Professional Documents

Culture Documents

Elemental Characterization by Edxrf of Imperial Longquan Celadon Porcelain Excavated From Fengdongyan Kiln, Dayao County

Uploaded by

Alexander Robert JennerOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Elemental Characterization by Edxrf of Imperial Longquan Celadon Porcelain Excavated From Fengdongyan Kiln, Dayao County

Uploaded by

Alexander Robert JennerCopyright:

Available Formats

bs_bs_banner

Archaeometry 57, 6 (2015) 966976

doi: 10.1111/arcm.12149

EL E M E N TA L CHARACT E RIZ AT IO N BY ED X R F O F I MPER I A L

LO N G Q UAN CE L ADON P ORCE LA I N EX C AVATED FR O M

FENGDONGYAN KIL N, D AYA O C O U N TY *

L. LI,1 L. T. YAN,1 S. L. FENG,1 Q. XU,1 L. LIU,1,2 Y. HUANG1,2 and X. Q. FENG1

1

Key Laboratory of Nuclear Radiation and Nuclear Energy Technology, Institute of High Energy Physics, Chinese Academy

of Sciences, 19 Yu Quan Lu, Beijing 100049, China

2

University of Chinese Academy of Sciences, Chinese Academy of Sciences, Beijing 100049, China

A mass of Longquan porcelain shards carved with Guan or the dragon patterns were

unearthed in the early Ming Dynasty layer of the Fengdongyan kiln site at Dayao County.

These celadon shards were fired in the Hongwu and Yongle eras of the Ming Dynasty. In order

to research the raw materials and firing technology of the imperial porcelain, 85 typical shards

were analysed by energy-dispersive X-ray fluorescence (EDXRF). The results indicate that the

contents of TiO2 and Fe2O3 in the body vary in the Hongwu and Yongle eras. Compared with

Longquan glazes in the Southern Song Dynasty, the average values of K2O, Fe2O3 and TiO2 are

higher, but that of CaO is lower in early Ming imperial porcelain glazes. Principal components analysis (PCA) shows that different degrees of elutriation of the same raw materials are

the main reason for this difference in the Hongwu and Yongle periods. However, the raw

materials of imperial porcelain glazes show no obvious changes and have inherited the earlier

tradition. The production and firing technology of imperial porcelain reached a higher level

and had not declined in the Early Ming Dynasty.

KEYWORDS: EDXRF, LONGQUAN KILN, IMPERIAL PORCELAIN, FENGDONGYAN

KILN, PCA

INTRODUCTION

Longquan celadons, with higher firing technology and greater artistic merit, play a significant

role in the history of ancient Chinese celadon. According to previous archaeological evidence (Li

1998), it is well known that the Longquan kilns, located in Longquan City in Zhejiang Province,

began to fire celadon in the Southern and Northern Dynasties (ad 420589), and developed in the

Southern Song (ad 11271279) and Yuan Dynasties (ad 12711368). It used to be thought that

the firing technology had declined in the Ming Dynasty (ad 13681644), as stated in several

references (Chou et al. 1973; The Light Industry Hall of Zhejiang Province 1989; Li 1998). But

did the firing technology of Longquan celadon really begin to decline in the Ming Dynasty? Were

the Longquan kilns still the famous kilns that made porcelain for the palace?

In the past, research interest was focused on the development history and the decorative arts of

the civilian porcelain of Longquan celadon (Li et al. 1984; Ye et al. 1999; Jin 2007). Due to the

lack of specimens, the raw materials and firing technology of the imperial porcelain of Longquan

celadon has been little investigated. But the excavation of the Fengdongyan kiln provides

physical evidence. From September 2006 to January 2007, the Fengdongyan kiln, located in

*Received 8 January 2014; accepted 8 September 2014

Corresponding author: email fengxq@ihep.ac.cn

2014 University of Oxford

Characterization by EDXRF of imperial Longquan celadon porcelain

967

Figure 1 The location map for the Dayao County kiln, amongst the Longquan kilns.

Dayao County, in Longquan City (see Fig. 1), was excavated by the Zhejiang Province Institute

of Cultural Relics and Archaeology, the School of Archaeology and Museology of Peking

University and the Longquan Museum. A mass of exquisite Longquan celadon shards of the Yuan

and Ming Dynasties were unearthed, including abundant civilian porcelain and a lot of official

wares carved with Guan or the dragon patterns in the Hongwu and Yongle eras of the Ming

Dynasty (Zhejiang Institute of Cultural Relics et al. 2009). The emergence of this imperial

porcelain has led to great repercussions in archaeology. Some scholars have published comparisons between the imperial porcelain of the Ming Dynasty and the Longquan porcelain of the

Southern Song Dynasty (Peng et al. 2009). However, what differences are there between the

imperial porcelain of the Ming Dynasty and the civilian porcelain of the Early Ming Dynasty? At

present, there is little research comparing imperial porcelain with civilian porcelain in the Ming

Dynasty.

In this paper, we have determined the chemical composition of imperial Longquan celadon

porcelain using energy-dispersive X-ray fluorescence (EDXRF). It is well known that the contents of major, minor and trace elements of the porcelain body and glaze are dependent on its raw

material and manufacturing technology (Li 1998; Kerr and Wood 2004; Artioli 2010), which can

be used to indicate the age of the porcelain and its provenance. From a statistical analysis of the

elemental data, the raw material and the development of porcelain firing technology are discussed. The information is used to display the inheritance relationship of the raw materials used

for the body and glaze in different periods.

2014 University of Oxford, Archaeometry 57, 6 (2015) 966976

968

L. Li et al.

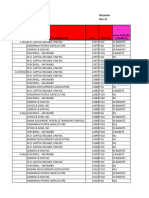

Figure 2 Photographs of imperial porcelain samples from the HWM and YLM periods.

