Professional Documents

Culture Documents

WI 15 Cement Testing

Uploaded by

Raja Varshney100%(1)100% found this document useful (1 vote)

92 views6 pagesOriginal Title

WI 15 Cement Testing.doc

Copyright

© © All Rights Reserved

Available Formats

DOC, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as DOC, PDF, TXT or read online from Scribd

100%(1)100% found this document useful (1 vote)

92 views6 pagesWI 15 Cement Testing

Uploaded by

Raja VarshneyCopyright:

© All Rights Reserved

Available Formats

Download as DOC, PDF, TXT or read online from Scribd

You are on page 1of 6

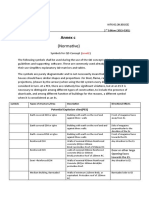

CEMENT TESTING

PURPOSE:

The purpose of this Instruction is to is to explain the steps required

to be followed for testing of Cement so as to ensure that testing is

done as per the requirements of relevant codes and standard test

methods.

The following Cement test methods are covered in this Work

Instruction :

A. Consistency

B. Initial & final Setting Time

C. Compressive strength

D. Fineness ( Same to be submitted to Central Lab. Thane)

Reference Standards

IS: 4031- Part 1to Part 11

Cement

IS: 3535

Cement

: Method of Physical Tests for

: Method of Sampling Hydraulic

PROCEDURES:A) Consistency of Cement Paste

APPARATUS:

The Vicat apparatus conforming to IS: 5513 with 10 mm diameter

plunger

STEPS :

The standard consistency of a cement paste is defined as that

consistency which will permit the Vicat plunger to penetrate to a

point 5 to 7 mm from the bottom of the Vicat mould.

1. Ensure the temperature of moulding room, dry materials and

water at

27 2 C and the relative humidity of the

moulding room at 65 5 % .

2. Prepare a paste of weighed quantity of cement (400g) with a

weighed quantity of water, (25 to 30% by wt of cement)

taking care that the time of gauging is not less than 3

minutes, or not more than 5 minutes, and the gauging shall

be completed before any signs of setting occur.

Approximately 400g of cement shall be taken and water in

the range of 25% to 30% shall be added. The gauging time

shall be counted from the time of adding water to the dry

cement until commencing to fill the mould.

3. Fill the Vicat mould with this paste, the mould resting upon

surface of the paste, making it level with the top of the

mould. The mould may be slightly shaken to expel the air.

4. Clean appliances shall be used for gauging.

5. In filling the mould, the operators hands and the blade of the

gauging towel shall alone be used. The trowel shall weigh

210 + 10g.

6. Place the test block in the mould, together with the nonporous testing plate, under the rod bearing the plunger,

lower the plunger gently to touch the surface of the test

block, and quickly release, allowing it to sink into the paste.

The operation shall be carried out immediately after filling

the mould.

7. Prepare trial pastes with varying percentages of water and

test as described above until the amount of water necessary

for making up the standard consistency. Express the result

as P amount of water as a percentage by weight of the dry

cement to one decimal place.

RECORDS:

Test results are maintained in format no. FT32.

B) Initial And Final Setting Time:

APPARATUS:

i. Vicat Apparatus Vicat apparatus shall conform to IS: 5513.

ii. Balance The balance shall have permissible variation of + 0.1 g at a

load of 1000 g.

iii. Gauging Trowel Gauging trowel shall conform to IS 10086

ENVIRONMENTAL CONDITION

Ensure the temperature of moulding room, dry materials and water at

27 2 C and the relative humidity of the moulding room at 65 5

%.

STEPS:

1. Preparation of Test Block

I. Take 400 g of cement and add potable or distilled water to it

(0.85 times the water required to give a paste of standard

consistency.)

II. Start a stopwatch at the instant when water is added to the

cement.

III. Mix thoroughly taking care that time of gauging is not less tan

3 minutes and not more than 5 minutes.

