30

32

42

82

4.0

5.2

130

29

27

12.5

17

22

39

11.0

12.0

300

35

37

15

22

27

49

Stockists of Industrial Fasteners, Engineering

Supplies and Health & Safety Products

BAPP

Group of Companies

Steelwork Fixings Type BR

Type BR

Malleable iron, bright zinc plated / hot dip galvanised

Flat Top

Nose

T

V

Y

Clamping

Area K

Tail

Skirt

Versatile clamp for steel beams or rails. The skirt prevents the clamp

rotating during installation. The BR tail spans slotted holes.

Suitable for flanges up to 8.

Order example: BR12 short HDG

Product

Code

Bolt 8.8

Z

BR12

12

Safe Working Loads

(5:1 Factor of Safety)

Tensile / 1 Bolt

Frictional / 2 Bolts

kN

kN

5.8

0.7

Torque

Nm

69

Y

mm

26

X

mm

13

Dimensions

Tail Length V

short medium

mm

mm

4

6

T

mm

13

Width

mm

29

BR16

16

7.3

1.5

147

30

16

16

35

BR20

20

14.7

285

36

19

10

19

42

BR24

24

19.7

4.5

491

48

25

12

25

54

Stockists of Industrial Fasteners, Engineering

Supplies and Health & Safety Products

BAPP

Group of Companies

Steelwork Fixings Type HW/HC

Type HW/HC

Malleable iron, bright zinc plated /

hot dip galvanised

X

Z

Hemispherical Washer

W2

W1 L

Y

10

Hemispherical Cup

For vertical suspension on angled surface of up to 10 swing either side of

the vertical. The hemispherical washer (HW) can be used without the cup.

Loads are subject to applications.

Product Code

Hemispherical Washer

Hemispherical Cup

mm

Order example: HC10 BZP

Hemispherical Washer

X

W1

mm

mm

Hemispherical Cup

Y

W2

mm

mm

Dimensions

Hemispherical Washer & Cup

R

L

mm

HW06

19

HW08

22

10

HW10

HC10

25

12

32

12

13

14

HW12

HC12

29

12

35

12

14

16

HW16

HC16

34

16

41

16

17

19

HW20

HC20

44

19

54

19

22

24

HW24

HC24

57

25

67

25

29

32

Stockists of Industrial Fasteners, Engineering

Supplies and Health & Safety Products

BAPP

Group of Companies

Floor Fixings Type FF

A - Nominal Clearance

Type FF - Floorfast

90

Malleable iron, Stainless Steel Grade 316,

bright zinc plated / hot dip galvanised

D

t

t1

Flange Width

Unique stepped

clamping face

Ferrule

Countersunk

Product

Code

Socket

setscrew

13

Position of hole centres:

flange width - A + 13mm

Bolt1)

Z

Floorplate

Thickness

t

mm

Flange

Thickness

mm

Countersunk for Bolt

BZP

HDG

D

mm

Hole

d

mm

Countersunk Depth for Bolt

BZP

HDG

t1

mm

Torque

Hexagon

Key

Nm

mm

FF08

M8

4.5 - 12

3 - 15

17

11

FF10

M10

5 - 12

3 - 15

11

21

19

22

FF12

M12

6 - 12

3 - 15

13.5

25

23

5.8

4.8

22

1) In hot dip galvanised (M10 and M12) a slotted countersunk screw is supplied.

20

Order example: FF12 HDG

Installation

Z

60

The product consists of a malleable iron body casting

with a countersunk socket screw; the eccentric stepped

web of the casting allows it to lock under the steelwork

providing full face contact when torque is applied.

For thicker flanges packing pieces will be supplied.

Lloyds Register Type Approval covers clamping force

and vibration.

1.

2.

1. Pre-assemble Floorfast on underside of floorplate

with stepped surface facing inwards.

2. Align castings with straight edge parallel

to the edge of the plate and hand tighten.

3. Lay floorplate into position

4. Using a hexagon key release the countersunk screw

one full turn.

5. Tighten down the countersunk socket screw.

3.

4.

5.

Removal

Using a hexagon key, give the Type FF one full anticlockwise turn to release connection from the flange.

