Professional Documents

Culture Documents

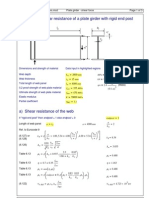

Cruciform Sections + NSCApril06 - Tech

Uploaded by

Iho1Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Cruciform Sections + NSCApril06 - Tech

Uploaded by

Iho1Copyright:

Available Formats

Technical

Design of

Cruciform Sections

using BS 5950-1:2000

Many engineers will be relatively unfamiliar with torsional modes of buckling, but they are

explicitly covered in the Eurocodes. Steel Construction Institute Senior Manager Charles King

explains what designers of bi-symmetric cruciform sections need to know about buckling.

1. CRUCIFORM SECTIONS AND

TORSIONAL BUCKLING

1.1 Whos heard of torsional modes of buckling?

There are several modes of buckling that affect

structures. Most structural engineers are familiar

with:

Fig1. Plain Cruciform

Fig 2. Flanged Cruciform

30

NSC April 2006

1. Flexural buckling, commonly referred to as

strut buckling, column buckling, compression

buckling or Euler buckling to distinguish it

from the buckling of a beam due to a bending

moment.

2. Lateral torsional buckling, commonly referred

to as beam buckling

3. Plate buckling, which one might expect in

slender components of box girders

4. Shear buckling, which is a type of plate

buckling

5. Local buckling, which is a common term for

plate buckling modes that might occur in

members.

Many structural engineers working with hot-rolled

members or fabricated plate members are less

familiar with, or are even unaware of, torsional

modes of buckling. Design codes for orthodox

structures commonly do not explicitly mention

these modes. However, codes do cover such

modes; for example the checks in Annex G of BS

5950 1:2000 are for buckling modes that are close

relatives of the torsional and torsional-flexural

buckling modes described in this article. Torsional

modes of buckling are explicitly covered in the

Eurocodes.

Torsional buckling modes are better known to

engineers designing cold-formed members, where

these modes are often critical, and are addressed by

design codes.

This article is written to assist in the design of

bi-symmetric cruciform sections, as shown in Figure

1 and Figure 2. Such sections are prone to torsional

buckling, but not to torsional-flexural buckling

because the centroid of the section coincides with

the shear centre.

1.2 Does it matter?

A good question is, If Ive never heard of these

modes, can they be important? The answer is that

these buckling modes are not the critical modes in

the most commonly used compression members

with the most common restraint arrangements.

Structural hollow sections have such high

torsional stiffness that torsional modes cannot be

the critical modes in normal sections. Torsional

modes will not be critical in bi-symmetric I-sections

(eg UCs) with both flanges restrained at the same

points along a member. However, where the flanges

are not equally restrained, torsional modes may be

the critical modes.

For all other sections, torsional modes are

likely to be the critical modes. In the case of angles,

channels and tees, this is effectively allowed for

in BS 5950-1 by the slenderness calculations to

4.7.10 and Table 25. For other mono-symmetric

or asymmetric sections, most codes give no

assistance. With the evolution of steel structures

towards more exotic structural forms, designers

need to be aware of these other modes. It is

especially worth noting that in an I-section with

different flanges, torsional-flexural buckling is

commonly the lowest mode.

1.3 What do these modes look like?

Torsional modes of buckling are commonly divided

into two categories:

1. Torsional buckling

2. Torsional-flexural buckling

Cruciform sections and similar sections all have

a torsional buckling mode, as shown in Figures

3 and 4.

Asymmetric sections are all prone to torsionalflexural buckling, as shown in Figure 5. Indeed, it

is common for torsional-flexural buckling to be the

critical mode of buckling, more onerous than pure

minor axis buckling (Figure 5)

Sections in which the shear centre does NOT

coincide with the centroid will be prone to torsionalflexural buckling and this should be expected to be

Technical

Fig 4. Asymmetric section

Fig 3. Plain Cruciform deforming in the torsional mode

the critical mode of buckling for a given effective

length. Sections in which the shear centre DOES

coincide with the centroid will NOT be prone to

torsional-flexural buckling.

This article is intended for the design of bisymmetric cruciform sections. In these sections, the

shear centre coincides with the centroid so they are

NOT prone to torsional-flexural buckling.

