Professional Documents

Culture Documents

GIS Hysong

Uploaded by

Vipinraj KrishnanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

GIS Hysong

Uploaded by

Vipinraj KrishnanCopyright:

Available Formats

TEST CERTIFICATE

DF-CA-21/36/01

IN FO RM ATI O N

SHEET

KERI(Korea Electrotechnology Research Institute) issues a Type Test Certificate and a Test Report as below.

1. Type Test Certificate

A Certificate contains a record of a series of type tests carried out strictly in accordance with IEC, and/or

regional standard and national standard that are identical to IEC standard. The test object has fulfil ed the

requirements of this standard and the relevant ratings assigned by the manufacturer are endorsed by KERI.

The Certificate is applicable only to the test object. KERI is responsible for the validity and the contents of

the Certificate. The responsibility for conformity of any apparatus having the same designation as the one

tested rests with the manufacturer. The certificate contains the essential drawings and a description of the

equipment tested. Detailed rules are given in KERI's Type Test Certification Procedure.

2. Test Report

2.1 Type Test Report

A Type Test Report contains a record of a series of type tests carried out strictly in accordance with a

standard recognized by KERI. The test object has fulfil ed the requirements of this standard and the

relevant ratings assigned by the manufacturer are endorsed by KERI. The Type Test Report is applicable

only to the test object. KERI is responsible for the validity and the contents of the Type Test Report. The

responsibility for conformity of any apparatus having the same designation as the one tested rests with the

manufacturer. The Type Test Report contains the essential drawings and a description of the equipment

tested. Detailed rules are given in KERI's Test Procedure.

2.2 Performance Test Report

A Performance Test Report contains a record of one or more tests which have been carried out according

to a recognized standard and/or the client's instructions. These tests are not necessarily in accordance with

a recognized standard. The test results do not verify ratings of the test object. Detailed rules are given in

KERI's Test Procedure.

KERI issues three types of Performance Test Report.

2.2.1 The tests have been carried out strictly in accordance with a recognized standard. The test object has

complied with the relevant requirements.

This sentence wil appear on the front page of Performance Test Report if the tests have been performed

in accordance with a recognized standard, but the series of tests does not completely fulfil the requirements

for a Certificate of Compliance (for example, if the number of test series is not a complete series of type

tests). The Report contains verified drawings and a description of the test object. The condition of the test

object after the tests is assessed and recorded in the Report.

2.2.2 The tests have been carried out in accordance with the client's instructions. Test procedure and test

parameters were based on a recognized standard.

This sentence wil appear on the front page of Performance Test Report if the number of test duties, the

test procedure and the test parameters are based on a recognized standard and related to the ratings

assigned by the manufacturer. Verification of the drawings (if submitted) and assessment of the condition

after the tests is only done on the client's request.

2.2.3 The tests have been carried out according to the client's instructions.

This sentence wil appear on the front page of Performance Test Report if the test shots, test procedure

and/or test parameters are not in accordance with a recognized standard.

3 KERI is a member of STL(Short-circuit Testing Liaison) and the accredited testing laboratory under Clause

2 of Article 2 in Guidelines on certified testing criteria and methods for electrical equipment (Public Notice

No. 2008-120, Ministry of Knowledge Economy, Korea).

DF-CA-21/27/06

2014TC00459

Table of contents

Items

Table of contents

Ratings of the test object

List of tests

Test results

Photographs

Circuit diagrams and parameters

Drawings

Attachments

Oscillograms

2/13

Sheet No.

3/13

5/13

6/13

7/13 10/13

2/13

4/13

11/13

12/13

13/13

Tested by :

Geum, Jae-Beom

KERI

Witnessed by :

Kim, Han-Gyun

HYOSUNG CORPORATION

Kang, Dong-Wan

HYOSUNG CORPORATION

Kim, Ki-Bum

HYOSUNG CORPORATION

Korea Electrotechnology Research Institute

DF-CA-21/33/01

2014TC00459

3/13

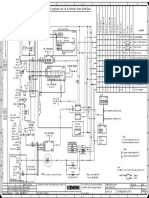

Drawings :

The manufacturer guarantees that the test object submitted is manufactured in accordance with the following

drawings. KERI verified that these drawings adequately represent the test object.

The following drawings are included in this test report:

Reference No.

Drawing No.

Revision No.

Date

Reference No.

Drawing No.

