Professional Documents

Culture Documents

SBM TECHNOLOGY - Advanced High Pressure Cooling Valve

Uploaded by

Ericsson BotchweyOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

SBM TECHNOLOGY - Advanced High Pressure Cooling Valve

Uploaded by

Ericsson BotchweyCopyright:

Available Formats

SBM TECHNOLOGY

Cooling / Air Recovery Valve

Part no. VSP15203x

Advanced high pressure seal technology

Integrated non-return valve

Robust, compact & lightweight design

Proven & reliable technology

Maintenance & service friendly

Excellent response time & repeatability

Low power consumption (2W)

Technical data

Typical application

Switching functions:

2/2-way valve, normally closed

Operation:

Poppet valve, solenoid pilot actuated

Nominal size / Kv value:

16mm / 7.4 m3/h

Type of mounting:

Direct surface mounting or mounting on base plate

Medium:

Compressed air (purity class 7.4.4) 1)

40m filtered, non-lubricated

Cooling or air recovery valve for stretch blow

moulding machines.

For rotary and linear SBM machines.

1)

Ordering information

For model numbers please refer to page 2.

3D CAD files are available on request.

Materials

Aluminium parts:

Valve piston & seal:

acc. to ISO 8573-1:2001

Pre-lubrication:

USDA H1 compliant (registered NSF class H1)

Pressure range (minmax):

Operating pressure

340 bar

Pilot air supply (PAS)

67 bar

Port sizes (when fitted on base plate):

Inlet (1)

G3/4 female

Outlet (2)

G3/4 female

Pilot air supply (PAS)

G1/8 female

Pilot valve:

3/2 NO sol/spring valve

24V DC / 2W, without manual override

Connector interface acc. to

15mm industry standard form C (9.4mm)

Maintenance free life time:

Typically exceeds 25 Million cycles

Temperatures:

Ambient temperature

0+50C

Medium temperature

+3+30C

01/08

O-rings:

Screws:

Retainer ring:

Closing balls:

anodised

FDA compliant

synthetic material

NBR

steel, zinc coated

tempered spring steel

stainless steel

Pneumatic diagram

Model numbers

Configuration diagram

Valve dimensions

Mounting instruction

Accessories (Plugs)

Our policy is one of continued research and development. We therefore reserve the right

to amend, without notice, the specification given in this document.

see page

2

2

3

4

6

8

N/VFB-003.01

SBM TECHNOLOGY Cooling / Air Recovery Valve

Pneumatic diagram

(Diagram shows Cooling / Air Recovery (AR) Valve without base plate.)

For configuration diagrams of Cooling / Air Recovery Valve in combination with PET Blow Valve Block please refer to next

page.

Model numbers

Model

Description

Weight

VSP152030

Cooling / Air Recovery Valve

on base plate

1.7 kg

VSP152031

Cooling / Air Recovery Valve

(without base plate)

1.2 kg

For part numbers on accessories please refer to page 8.

For part numbers on spare and wear parts as well as for data on response times and repeatability please refer to the

maintenance & instruction manual (ref. no. VSP152096).

For ordering manifold unit combining Cooling / Air Recovery Valve with PET Blow Valve Block, please contact Norgren.

N/VFB-003.02

Our policy is one of continued research and development. We therefore reserve the right

to amend, without notice, the specification given in this document.

01/08

SBM TECHNOLOGY Cooling / Air Recovery Valve

Configuration diagram

Diagram shows Cooling Valve in combination with PET Blow Valve Block (VSP152050):

Diagram shows Air Recovery Valve in combination with PET Blow Valve Block (VSP152050):

Note:

For further information on possible configuration please refer to the maintenance & instruction manual (ref. no. VSP152096).

For details on PET Blow Valve Block please refer to data sheet VFB-002.

01/08

Our policy is one of continued research and development. We therefore reserve the right

to amend, without notice, the specification given in this document.

N/VFB-003.03

SBM TECHNOLOGY Cooling / Air Recovery Valve

Dimensions

VSP152030 Cooling / Air Recovery Valve on base plate

1

2

Straight screw holes for top mounting (valve has to be disassembled) = 6.5mm (M6 screws)

Straight screw threads for bottom mounting = M8 screws, 29mm deep

Note:

Please refer to page 6 for top mounting instruction and page 7 for bottom mounting instruction.

