Professional Documents

Culture Documents

Papers - Pipe Conveyors - Development and Advantages

Uploaded by

Ankit SrivastavaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Papers - Pipe Conveyors - Development and Advantages

Uploaded by

Ankit SrivastavaCopyright:

Available Formats

7/6/2016

Papers:PipeConveyorsDevelopmentandAdvantages

PipeConveyorsDevelopmentandAdvantages

Print

G.A.Vaka

KruppRobins

1.Introduction

RobinsEngineers&Constructors,Inc.asheexclusiveUSlicenseeintroducedthepipeconveyortotheNorth

Americanmarketplaceearlyin1984.Thesaleofthefirstpipeconveyorin1985wasadifficulttasksincethe

conventionaltroughedbeltconveyorwastheacceptedandthemostwidelyusedmeansofcontinuoustransportation

ofbulkmaterialshandlingintheworld.initiallyourclientsviewedthepipeconveyorasadeparturefromthenormal

andacceptedformofmaterialhandling.

Sincethen,theparentcompanyofRobinsEngineersmergedwithKruppofGermanytoformKruppRobins,Inc.in

theUSA.Todatethereareover750pipeconveyorsoperatingworldwidewiththemajorityofthelongoverland

systemsdesignedandinstalledbyKruppRobins,Inc.Thepipeconveyorisnowbecomingthenorm,viewedby

thosewhoarefamiliarwithitscapabilitiesasthepreferredmethodoftransportationforallbulksolids.

2.DevelopmentofthePipeConveyor

JapanPipeConveyorCompanywasresponsiblefortheinitialdevelopmentofthepipeconveyorandpatentedthe

originaltechnologythatledtoitsfirstsuccessfulapplicationbackin1979.BridgestoneCorporationhassince

obtainedalltherightstotheJPCsystemandhasgrantedKruppRobins,Inc.theexclusivemarketingrightsinthe

UnitedStates.JointlyBridgestoneandKruppRobins,Inc.havedevelopedandrefinedthelimitedoriginal

technology.Advancedtechnologyallowsbothinplantandlongoverlandpipeconveyorswithmultiplehorizontal

curves,tooperatewiththereliabilityofconventionalconveyors(Fig.1).Designsareprogressivelytowardlonger

singleflightconveyorswitheachnewcontract.Forexample,a4,500ftlongcoalconveyor,agoldoreconveyor

6,575ftlong,anothercoaltransportationconveyor8,900ftlong,andyetanotherdownhillcoalhandlingconveyor

thatis11,500ftinlength.Currentlythelongestsingleflightpipeconveyorinstalledisover16,500ftinlength.The

conveyorcarriespetroleumcokeinonecontinuouslengthfromarefinerytoaportfacilitywhereshiploadingoccurs.

Fig1.TheHomestakemineinSouthDakota,showingthe

pipeconveyorleadingfromthemine(foreground)tothe

mill(background)transversingthroughthetown.

Theuseofthepipeconveyorisonlylimitedbytheimaginationoftheindividuallookingforthepossibleapplication.

Todatewefindthatanymaterialthatcanbeplacedonthepipeconveyorcanbeconveyed.Thetypicalmaterials

handledareores,coal,coke,limestone,crushedstone,shaleandoverburden.Someofthemoredifficultmaterials

thatarebeinghandledonthepipeconveyorarecopperconcentrate,petroleumcoke,clay,fluedust,readymixed

concrete,sludge,humidifiedflyash,coaltailings,aluminaandfilterdust.

http://www.ckit.co.za/secure/conveyor/papers/pipe/pipea.html

1/9

7/6/2016

Papers:PipeConveyorsDevelopmentandAdvantages

3.DesignDetails

3.1PipeConveyorBelt

ThebeltwasdevelopedforthepipeconveyorbyTheBridgestoneTireCompany.Itissimilartotheconventional

conveyorbeltbutincorporatesseveralimportantfeaturesinitsdesign.Thepipeconveyorbeltismanufacturedby

BridgestoneinJapanand,underlicense,byGoodyearintheUSA.

Withtheneedforbothstiffnessandflexibility,aspecialcarcassconstructionisemployed.Thebelthastohave

sufficientstiffnesstoformandmaintainthepipeshapeasitpassesthroughthecircleformingidlerrolls.Atthe

sametimeitmustremainflexibleforthetransitionfromtheflatshapeatthepulleystothepipeshapeatboththe

loadinganddischargeendsoftheconveyor.Thisisaccomplishedbyplacingalayerofrubberbetweeneachfabric

plyinthebelt.