IV. Fill the Vicat mould resting on a nonporous plate completely

and smooth off the surface of the paste making it level with

the top of the mould. The cement block thus prepared in the

mould is the test block.

V. Immediately after moulding, place the mould in the humidity

chamber which is maintained at 27 2 C and the relative

humidity not less then 90 % and allow the mould to remain in

humidity chamber except when determination of time of

setting is being made.

2. Determination of Initial Setting Time

I. Place the test block confined in the mould and resting on the

non-porous plate, under the rod bearing the initial setting

needle.

II. Lower the needle gently until it comes in contact with the

surface of the test block and quickly release, allowing it to

penetrate into the test block. In the beginning, the needle will

completely pierce the block.

III. Repeat this procedure until the needle, when brought in

contact with the test block and released as described above,

fail to pierce the block beyond 5.0 + 0.5 mm measured from

the bottom of the mould.

IV. The period elapsing between the time when water is added

to the cement and the time at which the needle fails to pierce

the test block to a point 5.0 + 0.5 mm measured from the

bottom of the mould shall be the initial setting time.

3. Determination of Final Setting Time

I. Replace the initial setting needle of the Vicat apparatus by the

final setting needle with an annular attachment.

II. Lower the needle gently until it comes in contact with the

surface of the test block and quickly release

III. The cement shall be considered as finally set when, upon

applying the needle gently to the surface of the test block,

the needle makes an impression thereon, while the

attachment fails to do so.

IV. The period elapsing between the times when water is added

to the cement and the time at which the needle makes an

impression on the surface of test block while the attachment

fails to do so shall be the final setting time.

The results of initial and final setting time shall be reported to

the nearest five minutes.

RECORDS:

Test results are maintained in format no. : FT 32

C) COMPRESSIVE STRENGTH OF CEMENT

APPARATUS:

1. Vibration Machine Vibration machine shall conform to IS:

10080. Schematic diagram of mortar vibration machine and

poking rod is shown in figure-1of IS 4031.

2. Poking Rod Poking rod shall conform to IS: 10080

3. Cube Mould The mould shall be of 70.6 mm size conforming

to IS: 10080.

4. Gauging Trowel The gauging trowel shall conform to IS:

10086

5. Balance The balance shall conform to the permissible

variation of + 1.0 g at a load of 1000 g.

6. Graduated Glass Cylinders The graduated glass cylinders

shall conform to the permissible variation of + 1.0 ml at a

volume of 150 to 200 ml capacity.

ENVIRONMENTAL CONDITIONS:

The temperature of the gauging room, dry materials and water

shall be maintained at 27 + 20C. The relative humidity of the

laboratory shall be 65 + 5 percent.

The humidity chamber shall be maintained at 27 + 20C and at a

relative humidity of not less than 90 percent.

STANDARD SAND:

The standard sand to be used in the test shall conform to IS:

650.The different fractions of sand shall be suitably combined in

proportions so as to meet the requirements as specified by the

standard.

PREPARATION OF TEST SPECIMENS:

1. Mix Proportions and Mixing Clean appliances shall be

used for mixing and the temperature of water and that of the

test room at the time when the above operations are being

performed shall be 27 + 20C. Potable/distilled water shall be

used in preparing the cubes.

2. The material for each cube shall be mixed separately and the

quantity of cement, standard sand and water shall be as

follows:

Cement = 200 g

Standard Sand = 600 g (Combining Grade I, II & III in proportions as

determined from Individual gradations results)

Water

(P / 4 + 3.0) x weight of cement and sand, g

100

Where P is the percentage of water required to produce a paste of

standard consistency.

3. Place on a nonporous plate, a mixture of cement and standard

sand. Mix it dry with a trowel for one minute and then with

weighed quantity of water until the mixture is of uniform color.

The time of mixing shall in any event be not less than 3 min

and should the time to obtain a uniform colour exceed 4 min.

