Professional Documents

Culture Documents

EOS Material-Datasheet Stainless-Steel-PH1 M290 en PDF

Uploaded by

Miguel A. ChávezOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

EOS Material-Datasheet Stainless-Steel-PH1 M290 en PDF

Uploaded by

Miguel A. ChávezCopyright:

Available Formats

Material data sheet

EOS StainlessSteel PH1 for EOS M 290

EOS StainlessSteel PH1 is a steel powder which has been optimized especially for processing on

EOS M systems.

This document provides information and data for parts built using EOS StainlessSteel PH1 powder (EOS art.-no. 9011-0019) on the following system specifications:

- EOS M 290 with EOSPRINT 1.2 and Original EOS Parameterset PH1_Surface 1.0

Description, application

EOS StainlessSteel PH1 is a pre-alloyed stainless steel in fine powder form. The chemistry of

EOS StainlessSteel PH1 conforms to the compositions of DIN 1.4540 and UNS S15500.

This kind of steel is characterized by having good corrosion resistance and excellent mechanical

properties, especially in the precipitation hardened state. This type of steel is widely used in variety of medical, aerospace and other engineering applications requiring high hardness, strength

and corrosion resistance.

This material is ideal for many part-building applications (DirectPart) such as functional metal

prototypes, small series products, individualised products or spare parts. Standard processing parameters use full melting of the entire geometry with 20 m layer thickness. Using standard

parameters the mechanical properties are fairly uniform in all directions. Parts made from

EOS StainlessSteel PH1 can be machined, spark-eroded, welded, micro shot-peened, polished

and coated if required. Unexposed powder can be reused.

Typical applications:

- engineering applications including functional prototypes, small series products, individualised products or spare parts.

- parts requiring high corrosion resistance, sterilisability, etc.

- parts requiring particularly high hardness and strength.

EOS GmbH - Electro Optical Systems

Robert-Stirling-Ring 1

D-82152 Krailling / Mnchen

EOS StainlessSteel PH1

HHE / 15.05

1/5

Telephone: +49 (0)89 / 893 36-0

Telefax:

+49 (0)89 / 893 36-285

Internet: www.eos.info

Material data sheet

Technical data

General process and geometric data

Minimum recommended layer thickness

20 m

0.8 mil

Typical achievable part accuracy [1]

- small parts

20 50 m

0.8 2.0 mil

- large parts

0.2 %

Min. wall thickness [2]

~ 0.4 mm

~ 0.016 in

Surface roughness

- after shot-peening

Ra ~ 5.0 m, Rz ~ 25.0 m

Ra ~ 0.2 mil, Rz ~ 1.0 mil

- after polishing

Rz up to < 0.5 m

(can be very finely polished)

Volume rate [3]

- standard parameters (20m layers, bulk part)

[1]

[2]

[3]

~ 2.0 mm/s

~ 0.40 in/h

Based on users' experience of dimensional accuracy for typical geometries, e.g. 20 m when parameters can

be optimized for a certain class of parts or 50 m when building a new kind of geometry for the first time.

Mechanical stability is dependent on geometry (wall height etc.) and application

Volume rate is a measure of build speed during laser exposure. The total build speed depends on the average

volume rate, the recoating time (related to the number of layers) and other factors such as DMLS-Start settings.

EOS GmbH - Electro Optical Systems

EOS StainlessSteel PH1

HHE / 15.05

2/5

Robert-Stirling-Ring 1

D-82152 Krailling / Mnchen

Material data sheet

Physical and chemical properties of parts

Material composition

steel including alloying elements

Fe (balance)

Cr (14 15.5 wt-%)

Ni (3.5 5.5 wt-%)

Cu (2.5 4.5 wt-%)

Mn (max. 1.00 wt-%)

Si (max. 1.00 wt-%)

C (max. 0.07 wt-%)

Mo (max. 0.5 wt-%)

Nb (0.15 - 0.45 wt-%)

Relative density with standard parameters

approx. 100 %

Density with standard parameters

~ 7.7 g/cm

~ 0.27 lb/in

EOS GmbH - Electro Optical Systems

EOS StainlessSteel PH1

HHE / 15.05

3/5

Robert-Stirling-Ring 1

D-82152 Krailling / Mnchen

Material data sheet

Mechanical properties of parts [4]