Thebeltedgestiffnessisreducedtoassurethatasealismaintainedattheoverlapsothatmaterialdoesnot

escape.Further,thetopandbottomrubbergradesandcuringtimesarecontrolledtoenhancethebelt'snatural

tendencytoassumethepipeshape.

Forlongsingleflightapplications,thepipeconveyorbeltisalsoavailableinsteelcordconstruction.Inthiscase,a

layeroftransversefabricisusedbothaboveandbelowthesteelcables.Again,aswiththefabricconstruction,a

layerofrubberseparatesthefabricandthesteelcords.

Forpurposesofemergencyrepair,metalfastenerscantemporarilybeusedoraconventionalbeltcanbesubstituted

untilapermanentrepaircanbemade.Theconventionalbeltdoesnothavethenecessarystiffnessandflexibility.It

wouldrestmainlyonthebottomsupportidlersandconsequentlywouldsufferprematurecrackingandfatigueor

couldcreateotherunforeseenproblems.Thebeltlifeofapipeconveyorbeltandtheconventionalbelt,whenused

onconventionaltroughedconveyorapplications,arevirtuallythesame.

Beltcleaningisaccomplishedwiththesameequipmentthatisusedonconventionalbeltapplications.Singleblade

andmultiplebladebeltscrapersaswellasrotarybrushesandreturnbelt"V"plowsmaybeused.

Hotmaterialscanbehandledonthepipeconveyorthroughtheuseofbeltsthatarespeciallymadeforthepurpose.

Standardgradebeltingisusedfortemperaturesupto140degF.Twohotmaterialgradesofbeltwillallow

temperaturesupto230degFand320degFrespectively.

Specialconsiderationtobothlumpsizeandbeltsurfacetemperaturemustbegivenfortheproperselectionofbelt.

Extremeheatconditionsatthebeltsurfacewillhaveapronouncedeffectonbeltlife.

3.2IdlersandSpacing

Whenthepipeconveyorisstraightandwithoutanyverticalorhorizontalcurves,thebottomthreeidlersofthetop

orloadcarryingsideofthepipeconveyorsupportsthebeltandmaterialload.Thetopthreeidlersmaintainthe

beltinitspipeshape.Shouldtheconveyorhavebothverticalandhorizontalcurvesections,thentheotheridlersthat

surroundthebeltmaybetheloadsupportingidlerswhiletheremainingidlersmaintainthebeltinthepipeshape.

Thesameappliestothebottomorreturnbeltsideofthepipeconveyor.Thereasonthatthebottomorreturnstrand

ofthebeltiskeptinthepipeshaperatherthantheflatshape,asonaconventionalconveyor,istopermitthesame

sizestructuretobeusedandtoguidethebeltthroughtheverticalorhorizontalcurves.

TheidlersthatsurroundthebeltareaptlycalledthePipeShapeKeepingIdlersorPSKIdlers.Thediameterand

spacingofidlersetsisdeterminedbythesizeofthepipeconveyorandthematerialthatitconveys.Duetothe

rigidityofthepipeshapetheidlerspacingcanbeincreasedwithoutexcessivebeltsagaswithconventional

conveyors.Table1showsthetypicalspacingusedforstraightpipeconveyors.Theidlerdiameterrelativetopipe

conveyorsizeisshowninTable2.

http://www.ckit.co.za/secure/conveyor/papers/pipe/pipea.html

2/9

7/6/2016

Papers:PipeConveyorsDevelopmentandAdvantages

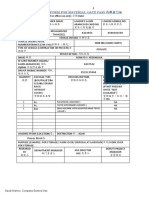

Table1.IdlerSpacing

PipeDiameter

Spacing

mm

in

50ft3

75ft3

100ft3

150

5'6"

5'0"

4'3"

200

6'0"

5'3"

5'0"

250

10

6'3"

5'6"

5'3"

300

12

6'6"

6'0"

5'6"

350

14

7'0"

6'3"

6'0"

400

16

7'3"

6'6"

6'3"

500

20

7'3"

7'3"

6'6"

600

24

8'0"

7'9"

7'3"

700

28

8'3"

8'3"

7'6"

850

34

8'6"

8'3"

8'0"

Table2.IdlerRollDiameter

PipeDiameter

IdlerRollDiameter

(in)

(in)

4or5*

10

4or5*

12

14

16

20

24

28

34

6or7*

*DependingonloadimposedandidlerRPM

Idlerspacingforpipeconveyorswithhorizontalcurvesmayhavetobereducedinareasofthecurves.Inallcases

thefinalselectionofidlerspacingisbasedonacompletereviewofthestaticanddynamictensionconditionsofthe

individualpipeconveyorandthetypeorcombinationofcurvesthatmaybeused.