MOULDING SPECIMENS:

1. In assembling the moulds ready for use, cover the joints

between the halves of the mould with a thin film of petroleum

jelly and apply a similar coating of petroleum jelly between the

contact surfaces of the bottom of the mould and its base plate

in order to ensure that no water escapes during vibration.

Treat the interior faces of the mould with a thin coating of

mould oil.

2. Place the assembled mould on the table of the vibration

machine and hold it firmly in position by means of a suitable

clamp. Attach a hopper of suitable size and shape securely at

the top of the mould to facilitate filling and this hopper shall not

be removed until the completion of the vibration period.

3. Immediately after mixing the mortar in accordance with place

the mortar in the cube mould and prod with the poking rod.

The mortar shall be prodded 20 times in about 8 sec to ensure

elimination of entrained air and honeycombing. Place the

remaining quantity of mortar in the hopper of the cube mould

and prod again as specified for the first layer and then

compact the mortar by vibration.

4. The period of vibration shall be two minutes at the specified

speed of 12000 + 400 vibrations per minute.

5. At the end of vibration, remove the mould together with the

base plate from the machine and finish the top surface of the

cube in the mould by smoothing the surface with the blade of

a trowel.

CURING SPECIMENS:

Keep the filled moulds in humidity chamber for 24 hours after

completion of vibration. At the end of that period, remove them from

the moulds and immediately submerge in clean fresh water and

keep there until taken out just prior to breaking. The water in which

the cubes are submerged shall be renewed every 7 days and shall

be maintained at a temperature of 27 + 2 0 C. After they have been

taken out and until they are broken, the cubes shall not be allowed

to become dry.

TESTING:

1. Test three cubes for compressive strength for each sample, for

a period of curing 3-days, 7-days & 28-days.

2. The cubes shall be tested on their sides without any packing

between the cube and the steel platens of the testing machine.

One of the platens shall be carried on a base and shall be selfadjusting and the load shall be steadily and uniformly applied,

starting from zero at a rate of 2.9 kN/s.

CALCULATION:

The measured compressive strength of the cubes shall be

calculated by dividing the maximum load applied to the cubes

during the test by the cross-sectional area, calculated from the

mean dimensions of the section and shall be expressed to the

nearest 1 kg/cm2.

In determining the compressive strength, do not consider

specimens that give strengths differing by more than 10 percent

from the average value of all the test specimens. After discarding

specimens or strength values, if less than two strength values are

left for determining the compressive strength at any given period, a

retest shall be made.

RECORDS:

The test results are maintained in format no. FT 31

END OF INSTRUCTION

You might also like

- Concrete Technology LABDocument52 pagesConcrete Technology LABBanoth Manjula SonuNo ratings yet

- Material Testing ManualDocument56 pagesMaterial Testing ManualJithin Benny JithinNo ratings yet

- CT Lab ManualDocument26 pagesCT Lab ManualJagathChandraNo ratings yet

- Standard Consistency, Setting Time,, and Fineness of CementDocument6 pagesStandard Consistency, Setting Time,, and Fineness of CementNur Syahira0% (1)

- CEE303 Concrete Lab ManualDocument23 pagesCEE303 Concrete Lab ManualSuraj AgrawalNo ratings yet

- Normal Consistancy and Settling Lab ManualDocument4 pagesNormal Consistancy and Settling Lab ManualAnonymous gQzqEs3No ratings yet

- CONCRETE LAB MANUALDocument20 pagesCONCRETE LAB MANUALsidNo ratings yet

- Concrete Lab Experiments GuideDocument8 pagesConcrete Lab Experiments GuideRaviteja GirijalaNo ratings yet

- Experiment No. 1 Fineness of Cement by Hand SievingDocument22 pagesExperiment No. 1 Fineness of Cement by Hand SievingUmed Abd-alsatarNo ratings yet