All dimensions in mm

N/VFB-003.04

Our policy is one of continued research and development. We therefore reserve the right

to amend, without notice, the specification given in this document.

01/08

SBM TECHNOLOGY Cooling / Air Recovery Valve

Dimensions

VSP152031 Cooling / Air Recovery Valve (without base plate)

Note:

A base plate with corresponding interface and surface roughness is required for mounting and operation of this valve.

Please comply with below information:

Torque M8 screws = 25 Nm

Flatness on whole interface = 0.2

Surface finish on whole interface = Ra1.6

All dimensions in mm

01/08

Our policy is one of continued research and development. We therefore reserve the right

to amend, without notice, the specification given in this document.

N/VFB-003.05

SBM TECHNOLOGY Cooling / Air Recovery Valve

Mounting instruction

Mounting option 1 (top mounting)

step 1:

Loosen mounting screws and

remove valve from base plate.

Provide interface of mounting

surface according to drawing

(view A).

step 2:

Use M6 screws (not supplied

with valve) to mount base

plate onto surface.

step 3:

Refit valve on base plate.

All dimensions in mm

N/VFB-003.06

Our policy is one of continued research and development. We therefore reserve the right

to amend, without notice, the specification given in this document.

01/08

SBM TECHNOLOGY Cooling / Air Recovery Valve

Mounting instruction

Mounting option 2 (bottom mounting)

Use two M8 screws (not

supplied with valve) to mount

complete unit from bottom.

Provide interface of mounting

surface according to drawing

(view B).

All dimensions in mm

01/08

Our policy is one of continued research and development. We therefore reserve the right

to amend, without notice, the specification given in this document.

N/VFB-003.07

SBM TECHNOLOGY Cooling / Air Recovery Valve

Accessories

Plug options

Model

Description

Weight

0589431

15mm plug

with cable gland

(incl. gasket and mounting screws)

0.01 kg

0589433

15mm plug

with moulded cable

(incl. gasket and mounting screws)

cable length 2m

0.10 kg

Technical data

Voltage:

24V DC

Indication:

LED yellow

Connector interface:

Industry standard form C (9.4mm)

Protection class:

IP65

Surge suppression:

Z-Diode

Wiring diagram:

Warning

These products are intended for use in industrial compressed air

systems only. Do not use these products where pressures and

temperatures can exceed those listed under Technical data.

Before using these products with fluids other than those specified,

for non-industrial applications, life-support systems, or other

applications not within published specifications, consult NORGREN.

Through misuse, age, or malfunction, components used in fluid

power systems can fail in various modes.

N/VFB-003.08

The system designer is warned to consider the failure modes of all

component parts used in fluid power systems and to provide

adequate safeguards to prevent personal injury or damage to

equipment in the event of such failure.

System designers must provide a warning to end users in the

system instructional manual if protection against a failure

mode cannot be adequately provided.

System designers and end users are cautioned to review specific

warnings found in instruction sheets packed and shipped with these

products

Our policy is one of continued research and development. We therefore reserve the right

to amend, without notice, the specification given in this document.

01/08

You might also like

- VFT 1000 LeafletDocument4 pagesVFT 1000 LeafletphucgenjiNo ratings yet

- W01 358 6900 Firestone Double Convoluted Air SpringDocument29 pagesW01 358 6900 Firestone Double Convoluted Air SpringMROstop.comNo ratings yet

- SibenergomashDocument47 pagesSibenergomashheroj83No ratings yet

- 2005 Valve Catalog Full ASAHIDocument150 pages2005 Valve Catalog Full ASAHIRicardo Rodriguez MartinezNo ratings yet

- Oil filter manual for on-load tap-changersDocument30 pagesOil filter manual for on-load tap-changersRAPRATSINNo ratings yet

- SV Pilot Crosby Type-93Document22 pagesSV Pilot Crosby Type-93MarcelocrossNo ratings yet