Intheareaoftransitionatthetallendwherethebeltgoesfromtheflattopipeshape,thebeltissupportedby

idlerswithvariableinclineendrollssimilartotheconventionalconveyorbelt.Inthislocationthebeltisloadedby

meansofaloadingchute.Theidlersbeneaththeloadingskirtboardsarespacedatcentersthatwillabsorbthe

impactoftheloadedmaterial.Atthebeginningofthepipeshapeaspecialidlersetisusedcontaining12idlerrolls

arrangedasoffsethexagons.Theresultingtwelvesidedfigureapproximatesacirclecloserthanthestandardsixside

idlerhexagonandiscapableofwithstandingthehigherloadsoftheclosingbelt.Inadditiontotheseidlers,aspecial

http://www.ckit.co.za/secure/conveyor/papers/pipe/pipea.html

3/9

7/6/2016

Papers:PipeConveyorsDevelopmentandAdvantages

singlerollguideidlerisusedtopressoneedgeofthebeltbelowtheotheredgeasthebeltcomestogether.This

idlerisinstalledjustaheadofthefirstcircularidlerset.Theidlereliminatesbeltedgeabrasionandallowsthe

properoverlapclosingofthebelt.

Idleralignmentandproperbeltloadingplayakeyroleinthestabilityandtrackingofthepipeconveyor.Ona

conventionalconveyorstructuretheidlersupportsteelandhorizontalandverticalalignmentarecriticalforproper

belttrainingandsuccessfuloperation.Impropertracking,orbeltmisalignment,iscorrectedthroughtheuseof

trainingidlers.Withthepipeconveyorbeltguidedbyidlerssurroundingthebeltonallsides,theconveyorisableto

negotiatecurvesandcenterlinemisalignments.Duringcommissioningofthepipeconveyor,idleralignmenttothe

beltisadjustedtomaintainthebeltoverlapinapositionthatislocatedasnearthetopaspossibleonthecarrying

side.However,whatactuallyassistsmostinbeltstabilityandkeepstheoverlapatorneartheupwardpositionis

theweightofthematerialconveyed.Theheavycenterofgravityinthelower75%crosssectionmaintainsthe

properdynamicattitudeoftheconveyorbelt.Onthereturnoremptyside,thebeltoverlapislocatedatthebottom

ofthepipeshape.Theextraweightoftheoverlapmaintainstheproperdynamicattitudeonthereturnrun.

CurvedsectionofthepipeconveyorasitapproachesthedischargepointatAES(AppliedEnergySystems)Barbers

Point.

Uniformfeedtothepipeconveyorisimportanttoitsstabilityandtracking.Forthisreasonitisrecommendedthat

thematerialisfedthroughtheuseofabeltfeederorvibratingfeederthatwillprovideaconstantanduniformflow.

Ifitisnotpossibletoprovideaconstantanduniformfeedthenamaterialcrosssectionmonitorandavariable

speedpipeconveyordriveisemployedtocreateadesirablecrosssectionthatissuitablefortheapplication.The

crosssectionmonitordetectsthematerialloadattheloadingchuteandprovidesasignaltovarythepipeconveyor

beltspeedtofacilitateauniformcrosssectionatalltimes.

Table3.Transitiondistance,minimumconveyorlength.

FabricBelt

SteelCOrdBelt

PipeDiameter

Transition

MinimumConversion

Transition

MinimumConversion

Length*

Length

Length

Length

Length

(in)

(ft)

(ft)

(ft)

(ft)

12.5

59

25

118

17.0

65

34

130

10

21.0

75

42

150

12

25.0

82

50

164

14

29.0

98

58

196

16

33.5

114

67

228

20

42.0

131

84

262

24

50.0

164

100

328

http://www.ckit.co.za/secure/conveyor/papers/pipe/pipea.html

4/9

7/6/2016

Papers:PipeConveyorsDevelopmentandAdvantages

28

58.5

196

117

392

34

71.0

229

142

458

*Basedonstraightconveyorswithnocurves.

Thelengthofthetransitionbetweenthetailpulleyandthepipeshape,andfromthepipeshapetothedischarge

pulleyisafunctionofthepipeconveyordiameter.Duetothetransitiondistancesatboththeheadandtailendof

theconveyor,aminimumpipeconveyorlengthisalsorecommended(Table3).

3.3Curves

Asstatedpreviously,asignificantadvantageofthepipeconveyoristheabilitytonegotiatecurvesofatightradius

ascomparedtotheradiusrequirementsoftheconventionalconveyor.Thisfeaturecombinedwithitsnarrowprofile

enablesthepipeconveyortobeinstalledwherephysicalconstraintswouldnormallyexcludeconventionalbelt

conveyorsorrequiretheuseofseveraltransferpoints.