Table 1

Detailed information on the celadon shards from the Fengdongyan kiln site

Group

Date

Number of shards

HWM

YLM

EM

Hongwu era of the Ming Dynasty

Yongle era of the Ming Dynasty

Early Ming Dynasty

32

53

48

Exterior characteristics

Celadon glaze, grey body

Celadon glaze, grey body

Celadon glaze, grey body

SAMPLES

In this work, 85 typical shards of imperial porcelain from the Fengdongyan kiln were provided

by Zhejiang Province Institute of Cultural Relics and Archaeology. These imperial porcelain

samples can be grouped into two cultural periods: the Hongwu (HWM group) and the Yongle

(YLM group) eras of the Ming Dynasty. Since Hongwu and Yongle are Early Ming, 48 shards

of civilian porcelain excavated at Fengdongyan dated to the Early Ming Dynasty (EM group)

were selected for comparison with the imperial porcelain. Some photographs of imperial porcelain shards are shown in Figure 2 and detailed information about the samples is listed in

Table 1.

THE EDXRF EXPERIMENT

A sample measuring 30 mm 10 mm was cut from the shard, and the cross-section was polished,

and then washed three times in an ultrasonic cleaner with deionized water and dried at 105C.

The EDXRF experiments were performed on an EDAX Eagle III spectrometer at the Institute of

High Energy Physics, CAS, Beijing, China. The spectrometer has a Mo tube and a 125 m Be

window with an incident beam angle of 65 and an emergence angle of 60. The detector is a

liquid-nitrogen-cooled Si(Li) crystal with a resolution of 160.3 eV at MnK. There is a vacuum

chamber and the diameter of the X-ray beam spot is selected to be 1 mm. The voltage and current

of the X-ray tube are 40 kV and 250 A, respectively. The software employed for spectrum

deconvolution and analysis is VISION32, which is associated with the instrument. A set

of standard reference samples with known chemical compositions, which were developed by the

2014 University of Oxford, Archaeometry 57, 6 (2015) 966976

969

Characterization by EDXRF of imperial Longquan celadon porcelain

Table 2

Experimental

value

Certified

value

The quantitative results for the ancient ceramic samples

Na2O

(%)

MgO

(%)

Al2O3

(%)

SiO2

(%)

K2O

(%)

CaO

(%)

TiO2

(%)

MnO

(%)

Fe2O3

(%)

Cu

(ppm)

Zn

(ppm)

Rb

(ppm)

Sr

(ppm)

0.65

0.62

24.34

67.54

2.27

0.54

0.88

0.022

2.77

46

54

119

109

0.44

0.70

23.90

67.50

2.30

0.62

0.95

0.026

2.70

27

59

113

103

Institute of High Energy Physics, are used to calibrate the ceramic matrix in order to obtain

reliable experimental data. The homogeneity of elements in these ceramic reference samples met

the requirements for non-destructive quantitative analysis (Li et al. 2010).

The elemental abundances of Na2O, MgO, Al2O3, SiO2, K2O, CaO, TiO2, MnO, Fe2O3, CuO,

ZnO, Rb2O and SrO are quantified by the fundamental parameter (FP) method (He and Espen

1991; Sitko 2008). This method assumes that the unknown samples have approximate compositions, and then calculates the fluorescence intensities based on the Sherman equation (Sherman

1955) and compared to the measured intensities (Lachance and Claisse 1994). Successive

adjustments of the composition are carried out until the theoretical and measured intensities are

consistent. The final concentrations are assumed to represent the actual compositions. In order to

get a better measure of the precision and accuracy of the data in this work, ancient ceramic

samples of known composition are selected to compare the expected and observed elemental

concentrations measured on the ceramic reference samples used in the analysis. The results show

that the experimental values are well in agreement with the certified ones (see Table 2).

The average values of each elemental composition in the porcelain body and glaze are

displayed below, in Tables 3 and 5, respectively. In this paper, the data for Na2O and MgO are

provided as references because of the poor fluorescent yields and low counts obtained for the

characteristic X-ray radiation.

DISCUSSION

The elemental characteristics of imperial porcelain with a Longquan celadon body

There are no evident differences between the average concentrations of SiO2, Al2O3 and MnO in

the imperial porcelain body for the HWM and YLM groups, as shown in Table 3. It can be seen

that the K2O contents in the Hongwu era of the Ming Dynasty are a little higher than those of the

Yongle era of the Ming Dynasty, while the CaO contents are lower, as can be seen in Figure 3.

The average TiO2 content in the HWM group is 0.21 0.03 % higher than that (0.14 0.02 %)

in the YLM group. The abundance change of Fe2O3 in the imperial porcelain body is similar to

that of TiO2, as shown in Figure 3. It is clearly observed that few differences exist in the major

elements of the porcelain body between the HWM and YLM groups. It is well known that in the

past, the raw material for making porcelain was obtained in the vicinity of the kiln sites.