- Force and Moment Reactions in V14Document3 pagesForce and Moment Reactions in V14hassani.meNo ratings yet

- Bollhoff Rivkle RivnutsDocument52 pagesBollhoff Rivkle RivnutsAce Industrial SuppliesNo ratings yet

- ParklistVZVZL Parts v7Document15 pagesParklistVZVZL Parts v7Steven Lambert0% (1)

- Sizing Ambient VaporizersDocument4 pagesSizing Ambient VaporizersUrMil SoniNo ratings yet

- Pumping MachinesDocument2 pagesPumping MachinesKerwinPerezNo ratings yet

- Muff Coupling & Split Muff CouplingDocument19 pagesMuff Coupling & Split Muff CouplingRamanathan DuraiNo ratings yet

- Gas Igniter Technical ManualDocument15 pagesGas Igniter Technical ManualIulian TitaNo ratings yet

- 2001 Jetta VR6 Cylinder Head Assembly - Service and RepairDocument3 pages2001 Jetta VR6 Cylinder Head Assembly - Service and Repairgigabyte3235840100% (1)

- Acople Nara CatalogDocument48 pagesAcople Nara Catalogmarcelo castillo100% (1)

- J-Series IM20140521E TornilloDocument210 pagesJ-Series IM20140521E TornilloFernando David RamirezNo ratings yet

- Sanyo Lcd-32k30 Chassis Uh4-BDocument41 pagesSanyo Lcd-32k30 Chassis Uh4-BAntonio Dalio100% (6)

- Vma DP 00697 D s01Document56 pagesVma DP 00697 D s01Pasc Claudiu100% (1)

- LMI-IOM-3390089000-02.10 - SG-User-Manual PETARYDocument56 pagesLMI-IOM-3390089000-02.10 - SG-User-Manual PETARYWilliam Melo100% (1)

- Build Basic Refrigeration CircuitsDocument8 pagesBuild Basic Refrigeration CircuitsMuhammad HafeezNo ratings yet

- V550 Vibrators ManualDocument56 pagesV550 Vibrators ManualchristelivanNo ratings yet

- Solenoid Valves Datasheet Series 21WA W WN PDFDocument38 pagesSolenoid Valves Datasheet Series 21WA W WN PDFdaliasssNo ratings yet

- INTERFLEX Catalogue (Conduits and Fittings)Document8 pagesINTERFLEX Catalogue (Conduits and Fittings)cherif yahyaouiNo ratings yet

- Astm D2911-10Document16 pagesAstm D2911-10Hernando Andrés Ramírez Gil100% (1)

- CF Combi, SLB Leaflet, enDocument4 pagesCF Combi, SLB Leaflet, enFlorian_AngererNo ratings yet

- Cgi Bindownload2.Cgidk 6irqr3rar86jw0xdtmym89mpo0w84778mdngz1g5na7n69qm&fid 13649&file Haier Hsu 18c0Document60 pagesCgi Bindownload2.Cgidk 6irqr3rar86jw0xdtmym89mpo0w84778mdngz1g5na7n69qm&fid 13649&file Haier Hsu 18c0Gayduk ValeriyNo ratings yet

- NoteBook FanControl - User ManualDocument13 pagesNoteBook FanControl - User ManualdomorodacNo ratings yet

- Deh 2350ubDocument62 pagesDeh 2350ubLuis XoocNo ratings yet

- Audi InformareDocument3 pagesAudi InformareIli IlieNo ratings yet

- Novaseptic GMP MixerDocument40 pagesNovaseptic GMP MixerAbarajithan RajendranNo ratings yet

- CBI Fleetwood Model 42 Rotofeeder ManualDocument85 pagesCBI Fleetwood Model 42 Rotofeeder ManualhauNo ratings yet

- 2010 Catalogo Americano CompletoDocument1,474 pages2010 Catalogo Americano CompletoisidriskyNo ratings yet

- The Beginners Guide To Powder Metal GearsDocument3 pagesThe Beginners Guide To Powder Metal GearsBakkiya Raj100% (1)