1.4 What should a designer do?

Designers would be wise to avoid the problem

wherever possible by using appropriate sections

and restraint arrangements. It is simplest to resist

compression either by UCs with both flanges

equally restrained or by hollow sections.

If you cannot avoid the problem, calculate the

compressive strengths for the torsional modes and

compare these with the compressive strength for

flexural buckling. Then calculate the compression

resistance of the member using the lowest

compressive strength and continue with the normal

codified design procedures.

2. COMPRESSIVE STRENGTH

2.1 Use of the elastic critical buckling strength

The elastic critical buckling stress is the stress at

which the member would buckle if it had an infinitely high yield stress and no imperfections. Engineers

learn about Euler buckling during their studies and

learn that the Euler buckling load of a strut is

2EI

PE =

L2

The Euler buckling stress is the elastic critical

buckling stress of the strut for flexural buckling. In

the case of Euler buckling, this can be written using

BS 5950 1 symbols as

pE =

PE

A

( )

2EI

L2

2E

=

( )

I

A

L2

( )

2E r 2

L2

Codes use the elastic critical buckling stress to

find the compressive strength of a member. In

BS 5950-1:2000, this can be seen in Annex C,

2E

(L/r )

Fig 5. Plain cruciform

section C.1. The procedure in Annex C can be

adapted to check other modes of buckling by using

the elastic critical stress of the mode of buckling

considered in place of the elastic critical stress from

the usual flexural mode.

To avoid having to use Annex C to calculate

pc from pE, it is more convenient to calculate the

equivalent slenderness, , from the equation in

Annex C and then find pc directly from tables in the

Standard.

Annex C gives pE = p2E/2. Therefore, can be

2E

found from =

pE

.

This allows the designer to use Table 24 of

BS 5950-1:2000 to find pc easily.

2.2 Torsional buckling

The elastic critical load for torsional buckling can

be found in classic references such as Timoshenko,

Strength of Materials, Part 2 or Timoshenko and

Gere, Theory of Elastic Stability. The elastic critical

buckling stress is simply [elastic critical load]/area.

Using symbols in BS 5950-1,

pE =

1

I0

GJ +

n22

L2

EH

where

I0 is the polar moment of area with respect

to the shear centre of the section. For

bi-symmetric cruciform sections, I0 = Ix + Iy .

G is the torsional modulus

pE =

E

2(1+v)

E

2(1+ 0.3)

E

2.6

J is the torsional constant.

For flanged cruciforms comprising two rolled

sections, J is the sum of the J values of the

component rolled sections.

n is the number of half-sine waves along

the outstands of the member. For members

restrained at both ends, this should be taken

as 1.0 unless you are sure you can prove it is

NSC April 2006

31

Technical

greater. For cantilever columns this should not

be taken as greater than 0.5.

L is the length of the member

E is Youngs modulus

and

H is the warping constant. For bi-symmetric cruciform sections such as in Figures 1 and 2, this

is the sum of the warping constants, H, for the

two component sections. H for a plain cruciform

is very small, so it is recommended that H is

taken as zero.

The formula for members with no warping stiffness

(such as a plain cruciform) reduces to:

pE =

1

I0

GJ

2.3 Selection of the buckling curve

Where there is a torsional component to the buckling, the buckling involves flexure of the flanges

similar to minor axis buckling of the component

parts of the member. Therefore the buckling curve

should be selected from Table 23 of BS 5950-1:2000

for the components as shown in Figure 6.

For example, a flanged cruciform made from UB

sections designed to

BS 5950-1:2000 would

use curves (b) or (c)

depending on the

thickness of the flange

being less than or

greater than 40mm. A

Fig 6. Similarity between torsional buckling and flexural

plain cruciform section

buckling about the minor axis of the component parts

would also use curves

(b) or (c) depending on the thickness of the flange

being less than or greater than 40mm.