Sincethepipebeltistotallycontainedbythesurroundingidlers,sidedriftdoesnotoccuraswithconventional

conveyors.Asanexample,thehorizontalcurveforaconventionalconveyorisgenerally,ataminimum,2,500ft.

Theconveyorbeltsizeisthenusuallyincreasedbyonesizetoallowforsided@ftbetweenemptyandloaded

conditions.Temperaturechangeandweatherconditionsarealsocriticalfactorsinsizingcurveradiiwiththecon

ventionalbeltconveyor.

Thepipeconveyorcanbecurvedinboththeverticalandhorizontalplaneaswellasincombinationofthetwo,

eliminatingtransfersorpassingaround,overorunderexistingplantequipment(Fig.2).Thecurvedsectionsare

begunonlyafterthebeltpassesthroughthetransitionsectionandisinthepipeshape.Thecurvedsectionsmustbe

completedwhilestillinthepipeshapepriortoexitingthroughthetransitionsectiontothedischargepulley.The

transitionsectionsmustbestraightatbothends.

Theradiusofthecurvesaregenerallyafunctionofthepipeconveyordiameter,thetypeofbeltandcurveused.In

generalthestandardminimumrecommendedradiusforhorizontalorconcavecurvesforafabricbeltis300times

thepipeconveyordiameterandis700timesthediameterforasteelcordbelt.However,shouldan"S"shape,

convexorcombinedhorizontalandconcavecurvebeusedthentheminimumradiusis400timesthediameterfor

fabricbeltand800timesthediameterforsteelcordbelt.Inthecaseofacombinedhorizontalandconvexcurvethe

minimumradiusisthen500timesthediameterforafabricbeltand900timesthediameterforasteelcordbelt.

Theforgoingisonlytobeusedasageneralguide.Inallcasesthefinalselectionofradiiisbasedonourengineer's

completereviewofthestaticanddynamictensionconditionsoftheindividualpipeconveyorandthetypeor

combinationofcurvesthatareused.

Table4.Pipeconveyorcapacity.

Pipe

Cross

diameter

section*

Beltspeed**FPM

NormalCapacity

Max.Lump

mm

in

ft2

Norm

Max

50lb/ft3

100lb/ft3

in

150

0.140

394

541

84

166

1.25

200

0.248

427

541

159

318

2.75

250

10

0.441

459

591

304

608

3.5

300

12

0.527

492

591

389

778

4.00

350

14

0.710

574

591

612

1224

4.75

http://www.ckit.co.za/secure/conveyor/papers/pipe/pipea.html

5/9

7/6/2016

Papers:PipeConveyorsDevelopmentandAdvantages

400

16

1.163

656

738

1144

2288

5.50

500

20

1.670

738

738

1848

3696

6.50

600

24

3.330

820

902

2861

5722

8.00

700

28

3.014

902

902

4079

8158

10.00

850

34

4.349

984

984

6420

12840

11.50

*At75%loadcross

**Normal/maximumbasedonidlerdiameterandmaximum

section

idlerrpm

3.4PowerRequirements

Whenthegeometryofapipeconveyoristhesameasastraightinclinedconventionalbeltconveyorofintermediate

length,(plus300ft)thepowerconsumptionandbelttensionsaregenerallyequai.Thepipeconveyorrequirements

maybeafewpercenthigherdependingoncapacityandsizeofconveyorscompared.

Ifthepipeconveyorisdesignedwithcurvedsectionsadditionalpowerisconsumedtochangethematerialdirection

withinthebelt.Belttensionandpowercalculationsforeachindividualpipeconveyorapplicationarecarriedoutin

accordancewithanexclusiveandproprietaryformuladevelopedbyBridgestoneCorporation.Althoughthepower

requirementmaybesomewhathigherforthecurvedpipeconveyorwhencomparedtoastraightconventional

conveyorofthesamelength,transferswiththeassociatedadditionalliftrequirementareeliminated.When

comparedtothemultipleflightconventionalbeltconveyorswiththeadditionalhorsepowerrequirementtoliftthe

materialtomakeeachtransfertothenextconveyor,theconsumedpowerrequirementsofthepipeconveyorare

thenquitecomparableormayevenbeless.

Eachspecificapplicationmustbesubjectedtoacarefulengineeringreviewforacomprehensiveevaluationofboth

powerrequirementsandbelttensionswhenacomparisonistobemadeagainsttheconventionalbeltconveyor.