According to the available documents (The Light Industry Hall of Zhejiang Province 1989), the

composition of Fe2O3 in the porcelain clay in the Longquan district is 0.331.24 %, which is less

than that (1.812.10 %) in the imperial porcelain body; however, the Fe2O3 content in Zijin clay

is greater than 8%, as shown in Table 4. Therefore, it seems that some Zijin clay was added: not

2014 University of Oxford, Archaeometry 57, 6 (2015) 966976

MgO (%)

0.48 0.06

0.46 0.06

0.45 0.06

Na2O (%)

0.56 0.08

0.65 0.10

0.64 0.11

Group

HWM

YLM

EM

2014 University of Oxford, Archaeometry 57, 6 (2015) 966976

20.5 0.5

20.6 0.5

20.8 0.9

Al2O3 (%)

70.4 0.7

70.7 0.8

70.6 1.2

5.36 0.31

5.20 0.42

5.19 0.48

K2O (%)

0.045 0.016

0.078 0.019

0.059 0.021

CaO (%)

0.21 0.03

0.14 0.02

0.13 0.03

TiO2 (%)

0.053 0.006

0.053 0.008

0.051 0.010

MnO (%)

2.10 0.10

1.81 0.12

1.82 0.13

Fe2O3 (%)

The average values of each composition in the bodies of the samples

SiO2 (%)

Table 3

59 6

58 5

57 6

CuO

(ppm)

101 10

107 21

104 22

ZnO

(ppm)

353 20

324 22

325 26

Rb2O

(ppm)

49 7

37 5

34 6

SrO

(ppm)

970

L. Li et al.

971

Characterization by EDXRF of imperial Longquan celadon porcelain

Figure 3 The histogram of the elemental contents in K2O, CaO, TiO2 and Fe2O3 by EDXRF.

Table 4 The chemical composition of porcelain clay and Zijin clay in Dayao County of Longquan City (The Light

Industry Hall of Zhejiang Province 1989)

Porcelain

clay

Zijin clay

of Dayao

County

SiO2 (%)

Al2O3 (%)

Fe2O3 (%)

TiO2

(%)

65.4175.75

16.0023.00

0.331.24

55.70

25.24

8.18

0.69

CaO (%)

A few

per cent

1.64

MgO (%)

K2O (%)

Na2O (%)

Trace amounts

2.715.35

0.021.12

A few per cent

2.61

0.82

only can it improve the strength of the body, but it can also increase the colour density of black

or grey in the porcelain body. The average contents of the trace elements Cu, Zn, Rb and Sr were

close to each other in the HWM and YLM periods.

In this work, principal components analysis (PCA) was used to study the raw material used

for the body in different cultural periods. The main objective of PCA is to reduce the dimensionality of the observations. Figure 4 shows a factorial analysis diagram from the composition

of the imperial porcelain bodies made in the Hongwu and Yongle periods. The data for K2O,

CaO, TiO2, Fe2O3, Rb and Sr are used and the eigenvalue sum of Factors 1 and 2 accounts for

81.12% of the total variance. Factor score 1 (F1) mainly includes the changes in TiO2 and

Fe2O3, while Factor score 2 (F2) represents the K2O content. In Figure 4, the data are divided

into two clusters by variation in F1, which shows that they clearly belong to the HWM and

YLM groups, respectively. The samples of the YLM group are situated in the lower region,

while most of samples in the HWM group are located in the upper region, and only a few

overlap with the YLM samples. This also shows that the difference between the porcelain

bodies of the Hongwu and Yongle periods is mainly caused by changes in the TiO2 and Fe2O3

contents in the imperial porcelain body. However, it can be seen from F2 that the samples in the

2014 University of Oxford, Archaeometry 57, 6 (2015) 966976

972

L. Li et al.

Figure 4 The distribution of the celadon body from the HWM and YLM periods by PCA: a plus sign (+) indicates the

celadon body of the Hongwu era of the Ming Dynasty and a triangle () represents the celadon body of the Yongle era.

HWM and YLM groups are distributed in the same area, so the concentration of K2O is not

significantly different according to the PCA results. The reason for this difference is the use of

different raw materials or differing degrees of elutriation of the same raw materials. In view of

the slightly different major element contents and the similar trace element contents, we conclude that differing degrees of elutriation of the same raw materials are the main reason for the

differences between the Hongwu and Yongle periods.

The EDXRF values for civilian porcelain bodies are also shown in Table 3. It can be seen that

the values for TiO2 and Fe2O3 in the HWM period are higher than those of the Early Ming

Dynasty (EM period), whereas the contents of other elements are similar. However, there are no

evident differences in the elemental features of the porcelain bodies in the YLM and EM groups.

Figure 5 shows the PCA factor analysis based on the chemical components in the porcelain

bodies of the HWM, YLM and EM groups. The same elements are selected as shown in Figure 4.

The eigenvalue sum of Factors 1 and 2 accounts for 77.5% of the total variance. Most of the data

in the HWM group are independently distributed in the upper region, while the samples from the

YLM and EM groups are situated in the lower region. This shows that the degree of elutriation

of the raw materials used for making imperial porcelain bodies in the Hongwu period was

different from that for the civilian porcelain bodies. The sample plots overlap each other in the

YLM and EM periods, and the data plots for the YLM period form a relatively concentrated

distribution. This means that similar processing of raw materials was used in the imperial

porcelain bodies of the Yongle period and the civilian porcelain bodies in the Early Ming

Dynasty.

The elemental characteristics of imperial porcelain with a Longquan celadon glaze

As shown in Table 5, there are no evident differences in the average concentration of each

composition in the porcelain glaze of the Hongwu and Yongle periods, and the elemental

2014 University of Oxford, Archaeometry 57, 6 (2015) 966976

Characterization by EDXRF of imperial Longquan celadon porcelain

973

Figure 5 The analytical results of PCA on porcelain bodies of the HWM, YLM and EM periods: a plus sign (+) indicates

the celadon body of the Hongwu era of the Ming Dynasty, a triangle () represents the celadon body of the Yongle era

and an asterisk (*) represents the civilian porcelain body of the Early Ming Dynasty.

values of the porcelain glaze are close to each other in the imperial and civilian porcelain.

According to the documentary evidence (Peng et al. 2009), the recipe for the glaze is made up

from plant ash and porcelain stone. From the perspective of the chemical composition of the

glaze, there are no obvious differences in the imperial porcelains, so the raw materials of the

imperial porcelain glaze of the Hongwu and Yongle periods are unchanged and have an inheritance relationship.