3. BENDING STRENGTH OF

CRUCIFORM SECTIONS

When checking the interaction of axial load and

bending moment, both axial and bending resistance

are required. The axial resistance should be checked

as above. The bending resistance can be calculated

using the advice in the following sections. Note that

the following advice is limited to bi-symmetric sections (torsional-flexural buckling is not critical). A

subsequent article will show how torsional flexural

buckling can be calculated for other sections

3.1 Flanged cruciform sections

The bending strength of flanged cruciform sections

is most conveniently found by calculating the slenderness, LT, using the method in BS 5950-1:2000. It

is recommended that when using Annex B, section

B.2.3, the value of gamma, g, is taken as 1.0 because

the value given in Annex B was derived for single

I-sections. It is also recommended that values of u

and x are calculated using the formula given for

channels with equal flanges to avoid assumptions

made for single I-sections. Tables 16 or 17 can then

be used as for lateral torsional buckling of single Isections.

32

NSC April 2006

3.2 Plain cruciform sections

It is recommended that the derivation of the

slenderness for plain cruciform sections, as shown

in Figure 1, is calculated assuming that the section is

Class 3 and that designers proceed as follows:

1. Calculate the elastic critical stress for lateral

torsional buckling for members with no warping

stiffness (such as a plain cruciform), which is:

pE =

Mcr

Zx

EIyGJ

Zx

2. Calculate the slenderness, LT, from the equation

in Annex B relating pE to slenderness, LT, which can

be re-arranged as

2E

LT =

pE

.

3. Use Table 17 of BS 5950-1:2000 to find pb.

4. DETAILING CRUCIFORM SECTIONS

Where the failure mode is by flexural buckling about

one of the rectangular axes of the cruciform, the

I-section that is on the axis of flexure relies on the

other I-section for stability. If the web of the I-section

that is on the axis of flexure is neither stiff enough

nor strong enough to make the flanges on the axis

of flexure deflect in the same shape as expected for

the whole, then these flanges will deflect more and

will unload, reducing the resistance of the cruciform.

The simple way to avoid this problem is to

add gussets between the webs and flanges (so that

all the elements are connected) at centres such

that the slenderness about the minor axis of the Isections (taking an effective length factor of 1.0) is

not greater than the slenderness of the full length

cruciform. A possible arrangement is shown in

Figures 7 and 8.

Fig 7.

Fig 8.

You might also like

- LongitudinalShearReinforcementDesign C10 bk800 PDFDocument7 pagesLongitudinalShearReinforcementDesign C10 bk800 PDFBehairy AhmedNo ratings yet

- Design of LacingDocument8 pagesDesign of LacingRonak KamdarNo ratings yet

- Chapter 3 Column and Compression MembersDocument60 pagesChapter 3 Column and Compression Membersbihanba100% (1)

- Truss DesignDocument16 pagesTruss DesignRabindraUpretiNo ratings yet

- Crack Width ConcreteDocument1 pageCrack Width ConcreteRuemu Godwin InikoriNo ratings yet

- Pile Capacity (Pile Cap - BS 8110) PDFDocument1 pagePile Capacity (Pile Cap - BS 8110) PDFlsatchithananthanNo ratings yet

- Singly Reinforced Concrete Beams AS3600Document6 pagesSingly Reinforced Concrete Beams AS3600Preston WilliamNo ratings yet

- Con 1302Document12 pagesCon 1302Sanket Arun More100% (1)

- Thesis FulltextDocument386 pagesThesis FulltextAlberto CaínNo ratings yet

- Sheet #4 - Stiffened PlatesDocument3 pagesSheet #4 - Stiffened PlatesHany EmadNo ratings yet

- Modal Mass, Stiffness and DampingDocument5 pagesModal Mass, Stiffness and Dampingkudrilya100% (1)

- Reinforced Concrete Column Combined Footing Analysis DesignDocument19 pagesReinforced Concrete Column Combined Footing Analysis DesignHaseeb Ahmed100% (1)

- 1-Structural-Design 2012 Yield LineDocument52 pages1-Structural-Design 2012 Yield LineJake BloggerNo ratings yet

- Instantaneous Center of Rotation MethodDocument3 pagesInstantaneous Center of Rotation MethodrammohanNo ratings yet

- Working Stress Design Method 1Document23 pagesWorking Stress Design Method 1kumaravajiraNo ratings yet

- Linear Analysis of Guyed MastDocument6 pagesLinear Analysis of Guyed MastPankaj_Taneja_9684No ratings yet