3.5MaterialLumpSize

Materiallumpsizeisimportantintheselectionofpipeconveyorsize.Table4showstheconveyorsize,capacityand

theassociatedlumpsizethatcannormallybehandled.Generallythemaximumlumpsizeis1/3ofthegivenpipe

diameter.Undercertainsizedistributionconditionslargerlumpsizesmaybeallowed.Thefeedofmaterialtoolarge

fortherecommendeddiametercouldbedetrimentaltothelifeofeitherthebeltortheidlersetsthatcontainthe

belt.Ifthepipediameterisdictatedbythelumpsizeofthematerialitmaybenecessarytoselectalargerpipe

diameterthanwhatotherwisemaybeselectedforcapacity.

3.6Construction

Theconstructionusedforthediaphragmpanelsthatsupporttheidlersisverysimple.Thepanelsarepressedfrom

plateandcanbemadeveryeconomically.Forthelargersizepipeconveyor,thepanelsarefabricatedfromangle

shapesandplatesections.Theidlermountingholesarejigdrilledtogivetherequiredaccuracyforidlermounting.

Supporttrusses,galleriesandbentsaresimilartothoseusedwithconventionalconveyors.Duetothediaphragm

effectoftheidlerpanel,thepipeconveyortrussthatincludeswalkwaysismuchstifferandthereforeallowsalighter

designtobeused.

Walkthrutypegalleriesarealsoavailableforthelongerspanrequirement.Walkwayscanbeprovidedononeor

bothsidesforconveyormaintenancedependingonthesizeofthepipeconveyor.Typicallytheshapeofthepipe

conveyorallowsforamorecompacttrussdesignthatconsequentlyreducesfoundationloads.

4.AdvantagesofthePipeConveyor.

http://www.ckit.co.za/secure/conveyor/papers/pipe/pipea.html

6/9

7/6/2016

Papers:PipeConveyorsDevelopmentandAdvantages

4.1EnvironmentallyAcceptable

Themostimportantadvantageofthepipeconveyoristhatthematerialiscoveyedcontainedwithintherolled

tubular,orpipeshapebelt,thusprovidinganenvironmentallyacceptablealternativetotheconventionaltroughed

beltwherespillingordustingcananddoesoccur.Theloadingofthepipeconveyorisexactlythesameasthe

conventionalconveyorbeltwhichisthroughaloadingchuteandskirtboardsnearthetailpulleyoftheconveyor.

Immediatelyfollowingtheloadingarea,thebeltisrolledintothepipeshapewithasealformedatthetopby

overlappingtheedgesofthebelt.Theconveyedmaterialiswithinthepipeshapebelt,eliminatinganyfurtherneed

foranenclosure.Attheheadend,thebeltpassesoveraconventionalpulleywhereitopenstotheflatshapeand

thematerialisdischarged,thesameaswithaconventionalbeltconveyor.Theareasatthetailandheadendsofthe

conveyor,wherethebelttakesthepipeshapeoropensbacktotheflatshape,arecalledthetransitionsections.

Idlersarrangedtoformahexagonareusedtosupportandguidethepipeshapedconveyorbeltwiththematerial

containedtherein.Dustingandspillageisreducedtoanabsoluteminimumbecausethematerialiscompletely

enclosedbythesurroundingbelt.

4.2AbilitytoNegotiateSharpRadii

Thesecondsignificantadvantageofthepipeconveyorisitsabilitytonegotiateactivelysharpradiicomparedto

otherformsofbelttransportation.Tomany,thisadvantageisconsideredthemostimportantsinceitcaneliminate

transfersthatarenormallynecessarywhenthereisarelativelysharpchangeinbeltdirection.

Theidlersformacircleandconstrainthebeltonallsidesallowingrelativelytightcurvestobenegotiatedinany

direction.Thecurvescanbehorizontal,verticalorcombinationsofbothplanes.Eliminationoftransferstationsalso

deletestheneedforadditionalpulleys,chutes,dustcollectionordustsuppressionequipment,foundationsandpower

distribution.Therefore,productdegradationisalsosignificantlyreduced.Butmostimportanttheassociated

maintenanceofatransferpointiscompletelyremoved.Apipeconveyorcanbeinstalledwithmultiplecurvessothat

onepipeconveyorcanreplacemultipleconventionalbeltconveyorsandtheassociatedtransferpointsandauxiliary

equipmentasoutlinedabove.

4.3AbilitytoNegotiateSteepAnglesofInclination

Thepipeconveyorcannegotiatemuchsteeperanglesofinclinationthanaconventionalbeltconveyor.Duetothe

roundcrosssection,increasedcontactareabetweenthematerialandthebeltoccursthatallowsagaininangleof

inclinationofapproximately50%toasmuchas27degrees.Withthesteeperinclinationtheconveyorcanbemade

shorter,providingfurthereconomicsorperhapsmakingittheonlyviablesolutionduetospaceorproperty

restrictions(Fig.3).