As manufactured

Hardened [6]

(mod H900 heat treatment)

Ultimate tensile strength

- in horizontal direction (XY)

1200 50 MPa

min. 1350 MPa

(typical 1450 100 MPa)

- in vertical direction (Z)

1200 50 MPa

min. 1340 MPa

(typical 1440 100 MPa)

- in horizontal direction (XY)

1025 75 MPa

min. 1250 MPa

(typical 1350 100 MPa)

- in vertical direction (Z)

940 75 MPa

min. 1200 MPa

(typical 1300 100 MPa)

- in horizontal direction (XY)

17 % 4 %

min 10 %

(typical 15 % 3 %)

- in vertical direction (Z)

14 % 4 %

min 10 %

(typical 13 % 3 %)

min 40 HRC

(typical 43 HRC)

Yield strength (Rp 0.2 %)

Elongation at break

Hardness [5]

- as built

[4]

[5]

[6]

Mechanical testing according to ISO 6892:1998(E) Annex C, proportional test pieces, Diameter of the neck

area 5mm, original gauge length 25mm, test pieces built in 20m layer-thickness.

Rockwell C (HRC) hardness measurement according to DIN EN ISO 6508-1. Note that depending on the measurement method used, the measured hardness value can be dependent on the surface roughness and can be

lower than the real hardness. To avoid inaccurate results, hardness should be measured on a polished surface.

Mechanical properties are expressed as minimum values to indicate that mechanical properties exceed the

min requirements of material specification standards such as ASTM A564-04 (XM12), ASTM A693-06 (XM12).

Hardening of EOS StainlessSteel PH1 done using modified H900 heat treatment (soaking time at precipitation

hardening temperature 525C elongated for 4 hours)

EOS GmbH - Electro Optical Systems

EOS StainlessSteel PH1

HHE / 15.05

4/5

Robert-Stirling-Ring 1

D-82152 Krailling / Mnchen

Material data sheet

The quoted values refer to the use of these materials with EOS M 290 systems according to current specifications

(including the latest released process software PSW and any hardware specified for the relevant material) and operating instructions. All values are approximate. Unless otherwise stated, the quoted mechanical and physical

properties refer to standard building parameters and test samples built in M 290 system with EOS StainlessSteel

PH1 powder product. Properties are dependent on the building parameters and strategies used, which can be varied

by the user according to the application. Measurements of the same properties using different test methods (e.g.

specimen geometries) can give different results.

The data are based on our latest knowledge and are subject to changes without notice. They are provided as an indication and not as a guarantee of suitability for any specific application.

EOS, EOSINT, DMLS and DirectPart are registered trademarks of EOS GmbH.

2015 EOS GmbH Electro Optical Systems. All rights reserved.

EOS GmbH - Electro Optical Systems

EOS StainlessSteel PH1

HHE / 15.05

5/5

Robert-Stirling-Ring 1

D-82152 Krailling / Mnchen

You might also like

- Operational Amplifier Noise: Techniques and Tips for Analyzing and Reducing NoiseFrom EverandOperational Amplifier Noise: Techniques and Tips for Analyzing and Reducing NoiseRating: 5 out of 5 stars5/5 (1)

- Hall-Effect Sensors: Theory and ApplicationFrom EverandHall-Effect Sensors: Theory and ApplicationRating: 5 out of 5 stars5/5 (1)

- SS GP1 M270 - 04 09 - enDocument5 pagesSS GP1 M270 - 04 09 - enPiotr PawłowskiNo ratings yet

- AlSi10Mg-M270 Material Data Sheet 07-09 enDocument4 pagesAlSi10Mg-M270 Material Data Sheet 07-09 eninam758388No ratings yet

- Data Sheet of Cobalt ChromiumDocument6 pagesData Sheet of Cobalt ChromiumDeva RajNo ratings yet

- Material Data Sheet: Eos Stainlesssteel Ph1 For Eosint M 270Document5 pagesMaterial Data Sheet: Eos Stainlesssteel Ph1 For Eosint M 270Charles SedilloNo ratings yet