Stockists of Industrial Fasteners, Engineering

Supplies and Health & Safety Products

BAPP

Group of Companies

Floor Fixings Type GF

Top Hat Bracket

Type GF - Grate-Fast

GF08 / GF10

Body: Malleable iron, mechanical galvanised

Top Hat: Mild Steel, mechanical galvanised

Socket Head

Cap Screw

GF210

D

min X

max X

Cast Body

Product

Code

GF08

GF10

GF210

Bolt

Z

Flange

T

mm

3 - 19

3 - 19

3 - 19

M8

M10

M10

Grating Bar

Depth

D

mm

22 - 38

20 - 30

19 - 32

Grating Bar

Width

W

mm

5 - 10

3-7

3 - 6.5

Bar

Distance

X

mm

19 - 48

25 - 45

30

Body

Width

Torque

Hexagon

Key

mm

16

20

20

Nm

5

11

11

mm

6

8

8

Order example: GF08

Installation

1. Position pre-assembled Grate-Fast with body

between grating bars and nose pointing towards the

steelwork. The arrows on the top hat bracket should

also be pointing towards supporting steelwork and

bracket itself resting on the bearing bars.

2. Slide Grate-Fast towards steelwork until nose fits

under the beam flange. Where necessary adjust

body/screw to approximate flange thickness/grating

depth.

Grating fixing for rectangular open bar grating with cast main body giving

superior clamping force.

GF10 with wider top-hat bracket for different grating sizes.

GF210 for use with 30mm width floor grating bars only.

GF08 with stainless steel top-hat bracket for GRP grating.

Lloyds Register Type Approval covers clamping force and vibration.

1.

2.

3.

3. Tighten cap screw; the Grate-Fast body will

automatically rotate until it locks under the bearing

bar, with the nose under the flange. Continue

tightening to the recommended torque.

Stockists of Industrial Fasteners, Engineering

Supplies and Health & Safety Products

BAPP

Group of Companies

Accessories for Type A & B

Type CW - Clipped Washer

Type P1 short / P2 short

Mild Steel, bright zinc plated /

hot dip galvanised

Mild Steel, malleable iron,

bright zinc plated / hot dip galvanised

T

Y

TP1

M12

38

P1S16

P2S16

44

P1S20

P2S20

57

P1S24

P2S24

CW12

M12

Y

mm

6

Dimensions

X

T

mm

mm

19.5

2.5

CW16

M16

17.5

CW20

M20

10

22

CW24

M24

12

29

Width

mm

31

Order example: CW12 BZP

Product

Code

P1

P2

P1S12 P2S12

Bolt

Z

Packing used to adjust the tail length of the clamp to meet

differing beam flange thicknesses.

Packing used to adjust the tail length of the clamp to meet

differing beam flange thicknesses.

Product

Code

TP2

Bolt

Z

Dimensions

TP1 TP2

mm mm

6

12

Width

mm

30

Y

mm

6

X

mm

16

M16

21

16

35

M20

10

23

10

20

43

M24

12

32

12

24

54

Order example: P1S12 BZP

Stockists of Industrial Fasteners, Engineering

Supplies and Health & Safety Products

BAPP

Group of Companies

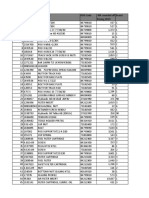

Cavity Fixings Type HB

Type HB - Hollo-Bolt

Collar

Steel, bright zinc plated plus JS 500

Steel, hot dip galvanised

Stainless Steel Grade 316

Rubber Washer

Sleeve

Suitable for hollow sections, tubes and where access is available from

one side only. For high corrosion protection the Hollo-Bolt comes with

additional JS500 protection as standard or hot dip galvanised.

Sizes M16 and M20 have a patented collapse mechanism for

optimised clamping force. Speedy installation with standard tools and

for the Type Hollo-Bolt Flush Fit with installation nut. (One free per box)

Cone

Awarded the Design Councils Millennium Product status for

innovation in the year 2000.