Fig3.AES(AppliedEnergySystems)Barberspointatthelocationwherethepipeconveyorcrossesthemainport

entranceroad.Thedischargeofthepipeconveyorisatthepowerplantinthebackground.

4.4PipeFormforReturnBelt

http://www.ckit.co.za/secure/conveyor/papers/pipe/pipea.html

7/9

7/6/2016

Papers:PipeConveyorsDevelopmentandAdvantages

Thereturnbeltofthepipeconveyorisalsoformedintothepipeshape.Thebeltisrolledsothattheoverlapis

placedatthebottomofthepipeshape.Thisnotonlyallowstheconveyortonegotiatethesamecurvedrouteasthe

carryingstrandbutitalsoenclosesthedirtysideofthebelt.Thepossibilityofdrippingorscatteringofmaterialthat

mayhavecarriedovertothedirtysideofthebeltisthereforeminimized.

4.5SameVolumeofMaterialTransportedaswithLargerConventionalBeltConveyor

Thepipeconveyorcantransportthesamevolumeofmaterialastheconventionalbeltconveyorthatistypically2.5

to3timesthesizeofagivenpipediameter.Asanexample,a300mm(12inch)diameterpipeconveyorwill

conveythesamecapacityasa30inchwideconventionalbeltconveyorusing20degreetroughingidlersanda20

degreesurchargeangle.Thistranslatestoasupportstructureforpipeconveyorthatisonly25incheswidein

comparisontotheconventionalbeltconveyorthatwillrequire,atminimum,awidthof41inchesforitssupport

structure.Wherespaceforaconveyorislimited,suchasinatunnel,theuseofthepipeconveyorwouldallowa

smallertunnelcrosssectiondesign(Table3).

4.6StandardComponents

Thesamestandardcomponentsthatareusedfortheconventionalconveyorsarealsousedforthepipeconveyor.

Sincethepipeconveyorbeltisflatatallhead,tailandtakeuppulleylocations,andbecausethebeltspeedsare

similar,standardconventionalconveyorpulleys,bearingsanddrivecomponentsareused.Theconveyorbeltitselfis

manufacturedbybothBridgestoneinJapanor,underlicense,byGoodyearintheUSA.Theuseofstandard

componentsavailablefromthelocalmarketplacemakesthepipeconveyoranacceptablealternativeusing

equipmentthatcustomersarefamiliarwithandhavefullconfidencein.

4.7ConveyanceonTopandReturnStrand

Aswithaconventionalconveyor,materialcanbeconveyedonthereturnstrandinadditiontothatbeingcarriedon

thetopstrand.Toaccomplishthis,thereturnbeltisturnedover180degreessothattheoverlapthatsealsthe

materialinthepipeshapeisonthetopwiththedirtysideofthebeltstillremainingontheinside.Although

additionalpulleysareneededandsupplementarydrivesmayberequired,theinstallationofonlyonepipeconveyor

couldprovideeconomicalbenefitsovertheinstallationoftwoseparateconventionalconveyors.

5.Installations

Todatethereareover600locationswhereover750pipeconveyorshavebeeninstalled.Theclient'sreasonsto

chosetheuseofthepipeconveyoroverconventionalconveyorhavevaried,butineachcaseitwasduetooneor

moreoftheinherentadvantagesofthepipeconveyorasoutlinedhere.Inafewinstancesthecostofthepipe

conveyorwasmorethanthecomparableconventionalconveyorbut,intheclientsopinion,themeritsofthefeatures

gainedfaroutweighedtheadditionalcosts.

6.Conclusion

Thepipeconveyorisstillarelativelynewandinnovativeconceptforthetransportationandhandlingofbulk

materialsascomparedtotheconventionalbeltconveyorthathasbeenunchangedsinceitsinceptionattheturnof

thecentury.Itoffersmanyadvantagesoverothermaterialhandlingsystemsbymakinguseofallthestandard

equipmentdevelopedfortheconventionalbeltconveyorandbyincorporatingtheadditionalfeaturesdescribed

herein.NowthataUSlicensehasbeenestablishedandahistoryofinstallationexists,thefeasibilityandeconomics

ofthepipeconveyorapplicationcaneasilybedetermined.

http://www.ckit.co.za/secure/conveyor/papers/pipe/pipea.html

8/9

7/6/2016

Papers:PipeConveyorsDevelopmentandAdvantages

http://www.ckit.co.za/secure/conveyor/papers/pipe/pipea.html

9/9

You might also like

- Robotics Annexure 1Document5 pagesRobotics Annexure 1Ankit SrivastavaNo ratings yet