- EMACO Product Catalog 2018 V 1 d19032018 (LR)Document59 pagesEMACO Product Catalog 2018 V 1 d19032018 (LR)Yasir ArafatNo ratings yet

- Rubber Insulated Cable Technical SpecificationsDocument2 pagesRubber Insulated Cable Technical Specificationscorsini999No ratings yet

- Doutec ProductsDocument13 pagesDoutec Productshemispheretorqueweld100% (1)

- Manifolds Catalog 79011 10.12 PDFDocument22 pagesManifolds Catalog 79011 10.12 PDFLenzy Andre FamelaNo ratings yet

- DS C2500 D5aDocument3 pagesDS C2500 D5aanon_568723957100% (1)

- Ficha Tecnica - HP-2402Document10 pagesFicha Tecnica - HP-2402Benjamin MillerNo ratings yet

- TECO AESV/AESU/AESV-LA Series Squirrel Cage Induction MotorsDocument32 pagesTECO AESV/AESU/AESV-LA Series Squirrel Cage Induction MotorsKhusnulNo ratings yet

- Lennox DMS4 ManualDocument107 pagesLennox DMS4 ManualdwilhNo ratings yet

- LMF-GP LX15-8 - 10 - 13Document2 pagesLMF-GP LX15-8 - 10 - 13MAZEN0% (1)

- Fill Unit - Nitrogen 98F29103500000: GSE/Tool User GuideDocument18 pagesFill Unit - Nitrogen 98F29103500000: GSE/Tool User GuideJivendra KumarNo ratings yet

- Nuwe OT 020 - User ManualDocument14 pagesNuwe OT 020 - User ManualNikolay PenevNo ratings yet

- Charging Testing KitsDocument15 pagesCharging Testing Kitsprosenjit2001No ratings yet

- Amtrobox: Limit Switch Box For Pneumatic Actuators Actair and Dynactair, and Manual Actuators MRDocument12 pagesAmtrobox: Limit Switch Box For Pneumatic Actuators Actair and Dynactair, and Manual Actuators MRRijal HarunNo ratings yet

- Honeywell Mp953 Pneumatic PositionerDocument4 pagesHoneywell Mp953 Pneumatic PositionerMartin BourgonNo ratings yet

- Service Manual MIH Series Condensing Units Heat Pump: 1.5 Tons To 5 TonsDocument30 pagesService Manual MIH Series Condensing Units Heat Pump: 1.5 Tons To 5 TonsHenry Javier RíosNo ratings yet

- Hydraulic Cylinder Tie Rod Design: Replaces: 02.13Document68 pagesHydraulic Cylinder Tie Rod Design: Replaces: 02.13Juan Diego Garcia EsquenNo ratings yet

- Double Pole Limit Switches Standard Environment Butt Contacts EA170 EA700Document4 pagesDouble Pole Limit Switches Standard Environment Butt Contacts EA170 EA700prabumunishNo ratings yet

- Bonding Proccess 1Document21 pagesBonding Proccess 1Sonel Smith100% (2)

- Tomos Streetmate A55 - Information and Tuning ManualDocument29 pagesTomos Streetmate A55 - Information and Tuning ManualAdamLomazoff100% (1)

- Lnlet ValveDocument9 pagesLnlet ValveZewduErkyhunNo ratings yet

- Dosing Pump (Lmi-Metering Pump)Document44 pagesDosing Pump (Lmi-Metering Pump)Arifuddin NurdinNo ratings yet

- Kenco KlceDocument6 pagesKenco KlcenelsonNo ratings yet

- Universal 2-Finger Parallel Gripper PGN 125Document8 pagesUniversal 2-Finger Parallel Gripper PGN 125Dan001500No ratings yet

- ActairDocument16 pagesActairvj100% (1)

- High Pressure HIP AccessoriesDocument29 pagesHigh Pressure HIP Accessoriesrps1977No ratings yet

- Solar Optical Materials: Applications & Performance of Coatings & Materials in Buildings & Solar Energy SystemsFrom EverandSolar Optical Materials: Applications & Performance of Coatings & Materials in Buildings & Solar Energy SystemsM. G. HutchinsNo ratings yet