The quality and formula changes of the Longquan celadon glazes varied over time (Li 1998).

During the Southern Song Dynasty, the quality of the celadon glaze had been significantly

improved, and the very famous Fen ching (lavender grey) and Meizi ching (plum green) had been

created (Li 1998). However, the colour of the Longquan imperial porcelain in the Ming Dynasty

was mainly yellowgreen (see Fig. 2). So, what changes in the imperial porcelain glaze had taken

place as compared with that of the Southern Song Dynasty? The formation of the glaze colour is

related to many factors, and the major influences are the recipe, the glazing craft and firing

temperature, and so on. In this paper, the data of Fen ching and Meizi ching (Li 1998; Xiong et al.

2004) for the Longquan glazes dating from the Southern Song Dynasty are compared with the

analytical results obtained by EDXRF for the imperial porcelain samples of the Ming Dynasty.

As shown in Table 6, the average K2O contents of the Fen ching and Meizi ching glazes

(4.005.36 %) were lower than those for the imperial porcelain samples (5.785.83 %) in the

Ming Dynasty, while the change of concentration for CaO was opposite to that for K2O. In the

ceramics, K2O and CaO are often referred to the flux, which was used to reduce the firing

temperature of the body and glaze. The difference is that the fluxing ability of K2O is stronger

than that of CaO. In addition, the glossiness of the glaze is closely related to the oxide content

with a high refractive index, the content of the flux and the glass phase (Zhang 1998). Increasing

the chemical composition of K2O is advantageous for improving the refractive index of the glaze

layer, reducing the firing temperature and the high-temperature viscosity of the glaze and

2014 University of Oxford, Archaeometry 57, 6 (2015) 966976

MgO (%)

0.67 0.16

0.67 0.11

0.63 0.14

Na2O (%)

0.47 0.13

0.59 0.13

0.50 0.13

Group

HWM

YLM

EM

2014 University of Oxford, Archaeometry 57, 6 (2015) 966976

12.3 1.2

13.0 1.1

12.7 1.2

Al2O3 (%)

69.4 3.4

69.2 1.9

69.7 2.6

SiO2 (%)

Table 5

5.78 0.82

5.83 0.32

5.84 0.69

K2O (%)

7.80 2.05

7.25 1.79

7.31 2.10

CaO (%)

0.18 0.03

0.18 0.04

0.17 0.03

TiO2 (%)

0.31 0.09

0.35 0.07

0.32 0.08

MnO (%)

2.16 0.13

2.17 0.26

2.06 0.30

Fe2O3 (%)

The average values of each composition in the sample glaze

73 8

74 8

68 9

CuO

(ppm)

140 40

124 36

112 44

ZnO

(ppm)

291 18

296 16

286 24

Rb2O

(ppm)

547 125

509 95

568 144

SrO (ppm)

974

L. Li et al.

Characterization by EDXRF of imperial Longquan celadon porcelain

975

Table 6 The data of Fen ching and Meizi ching for Longquan glaze

dating from the South Song Dynasty (Li Jiazhi 1998; Xiong Yingfei 2004)

K2O (%)

CaO (%)

TiO2 (%)

Fe2O3 (%)

Fen ching (lavender grey)

4.87

8.39

5.06

9.94

4.53

7.95

4.25

10.7

0.07

0.06

0.95

1.1

1.54

1.29

Meizi ching (plum green)

4.41

9.88

5.36

9.05

4.12

9.21

4.00

9.99

0.06

0.08

0.91

1.32

0.82

1.68

increasing liquid formation at high temperature. Compared with Fen ching and Meizi ching in the

Southern Song Dynasty, the increased K2O content in the imperial porcelain glaze of the Ming

Dynasty gives a glaze with good transparency and gloss.

In Tables 5 and 6, it can be also seen that the TiO2 and Fe2O3 contents of the imperial porcelain

glaze of the Ming Dynasty are higher than those of the Southern Song Dynasty. The colour of

celadon glaze mainly depends on the Fe2O3 content and on the firing temperature and atmosphere.

The high levels of Fe2O3 in imperial porcelain make the glaze take on a yellowgreen colour, as

shown in Figure 2.

According to the available documents, imperial porcelain began to be fired at the Fengdongyan

kiln in the Hongwu era (ad 13681398) of the Ming Dynasty (Zhejiang Institute of Cultural

Relics et al. 2009). As is known, in ancient times the best-quality porcelain was dedicated for

palace use. In this work, the results of the analysis show that the raw materials for both the body

and the glaze of the imperial porcelain are similar to those of civilian porcelain. Therefore, we can

conclude that the production and firing technology of Longquan celadon had reached a higher

level and did not decline in the Early Ming Dynasty.

CONCLUSION

In this paper, EDXRF has been applied to analyse the elemental composition of Longquan

imperial porcelain that was fired at the Fengdongyan kiln in the Hongwu (ad 13681398) and

Yongle (ad 14021424) eras of the Ming Dynasty. The elemental contents of TiO2 and Fe2O3 in

the body vary in the different cultural periods. Compared with Longquan glaze dating from the

Southern Song Dynasty (ad 11271279), the average values for K2O, Fe2O3 and TiO2 are higher,

but the CaO content is lower in the imperial porcelain glaze. The PCA results show that the degree

of elutriation of the raw material used for making the imperial porcelain body in the Hongwu

period was different from that of the civilian porcelain, but the Yongle body is similar to that of

the civilian porcelain in the Early Ming Dynasty. However, the raw materials of the imperial

porcelain glaze of the Hongwu and Yongle periods show no obvious change and show an

inherited relationship. The production and firing technology of Longquan imperial celadon had

not declined in the Early Ming Dynasty.