- SSC Selection Post ApplicationDocument3 pagesSSC Selection Post ApplicationAnkit SrivastavaNo ratings yet

- Structural Analysis in Nastran: Structure's Response Are Assumed To Vary Slowly With Respect To TimeDocument8 pagesStructural Analysis in Nastran: Structure's Response Are Assumed To Vary Slowly With Respect To TimeAnkit SrivastavaNo ratings yet

- EtncfinhomeDocument15 pagesEtncfinhomePranav Sharma100% (1)

- Cooling Home NaturallyDocument8 pagesCooling Home NaturallyLinggawatiAditopoNo ratings yet

- 08 MTechConstructionTechnologyDocument2 pages08 MTechConstructionTechnologyAnkit SrivastavaNo ratings yet

- Barc ResultDocument28 pagesBarc ResultAnkit SrivastavaNo ratings yet

- Questions on steam power cycle efficiency and turbine output calculationsDocument3 pagesQuestions on steam power cycle efficiency and turbine output calculationsAnkit SrivastavaNo ratings yet

- White Paper On Solar Air-ConditioningDocument8 pagesWhite Paper On Solar Air-ConditioningAnkit SrivastavaNo ratings yet

- Mathematical Elements For Computer Graphics - David F. RogersDocument5 pagesMathematical Elements For Computer Graphics - David F. RogersSuraj Dahotre6% (18)

- IISC BangaloreDocument1 pageIISC BangaloreVikas PsNo ratings yet

- English Notice ESE 2016 PDFDocument24 pagesEnglish Notice ESE 2016 PDFUploadingfilesNo ratings yet

- Absorption Chiller GuidelineDocument97 pagesAbsorption Chiller Guidelineeng_badawy20044942100% (3)

- NMDC Job Application GuideDocument3 pagesNMDC Job Application GuideArunNo ratings yet

- TransformationDocument10 pagesTransformationzex007No ratings yet

- GATE 2014 - OTG Schedule - Final PDFDocument1 pageGATE 2014 - OTG Schedule - Final PDFgokuler137No ratings yet

- Final MT 2015 Advt.Document8 pagesFinal MT 2015 Advt.manohar487No ratings yet

- Energy Security and Conservation: A Major Part of The Solution To Energy Generation and Environmental DegradationDocument85 pagesEnergy Security and Conservation: A Major Part of The Solution To Energy Generation and Environmental DegradationAnkit SrivastavaNo ratings yet

- Skip To NavigationSkip To ContentHelp Using This WebsiteDocument19 pagesSkip To NavigationSkip To ContentHelp Using This WebsiteAnkit SrivastavaNo ratings yet

- 3.3 Energy Efficient Lighting Systems Ppt-Ak - KhanraDocument25 pages3.3 Energy Efficient Lighting Systems Ppt-Ak - KhanraumisygNo ratings yet

- Accommodation at IitbDocument2 pagesAccommodation at IitbAnkit SrivastavaNo ratings yet

- Basics of SOLARDocument40 pagesBasics of SOLARHaunted MemoriesNo ratings yet

- Answer keys for recruitment test held on 03.07.2016Document5 pagesAnswer keys for recruitment test held on 03.07.2016Ankit SrivastavaNo ratings yet

- BEL India Details of Advertisement 2015Document9 pagesBEL India Details of Advertisement 2015dilesh555No ratings yet

- Advt - 12 - 16 - JWM MechDocument46 pagesAdvt - 12 - 16 - JWM MechAnkit SrivastavaNo ratings yet

- Product Design Is The Process of Creating A New Product To Be Sold by A Business To Its CustomersDocument5 pagesProduct Design Is The Process of Creating A New Product To Be Sold by A Business To Its CustomersAnkit SrivastavaNo ratings yet

- RoboticsDocument33 pagesRoboticsAnkit SrivastavaNo ratings yet

- Bearing lubrication and elastohydrodynamic lubricationDocument6 pagesBearing lubrication and elastohydrodynamic lubricationAnkit SrivastavaNo ratings yet

- Winning Story At Kirtu ContestDocument8 pagesWinning Story At Kirtu ContestAnkit SrivastavaNo ratings yet

- Latest Job & Admission NotificationsDocument3 pagesLatest Job & Admission NotificationsAnkit SrivastavaNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5784)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Unit 1 - Introduction - V5Document45 pagesUnit 1 - Introduction - V5Aleix Cánovas EstebanNo ratings yet

- Iso 492-2014-09Document74 pagesIso 492-2014-09Geet Deokate100% (2)