- Muddasar Ahmed (Cms Id 6139) Material Engineering Lab PracticalsDocument15 pagesMuddasar Ahmed (Cms Id 6139) Material Engineering Lab PracticalsAafaq Ur RehmanNo ratings yet

- Various Lab Test On CementDocument4 pagesVarious Lab Test On Cementhncc ghazniNo ratings yet

- Procedures of TestingsDocument54 pagesProcedures of TestingsSK Emran AliNo ratings yet

- Tests On CementDocument138 pagesTests On CementKalasekar M Swamy50% (2)

- Experiment No. 01: S.A-I Laboratory Manual 1 Prepared By: Nishant SharmaDocument13 pagesExperiment No. 01: S.A-I Laboratory Manual 1 Prepared By: Nishant Sharmasaket01nemaNo ratings yet

- Lecture 2 Cement Contd.Document29 pagesLecture 2 Cement Contd.Jappu KumarNo ratings yet

- Initial and Final Setting Time of Cement: Fig. 1: BalanceDocument3 pagesInitial and Final Setting Time of Cement: Fig. 1: BalanceHimanku BoraNo ratings yet

- Concrete Technology - LabDocument3 pagesConcrete Technology - LabSasi ShashNo ratings yet

- Cycle 2 Som LabDocument10 pagesCycle 2 Som LabAnonymous SEDun6PWNo ratings yet

- Quality Control SectionDocument43 pagesQuality Control SectionVivek KumarNo ratings yet

- Testing Procedures Adopted For Cement and SteelDocument6 pagesTesting Procedures Adopted For Cement and Steelp.v.n. lakshmanNo ratings yet

- Test On Cement PDFDocument6 pagesTest On Cement PDFIrfan NazirNo ratings yet

- Concrete Manual 2023Document31 pagesConcrete Manual 2023amdaNo ratings yet

- Standard Consistency and Setting TimeDocument3 pagesStandard Consistency and Setting TimeFirdaus RoslimNo ratings yet

- Determination of Consistency of Cement: ObjectiveDocument26 pagesDetermination of Consistency of Cement: ObjectiveSruthiNo ratings yet

- Consistency of Standard Cement PasteDocument53 pagesConsistency of Standard Cement PasteLakshay SinghalNo ratings yet

- Laboratory Manual: CIV206 Unified Lab-IDocument35 pagesLaboratory Manual: CIV206 Unified Lab-IItinderjot SinghNo ratings yet

- DETERMINING INITIAL & FINAL SETTING TIMESDocument4 pagesDETERMINING INITIAL & FINAL SETTING TIMESHamza MughalNo ratings yet

- Tests On CementDocument24 pagesTests On CementIan BondocNo ratings yet

- Cemetn TestingDocument20 pagesCemetn TestingKrishnan SubramaniamNo ratings yet

- Chapter 3 MethodologyDocument22 pagesChapter 3 MethodologySiva KrishnaNo ratings yet

- Concrete Technology (Lab Manual)Document23 pagesConcrete Technology (Lab Manual)VipulShukla100% (3)

- Bulking of SandDocument12 pagesBulking of SandTauseefNo ratings yet

- Determination of Setting Time of Hydraulic CementDocument20 pagesDetermination of Setting Time of Hydraulic CementMara Erna TagupaNo ratings yet

- CT Lab ManualDocument38 pagesCT Lab ManualAadi KmrNo ratings yet

- Compressive Strength Test (IS: 4031 (Part 6) - 1988)Document2 pagesCompressive Strength Test (IS: 4031 (Part 6) - 1988)সন্দীপ চন্দ্রNo ratings yet

- Normal Consistency of CementDocument2 pagesNormal Consistency of CementSandeep Reddy100% (4)

- Lab Manual.1pdfDocument31 pagesLab Manual.1pdfAshish KumarNo ratings yet

- Determination of Initial & Final Setting Time (Ist & FST)Document1 pageDetermination of Initial & Final Setting Time (Ist & FST)XOXOXOXO XOXOXOXONo ratings yet