Revision No.

Date

001

YE145D4004

0

The following drawings have been returned to the client and listed for reference.

002

003

004

005

006

007

008

009

010

011

012

013

014

015

016

017

018

019

020

021

022

023

024

025

026

DYA0204214

DYA0304288

DYA0304289

DYA0304290

DYB0302461

DYB0302458

DYB0302836

DYB0302618

DYA0204215

DYA0204216

DYA0207218

DYA0304255

DYB0305719

DYB0303235

DYB0303232

DYB0302033

DYA0207315

DYA0303409

DYB0303231

DYA0204224

DYA0400247

DYB0303244

DYB0303760

DYB0500516

DYA0204219

Korea Electrotechnology Research Institute

0

2

2

2

1

1

2

5

0

0

3

0

1

5

6

4

1

1

4

4

6

2

3

2

3

2013.11.05

2013.11.26

2013.06.25

2012.09.06

2012.09.06

2012.07.05

2012.07.05

2012.07.05

2012.07.05

2012.09.06

2013.09.16

2013.11.15

2013.03.21

2013.11.08

2013.12.13

2013.12.13

2013.11.27

2013.11.15

2013.06.21

2013.12.13

2013.10.02

2013.10.02

2013.07.26

2013.01.11

2013.08.13

2012.11.12

DF-CA-21/33/01

2014TC00459

4/13

Three phase SF 6 gas-insulated metal-enclosed switchgear and controlgear with gas

circuit-breaker, disconnector and earthing switch

Manufacturer

HYOSUNG CORPORATION

Type

HSG-144D

Serial number

H1980363-3

Ratings of the test object assigned by manufacturer and proved by tests

Voltage

Frequency

Normal current

145 kV

50 / 60 Hz

3 150 A

Ratings of the test object assigned by manufacturer

Supply voltage

Closing and opening device

DC 110

Motor for operating mechanism

DC 110

Space heater

AC 110

SF6 gas pressure for GCB(at 20 oC, gauge)

Design

0.77

MPa

Rated

0.60

MPa

1st alarm

Minimum(second alarm signal & locking)

0.57

0.55

MPa

MPa

Design

0.65

MPa

Rated

0.50

MPa

1st alarm

0.45

MPa

Minimum(second alarm signal & locking)

0.40

MPa

SF6 gas pressure for DS/ES(at 20 oC, gauge)

Korea Electrotechnology Research Institute

DF-CA-21/33/01

2014TC00459

5/13

Gas circuit-breaker

Manufacturer

Type

Serial number

HYOSUNG CORPORATION

HCSP-144D

H1980363-3.1

Disconnector

Manufacturer

Type

Line DS (3DS)

Bus DS (1DS)

Serial No.

Line DS (3DS)

Bus DS (1DS)

HYOSUNG CORPORATION

HDMO-144C

HDMO-144D

H1980363-3.2

H1980363-3.3

Earthing switch

Manufacturer

Type

Serial No.

Line ES (3ES)

Bus ES (1ES)

HYOSUNG CORPORATION

HEMO-144C

H1980363-3.5

H1980363-3.6

High speed earthing switch (HES)

Manufacturer

Type

Serial number

Korea Electrotechnology Research Institute

HYOSUNG CORPORATION

HEMS-144C

H1980363-3.4

DF-CA-21/33/01

2014TC00459

6/13

List of tests

Test items

1 Temperature-rise tests

Standard and clause

Test date

IEC 62271-203 : 2011-09

2014.03.18.

6.5

Sheet No.

20

7/13

1.1 Main circuit

2014.03.19

9/13

1.2 Test on auxiliary and control circuit

2014.03.20

9/13

1.3 Measurement of the resistance of the main circuit

2 Description of tests

Korea Electrotechnology Research Institute

IEC 62271-203 : 2011-09

2014.03.18.

6.4

-

20

10/13

10/13

DF-CA-21/33/01

2014TC00459

7/13

Temperature-rise tests

1.1 Main circuit

Test requirements

Test current

A

Test frequency

Hz

Test duration

h

Temporary conductors for the

connection to terminal

3 150

60

9.5

* Temporary input conducts : 80 1 000(L) mm (in SF6 Gas)

* Temporary output conducts : 80 1 000(L) mm (in SF6 Gas)

Test results

Measuring spot

Ambient temperature

Temperature-rise

limits

K

(+10 +40)

Temperature-rise value

K

Phase A

Phase B Phase C

Osc.

