Professional Documents

Culture Documents

4715 General Procedure For Purchase of Field Fabrication of Standard Prefabricated Assemblies

Uploaded by

LorenaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

4715 General Procedure For Purchase of Field Fabrication of Standard Prefabricated Assemblies

Uploaded by

LorenaCopyright:

Available Formats

Engineering Standards

Standard

4715

Page

1 of 4

GENERAL PROCEDURE FOR

PURCHASE OF FIELD FABRICATION

OF STANDARD PREFABRICATED ASSEMBLIES

Issue Date

Rev. No.

Date

1.

03/90

1

05/91

SCOPE

This standard establishes a uniform procedure for the purchase or field fabrication of standard fabricated

assemblies such as meter tubes, pig launchers and receivers and gathering system drips and for the disposition of

the required permanent records.

2.

3.

RELATED ENGINEERING STANDARDS

2.1

The requisitioner should obtain working copies of applicable Engineering Standards by copying from the

standards manual except for reduced fabrication drawings which may be obtained in a larger scale upon

request from the Drafting Section of Design Engineering. Fabrication drawings for typical pipeline

assemblies which are not included in Engineering Standards may also be available from the Drafting

Section.

2.2

See Engineering Standard 2305 for general specifications to be used when applicable for purchasing

fabricated pipeline assemblies.

2.3

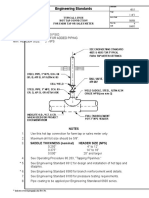

See Engineering Standard 5400 series for standards for purchase and fabrication drawings for meter tubes

and skid mounted meter assemblies.

2.4

See Engineering Standards 4850, 4851 and 4861 for fabrication drawings for typical gathering system

drips.

2.5

See Engineering Standards 8703 through 8707 for general as-built requirements and procedures.

PURCHASED FABRICATIONS

3.1

The requisitioner will state, as applicable, the quantity, type, size, pressure rating and design factor of the

prefabricated item and reference the applicable fabrication drawing on the requisition and, if applicable,

on the specification sheet contained in the appropriate standard for purchase.

3.1.1

Fabrication and fabrication certification in accordance with Engineering Standard 2305 are

required unless the "standard for purchase" of the specific type item includes equivalent

requirements, e.g., Engineering Standard 5421 for orifice meter tubes.

3.1.2

For multiple units, unit serial numbers will be determined in accordance with the standard for

purchase or as noted on the fabrication drawings, e.g., Purchase Order number plus sequential

numerical suffix. As-built drawings will reflect the serial number of each unit installed.

3.2

The requisitioner will furnish to Materials Management one set of good quality copies of the purchase

specifications including, as applicable, the standard for purchase (or specification) with completed

specification sheet and the fabrication drawing(s).

3.3

The requisitioner should also consider furnishing a copy of the purchase specifications to the receiving

location if the material to be purchased will not be shop inspected or if it is otherwise deemed necessary in

order for the material to be properly verified as being correct at the receiving location.

3.4

Purchase Orders will be issued by Materials Management for prefabricated assemblies such as meter

tubes, pig launchers and receivers and drips. Blanket or Release Orders should not be used for these

purchases.

* Indicates revised paragraph, this Rev. No.

Engineering Standards

Standard

4715

Page

2 of 4

GENERAL PROCEDURE FOR

PURCHASE OF FIELD FABRICATION

OF STANDARD PREFABRICATED ASSEMBLIES

Issue Date

Rev. No.

Date

3.5

Materials Management will furnish one set copies of the applicable standards, specifications and drawings

to the Vendor(s) at the time of the bid request or the purchase order issue, whichever is applicable, and

will retain one set of copies for the purchase order file.

3.6

Inspection and acceptance of equipment fabricated at Vendor's facilities will be coordinated by Materials

Management and carried out by the unit responsible for the project construction unless other

arrangements are made. This inspection should normally be done before shipment and will consist of

verification that requirements of drawings and specifications have been fulfulled.

3.7

4.

FIELD FABRICATED ASSEMBLIES

5.

03/90

1

05/91

When a large number of meter tubes is involved in an order, the required "Miking" of internal diameters

will be done at the Vendor's facility by a Field Operations specialist or technician. Materials Management

will arrange for this activity.

4.1

Standard assemblies fabricated by construction contractors or Field Operations will be fabricated in

accordance with Company approved fabrication drawings. For example, see Engineering Standards 4850,

4851 and 4861 for gathering system drips.