Hollo-Bolt: M8, M10, M12

H

Hollo-Bolt: M16, M20

H

L

d

D

Rubber Washer

W

Rubber Washer compressed /

increased clamping force

Head Variations

r8

10

Flush Fit

Countersunk

(Head)

Hexagonal Head

Socket Head

Cap Screw

Button Head Security

M8-M12

M8-M16

M8-M20

Supplied to order

Supplied to order

Stockists of Industrial Fasteners, Engineering

Supplies and Health & Safety Products

BAPP

Group of Companies

Cavity Fixings Load Table - Type HB

Type HB - Hollo-Bolt

Torque

1)

Length

Outer

d

mm

Height

2)

11

min t

mm

-

L

mm

30

49

68

HB08-1

HB08-2

HB08-3

M8x50

M8x70

M8x90

HB10-1

HB10-2

HB10-3

M10x55

M10x75

M10x90

3 - 22

22 - 41

41 - 60

HB12-1

HB12-2

HB12-3

M12x60

M12x90

M12x110

3 - 25

25 - 47

47 - 69

HB16-1

HB16-2

HB16-3

M16x75

M16x100

M16x120

HB20-1

HB20-2

HB20-3

M20x90

M20x120

M20x150

H D

mm mm

Dimensions

mm

140x140x5.0

150x150x6.3

200x200x10.0

100x100x6.3

140x140x5.0

140x140x8.0

150x150x6.3

180x180x8.0

200x200x10.0

140x140x5.0

140x140x8.0

150x150x6.3

180x180x8.0

200x200x10.0

100x100x6.3

100x100x10.0

140x140x5.0

140x140x6.3

140x140x8.0

140x140x12.5

150x150x6.3

180x180x8.0

200x200x10.0

140x140x6.3

140x140x8.0

140x140x10.0

140x140x12.5

150x150x6.3

180x180x8.0

200x200x10.0

kN

4.0

4.0

4.0

7.0

6.0

8.5

8.0

7.0

8.0

6.5

10.5

10.0

10.0

10.5

13.5

18.5

8.0

15.0

20.0

21.0

11.5

17.0

15.0

16.0

23.0

25.0

35.0

12.5

18.0

19.0

A/F

Material

W

mm

3 - 22

22 - 41

41 - 60

(5:1 Factor of Safety)

Tensile

Single

Shear

mm

Nm

13.75

22

19

23

S275

30

48

67

17.75

29

24

45

S275

35

57

79

19.75

32

30

80

S275

12 - 29

29 - 50

50 - 71

8

8

8

41.5

63

84

25.75

38

36

190

S275

12 - 34

34 - 60

60 - 86

8

8

8

50

76

102

32.75

10 51

46

300

S275

kN

5.0

10.0

15.0

1) The thickness of the outer ply needs to be at least 8mm.

If necessary spacer washers should be used beneath the collar

to increase the thickness to 8mm.

2) The Hollo-Bolt

can be used on a wide variety of SHS sections;

those shown above are only representative to give an

indication of variations in Hollo-Bolt capacity.

The safe working loads, in both tension and shear,

are applicable to the Hollo-Bolt only, failure of the section,

particularly on those with thin walls and a wide chord face,

could occur at a lower figure and its strength should be

checked using the Green Book design guide.

Order example: HB08-1 BZP plus JS 500

30.0

40.0

Stockists of Industrial Fasteners, Engineering

Supplies and Health & Safety Products

BAPP

Group of Companies

Cavity Fixings Load Table - Type HBFF

Type HBFF - Hollo-Bolt Flush Fit

C ode

S unk

Bolt

T h ic k n e s s

mm

P ly

Length

Outer

d

mm

W

mm

min t

mm

L

mm

Height

H D

mm mm

To o l

A/F

Material

mm

Nm

HBFF08-1

M8x50

10 - 27

30

13.75

24

19

23

S275

HBFF10-1

M10x60

12 - 27

10

30

17.75

30

24

45

S275

HBFF12-1

M12x60

12 - 30

10

35

19.75

33

30

80

S275

Dimensions

mm

140x140x5.0

150x150x6.3

180x180x8.0

200x200x10.0

100x100x6.3

140x140x5.0

140x140x8.0

150x150x6.3

180x180x8.0

200x200x10.0

140x140x5.0

140x140x8.0

150x150x6.3

180x180x8.0

200x200x10.0

(5 : 1 F a c to r o f S a fe ty )