- Concrete TestsDocument111 pagesConcrete Testschaitanyatripathi4321No ratings yet

- CT Lab ManualDocument29 pagesCT Lab Manualamanvermaav089No ratings yet

- Concrete &highway Lab New ManualDocument40 pagesConcrete &highway Lab New Manualshruthicivil100% (4)

- Basic Civil Engineering Lab-2-1Document8 pagesBasic Civil Engineering Lab-2-1KUNDAN SHARMANo ratings yet

- Concrete Technology - LabDocument2 pagesConcrete Technology - LabSasi ShashNo ratings yet

- Concrete Lab TestsDocument54 pagesConcrete Lab TestsAxumawi Ebuy TekaNo ratings yet

- Concrete Technology: University of Kirkuk College of Engineering Department of Civil EngineeringDocument8 pagesConcrete Technology: University of Kirkuk College of Engineering Department of Civil Engineeringmemettsnly71No ratings yet

- REPORT Slump TestDocument6 pagesREPORT Slump TestFatin Khairunnisa79% (19)

- Test For Properties of Cement: Physical & ChemicalDocument4 pagesTest For Properties of Cement: Physical & ChemicalmuqeetNo ratings yet

- Lab 2 Standard Consistency, Setting Time & Finess of Cement (Level 0)Document6 pagesLab 2 Standard Consistency, Setting Time & Finess of Cement (Level 0)Zaffira RahmanNo ratings yet

- Standard Consistency For CementDocument6 pagesStandard Consistency For CementTokki TokkiNo ratings yet

- Lju CT Lab Manual Dku FinalDocument52 pagesLju CT Lab Manual Dku FinalAryan RathodNo ratings yet

- Cover Page For Uche NwokoroDocument6 pagesCover Page For Uche NwokoroShammah ChidiNo ratings yet

- Cement ManualDocument10 pagesCement ManualyowmaNo ratings yet

- CT Lab FDocument8 pagesCT Lab FFausto Da GamaNo ratings yet

- Compressive Strength of Cement Mortars Using 50 MM Cube Specimens T 106 & C109Document4 pagesCompressive Strength of Cement Mortars Using 50 MM Cube Specimens T 106 & C109YasirNo ratings yet

- Determine cement properties using Vicat apparatusDocument7 pagesDetermine cement properties using Vicat apparatusNavneet SinghNo ratings yet

- NORMAL CONSISTENCY TEST ON CEMENT A4 SheetDocument3 pagesNORMAL CONSISTENCY TEST ON CEMENT A4 Sheetasishraj2003No ratings yet

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- Engineering Bulletin No 1: Boiler and Furnace TestingFrom EverandEngineering Bulletin No 1: Boiler and Furnace TestingRating: 4.5 out of 5 stars4.5/5 (2)

- The Fabrication of Materials: Materials TechnologyFrom EverandThe Fabrication of Materials: Materials TechnologyRating: 5 out of 5 stars5/5 (1)

- Cross-Section of RHPF (PP)Document1 pageCross-Section of RHPF (PP)Raja VarshneyNo ratings yet

- Excel Sheet Transfer Macros FilterDocument30 pagesExcel Sheet Transfer Macros FilterRaja VarshneyNo ratings yet

- Selection For The Post of Director Personnel, A Schedule A CPSEDocument1 pageSelection For The Post of Director Personnel, A Schedule A CPSERaja VarshneyNo ratings yet

- C4M Bar Bending Schedule BBS FormatDocument8 pagesC4M Bar Bending Schedule BBS FormatRaja VarshneyNo ratings yet

- RCC BOX BRIDGE DESIGNDocument53 pagesRCC BOX BRIDGE DESIGNSreeraja SreevilasanNo ratings yet