- Fin Plate G3Document3 pagesFin Plate G3jiun yee chinNo ratings yet

- Design of Advanced Reinforced Concrete MembersDocument226 pagesDesign of Advanced Reinforced Concrete MembersĐỗ Nguyên KhôiNo ratings yet

- Structural,: PDF Compression, Ocr, Web-Optimization With Cvision'S PdfcompressorDocument174 pagesStructural,: PDF Compression, Ocr, Web-Optimization With Cvision'S PdfcompressorZuhal ZaeemNo ratings yet

- Design of Composite ColumnsDocument7 pagesDesign of Composite Columnsabozaid19No ratings yet

- Beam ColumnsDocument21 pagesBeam ColumnsSherif Mohamed Ibrahim100% (1)

- Class A Loads Govt. of West Pakistan - Code of Practice Highway BridgesDocument1 pageClass A Loads Govt. of West Pakistan - Code of Practice Highway BridgesBunkun150% (1)

- Effective LengthDocument17 pagesEffective LengthJob NantawatNo ratings yet

- TR12 PDFDocument24 pagesTR12 PDFramorusoNo ratings yet

- Sand Heap AnalogyDocument23 pagesSand Heap AnalogyTatyGendadeReynosoNo ratings yet

- Bracing Connection Work Point PDFDocument2 pagesBracing Connection Work Point PDFaams_sNo ratings yet

- Plate Girders 2008Document20 pagesPlate Girders 2008Tharmalingam VijayNo ratings yet

- COLUMN EFFECTIVE LENGTH - Yura1971q2Document6 pagesCOLUMN EFFECTIVE LENGTH - Yura1971q2ellisbl100% (1)

- SAP2000 Section PropertiesDocument3 pagesSAP2000 Section PropertiesCon Can100% (1)

- Part2 - Lateral Earth Pressure PDFDocument29 pagesPart2 - Lateral Earth Pressure PDFChan Nov100% (1)

- Instability Zero StiffnessDocument3 pagesInstability Zero StiffnessAnonymous IwqK1NlNo ratings yet

- Pages From PCA Notes On ACI318-08Document4 pagesPages From PCA Notes On ACI318-08Jorge Rubén TorresNo ratings yet

- As 3600 2018 One Way Slab End SpanDocument10 pagesAs 3600 2018 One Way Slab End SpanSteven SebastianNo ratings yet

- Design of Prestressed Concrete Pile PDFDocument14 pagesDesign of Prestressed Concrete Pile PDFvindyavNo ratings yet

- 03 2 Storey 8 Rooms RCC DOE 1480490469 PDFDocument24 pages03 2 Storey 8 Rooms RCC DOE 1480490469 PDFJoe Njore100% (1)

- Strut and Tie MethodDocument19 pagesStrut and Tie MethodRizki Amalia Tri CahyaniNo ratings yet

- Ec9 Ex61 Shear No StiffenersDocument3 pagesEc9 Ex61 Shear No StiffenersimotalpNo ratings yet

- Chapter 2 Reinforced Concrete Beams and SlabsDocument56 pagesChapter 2 Reinforced Concrete Beams and SlabsHasnain BukhariNo ratings yet

- Industrial Buildings-Guidelines and CriteriaDocument5 pagesIndustrial Buildings-Guidelines and CriteriaAlexander Tavarez SantanaNo ratings yet

- Shallow Foundation,,,, PDFDocument48 pagesShallow Foundation,,,, PDFJKDLJSJFLSNo ratings yet

- Week 9 - Session 1 - Concrete Design - Punching Shear in RC Flat SlabsDocument5 pagesWeek 9 - Session 1 - Concrete Design - Punching Shear in RC Flat SlabsengkjNo ratings yet

- BS 5950-2000 Example 001Document5 pagesBS 5950-2000 Example 001Anitha Hassan KabeerNo ratings yet

- Development of Column Interaction Curves For Higher Grades of ConcreteDocument22 pagesDevelopment of Column Interaction Curves For Higher Grades of Concreteyedida v r aviswanadhNo ratings yet

- Portal Frame Practice ProblemsDocument10 pagesPortal Frame Practice ProblemsBoyzz ChinNo ratings yet