- Norgren V51 Solenoid ManualDocument5 pagesNorgren V51 Solenoid ManualjadetorresNo ratings yet

- Pay Me Back My Money SpellDocument2 pagesPay Me Back My Money SpellEricsson Botchwey40% (5)

- Pentacle and PsalmsDocument2 pagesPentacle and PsalmsEricsson Botchwey100% (2)

- Games Time Table: Draw ResultsDocument4 pagesGames Time Table: Draw ResultsEricsson Botchwey100% (3)

- Pentacles of SolomonDocument21 pagesPentacles of SolomonJoseph Burns100% (3)

- Pet Bottle FaultsDocument40 pagesPet Bottle FaultsPiyalarp Ludeelerd100% (2)

- Blow Molding SafetyDocument5 pagesBlow Molding SafetyEricsson BotchweyNo ratings yet

- Pet Bottle FaultsDocument40 pagesPet Bottle FaultsPiyalarp Ludeelerd100% (2)

- Solar Generation PowerplantsDocument52 pagesSolar Generation Powerplantservin custovicNo ratings yet

- Blow Moulder Operation and Maintenance GuideDocument10 pagesBlow Moulder Operation and Maintenance GuideAnonymous 8VsLvQKNo ratings yet

- Prayers To Attain High HonorDocument1 pagePrayers To Attain High HonorEricsson BotchweyNo ratings yet

- Potential Anti Hiv Activity of Jatropha Curcas Linn Leaf Extracts Jaa.1000082 PDFDocument6 pagesPotential Anti Hiv Activity of Jatropha Curcas Linn Leaf Extracts Jaa.1000082 PDFEricsson BotchweyNo ratings yet

- One Point Lesson Item: Bottle Defects Location: Cube Equipment: Bottle BlowerDocument2 pagesOne Point Lesson Item: Bottle Defects Location: Cube Equipment: Bottle BlowerEricsson Botchwey100% (1)

- Names PrayerDocument10 pagesNames PrayerEricsson BotchweyNo ratings yet

- 4th PentDocument1 page4th PentEricsson BotchweyNo ratings yet

- 31 NEW Unlocking KEY 4Document1 page31 NEW Unlocking KEY 4Ericsson Botchwey100% (3)

- GH 5/90 Lotto KeysDocument3 pagesGH 5/90 Lotto KeysEricsson Botchwey85% (85)

- OkuobakaDocument29 pagesOkuobakaEricsson BotchweyNo ratings yet

- The Seals of TzedekDocument7 pagesThe Seals of TzedekEricsson Botchwey100% (2)

- 31 NEW Unlocking KEY 4Document1 page31 NEW Unlocking KEY 4Ericsson Botchwey94% (16)

- Prayer For Retentive MemoryDocument1 pagePrayer For Retentive MemoryEricsson Botchwey100% (1)

- Arts ApplicationDocument15 pagesArts ApplicationEricsson BotchweyNo ratings yet

- Anointing Oil Incense and PerfumeDocument1 pageAnointing Oil Incense and PerfumeEricsson BotchweyNo ratings yet

- How Reverse Osmosis Works: Conductivity MeterDocument21 pagesHow Reverse Osmosis Works: Conductivity MeterEricsson BotchweyNo ratings yet

- Digital Planet: Tomorrow's Technology and You: Hardware BasicsDocument28 pagesDigital Planet: Tomorrow's Technology and You: Hardware BasicsYazanNo ratings yet

- Dervasil Route de Popenot - 42800 Saint Joseph - France Tel: +33 (0) 4 77 83 22 81 - Fax: +33 (0) 4 77 83 22 80Document48 pagesDervasil Route de Popenot - 42800 Saint Joseph - France Tel: +33 (0) 4 77 83 22 81 - Fax: +33 (0) 4 77 83 22 80Hồ ThànhNo ratings yet

- Memory Built-In Self-Repair Using Redundant WordsDocument7 pagesMemory Built-In Self-Repair Using Redundant Wordsaditya_pundirNo ratings yet

- Intorduction Blow by Tool PDFDocument10 pagesIntorduction Blow by Tool PDFNopNo ratings yet