- CHÑ, MÑ F) O"Khz Ikb Øe Ços'K: 'KSF (KD VGZRKDocument1 pageCHÑ, MÑ F) O"Khz Ikb Øe Ços'K: 'KSF (KD VGZRKRaja VarshneyNo ratings yet

- BRIDGE DESIGN Specifications by Practise EngineersDocument171 pagesBRIDGE DESIGN Specifications by Practise EngineersRaja VarshneyNo ratings yet

- Cal District 2018Document1 pageCal District 2018Raja VarshneyNo ratings yet

- Pictorial ReportDocument6 pagesPictorial ReportRaja VarshneyNo ratings yet

- May Position PDFDocument1 pageMay Position PDFRaja VarshneyNo ratings yet

- ACE 2018 Job Fair Compnay Details - by Ragavan Ramu-7395903133-SJTCSDocument2 pagesACE 2018 Job Fair Compnay Details - by Ragavan Ramu-7395903133-SJTCSRaja VarshneyNo ratings yet

- Ranking of PSUDocument12 pagesRanking of PSURaja VarshneyNo ratings yet

- 01022018Document1 page01022018Raja VarshneyNo ratings yet

- Cash Flow ModelnewDocument29 pagesCash Flow ModelnewSureshKumarNo ratings yet

- Aggregates Crushing Value Test PurposeDocument2 pagesAggregates Crushing Value Test PurposeRaja VarshneyNo ratings yet

- WI 5 AIV TestDocument2 pagesWI 5 AIV TestRaja VarshneyNo ratings yet

- WI 3 SG & Absortion of Aggregates Issue 2-1Document3 pagesWI 3 SG & Absortion of Aggregates Issue 2-1Raja VarshneyNo ratings yet

- Two Pile GroupDocument12 pagesTwo Pile GroupJammy KingNo ratings yet

- WI 8 Flexural StrengthDocument2 pagesWI 8 Flexural StrengthRaja VarshneyNo ratings yet

- WI 9 Slump TestDocument1 pageWI 9 Slump TestRaja VarshneyNo ratings yet

- WI 18 Setting Time of ConcreteDocument3 pagesWI 18 Setting Time of ConcreteRaja VarshneyNo ratings yet

- WI 9 Slump TestDocument1 pageWI 9 Slump TestRaja VarshneyNo ratings yet

- Aggregates Crushing Value Test PurposeDocument2 pagesAggregates Crushing Value Test PurposeRaja VarshneyNo ratings yet

- WI 9 Slump TestDocument1 pageWI 9 Slump TestRaja VarshneyNo ratings yet

- WI 9 Slump TestDocument1 pageWI 9 Slump TestRaja VarshneyNo ratings yet

- WI 2 Moisture Content of AggregatesDocument2 pagesWI 2 Moisture Content of AggregatesRaja VarshneyNo ratings yet

- WI 8 Flexural StrengthDocument2 pagesWI 8 Flexural StrengthRaja VarshneyNo ratings yet

- Aggregates Crushing Value Test PurposeDocument2 pagesAggregates Crushing Value Test PurposeRaja VarshneyNo ratings yet

- Aggregates Crushing Value Test PurposeDocument2 pagesAggregates Crushing Value Test PurposeRaja VarshneyNo ratings yet

- Powder Chopped Stand Mats: General PurposeDocument1 pagePowder Chopped Stand Mats: General Purposehamza OUADINo ratings yet

- Project ReportDocument599 pagesProject ReportFarzad DehghanNo ratings yet

- CR Content in Alloy Steel and Phosphate CoatingsDocument8 pagesCR Content in Alloy Steel and Phosphate Coatingsgacm98No ratings yet

- In-Line Pulsation Dampeners For Bredel 25-100, APEX 28 and APEX 35 PumpsDocument2 pagesIn-Line Pulsation Dampeners For Bredel 25-100, APEX 28 and APEX 35 PumpsVruno Velasquez LNo ratings yet