4.2

The fabrication certification required by Engineering Standard 2305 are intended for purchased

assemblies prefabricated in a Vendor's shop and is not required for fabricated assemblies made in the field,

supervised/inspected by the Company's representative and documented component-by-component as for

normal construction.

4.3

When the fabrications are completed, an as-built copy of the fabrication drawing and applicable

documentation shall be included in the project as-built package. When multiple fabrications are made and

placed in stock for future projects, the applicable documentation will be retained at the stock location or

otherwise managed to assure that a copy will be forwarded with each assembly and included in the as-built

package at the time of installation.

PRESSURE TESTING

5.1

See Engineering Standard 8100 and 8101 for general pressure testing requirements and specifications for

pre and post installation tests.

5.2

Purchase specifications for prefabricated units will normally require a pre-test by the fabricator at a

minimum test pressure of 1.5 times MAOP for 4 hours minimum duration. Pre-testing of field fabricated

units is discretionary unless required for MAOP qualification.

5.3

Prefabricated assemblies are not required to be re-tested at the time of installation if a post installation test

is impractical and they are pre-tested in accordance with Engineering Standard 8100 prior to installation.

* Indicates revised paragraph, this Rev. No.

Engineering Standards

Standard

4715

Page

3 of 4

GENERAL PROCEDURE FOR

PURCHASE OF FIELD FABRICATION

OF STANDARD PREFABRICATED ASSEMBLIES

Issue Date

Rev. No.

Date

6.

03/90

1

05/91

ENGINEERING RECORDS

6.1

Vendor Data

6.1.1

Materials Management will specify on the Purchase Order the Vendor's distribution of the

Vendor documentation which will be required by the purchase specifications. Minimum

distribution of Vendor documentation shall be as indicated below and will normally include

items such as certified drawings, fabrication certifications, material certifications, heat

treatment records and radiographic examination and pressure test reports.

a.

b.

c.

d.

6.2

One complete set to the appropriate Purchasing Agent for the Purchase Order file;

One complete set to the Engineering Records Section of Design Engineering;

One set to the material receiving location;

Radiographic film (if required) to the material receiving location.

6.1.2

The Vendor's fabrication certification form is acceptable provided it is equivalent to that

contained in Engineering Standard 2305 or the standard for purchase, whichever is

applicable.

6.1.3

The material should not be reported as being received on the material receiving report until all

required documentation has been received from the Vendor.

6.1.4

When the required Vendor documentation has been received by Materials Management, it will

be placed in the Purchase Order file along with the purchase specifications.

As-built Records

6.2.1

As-built documentation for field fabricated assemblies will be required in accordance with the

applicable requirements in Engineering Standards 8702 through 8707 for field contruction.

6.2.2

Materials Management shall be responsible for maintaining records for prefabricated

assemblies purchased in accordance with this standard for the life of the facility in which they

are installed. Such records shall be retrievable by Purchase Order number and shall include

all of the Company purchase specifications/drawings and all required Vendor documentation.

6.2.3

For purchased prefabricated units, the unit serial number including the Purchase Order

number, must be included in all applicable unit and project as-built data to be able to correlate

to Purchase Order file documentation.

* Indicates revised paragraph, this Rev. No.

Engineering Standards

Standard

4715

Page

4 of 4

GENERAL PROCEDURE FOR

PURCHASE OF FIELD FABRICATION

OF STANDARD PREFABRICATED ASSEMBLIES

Issue Date

Rev. No.

Date

6.2.4

03/90

1

05/91

Pipe and piping components which are individually documented in the certified fabrication

drawings for a prefabricated assembly are not required to be itemized in the project drawings

or material lists. Prefabricated assemblies should be noted on project drawings or material

lists by type, size, design pressure, design factor and serial number. For example:

a.

Prefabricated 16" Drip, 1000 psig design @ 0.60 D.F.,

Serial No.

b.

Prefabricated 3"-Meter Skid, 1440 psig design @ 0.50 D.F.,

Serial No.

6.2.5

For prefabricated units qualified by a pre-test, the qualification test pressure for documentation

purposes will be the minimum test pressure which appears on the as-built fabrication drawing,

or Vendor certification if applicable, unless stated otherwise and properly documented with

test charts.

* Indicates revised paragraph, this Rev. No.