2014 University of Oxford, Archaeometry 57, 6 (2015) 966976

976

L. Li et al.

ACKNOWLEDGEMENTS

The authors greatly appreciate the Zhejiang Province Institute of Cultural Relics and Archaeology, which provided ancient Chinese celadon excavated from the Fengdongyan site of the

Longquan kiln. This work was financially supported by the National Natural Science Foundation

of China (11205167, 11305183 and 11175190).

REFERENCES

Artioli, G., 2010, Scientific methods and cultural heritagean introduction to the application of materials science to

archaeometry and conservation science, Oxford University Press, Oxford.

Chou, J., Chang, F. K., and Cheng, Y. F., 1973, Technical studies on the Lungchuan celadons of successive dynasties, Acta

Archaeologica Sinica, 1, 13156.

He, F., and Espen, P. J., 1991, General approach for quantitative energy dispersive X-ray fluorescence analysis based on

fundamental parameters, Analytical Chemistry, 63, 223744.

Jin, W. L., 2007, The reason of prosperity of Longquan porcelain wares in the Southern Song Dynasty, China Ceramics,

43(11), 779.

Kerr, R., and Wood, N., 2004, Science and civilization in China, vol. 5: Chemistry and chemical technology, part 12,

ceramic technology, Cambridge University Press, Cambridge, UK.

Lachance, G. R., and Claisse, F., 1994, Quantitative X-ray fluorescence analysis: theory and application, John Wiley &

Sons, Inc., New York.

Li, H. H., Mei, Q., Sun, J. X., Wang, Y. Q., Chen, B. R., and Zhang, Y. J., 1984, Assay of trace elements in Longquan

green ware by neutron activation analysis, Journal of the Chinese Ceramic Society, 12(3), 34854.

Li, J. Z., 1998, History of science and technology in China: ceramic, Science Press, Beijing (in Chinese).

Li, L., Feng, S. L., Zhu, J. H., Feng, X. Q., Xie, G. X., and Yan, L. T., 2010, Homogeneity test of the ceramic reference

materials for non-destructive quantitative analysis by -XRF, Nuclear Techniques, 33(3), 1659.

Peng, B., Zhou, S. H., Shen, Y. M., and Li, B. Q., 2009, EDXRF study on Ming Dynasty celadons sherds unearthed from

Longquan Feng Dong Rock, Journal of the Chinese Ceramic Society, 39(11), 19038.

Sherman, J., 1955, The theoretical derivation of fluorescent X-ray intensities from mixtures, Spectrochimica Acta, Part

B, 7, 283306.

Sitko, R., 2008, Study on the influence of X-ray tube spectral distribution on the analysis of bulk samples and thin films:

fundamental parameters method and theoretical coefficient algorithms, Spectrochimica Acta, Part B, 63, 1297302.

The Light Industry Hall of Zhejiang Province, 1989, Study on Longquan celadon, Cultural Relics Press, Beijing (in

Chinese).

Xiong, Y. F., He, W. Q., Li, G. Y., Yang, G. F., and Wu, Q. H., 2004, Preliminary study on the glazes of Longquan

celadons, Sciences of Conservation and Archaeology, 16(2), 4550.

Ye, H. M., Li, G. Z., Guo, Y. Y., Zhou, S. D., Ye, P. H., Hu, Z. X., Shen, S. G., Ye, G. Z., Cao, H. W., and Cheng, Z. H.,

1999, A study on recovering the technology of Song Dynasty Longquan celadon, Journal of Ceramics, 20(2), 6478.

Zhang, Y. B., 1998, Study on improving the glossiness of glaze, Hebei Ceramics, 26(2), 3840.

Zhejiang Institute of Cultural Relics, School of Archaeology and Museology in Peking University and Longquan Celadon

Museum, 2009, Porcelain excavated from Fengdongyan kiln site at Dayao County of Longquan City, Cultural Relics

Publishing House, Beijing (in Chinese).

2014 University of Oxford, Archaeometry 57, 6 (2015) 966976

You might also like

- Archaeological Sciences 1995: Proceesings of a conference on the application of scientific techniques to the study of archaeologyFrom EverandArchaeological Sciences 1995: Proceesings of a conference on the application of scientific techniques to the study of archaeologyAnthony SinclairNo ratings yet

- Determiningthefiringtemperatureoflow-Fired Ancientpottery:Anexamplefromthedonghulin Site, Beijing, ChinaDocument11 pagesDeterminingthefiringtemperatureoflow-Fired Ancientpottery:Anexamplefromthedonghulin Site, Beijing, ChinaIS AANo ratings yet

- Study On Firing Temperature of The Song Dynasty (960-1279AD) Greenish-White Porcelain in Guangxi, China by Thermal Expansion MethodDocument10 pagesStudy On Firing Temperature of The Song Dynasty (960-1279AD) Greenish-White Porcelain in Guangxi, China by Thermal Expansion Methodmap vitcoNo ratings yet

- J Ceramint 2021 05 303Document6 pagesJ Ceramint 2021 05 303FURY FURIONNo ratings yet

- Ş - Demirci, E. N. Caner - Saltık, A. Türkmenoğlu S. Özçilingir-Akgün, Ö. BakırerDocument5 pagesŞ - Demirci, E. N. Caner - Saltık, A. Türkmenoğlu S. Özçilingir-Akgün, Ö. BakırerAHMED DERBESSNo ratings yet

- Micro Analysis Crystals 1Document15 pagesMicro Analysis Crystals 1nikrouNo ratings yet

- Photoluminescence Emissions of Ceramics: A Marker of Production TechnologyDocument4 pagesPhotoluminescence Emissions of Ceramics: A Marker of Production TechnologyRupeshRaoNo ratings yet