- Fellenius Static Test and PredictionDocument10 pagesFellenius Static Test and PredictionJohn STCNo ratings yet

- Descriptive Analysis of Advantages and Disadvantages of Expanded Polystyrene Monolytic Panels - EPSDocument11 pagesDescriptive Analysis of Advantages and Disadvantages of Expanded Polystyrene Monolytic Panels - EPSWilson Bryan RegaladoNo ratings yet

- ENVIRONMENTAL CONTROL SYSTEMS (3681) Lec 2-3Document73 pagesENVIRONMENTAL CONTROL SYSTEMS (3681) Lec 2-3shariq talatNo ratings yet

- Fde 1Document19 pagesFde 1Ivan MarijanovićNo ratings yet

- Secondary Seal For Sealed Insulating Glass Units For Structural Sealant Glazing ApplicationsDocument12 pagesSecondary Seal For Sealed Insulating Glass Units For Structural Sealant Glazing ApplicationsAbdullah NajjarNo ratings yet

- IATG 02.20 symbolsDocument3 pagesIATG 02.20 symbolsturamyuwiteka samuelNo ratings yet

- Beep 2 CdevDocument1,241 pagesBeep 2 CdevIzio SilvaNo ratings yet

- 2 Lateral-Load-Transfer Session-2 2perDocument56 pages2 Lateral-Load-Transfer Session-2 2perLuis CortesNo ratings yet

- TDS - Bronco Pre HDPE Membrane (S)Document3 pagesTDS - Bronco Pre HDPE Membrane (S)Shreyansh UdaniNo ratings yet

- Pipeline Stress Analysis With Caesar IIDocument16 pagesPipeline Stress Analysis With Caesar IISathish KumarNo ratings yet

- HVAC Systems Duct DesignDocument39 pagesHVAC Systems Duct Designsardarmkhan100% (2)

- Flexural Toughness and Strength of Fiber ConcreteDocument8 pagesFlexural Toughness and Strength of Fiber ConcreteGabriel Cachi Cerna100% (2)

- Fabrication and Processing of CeramicsDocument14 pagesFabrication and Processing of CeramicsMinJing ParkNo ratings yet

- (0000+) Comparison of Static Pushover and Dynamic Analyses Using RC BuildingDocument11 pages(0000+) Comparison of Static Pushover and Dynamic Analyses Using RC BuildingmgdarioNo ratings yet

- Thorn Cetus LED 96242096Document2 pagesThorn Cetus LED 96242096ShiHong KuangNo ratings yet

- Carbothane 134 HG PDSDocument4 pagesCarbothane 134 HG PDSTeknik produksi wikonNo ratings yet

- Bill 10 UG Water Tank and Pump RoomDocument92 pagesBill 10 UG Water Tank and Pump RoomLevy MalagambaNo ratings yet

- TWI Control of Welding DistortionDocument12 pagesTWI Control of Welding DistortionClaudia Mms100% (2)

- Advanced Fluid MechanicsDocument154 pagesAdvanced Fluid MechanicsMohammad irfanNo ratings yet

- Ga Marta ViewDocument188 pagesGa Marta ViewAndes PutraNo ratings yet

- PRL Design Study Of NMA Chemical Storage TankDocument56 pagesPRL Design Study Of NMA Chemical Storage TankShayan Hasan KhanNo ratings yet

- INCLUSION & Its Impact: What Is An Inclusion ?Document18 pagesINCLUSION & Its Impact: What Is An Inclusion ?Rinku SingrohaNo ratings yet

- Hot Works SafetyDocument33 pagesHot Works Safetypammu18No ratings yet

- Elbows Couplings and Nipples BrochureDocument8 pagesElbows Couplings and Nipples BrochurekimiesmithNo ratings yet

- Dry EtchingDocument12 pagesDry EtchingMosaddekNo ratings yet

- Aropol LP 67400Document2 pagesAropol LP 67400Ahmed ZamanNo ratings yet