You might also like

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Manage Risks and Seize OpportunitiesDocument5 pagesManage Risks and Seize Opportunitiesamyn_s100% (2)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Principles of Failure AnalysisDocument2 pagesPrinciples of Failure AnalysisLuis Kike Licona DíazNo ratings yet

- PVC Pipe Longevity ReportDocument24 pagesPVC Pipe Longevity ReportUnibellNo ratings yet

- Civilian Products BaikalDocument51 pagesCivilian Products BaikalMUHAMMAD SAQIB LATIF CHAUDHARYNo ratings yet

- Collaborative Cyber Threat Intelligence Detecting and Responding To Advanced Cyber Attacks at The National LevelDocument566 pagesCollaborative Cyber Threat Intelligence Detecting and Responding To Advanced Cyber Attacks at The National Levelanon_760702463No ratings yet

- Fire protection system philosophy for Collie Urea PlantDocument60 pagesFire protection system philosophy for Collie Urea PlantLorena Dávila100% (1)

- C 20 Series - Lubrication and Maintenance Schedule - 2010Document22 pagesC 20 Series - Lubrication and Maintenance Schedule - 2010Centrifugal SeparatorNo ratings yet

- Flare System PDFDocument41 pagesFlare System PDFAzar Deen100% (1)

- Selecting and Designing Branch ConnectionsDocument8 pagesSelecting and Designing Branch ConnectionsLorenaNo ratings yet

- Trusting JesusDocument1 pageTrusting JesusLorenaNo ratings yet

- 2813 HXGN Live 2813 MccombDocument19 pages2813 HXGN Live 2813 MccombLorenaNo ratings yet

- Tower of BabelDocument5 pagesTower of BabelLorenaNo ratings yet

- Report DesignerDocument255 pagesReport Designerdgrant775No ratings yet

- Fluidos Termicos y Circuitos de CalentamientoDocument38 pagesFluidos Termicos y Circuitos de CalentamientoClaudio Antonio Figueroa PulgarNo ratings yet

- What's New - CADWorx 2016Document5 pagesWhat's New - CADWorx 2016LorenaNo ratings yet

- 4940-w3 Standard For Purchase of Valves For Critical Gas ServiceDocument8 pages4940-w3 Standard For Purchase of Valves For Critical Gas ServiceLorena DávilaNo ratings yet

- Good Cooling Tower PractiseDocument59 pagesGood Cooling Tower Practiseamahmoud3No ratings yet

- 4907-w0 Standard For Purchase of Line Pipe For Low Temperature Service (Supplement To ASTM A333)Document3 pages4907-w0 Standard For Purchase of Line Pipe For Low Temperature Service (Supplement To ASTM A333)LorenaNo ratings yet

- Good Cooling Tower PractiseDocument59 pagesGood Cooling Tower Practiseamahmoud3No ratings yet

- 4910-w1 Engineering Guideline For Flexible Metal HoseDocument1 page4910-w1 Engineering Guideline For Flexible Metal HoseLorenaNo ratings yet

- Onshore and Offshore: Echnical PresentationDocument66 pagesOnshore and Offshore: Echnical PresentationAnonymous 4MwmDaNbNo ratings yet

- Series 1500 Cooling Tower SpecificationDocument9 pagesSeries 1500 Cooling Tower SpecificationLorenaNo ratings yet

- Demonstration of Hydrogen Air-Assisted FlaDocument18 pagesDemonstration of Hydrogen Air-Assisted Flahk168No ratings yet

- 4895-w2 Standard For Purchase of Forged Flanges and FittingsDocument3 pages4895-w2 Standard For Purchase of Forged Flanges and FittingsLorenaNo ratings yet

- 4760-w0 Typical Stream or Ditch Pipeline UndercrossingDocument1 page4760-w0 Typical Stream or Ditch Pipeline UndercrossingLorena100% (1)

- 4890 Guide Bar Installation For Weld TeesDocument2 pages4890 Guide Bar Installation For Weld TeesLorena DávilaNo ratings yet

- 4815 Typical 1 Hot Tap Connection For Farm Tap or Sales MeterDocument1 page4815 Typical 1 Hot Tap Connection For Farm Tap or Sales MeterLorenaNo ratings yet

- 4752-w2 Typical Natural Gas Pipeline and Pipeline Insulator Installation For Railroad UndercrossingDocument1 page4752-w2 Typical Natural Gas Pipeline and Pipeline Insulator Installation For Railroad UndercrossingLorenaNo ratings yet

- 4763-w2 Yard Applied Concrete Pipe CoatingDocument7 pages4763-w2 Yard Applied Concrete Pipe CoatingLorena DávilaNo ratings yet