No.

21.0

21.2

21.0

20.7

4

47.4

Test common bond

65 (Al-Ag)

43.7

48.7

1 m apart from No.4

No.4 5

51.8

1 m apart from No.5

No.5 5

47.3

1 m apart from No.6

No.6 5

51.3

Contacted part of fixed DS

65 (Al-Ag)

52.9

52.2

5

6

10

11

12

SF6 gas in 3PDS

13

14

11.7

Enclosure of 3PDS

40(Al)

28.6

Connected part of moving DS

75 (Al)

48.1

42.1

45.2

39.2

18

46.3

19

40.2

33.5

21

41.1

22

45.5

15

16

17

20

23

Contactor of moving DS

Contactor of fixed DS

65 (Al-Ag)

45.3

24

46.1

25

44.1

43.7

44.7

26

Puffer cylinder part of CB

65 (Cu-Ag)

Main contactor of moving CB

27

Korea Electrotechnology Research Institute

65 (Al-Ag)

65 (Cu-Ag)

HV01

DF-CA-21/33/01

2014TC00459

8/13

Test results

Measuring spot

Temperature-rise

limits

K

28

Temperature-rise value

K

Phase A

Phase B Phase C

41.0

40.0

30

40.8

31

32.8

32.1

33.3

54.4

52.9

47.6

46.6

38.1

39.2

48.5

49.0

29

32

Main contactor of fixed CB

Fixed arc contact of CB

65 (Cu-Ag)

65 (Cu-Ag)

33

34

35

36

37

38

39

40

41

Connected conductor part of CB

75 (Al-Ag)

Contacted conductor part of CB

65 (Al-Ag)

Connected part of fixed CB conductor

75 (Al-Ag)

Contacted conductor part of CT

65 (Al-Ag)

42

Handle of Mechanism

30 (STS)

5.7

43

Accessible part of mechanism

30 (SS)

2.8

45

Enclosure of CB

40 (Al)

25.9

Surface of BCT

65 (Class A)

46

47

48

Spacer of CB

49

32.2

35.4

Enclosure of CT

40 (Al)

27.0

50

Enclosure of line 3PDS

40 (Al)

29.6

51

SF6 gas in line 3PDS

22.7

52

Spacer of line 3PDS

65 (Epoxy)

30.5

53

HV01

30.0

65 (Epoxy)

46.5

47.7

55

45.5

56

49.7

53.3

58

51.2

59

57.5

59.4

56.8

54

57

60

Contactor of fixed line DS

Contactor of moving line DS

Connection part of Terminal

61

Korea Electrotechnology Research Institute

65 (Al-Ag)

65 (Cu-Ag)

65 (Al-Ag)

Osc.

No.

DF-CA-21/33/01

2014TC00459

9/13

Test results

Temperature-rise value

K

Temperature-rise

limits

K

Measuring spot

Osc. No.

Phase A Phase B Phase C

62

1 m apart from No.59

No.59 5

58.5

63

1 m apart from No.60

No.60 5

60.4

64

1 m apart from No.61

No.61 5

56.1

HV01

Remarks

* SF6 gas pressure(gauge) : CB - 0.55 MPa, others

0.40 MPa

* During the temperature-rise test, the functional components of the auxiliary and control

circuit such as digital relay, auxiliary, status lamp, spacer heater, illumination and so on

were applied at those rated conditions.

* Photo. HV01 : Temperature-rise tests

1.2 Auxiliary and control circuit

Resistance of coil

Description

Closing coil

Opening coil

Before test

After test

36.0

36.1

29.9

Ambient air temperature

Before test

After test

Temperaturerise limits

K

20.3

20.2

30

Temperaturerise value

K

0.9

30.0

1.1

* The tests were performed according to the IEC 62271-1 : 2011, Clause 6.5.5 a.

* The temperature-rise values were determined by the method of resistance variation as

following formula.