- Foldable Puzzle Mat Game MatDocument36 pagesFoldable Puzzle Mat Game MatAaronNo ratings yet

- Machine Vibration TutorialDocument12 pagesMachine Vibration TutorialabhishekNo ratings yet

- AutoCAD1 Land Development Desktop Release 2iDocument2 pagesAutoCAD1 Land Development Desktop Release 2iRajo Ameh100% (1)

- Results of Competition: Faraday Battery Challenge: Innovation R&D Studies Round 3 Competition Code: 1809 - CRD - MMM - ISCF - FARADAY - R3Document26 pagesResults of Competition: Faraday Battery Challenge: Innovation R&D Studies Round 3 Competition Code: 1809 - CRD - MMM - ISCF - FARADAY - R3Jack PadiNo ratings yet

- 2 HVPD Night 2 On Line Partial Discharge OLPD Monitoring of Complete HV Networks OG Industry Oct.14Document171 pages2 HVPD Night 2 On Line Partial Discharge OLPD Monitoring of Complete HV Networks OG Industry Oct.14Tarun BhatiaNo ratings yet

- Improving BOLDFlash's Internal ProcessesDocument10 pagesImproving BOLDFlash's Internal Processessivaabhilash100% (1)

- HDK® H30: Product DescriptionDocument2 pagesHDK® H30: Product DescriptionjaviomoteroNo ratings yet

- PNG Standard Classification (Jan 09)Document124 pagesPNG Standard Classification (Jan 09)Christian BarNo ratings yet

- Evaluation of DFXDocument5 pagesEvaluation of DFXRajeshLSNo ratings yet

- Approval Form For Material Gate Pass 内部出门证: COD Muhammed Thanzeel 8424503 0580281560Document1 pageApproval Form For Material Gate Pass 内部出门证: COD Muhammed Thanzeel 8424503 0580281560Muhammed ThanzeelNo ratings yet

- A Guide To The Design of An Effective Low Pressure VAV Air Distribution SystemDocument11 pagesA Guide To The Design of An Effective Low Pressure VAV Air Distribution SystemAbdul RaheemNo ratings yet

- 200-1013-06-003 RFQ Full Package and High Pressure Coil Design CalculationDocument15 pages200-1013-06-003 RFQ Full Package and High Pressure Coil Design CalculationBilel MahjoubNo ratings yet

- PCI GFRC Manual 2nd EditionDocument183 pagesPCI GFRC Manual 2nd EditionNuno Ferreira100% (4)

- Air Assisted FlaresDocument2 pagesAir Assisted FlaresUr FriendNo ratings yet

- SR EN ISO 3452-1 (2021e PDFDocument34 pagesSR EN ISO 3452-1 (2021e PDFAdrian100% (6)

- Academic Task 3 Simulation QuestionsDocument9 pagesAcademic Task 3 Simulation QuestionsAnshulNo ratings yet

- A High Performace HMIDocument50 pagesA High Performace HMIAnonymous FFMmIJy100% (1)

- Ms - Installation of Electric PVC Conduits and AccessoriesDocument6 pagesMs - Installation of Electric PVC Conduits and AccessoriesDuel TimeNo ratings yet

- 2012 Conveyor Components CatalogDocument53 pages2012 Conveyor Components Catalogbandara123100% (1)

- Substation Structures: An engineering insight into low-profile cost savingsDocument111 pagesSubstation Structures: An engineering insight into low-profile cost savingsdavidfc26No ratings yet

- ERICA Campus MapDocument1 pageERICA Campus MapJulie HERVENo ratings yet

- Describe The Health and Safety Requirements and Safe Working Practices and Procedures Required For The Hand Fitting Activities UndertakenDocument7 pagesDescribe The Health and Safety Requirements and Safe Working Practices and Procedures Required For The Hand Fitting Activities UndertakenPxre LxckNo ratings yet

- Pile Foundation Design A Student GuideDocument79 pagesPile Foundation Design A Student GuideAref MalkawiNo ratings yet

- B767 BrakesDocument6 pagesB767 BrakesGustavo Avila RodriguezNo ratings yet

- TWI Control of Welding DistortionDocument12 pagesTWI Control of Welding DistortionClaudia Mms100% (2)

- Index - Foundation of Software TestingDocument3 pagesIndex - Foundation of Software TestingJItendra KNo ratings yet

- PDF File: Tally TDL Learning Guide Short ReviewsDocument2 pagesPDF File: Tally TDL Learning Guide Short Reviewswaahidscribed0% (2)

- Nabl 400 PDFDocument275 pagesNabl 400 PDFMovin Menezes100% (1)