- Microsoft Word - Design Station Purlins & Girts-Rev3Document31 pagesMicrosoft Word - Design Station Purlins & Girts-Rev3khairul4008No ratings yet

- Computation: Reinforced Concrete Slab DesignDocument4 pagesComputation: Reinforced Concrete Slab DesignARSENo ratings yet

- Advanced Opensees Algorithms, Volume 1: Probability Analysis Of High Pier Cable-Stayed Bridge Under Multiple-Support Excitations, And LiquefactionFrom EverandAdvanced Opensees Algorithms, Volume 1: Probability Analysis Of High Pier Cable-Stayed Bridge Under Multiple-Support Excitations, And LiquefactionNo ratings yet

- CVL-243 Reinforced Concrete Design Semester 1, 2020-21: Sahil Bansal, IIT Delhi 1Document23 pagesCVL-243 Reinforced Concrete Design Semester 1, 2020-21: Sahil Bansal, IIT Delhi 1Ekant YadavNo ratings yet

- Introduction To Beams: Part ADocument49 pagesIntroduction To Beams: Part AMorad AJNo ratings yet

- Week 5 - Practice Problem (Solution)Document6 pagesWeek 5 - Practice Problem (Solution)benzhuNo ratings yet

- CON4338A2TO180829BL Ch4 PrestressedConcreteDocument26 pagesCON4338A2TO180829BL Ch4 PrestressedConcretelau lauNo ratings yet

- 5.5 Load Calculation - Earthquake LoadDocument9 pages5.5 Load Calculation - Earthquake Loadarit bhattacharyaNo ratings yet

- Inverted-T Capacity Calculation@Phase1v2Document11 pagesInverted-T Capacity Calculation@Phase1v2satyaNo ratings yet

- Load Combination (STEEL AND TIMBER DESIGN)Document11 pagesLoad Combination (STEEL AND TIMBER DESIGN)Mahmuddin AminNo ratings yet

- End Plates - Worked Examples With Partial Depth End Plate - Example 5Document1 pageEnd Plates - Worked Examples With Partial Depth End Plate - Example 5Kimutai Kirui AlphonceNo ratings yet

- Determining Moment-Curvature Relationship of Reinforced Concrete Columns (#364338) - 379911Document7 pagesDetermining Moment-Curvature Relationship of Reinforced Concrete Columns (#364338) - 379911srikantheraNo ratings yet

- Bolt Design For Repeated LoadingDocument13 pagesBolt Design For Repeated LoadingMohammed A. AL-AhmareNo ratings yet

- Members With Combined Bending and Axial ForceDocument32 pagesMembers With Combined Bending and Axial ForceJohn RomanusNo ratings yet

- Stiffeners and Doublers Handout - 2per PDFDocument61 pagesStiffeners and Doublers Handout - 2per PDFIho1No ratings yet

- The Infrastructure Crisis: A Trillion Dollar Challenge: Nemy Banthia and Axel MeisenDocument37 pagesThe Infrastructure Crisis: A Trillion Dollar Challenge: Nemy Banthia and Axel MeisenIho1No ratings yet

- Bu Mat 05VCC PJostDocument19 pagesBu Mat 05VCC PJostIho1No ratings yet

- Design of An Industrial Crane Building Session 5 PDFDocument18 pagesDesign of An Industrial Crane Building Session 5 PDFIho1100% (1)

- Design of Reinforcement For Steel Members-1Document58 pagesDesign of Reinforcement For Steel Members-1Iho1No ratings yet

- Where Did That Force Come FromDocument54 pagesWhere Did That Force Come FromIho1No ratings yet

- WLG2445 - Chain Link FenceDocument38 pagesWLG2445 - Chain Link FenceIho1No ratings yet

- Anchors Fundamentals - Hilti PDFDocument24 pagesAnchors Fundamentals - Hilti PDFIho1No ratings yet

- ASCE Anchor Bolt Design For Petrochemical Facilities PDFDocument27 pagesASCE Anchor Bolt Design For Petrochemical Facilities PDFIho1No ratings yet

- Checkered PlateDocument2 pagesCheckered PlateIho1No ratings yet

- Diaphragm Presentation3Document78 pagesDiaphragm Presentation3Iho1100% (3)