Remarks

Tr

Ti

Tf

Ri

Rf

: Temperature-rise value of coil ( )

: Ambient air temperature before test ( )

: Ambient air temperature after test ( )

: Resistance of coil before test ( )

: Resistance of coil after test ( )

* Designed resistance value of closing coil : (36.5 1.8)

(at 20

* Designed resistance value of opening coil : (30.7 1.5)

(at 20

where,

Korea Electrotechnology Research Institute

)

)

DF-CA-21/33/01

2014TC00459

10/13

1.3 Measurement of the resistance of the main circuit

Test results

Resistance

Descriptions

Measuring

positions

Phase A

Measured

value

Before

temperature-rise

tests

A-E

After

temperature-rise

tests

A-E

114.7

Phase B

Phase C

Converted

Converted

Converted

Measured

Measured

value to

value to

value to

value

value

20 C

20 C

20 C

117.5

117.2

120.0

113.9

116.6

Ambient

temperature

C

Variation

%

14.0

2.3

110.5

114.5

114.7

118.8

109.8

113.8

11.1

* Test results are made with DC 100 A by measuring the voltage drop.

* The measured value after the test shall not be increased by more than 20 %.

Remarks

Description of tests

2.1 These tests were carried out with the sample confirmed and supplied by client.

Korea Electrotechnology Research Institute

DF-CA-21/33/01

2014TC00459

11/13

Photographs

Photo. HV01 : Temperature-rise tests

Korea Electrotechnology Research Institute

DF-CA-21/33/01

2014TC00459

12/13

Drawings

Korea Electrotechnology Research Institute

DF-CA-21/33/01

2014TC00459

13/13

Oscillograms

Osc. HV01 : Recording paper of temperature-rise tests

Korea Electrotechnology Research Institute

DF-CA-21/33/01

You might also like

- Pico ScopeDocument161 pagesPico ScopeDavianGiurca100% (1)

- Draft Letter To POWERGRID Re Cl. 5.2 Bof Tech SpecDocument1 pageDraft Letter To POWERGRID Re Cl. 5.2 Bof Tech Specsitam_nitj4202No ratings yet

- Earth Design-33kV-Assignment-Rev1Document9 pagesEarth Design-33kV-Assignment-Rev1Vipinraj KrishnanNo ratings yet

- Earthing Calculation PDFDocument65 pagesEarthing Calculation PDFcdsenthilNo ratings yet

- NDT Method SummaryDocument3 pagesNDT Method SummaryHossamGaballah100% (1)

- General Data and InformationDocument5 pagesGeneral Data and InformationSunil SinghNo ratings yet

- A Working Manual of High Frequency Currents ( (c1920) )Document328 pagesA Working Manual of High Frequency Currents ( (c1920) )Use SanchezNo ratings yet

- RF-Microwave PCB Design and LayoutDocument33 pagesRF-Microwave PCB Design and LayoutName100% (8)

- PT TestingDocument7 pagesPT TestingNaveedNo ratings yet

- Switch YardDocument60 pagesSwitch Yardjigdung100% (3)

- M03 Testing CompDocument132 pagesM03 Testing CompGizaw TadesseNo ratings yet

- Chap 6 - High Voltage Testing of EquipmentDocument16 pagesChap 6 - High Voltage Testing of Equipmenthadrien100% (1)

- Sunrise Telecom SunSet MTTDocument3 pagesSunrise Telecom SunSet MTTescalimetroNo ratings yet

- Chapter 3 - Choppers - PDFDocument75 pagesChapter 3 - Choppers - PDFZahidullah100% (1)

- Current Transformer (TPU 50.23) - FAT ReportsDocument45 pagesCurrent Transformer (TPU 50.23) - FAT Reportsmad_sam282729No ratings yet

- Inspection Test Plan: PT - Bambang DjajaDocument4 pagesInspection Test Plan: PT - Bambang DjajabimoNo ratings yet

- AAAC Advantages Over ACSRDocument2 pagesAAAC Advantages Over ACSRVivek KumarNo ratings yet

- 132kv Grid Station FNF, SheikhupuraDocument18 pages132kv Grid Station FNF, Sheikhupurasyed waheedNo ratings yet

- Signature: - Signature: - Name: Name: Mohd Abdul FattahDocument2 pagesSignature: - Signature: - Name: Name: Mohd Abdul FattahafaqNo ratings yet

- 550kV Isolater Type Test ReportDocument18 pages550kV Isolater Type Test Reportashwani2101No ratings yet

- 415v Air Circuit Breaker-14Document2 pages415v Air Circuit Breaker-14Subhransu MohapatraNo ratings yet