Tensile

Single

Shear

kN

4.0

4.0

4.0

4.0

7.0

6.0

8.5

8.0

7.0

8.0

6.5

10.5

10.0

10.0

10.5

kN

5.0

10.0

15.0

Order example: HBFF08-1 BZP plus JS 500 without / with ____ installation nut(s)

12

Stockists of Industrial Fasteners, Engineering

Supplies and Health & Safety Products

BAPP

Group of Companies

You might also like

- Uxa6 65BDDocument2 pagesUxa6 65BDBryan PittmanNo ratings yet

- 08 Dynamic Wheel Loadsfrom Heavy Vehiclesedr 93545Document11 pages08 Dynamic Wheel Loadsfrom Heavy Vehiclesedr 93545Oladunni AfolabiNo ratings yet

- PDS StructuralEnterprise LTR 0517 LR FDocument2 pagesPDS StructuralEnterprise LTR 0517 LR FJean Paul Ramirez AzañeroNo ratings yet

- ASI Standard Steelwork Drawing Notes V10Document19 pagesASI Standard Steelwork Drawing Notes V10thakrarhitsNo ratings yet

- 140mm Pure Wings 2 Fans Silent CoolingDocument2 pages140mm Pure Wings 2 Fans Silent CoolingBryan PittmanNo ratings yet

- Type WF by Lindapter 1152Document1 pageType WF by Lindapter 1152Bryan PittmanNo ratings yet

- ASI TN004 V2 Design Properties Crane BeamsDocument4 pagesASI TN004 V2 Design Properties Crane Beamskayakeras3335No ratings yet

- 11HandbookIndoorAirQuality2018 PDFDocument133 pages11HandbookIndoorAirQuality2018 PDFBryan PittmanNo ratings yet

- Tips For Avoiding Crane Runway ProblemsDocument25 pagesTips For Avoiding Crane Runway ProblemsAshishNo ratings yet

- Pds Ramsteel LTR en LRDocument2 pagesPds Ramsteel LTR en LRVengatesh HariNo ratings yet

- Beam ProductsDocument1 pageBeam ProductsBryan PittmanNo ratings yet

- Wind Speed Design GuideDocument4 pagesWind Speed Design Guidepaperinik_papNo ratings yet

- Structaset 401 TDS April 2015Document12 pagesStructaset 401 TDS April 2015Bryan PittmanNo ratings yet

- Walkway 1Document5 pagesWalkway 1Bryan PittmanNo ratings yet

- Inspection and Testing: 7.1. Flaws, Non - Conformities and DefectsDocument8 pagesInspection and Testing: 7.1. Flaws, Non - Conformities and Defectsit4scribdNo ratings yet

- Inspection and Testing: 7.1. Flaws, Non - Conformities and DefectsDocument8 pagesInspection and Testing: 7.1. Flaws, Non - Conformities and Defectsit4scribdNo ratings yet

- MC3423 DDocument10 pagesMC3423 DBryan PittmanNo ratings yet

- RFS UD Series DipoleDocument2 pagesRFS UD Series DipoleBryan PittmanNo ratings yet

- Create A PDF File: Exercise 1 and Exercise 2 Produce The Same Result. Choose The One That Works Best For YouDocument6 pagesCreate A PDF File: Exercise 1 and Exercise 2 Produce The Same Result. Choose The One That Works Best For YouBryan PittmanNo ratings yet

- Deflection Check BeamDocument2 pagesDeflection Check BeamAnonymous wWOWz9UnWNo ratings yet

- Pull Out StrengthDocument2 pagesPull Out Strengthambryx2001100% (2)

- Rev It Structure 2010 LinkDocument6 pagesRev It Structure 2010 LinkozbuildNo ratings yet

- Aalco Metals LTD Aluminium Alloy 6060 T5 T595 144Document2 pagesAalco Metals LTD Aluminium Alloy 6060 T5 T595 144Bryan PittmanNo ratings yet

- Rubble Mound Breakwater: Christian Linde OlsenDocument11 pagesRubble Mound Breakwater: Christian Linde OlsenFoong Tong WengNo ratings yet

- Pull Out StrengthDocument2 pagesPull Out Strengthambryx2001100% (2)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- HLB Flier MisumiDocument1 pageHLB Flier MisumiJayden BarnesNo ratings yet