- Dffa b10333 00 7600Document8 pagesDffa b10333 00 7600BlAdE 12No ratings yet

- IS550 MidTerm Spring 2015 SolutionDocument7 pagesIS550 MidTerm Spring 2015 Solutionaboaziz2130No ratings yet

- Soft Starting of Three Phase Induction Motor: AbstractDocument2 pagesSoft Starting of Three Phase Induction Motor: AbstractethrottleNo ratings yet

- CSP Application GuideDocument16 pagesCSP Application Guidernp246000No ratings yet

- Introduction To Numerical Controlled Machines and AutomationDocument7 pagesIntroduction To Numerical Controlled Machines and AutomationShanna0% (1)

- CG Course PlanDocument16 pagesCG Course PlanRAHUL DHANOLANo ratings yet

- Blackrock Methods of Delay AnalysisDocument36 pagesBlackrock Methods of Delay AnalysisAhmed MoubarkNo ratings yet

- Retrofit Assessment ChecklistDocument8 pagesRetrofit Assessment ChecklistPrakash SIngh RawalNo ratings yet

- Advertisement Faculty 13.07.23Document48 pagesAdvertisement Faculty 13.07.23digvijay singhNo ratings yet

- Catalogo Interpact 40 A 2500A PDFDocument160 pagesCatalogo Interpact 40 A 2500A PDFsebadolzNo ratings yet

- Calculation DraftDocument12 pagesCalculation DraftJem YumenaNo ratings yet

- AHPP15e ARE5 PDDDocument3 pagesAHPP15e ARE5 PDDBrookes SteppNo ratings yet

- Design of Nonstructural Systems and ComponentsDocument42 pagesDesign of Nonstructural Systems and ComponentsJV LopezNo ratings yet

- Minor New CurrDocument20 pagesMinor New CurrAnanyaNo ratings yet

- Eaton 9155 Ups User Guide Manual 164201553 PDFDocument98 pagesEaton 9155 Ups User Guide Manual 164201553 PDFEdwin RTNo ratings yet

- Cable Ampacity in Free AirDocument1 pageCable Ampacity in Free AirEdith LasinNo ratings yet

- BIMDocument8 pagesBIMMuhd ZulFadliNo ratings yet

- Building Planning and DrawingDocument35 pagesBuilding Planning and DrawingArun Bhuyan100% (2)

- Lab 3Document8 pagesLab 3amraqstnaNo ratings yet

- 2 Delmia Quest PDFDocument6 pages2 Delmia Quest PDFAlan Kottommannil ThomsonNo ratings yet

- IS 16172 2014 Coupler Splice BarDocument16 pagesIS 16172 2014 Coupler Splice BarMayank KumarNo ratings yet

- MEC522 PBL - ArduinoDC - MotorEncoder - Close LoopDocument3 pagesMEC522 PBL - ArduinoDC - MotorEncoder - Close Loopzaiful hakimNo ratings yet

- PIP STE05121 Anchor Bolt Design Guide PDFDocument56 pagesPIP STE05121 Anchor Bolt Design Guide PDFjamilNo ratings yet

- Design and Analysis of Tank Ring Wall Fo PDFDocument3 pagesDesign and Analysis of Tank Ring Wall Fo PDFsatyakamNo ratings yet

- Msar MHT Pa Ic Zn1 TC Fwi DWG STR 0401 Msar MHT Pa Ic Zn1 TC Fwi DWG STR 0401Document1 pageMsar MHT Pa Ic Zn1 TC Fwi DWG STR 0401 Msar MHT Pa Ic Zn1 TC Fwi DWG STR 0401柔道—Ibn MasudNo ratings yet

- Facade Renewal of Generalštab BuildingDocument26 pagesFacade Renewal of Generalštab BuildingEmilija NikolicNo ratings yet

- Coursera Essential Skills Map - MasterDocument7 pagesCoursera Essential Skills Map - Masterarum2008100% (1)

- CO326 - Variation Proposal From ContractorDocument2 pagesCO326 - Variation Proposal From ContractorLiew Kuet KongNo ratings yet

- M. Tech SynopsisDocument8 pagesM. Tech SynopsisemtiazNo ratings yet

- 3 PilesDocument37 pages3 PilesAnonymous nwByj9LNo ratings yet