- Research Communications: Nondestructive Evaluation of The Delhi Iron PillarDocument9 pagesResearch Communications: Nondestructive Evaluation of The Delhi Iron PillarrajivonNo ratings yet

- Exrs-Boa - PC 33 PDFDocument290 pagesExrs-Boa - PC 33 PDFkerurNo ratings yet

- Luminescence DatingDocument74 pagesLuminescence DatingmonbistritaNo ratings yet

- Chemical Studies of Chinese Coinage II FDocument15 pagesChemical Studies of Chinese Coinage II FtorinuarizasutantoNo ratings yet

- X-Ray Fluorescence Spectrometry in Art and Archaeology: Michael Mantler and Manfred SchreinerDocument15 pagesX-Ray Fluorescence Spectrometry in Art and Archaeology: Michael Mantler and Manfred SchreinerJulio César Sierra PalominoNo ratings yet

- The Use of Antimony and Its Implication For The Luminescence Properties of Ancient Mosaic TesseraeDocument6 pagesThe Use of Antimony and Its Implication For The Luminescence Properties of Ancient Mosaic TesseraeгогавагановNo ratings yet

- Egyptian Blue Cakes From The Ayanis FortressDocument8 pagesEgyptian Blue Cakes From The Ayanis FortressJuliana CarvalhoNo ratings yet

- 13 50 SheaDocument49 pages13 50 SheaEin Dray Pyone HanNo ratings yet

- The Origins of Low-Fire Polychrome Glazed Pottery in ChinaDocument8 pagesThe Origins of Low-Fire Polychrome Glazed Pottery in Chinasnickercat.meowNo ratings yet

- The Investigation of Microstructure and Hardness of Archaeological AlloysDocument14 pagesThe Investigation of Microstructure and Hardness of Archaeological Alloysaleksa8650No ratings yet

- Journal of Archaeological Science: Shuya Wei, Qinglin Ma, Manfred SchreinerDocument6 pagesJournal of Archaeological Science: Shuya Wei, Qinglin Ma, Manfred SchreinerBárbara BerettaNo ratings yet

- Palamara Et Al - 2016 - Glazed PotteryDocument43 pagesPalamara Et Al - 2016 - Glazed PotteryMariaNo ratings yet

- TEKTITE OR OBSIDIAN-CALI GLASSDocument2 pagesTEKTITE OR OBSIDIAN-CALI GLASSLaura Daniela Jimenez PradaNo ratings yet

- Ceramic Materials in Fire Assay PracticesDocument11 pagesCeramic Materials in Fire Assay PracticesChristophe GarnierNo ratings yet

- Characterization of Historical Ceramics: A Case StudyDocument14 pagesCharacterization of Historical Ceramics: A Case StudyConstantin InelNo ratings yet

- Ceramics Science IntroductionDocument68 pagesCeramics Science IntroductionLaura BárbaroNo ratings yet

- Burgio, L. Lustre Ceramics Analysis. 2005Document2 pagesBurgio, L. Lustre Ceramics Analysis. 2005Trinidad Pasíes Arqueología-ConservaciónNo ratings yet

- Black glass from the northern roman empireDocument23 pagesBlack glass from the northern roman empireDanielnjbNo ratings yet

- CR 030698Document54 pagesCR 030698ThatoNo ratings yet

- Evidence For The Extraterrestrial Origin of A Natural QuasicrystalDocument6 pagesEvidence For The Extraterrestrial Origin of A Natural QuasicrystalChiara MichelazziNo ratings yet

- And Bronze Age ScotlandDocument184 pagesAnd Bronze Age ScotlandfilaleteNo ratings yet

- (Sici) 1097 4539 (199611) 25:6 281::aid xrs174 3.0.co 2 7Document5 pages(Sici) 1097 4539 (199611) 25:6 281::aid xrs174 3.0.co 2 7FURY FURIONNo ratings yet

- Sio2 Ftir Indian STHDocument3 pagesSio2 Ftir Indian STHMaria TănaseNo ratings yet

- Investigating EarlyMiddle Bronze Age Copper and Bronze Axes by MicroDocument8 pagesInvestigating EarlyMiddle Bronze Age Copper and Bronze Axes by MicroMarco StanojevNo ratings yet

- Fenrg 09 710907Document10 pagesFenrg 09 710907vikramNo ratings yet

- SAS3803Document32 pagesSAS3803Alejandro O. LunaNo ratings yet

- Characterising medieval coins through X-ray analysisDocument7 pagesCharacterising medieval coins through X-ray analysismariaNo ratings yet

- ZIMMERMANN, T. Et Alii, The Metal Tablet From Boğazköy-Hattuša. First Archaeometric ImpressionsDocument6 pagesZIMMERMANN, T. Et Alii, The Metal Tablet From Boğazköy-Hattuša. First Archaeometric ImpressionsAngel Carlos Perez AguayoNo ratings yet

- Ancient and Historic Metals 2/3Document98 pagesAncient and Historic Metals 2/3argaricoNo ratings yet

- Metallography PDFDocument185 pagesMetallography PDFTunjung Harry MuktiNo ratings yet

- Erdogu B. Neolithic and Chalcolithic in ThraceDocument425 pagesErdogu B. Neolithic and Chalcolithic in Thracemrazum100% (2)

- 10.1007@s12520 020 01074 6 PDFDocument20 pages10.1007@s12520 020 01074 6 PDFZhang XimingNo ratings yet

- Characterisation of Proto-historic Bronze Collection Using Micro-EDXRFDocument6 pagesCharacterisation of Proto-historic Bronze Collection Using Micro-EDXRFBojan TanaskovskiNo ratings yet

- Communication and Exchange Between The N PDFDocument20 pagesCommunication and Exchange Between The N PDFIsus DaviNo ratings yet