- Trafo Feeder RP - Base Design - Pages From 1473 11-0.415kV Auxiliary Transformer Feeder Bse Design For Comm SSDocument1 pageTrafo Feeder RP - Base Design - Pages From 1473 11-0.415kV Auxiliary Transformer Feeder Bse Design For Comm SSVipinraj KrishnanNo ratings yet

- E50 MIB To GC Test ReportDocument13 pagesE50 MIB To GC Test ReportTesting PLQNo ratings yet

- PART II 02 500 MVA 400 220 33 KV R 0 Mar 12 PDFDocument96 pagesPART II 02 500 MVA 400 220 33 KV R 0 Mar 12 PDFGuru Mishra100% (1)

- Power Circuit Breaker MaintenanceDocument22 pagesPower Circuit Breaker MaintenanceHemendra Jani100% (1)

- Tech - Spec. LA For WBSEDCL Sept.07, ArresterDocument6 pagesTech - Spec. LA For WBSEDCL Sept.07, ArresterThanh NguyenNo ratings yet

- E1004-99 EC Electrical Conductivity PDFDocument4 pagesE1004-99 EC Electrical Conductivity PDFFarhan ShahNo ratings yet

- Transmission Line Tower Earthing Analysis Using SafeGrid PDFDocument5 pagesTransmission Line Tower Earthing Analysis Using SafeGrid PDFBaskar ElNo ratings yet

- PLCC Tech SpecsDocument42 pagesPLCC Tech Specsevonik123456No ratings yet

- LA Leakage Current Testing (With Graphs) PDFDocument15 pagesLA Leakage Current Testing (With Graphs) PDFanurag_pugaliaaNo ratings yet

- Final Intership ReportDocument54 pagesFinal Intership Reportwubie100% (2)

- 005-Use of HTLS ConductorsDocument153 pages005-Use of HTLS ConductorsHikmat Ayer100% (2)

- Lightening Arrester 500kVTest Report EnglishDocument20 pagesLightening Arrester 500kVTest Report Englishashwani2101No ratings yet

- CBIP Guidelines On Protection: Auto-ReclosingDocument7 pagesCBIP Guidelines On Protection: Auto-Reclosingss_chinniNo ratings yet

- 550kV隔离开关 试验报告 武高所 英文版Document8 pages550kV隔离开关 试验报告 武高所 英文版ashwani2101No ratings yet

- Kema Ageing Test 5000 Hrs.Document12 pagesKema Ageing Test 5000 Hrs.Tarun AggarwalNo ratings yet

- Data Book-CVT PDFDocument97 pagesData Book-CVT PDFĐỗ Hồng Sơn100% (1)

- Test On T LinesDocument18 pagesTest On T LinesGhayas Ud-din Dar100% (1)

- RAP-37R-G76-365: Test Report IPMR 064/B/06 Qualification Type Test Report For Composite Insulator ProductsDocument17 pagesRAP-37R-G76-365: Test Report IPMR 064/B/06 Qualification Type Test Report For Composite Insulator ProductsZineddine BENOUADAHNo ratings yet

- TFR - 200902678 - 015 (Van Hanh Dinh Muc)Document14 pagesTFR - 200902678 - 015 (Van Hanh Dinh Muc)Nguyen ngoc thongNo ratings yet

- Different Types of InsulatorsDocument30 pagesDifferent Types of InsulatorsZineddine BENOUADAHNo ratings yet

- L.E.M.T.: TEST REPORT n°51251689EADocument9 pagesL.E.M.T.: TEST REPORT n°51251689EANguyen ngoc thongNo ratings yet

- 2018 CIGRE SESSION Technical - Programme June15thDocument34 pages2018 CIGRE SESSION Technical - Programme June15thVenkatasubramanian IyerNo ratings yet

- Technnical Schedule of BR10-PS-25 - Reply - 20170814Document5 pagesTechnnical Schedule of BR10-PS-25 - Reply - 20170814HopNo ratings yet

- Performance of Composite Insulators With and Without Bio ContaminationDocument4 pagesPerformance of Composite Insulators With and Without Bio ContaminationSiva KumarNo ratings yet

- Advisory Boards 36A 37: Section 35Document48 pagesAdvisory Boards 36A 37: Section 35kittiey100% (6)

- 1HC0072614-AB 420kV 4000A 63ka 60Hz First PagesDocument50 pages1HC0072614-AB 420kV 4000A 63ka 60Hz First PagesJairo MoralesNo ratings yet