- Pic 190508Document1 pagePic 190508Hosein AlaviNo ratings yet

- Compact Temperature Switch For The Process Industry Model TCSDocument5 pagesCompact Temperature Switch For The Process Industry Model TCSمحمد فرحاتNo ratings yet

- Operating Instructions: MVSQ-60, - 100, - 150 MVSQ-60-Ex, - 100-Ex, - 150-ExDocument36 pagesOperating Instructions: MVSQ-60, - 100, - 150 MVSQ-60-Ex, - 100-Ex, - 150-Exdomin_sz100% (2)

- Geared VS Gearless Drive Solutions For Grinding MillsDocument15 pagesGeared VS Gearless Drive Solutions For Grinding MillsLuis B100% (1)

- WiringDocument10 pagesWiringOlga PlohotnichenkoNo ratings yet

- NJQS Product and Service Code GuidanceDocument40 pagesNJQS Product and Service Code GuidanceAF Dowell MirinNo ratings yet

- Honeywell Solar Modules Specsheet P72W PDFDocument2 pagesHoneywell Solar Modules Specsheet P72W PDFSANRASNINo ratings yet

- Stacker ManualDocument60 pagesStacker ManualAkhtar QuddusNo ratings yet

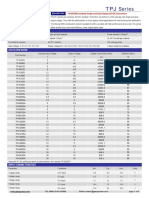

- TPJ, 1W SIP7 DC-DC Converters Power SupplyDocument3 pagesTPJ, 1W SIP7 DC-DC Converters Power SupplytoppowerNo ratings yet

- Google+ Búsqueda Imágenes Maps Play Youtube Noticias Gmail MásDocument21 pagesGoogle+ Búsqueda Imágenes Maps Play Youtube Noticias Gmail MásOsvaldo Dario AlarconNo ratings yet

- Exii Controller ChartDocument1 pageExii Controller ChartcharlysosoNo ratings yet

- Ficha Tecnica - Bomba Hidraulica Sauer Danfoss PDFDocument220 pagesFicha Tecnica - Bomba Hidraulica Sauer Danfoss PDFpokebalomanNo ratings yet

- Progress Report - CuramDocument6 pagesProgress Report - Curammanalangarjane1No ratings yet

- TransformerDocument25 pagesTransformerJerald SagusayNo ratings yet

- Arduino Basics NCDocument13 pagesArduino Basics NCMansur CanNo ratings yet

- Types of Strain GaugesDocument3 pagesTypes of Strain Gaugesprabhushankar05No ratings yet

- Wärtsilä lubrication system manualDocument10 pagesWärtsilä lubrication system manualLIVIANo ratings yet

- Crash Bar - HONDA NC750X Product InstructionsDocument8 pagesCrash Bar - HONDA NC750X Product InstructionsromaNo ratings yet

- 801 Aeronca PDFDocument17 pages801 Aeronca PDFVishveshNo ratings yet

- PHL Series Diaphragm Pump Instruction ManualDocument46 pagesPHL Series Diaphragm Pump Instruction ManualnadipallsrirajNo ratings yet

- Price List: Fourstar Electronic Technology Co., Ltd. Deyang ChinaDocument30 pagesPrice List: Fourstar Electronic Technology Co., Ltd. Deyang ChinaSanjeev JangraNo ratings yet

- Monocable Aerial Ropeway system-ARUNKUMAR PDFDocument11 pagesMonocable Aerial Ropeway system-ARUNKUMAR PDFsudishett100% (1)

- MB4 CNC Conversion: Parts List Description Product NameDocument4 pagesMB4 CNC Conversion: Parts List Description Product NameRichard RichardNo ratings yet

- Clevo C4100 - C4105 - Clevo - C4100 - DDR3 PDFDocument92 pagesClevo C4100 - C4105 - Clevo - C4100 - DDR3 PDFPauloLamesNo ratings yet

- DS20424sanyo PDFDocument26 pagesDS20424sanyo PDFdwi aryantoNo ratings yet

- Hardware Users Guide - OS6900Document100 pagesHardware Users Guide - OS6900amel632No ratings yet