- Some Problems of Separation of Mixtures: N. N. KulovDocument12 pagesSome Problems of Separation of Mixtures: N. N. KulovIman Fadhul HadiNo ratings yet

- Firing Temperatures of Ancient PotteryDocument6 pagesFiring Temperatures of Ancient PotteryAnchal SharmaNo ratings yet

- Adichanallur Pottery - Journal of Molecular Structure 2012 PDFDocument6 pagesAdichanallur Pottery - Journal of Molecular Structure 2012 PDFAnchal SharmaNo ratings yet

- 29 4 693 PDFDocument15 pages29 4 693 PDFMilenita Paez AcuñaNo ratings yet

- Complex Oxides On FireDocument2 pagesComplex Oxides On FirePalash RoyChoudhuryNo ratings yet

- Identification of clay minerals and micas in sedimentary rocks using FTIR and thermal analysisDocument10 pagesIdentification of clay minerals and micas in sedimentary rocks using FTIR and thermal analysisJeysson Condori CcamaNo ratings yet

- Icst 2010Document3 pagesIcst 2010International Jpurnal Of Technical Research And ApplicationsNo ratings yet

- Ceramics and Pigments From Kostienki 1 PDFDocument58 pagesCeramics and Pigments From Kostienki 1 PDFtoddsawickiNo ratings yet

- Bone and Antler Combs: Towards A Methodology For The Understanding of Trade and Identity in Viking Age England and ScotlandDocument10 pagesBone and Antler Combs: Towards A Methodology For The Understanding of Trade and Identity in Viking Age England and ScotlandJustyna OrłowskaNo ratings yet

- MetalsDocument20 pagesMetalsCiera CorcaNo ratings yet

- A Multi Method Study of A Chalcolithic KDocument20 pagesA Multi Method Study of A Chalcolithic KmiruNo ratings yet

- Los Espejos Mágicos ChinaDocument9 pagesLos Espejos Mágicos Chinalucre88No ratings yet

- Polarized Crystal Spectra of CoF2Document14 pagesPolarized Crystal Spectra of CoF2csrpifNo ratings yet

- Neutron DiffractionDocument8 pagesNeutron DiffractionnghlsbstnNo ratings yet

- Lillie Et Al - Carpentry MesolithicDocument4 pagesLillie Et Al - Carpentry MesolithicPado BriogNo ratings yet

- 中essayDocument7 pages中essaywyr1110607No ratings yet

- McGovern 40a Ancient Ceramic TechDocument19 pagesMcGovern 40a Ancient Ceramic TechjbsingletonNo ratings yet

- Selenium 5. PRODUCTION, IMPORT/EXPORT, USE, AND DISPOSALDocument6 pagesSelenium 5. PRODUCTION, IMPORT/EXPORT, USE, AND DISPOSALAlexander Robert JennerNo ratings yet

- Al Chemfile v5 n6 PDFDocument24 pagesAl Chemfile v5 n6 PDFAlexander Robert JennerNo ratings yet

- Effect of Composition On Structure and Mechanical Properties of Metakaolin Based PSS-GeopolymerDocument7 pagesEffect of Composition On Structure and Mechanical Properties of Metakaolin Based PSS-GeopolymerAlexander Robert JennerNo ratings yet

- Quantum Mind 2007 Abstract ProceedingsDocument53 pagesQuantum Mind 2007 Abstract ProceedingsAlexander Robert Jenner100% (2)

- Hyle & CoahylDocument72 pagesHyle & Coahylganyesod80% (5)

- Whole Brain Emulation - A RoadmapDocument130 pagesWhole Brain Emulation - A Roadmapgluckspilz fliegenpilzNo ratings yet

- The Analysis and Characterization of Trace Elements, in Particular Bromine, Selenium and Arsenic in Marine OrganismsDocument152 pagesThe Analysis and Characterization of Trace Elements, in Particular Bromine, Selenium and Arsenic in Marine OrganismsAlexander Robert JennerNo ratings yet

- Albania's Abundant Mineral ResourcesDocument13 pagesAlbania's Abundant Mineral ResourcesAlexander Robert JennerNo ratings yet

- Micro-XRF For Characterization of Moroccan Glazed Ceramics and Portuguese TilesDocument11 pagesMicro-XRF For Characterization of Moroccan Glazed Ceramics and Portuguese TilesAlexander Robert JennerNo ratings yet

- Influence of Chemical and Mineralogical Composition of Metakaolin On Mortar CharacteristicsDocument6 pagesInfluence of Chemical and Mineralogical Composition of Metakaolin On Mortar CharacteristicsAlexander Robert JennerNo ratings yet

- Chemcraft ManualDocument72 pagesChemcraft Manualc1816488100% (2)

- Actum Leyden Letter Version 2Document3 pagesActum Leyden Letter Version 2Alexander Robert JennerNo ratings yet

- Extraction TechniquesDocument40 pagesExtraction TechniquesAlexander Robert JennerNo ratings yet

- Complete Chemist by C. GlaserDocument124 pagesComplete Chemist by C. GlaserAlexander Robert Jenner100% (1)

- Paracelsus and The Medical Revolution of The Renaissance R20071010ADocument18 pagesParacelsus and The Medical Revolution of The Renaissance R20071010Akvirgil100% (1)

- Analysis and PurificationDocument88 pagesAnalysis and PurificationAlexander Robert JennerNo ratings yet

- Prophecy and Alchemy: Uncovering the Origins of Eirenaeus PhilalethesDocument22 pagesProphecy and Alchemy: Uncovering the Origins of Eirenaeus PhilalethesAlexander Robert Jenner100% (2)

- The Craig Countercurrent Distribution TrainDocument3 pagesThe Craig Countercurrent Distribution TrainAlexander Robert JennerNo ratings yet