- 41-P-135 (Earthing Platform)Document6 pages41-P-135 (Earthing Platform)RamzanNo ratings yet

- Narrative Report TransformerDocument6 pagesNarrative Report TransformerMarvin GagarinNo ratings yet

- 1MRG033422 A en KEMA Type Test Certificate of Complete Type Tests 670 and 650 Series Version 2.2Document22 pages1MRG033422 A en KEMA Type Test Certificate of Complete Type Tests 670 and 650 Series Version 2.2Boudam BoudjemaNo ratings yet

- Areva CT CCV CC English 72.5 20a 20765kVDocument4 pagesAreva CT CCV CC English 72.5 20a 20765kVnarinderNo ratings yet

- 3e Artificial Pollution Test Solid Layer Method ESDD 0 25 NSSD 2 5Document4 pages3e Artificial Pollution Test Solid Layer Method ESDD 0 25 NSSD 2 5Assistant EngineerNo ratings yet

- Kingsa FD90 Test Report Body Cote - UnlockedDocument35 pagesKingsa FD90 Test Report Body Cote - UnlockedsmartscsNo ratings yet

- Technical Specification FOR 220Kv Isolators: Gujarat State Electricity Corporation LTDDocument22 pagesTechnical Specification FOR 220Kv Isolators: Gujarat State Electricity Corporation LTDVelu SamyNo ratings yet

- Amwaj CatalogDocument95 pagesAmwaj CatalogFadi Ibrahim0% (1)

- 6 400KV CB PirDocument36 pages6 400KV CB PirRAPRATSINNo ratings yet

- IEC Type Test Report Report No. EU1527-H-00.1 PH3 Series Polymer-Housed Arrester 10,000 A Line Discharge Class 3Document89 pagesIEC Type Test Report Report No. EU1527-H-00.1 PH3 Series Polymer-Housed Arrester 10,000 A Line Discharge Class 3Raniel Operiano NecesitoNo ratings yet

- 3 66kv630 SQMM 1c Power CableDocument26 pages3 66kv630 SQMM 1c Power CableKeval VelaniNo ratings yet

- VMT ERT 03 REPORT 220 KV LUCKNOWDocument27 pagesVMT ERT 03 REPORT 220 KV LUCKNOWAnoop DikshitNo ratings yet

- GTP BatteryDocument17 pagesGTP Batteryraj_stuff006No ratings yet

- FRP Rods For Brittle Fracture ResistantDocument9 pagesFRP Rods For Brittle Fracture Resistantdmsoares1989No ratings yet

- Ascent Engineers & Projects: A 33kV Tranmsission Line - Approx 1 KM II 33kV, 11 MTR, Lattice Structure Sl. No. Unit QtyDocument6 pagesAscent Engineers & Projects: A 33kV Tranmsission Line - Approx 1 KM II 33kV, 11 MTR, Lattice Structure Sl. No. Unit QtygohilnarendraNo ratings yet

- OCP - 01 Current Transformer (SWYD)Document9 pagesOCP - 01 Current Transformer (SWYD)NaveedNo ratings yet

- Test Report: Measurement of Turns RatioDocument2 pagesTest Report: Measurement of Turns RatioJRC TestingNo ratings yet

- AHU ManualDocument41 pagesAHU Manualajayvarma02626100% (1)

- D.D. Builders Limited: Idax Consulting & Research PVT - LTDDocument8 pagesD.D. Builders Limited: Idax Consulting & Research PVT - LTDTARUNNo ratings yet

- Battery 1 Checklist and ReportDocument10 pagesBattery 1 Checklist and ReportNaveedNo ratings yet

- 13 P 129 2011 (Voltage Transformers)Document32 pages13 P 129 2011 (Voltage Transformers)RamzanNo ratings yet

- Turret CT &tan Delta ReportDocument4 pagesTurret CT &tan Delta ReportSantosh BagadeNo ratings yet

- PF95590Document39 pagesPF95590joemoneyNo ratings yet

- Doe STD 3020 2005 Hepa StandartiDocument23 pagesDoe STD 3020 2005 Hepa StandartiFuriaServaNo ratings yet

- Module 6 System Operation Version CDocument97 pagesModule 6 System Operation Version CVipinraj KrishnanNo ratings yet