- 4802-w2 Concrete Anchor Block - Installation DetailsDocument2 pages4802-w2 Concrete Anchor Block - Installation DetailsLorenaNo ratings yet

- 4764-n1 Typical Pipeline Bolt On Type Concrete Weight For 42 O.D. PipelineDocument1 page4764-n1 Typical Pipeline Bolt On Type Concrete Weight For 42 O.D. PipelineLorenaNo ratings yet

- Enron Gas Pipeline Engineering Standards for Concrete Pipeline WeightsDocument2 pagesEnron Gas Pipeline Engineering Standards for Concrete Pipeline WeightsLorenaNo ratings yet

- 4762-w0 Typical Canal Undercrossing, Lined or UnlinedDocument1 page4762-w0 Typical Canal Undercrossing, Lined or UnlinedLorenaNo ratings yet

- 4748-w0 Typical Pipeline and Casing Support at Cased UndercrossingsDocument1 page4748-w0 Typical Pipeline and Casing Support at Cased UndercrossingsLorenaNo ratings yet

- 4758-w0 Restoration of TerracesDocument1 page4758-w0 Restoration of TerracesLorenaNo ratings yet

- 4747-w2 Typical Natural Gas Pipeline and Pipeline Insulator Installation For Cased Highway UndercrossingDocument1 page4747-w2 Typical Natural Gas Pipeline and Pipeline Insulator Installation For Cased Highway UndercrossingLorenaNo ratings yet

- Muh Eng 50hzDocument8 pagesMuh Eng 50hzaleks canjugaNo ratings yet

- Wind Load On Cable TraysDocument10 pagesWind Load On Cable TraysAaron EasleyNo ratings yet

- SAMSUNG SDI Confidential Proprietary Spec. No. INR18650-32E Version No. 2.0Document19 pagesSAMSUNG SDI Confidential Proprietary Spec. No. INR18650-32E Version No. 2.0Andrei DanNo ratings yet

- Joybook A52 Series EnglishDocument44 pagesJoybook A52 Series EnglishTudor VladNo ratings yet

- Assignment ADocument2 pagesAssignment AUbair khan0% (3)

- Architectural Design of Bangalore Exhibition CentreDocument24 pagesArchitectural Design of Bangalore Exhibition CentreVeereshNo ratings yet

- Baremos Espanoles CBCL6-18 PDFDocument24 pagesBaremos Espanoles CBCL6-18 PDFArmando CasillasNo ratings yet

- 2021 Feb EMTEK Door Hardware Price Book WebDocument228 pages2021 Feb EMTEK Door Hardware Price Book WebAlejandro LópezNo ratings yet

- Psa 3000Document2 pagesPsa 3000diegoh_silvaNo ratings yet

- VingDocument8 pagesVingNguyễnĐắcĐạt100% (1)

- Endress KatalogDocument72 pagesEndress KatalogpnsanatNo ratings yet

- Nikola Tesla PaperDocument6 pagesNikola Tesla Paperapi-302403539No ratings yet

- docPOI UkDocument27 pagesdocPOI UkpvitruvianNo ratings yet

- w13 - CRM How It Works and Help BusinessDocument15 pagesw13 - CRM How It Works and Help BusinessYahya Vernanda RamadhaniNo ratings yet

- Bharat Institute of EngineeringDocument2 pagesBharat Institute of EngineeringdasarioramaNo ratings yet

- C ProgramsDocument54 pagesC Programskodali_madhav100% (3)

- Binary WorksheetDocument4 pagesBinary WorksheetMariell EllanoNo ratings yet

- Data Visualization Nanodegree Program Syllabus PDFDocument4 pagesData Visualization Nanodegree Program Syllabus PDFsergio paredesNo ratings yet

- Adaptive Bit LoadingDocument10 pagesAdaptive Bit LoadingKrrish BommanaNo ratings yet

- Squid InvaderDocument14 pagesSquid InvaderMikhail Roy Dela CruzNo ratings yet

- Investment Opportunities in OdishaDocument28 pagesInvestment Opportunities in OdishaNiladri MandalNo ratings yet

- Manual CleviteDocument180 pagesManual CleviteJacko JaraNo ratings yet

- Vibration PPV EstimationDocument8 pagesVibration PPV EstimationJensen TanNo ratings yet

- KATANA 5040R/5055R: High-End ImagesetterDocument4 pagesKATANA 5040R/5055R: High-End ImagesetterAgence CreapubNo ratings yet