- Micro Chemical AssaysDocument156 pagesMicro Chemical AssaysAlexander Robert JennerNo ratings yet

- Inorganic Chemistry: Laboratory Manual IIDocument29 pagesInorganic Chemistry: Laboratory Manual IIVictor Manuel Enriquez GNo ratings yet

- Giordano, Reverse TransmutationsDocument51 pagesGiordano, Reverse TransmutationsAlexander Robert Jenner100% (1)

- Inorganic Lab ManualDocument50 pagesInorganic Lab Manualiugulescu laurentiuNo ratings yet

- How Vacuum Tubes Are Made - 1923Document7 pagesHow Vacuum Tubes Are Made - 1923Alexander Robert JennerNo ratings yet

- Paracelsus and The Medical Revolution of The Renaissance R20071010ADocument18 pagesParacelsus and The Medical Revolution of The Renaissance R20071010Akvirgil100% (1)

- Fumehoods GuideDocument12 pagesFumehoods GuideAlexander Robert JennerNo ratings yet

- FormulasDocument48 pagesFormulasAlexander Robert Jenner100% (2)

- Periodic TableDocument1 pagePeriodic TableAlexander Robert Jenner50% (2)

- I.V. Sterile Productoin StandardsDocument16 pagesI.V. Sterile Productoin StandardsAlexander Robert JennerNo ratings yet

- Ancient Blacksmiths, The Iron Age, Damascus Steels and Modern MetallurgyDocument11 pagesAncient Blacksmiths, The Iron Age, Damascus Steels and Modern Metallurgykalyanaraman7No ratings yet

- Aeration PaperDocument11 pagesAeration PapersehonoNo ratings yet

- Decision Model Using ExcelDocument236 pagesDecision Model Using Excelসামিউল ইসলাম রাজু100% (3)

- ME4111 Engineering and Mechanical PrinciplesDocument5 pagesME4111 Engineering and Mechanical PrinciplesEdvard StarcevNo ratings yet

- PermutationDocument3 pagesPermutationKhairuddin MuhamadNo ratings yet

- Matrix Inversion Note in Mathematics MagazineDocument2 pagesMatrix Inversion Note in Mathematics Magazinejuan carlos molano toroNo ratings yet

- A Prediction of Water Quality Analysis Using Machine LearningDocument6 pagesA Prediction of Water Quality Analysis Using Machine LearningmonacmicsiaNo ratings yet

- Central Angles and Inscribed Angles GuideDocument22 pagesCentral Angles and Inscribed Angles GuideEric de Guzman100% (1)

- Chapter 1Document11 pagesChapter 1bekemaNo ratings yet

- Wound ScaleDocument4 pagesWound ScaleHumam SyriaNo ratings yet

- Pines City National High School Science 10 Quarter 2 Week 1 Answer SheetsDocument8 pagesPines City National High School Science 10 Quarter 2 Week 1 Answer SheetsAaron BalsaNo ratings yet

- JasminDocument125 pagesJasminudoraboxNo ratings yet

- Research BulletsDocument18 pagesResearch BulletsVong Albios DogomeoNo ratings yet

- Analysis of Rack and Pinion Using AnsysDocument21 pagesAnalysis of Rack and Pinion Using AnsysTejas Prakash100% (1)

- Sybsc Physics Practical Usphp3Document3 pagesSybsc Physics Practical Usphp3Ujjwala GokheNo ratings yet

- GBE Version 3: API: New API SpecificationDocument44 pagesGBE Version 3: API: New API SpecificationAdi BauNo ratings yet

- Math10 Week3Day4 Polynomial-EqnsDocument44 pagesMath10 Week3Day4 Polynomial-EqnsMark Cañete PunongbayanNo ratings yet

- Work MeasurementDocument15 pagesWork MeasurementBalaji BabuNo ratings yet

- Tools - For - Problem - Solving (Appendix B), R.K. Malik's Newton Classes PDFDocument48 pagesTools - For - Problem - Solving (Appendix B), R.K. Malik's Newton Classes PDFMoindavis DavisNo ratings yet

- Expanding Wired Connectivity For SOHO Networks: Plus Gigabit Ethernet SwitchesDocument4 pagesExpanding Wired Connectivity For SOHO Networks: Plus Gigabit Ethernet SwitchesAndré LinharesNo ratings yet

- Modular Forms Exam - Homework RewriteDocument2 pagesModular Forms Exam - Homework RewritejhqwhgadsNo ratings yet

- DL-H61M-VG4: Motherboard User ManualDocument52 pagesDL-H61M-VG4: Motherboard User ManualSutripti Bardhan100% (1)

- AdvancesDocument328 pagesAdvanceshanumsj123No ratings yet

- Rac NotesDocument16 pagesRac NotesJohnRay LominoqueNo ratings yet

- Influence of Ring-Stiffeners On Buckling Behavior of Pipelines UnderDocument16 pagesInfluence of Ring-Stiffeners On Buckling Behavior of Pipelines UnderSUBHASHNo ratings yet

- GSM Modem XM1510S-B00-103 ManualDocument19 pagesGSM Modem XM1510S-B00-103 ManualPaul MaposaNo ratings yet

- Python Notes - 1Document364 pagesPython Notes - 1hopefulantonelliNo ratings yet

- Inductive Proximity Sensors: Brett Anderson ECE 5230 Assignment #1Document27 pagesInductive Proximity Sensors: Brett Anderson ECE 5230 Assignment #1Rodz Gier JrNo ratings yet

- Mammography View ChapterDocument60 pagesMammography View ChapterSehar GulNo ratings yet

- Nov. AbwDocument50 pagesNov. Abwjbyarkpawolo70No ratings yet

- Machine DesignDocument69 pagesMachine DesignSushant TiwariNo ratings yet