- Key Single Line Diagram: Earth Pits Secondary Earth Bar Cable Sealing End 33kV Isolator CTDocument1 pageKey Single Line Diagram: Earth Pits Secondary Earth Bar Cable Sealing End 33kV Isolator CTVipinraj KrishnanNo ratings yet

- Electricity Substation Design, Earthing and Bonding: Version B 80Document1 pageElectricity Substation Design, Earthing and Bonding: Version B 80Vipinraj KrishnanNo ratings yet

- Approved SCE Count 2019 T0 2015Document2 pagesApproved SCE Count 2019 T0 2015Vipinraj KrishnanNo ratings yet

- Ferroresonance ReportDocument18 pagesFerroresonance ReportDoydoy Merida100% (1)

- 21 1 Physics 6b Ac CircuitsDocument16 pages21 1 Physics 6b Ac CircuitsJonathan AladinNo ratings yet

- CW-DSC-005 - Offshore Installation InstructionDocument32 pagesCW-DSC-005 - Offshore Installation InstructionMichel NgiangiNo ratings yet

- Marine Frequency ConvertersDocument20 pagesMarine Frequency Convertersrajee7No ratings yet

- 4 Point Starter - Working Principle and Construction of Four Point StarterDocument3 pages4 Point Starter - Working Principle and Construction of Four Point StarterMohd Rashid SiddiquiNo ratings yet

- Kendriya Vidyalaya Bhopal Region Pre Term-I Examination Subject (Code) : Physics (042) CLASS: XII (Set-I)Document8 pagesKendriya Vidyalaya Bhopal Region Pre Term-I Examination Subject (Code) : Physics (042) CLASS: XII (Set-I)jhjhghghgghNo ratings yet

- Features: Lt1937 White Led Step-Up Converter in Sc70 and ThinsotDocument12 pagesFeatures: Lt1937 White Led Step-Up Converter in Sc70 and ThinsotStri GunawanNo ratings yet

- Namma Kalvi 12th Physics Slow Learners Study Material em 217988Document15 pagesNamma Kalvi 12th Physics Slow Learners Study Material em 217988Jeyanth A.KNo ratings yet

- Making CoilsDocument9 pagesMaking CoilsSleshi MekonnenNo ratings yet

- Ground Bounce Basics and Best Practices: Phil King, Agilent TechnologiesDocument10 pagesGround Bounce Basics and Best Practices: Phil King, Agilent TechnologiesShanker MarimuthuNo ratings yet

- Control Electronico Sundstrans S20BLN-95-8965 - G&a HST - Ti - Rev 15 PDFDocument16 pagesControl Electronico Sundstrans S20BLN-95-8965 - G&a HST - Ti - Rev 15 PDFHernan Lopez100% (1)

- PHY102 Numerical-Problems-6 Summer2020Document1 pagePHY102 Numerical-Problems-6 Summer2020Ambrin AishaNo ratings yet

- Eee 212 NoteDocument40 pagesEee 212 NoteIgwe WinnerNo ratings yet

- Electrical and Electronic Measurement and Instrumentation LecDocument25 pagesElectrical and Electronic Measurement and Instrumentation LecAbdulhamid DaudaNo ratings yet

- Dynamics of StructureDocument17 pagesDynamics of StructureKurt CargoNo ratings yet

- Instant Download Ebook PDF Electric Circuits 11th Global Edition PDF ScribdDocument41 pagesInstant Download Ebook PDF Electric Circuits 11th Global Edition PDF Scribdjames.schultz763100% (45)

- Physics-272 Lecture 20: - AC Power - Resonant Circuits - Phasors (2-Dim Vectors, Amplitude and Phase)Document37 pagesPhysics-272 Lecture 20: - AC Power - Resonant Circuits - Phasors (2-Dim Vectors, Amplitude and Phase)J Naveen KumarNo ratings yet

- 7 Electrical Drawing: ObjectivesDocument25 pages7 Electrical Drawing: ObjectivesSergey ShkapovNo ratings yet

- 2012 10 07 ReInventing The Wheel Part1 Clemente FigueraDocument15 pages2012 10 07 ReInventing The Wheel Part1 Clemente FiguerasinergicusNo ratings yet

- 5 6082617462954656629Document432 pages5 6082617462954656629Pratik PathareNo ratings yet

- Electrical and Electronincs MeasurementsDocument51 pagesElectrical and Electronincs Measurementsrao asadNo ratings yet