- 2013 Kawasaki KX65AD Service Repair Manual PDFDocument25 pages2013 Kawasaki KX65AD Service Repair Manual PDFjkmoseiodkk0% (1)

- BS 2151.01, 2151.011-U Manual de ManttoDocument28 pagesBS 2151.01, 2151.011-U Manual de ManttoAndrés Rivera MartínezNo ratings yet

- ASME PCC-1 - 2013 Guidelines For Pressure Boundary Bolted Flange Joint AssemblyDocument4 pagesASME PCC-1 - 2013 Guidelines For Pressure Boundary Bolted Flange Joint AssemblyIrshad AhmadNo ratings yet

- Wirtgen Price List 2019 PDFDocument2,441 pagesWirtgen Price List 2019 PDFram singh70% (10)

- High Masts Installation GuideDocument10 pagesHigh Masts Installation GuidemaninderpreetNo ratings yet

- Instruction Sheet Is-Cn346 Style Number: Cn346An: Package ContentsDocument4 pagesInstruction Sheet Is-Cn346 Style Number: Cn346An: Package Contentsdayshift5No ratings yet

- Nuts and Washers DetailsDocument0 pagesNuts and Washers DetailsfastenersworldNo ratings yet

- TC56 Combine Parts ManualDocument783 pagesTC56 Combine Parts ManualgabrieltractoNo ratings yet

- Operator'S Manual: John DeereDocument28 pagesOperator'S Manual: John DeerejcnegNo ratings yet

- Plays-Kool MSA Approved Cage Fitting InstructionsDocument3 pagesPlays-Kool MSA Approved Cage Fitting Instructionsnovocaine67No ratings yet

- .Trashed 1660206808 SK1020 Shop ManualDocument316 pages.Trashed 1660206808 SK1020 Shop ManualJaime MurilloNo ratings yet

- Propeller Shaft and Rear Axle AssemblyDocument16 pagesPropeller Shaft and Rear Axle AssemblyMonte CarloNo ratings yet

- Flange Gasket Installation-InstructionsDocument4 pagesFlange Gasket Installation-InstructionstonytayicNo ratings yet

- 2023 CRF250R Competition HandbookDocument126 pages2023 CRF250R Competition HandbookH:H H:HNo ratings yet

- LOGOSOL Big Mill System Manual UKDocument52 pagesLOGOSOL Big Mill System Manual UKRazman100% (1)

- Multi Port Valve ManualDocument2 pagesMulti Port Valve ManualJithin JamesNo ratings yet

- Enwl Approved Equipment List 26-10-20Document155 pagesEnwl Approved Equipment List 26-10-20Mosa Elnaid ElnaidNo ratings yet

- Service Manual Huskie Old Style HH750,1000Document44 pagesService Manual Huskie Old Style HH750,1000Somboonpanmaingam PapromNo ratings yet

- GRV Circular Formwork Instructions For Assembly and UseDocument58 pagesGRV Circular Formwork Instructions For Assembly and UseVivekNo ratings yet

- End Carriage DFW S E AssmeblyDocument52 pagesEnd Carriage DFW S E AssmeblycutenganNo ratings yet

- Industrial Maintenance Loctite® Wastewater Treatment GuideDocument6 pagesIndustrial Maintenance Loctite® Wastewater Treatment GuideDragoslav DzolicNo ratings yet

- Abey Plumbers Guide 2017 WebDocument31 pagesAbey Plumbers Guide 2017 WebalfredharveyeNo ratings yet

- Ve Pump Denso Repair Manual PDFDocument32 pagesVe Pump Denso Repair Manual PDFNikola Mitev100% (2)

- Overhead transmission lines spacersDocument20 pagesOverhead transmission lines spacersKy TaNo ratings yet

- Ata 78 I-Aea1Document29 pagesAta 78 I-Aea1Antonio CorteNo ratings yet

- CBR250RDocument29 pagesCBR250RShone Munasinghe50% (2)

- Woodco: Hub and Clamp Reference ChartDocument11 pagesWoodco: Hub and Clamp Reference Chartkrishnsgk100% (2)

- Kawasaki Zx-6R 2005 Parts CatalogDocument71 pagesKawasaki Zx-6R 2005 Parts CatalogAlejandro MercadoNo ratings yet