- Material Data Sheet - Flexline: DescriptionDocument4 pagesMaterial Data Sheet - Flexline: DescriptionRaj RajeshNo ratings yet

- Material Data Sheet: Eos Stainlesssteel Gp1 For Eosint M 270Document5 pagesMaterial Data Sheet: Eos Stainlesssteel Gp1 For Eosint M 270Charles SedilloNo ratings yet

- Material Data Sheet - Flexline: DescriptionDocument4 pagesMaterial Data Sheet - Flexline: DescriptionRaj RajeshNo ratings yet

- EOS Titanium TiCP Grade 2 - M290 - Material - Data - Sheet - 05-16 - FlexLine - en PDFDocument4 pagesEOS Titanium TiCP Grade 2 - M290 - Material - Data - Sheet - 05-16 - FlexLine - en PDFrajatNo ratings yet

- CoCr MP1 M270 Material Data SheetDocument6 pagesCoCr MP1 M270 Material Data Sheetgpiprototype.comNo ratings yet

- z3T - Stainless Steel 15-5 PH (EOS SS PH1)Document1 pagez3T - Stainless Steel 15-5 PH (EOS SS PH1)Martin McMahonNo ratings yet

- Material Data Sheet: Eos Maragingsteel Ms1Document6 pagesMaterial Data Sheet: Eos Maragingsteel Ms1qualityfreekNo ratings yet

- SpekrometerDocument16 pagesSpekrometerPutra AjaNo ratings yet

- Humboldt: Humboldt HS-5001EZ Nuclear Density GaugeDocument2 pagesHumboldt: Humboldt HS-5001EZ Nuclear Density GaugeSofiaIsabelaPalaciosRosellNo ratings yet

- Material Data Sheet: ApplicationDocument2 pagesMaterial Data Sheet: ApplicationqualityfreekNo ratings yet

- Oe Series App Note FeDocument8 pagesOe Series App Note Fetinaungkyi845No ratings yet

- Material Data Sheet: Eos Maragingsteel Ms1Document5 pagesMaterial Data Sheet: Eos Maragingsteel Ms1Raj RajeshNo ratings yet

- Byspeed 3015 Laser Cutting System Technical SpecsDocument2 pagesByspeed 3015 Laser Cutting System Technical Specstaurus1108No ratings yet

- Foundry Master Pro BrochureDocument4 pagesFoundry Master Pro BrochureDarin NabilNo ratings yet

- Material Data Sheet: DescriptionDocument6 pagesMaterial Data Sheet: DescriptionRaj RajeshNo ratings yet

- SLS DATA SHEET Mds-StrongflexDocument2 pagesSLS DATA SHEET Mds-Strongflexhitesh cHAUDHARINo ratings yet

- Conarc49 EngDocument2 pagesConarc49 Engdeepak2803No ratings yet

- Ti64 PDFDocument5 pagesTi64 PDFqualityfreekNo ratings yet

- Namson laser portable welding machineDocument5 pagesNamson laser portable welding machineChitMoeNo ratings yet

- Low Cost, Industrial ICP AccelerometerDocument2 pagesLow Cost, Industrial ICP AccelerometerkooolmaNo ratings yet

- Rapid Manufacturing Techniques for Patient-Specific ImplantsDocument16 pagesRapid Manufacturing Techniques for Patient-Specific ImplantsAbhijeet GangulyNo ratings yet

- High Strength Cold Forming Steel with 340-420 MPa Yield StrengthDocument1 pageHigh Strength Cold Forming Steel with 340-420 MPa Yield StrengthPrashantha RajuNo ratings yet

- Endress-Hauser Proline Promag E 100 5E1B enDocument4 pagesEndress-Hauser Proline Promag E 100 5E1B enShadab AmeenNo ratings yet

- Allen-Bradley 30.5mm 3-Hole EnclosureDocument2 pagesAllen-Bradley 30.5mm 3-Hole EnclosureCARLOS COANo ratings yet

- A07-297 OD Expanded Small PartsDocument12 pagesA07-297 OD Expanded Small PartsKyle DriscollNo ratings yet

- Foundry Master UvDocument2 pagesFoundry Master UvLucianoBorasiNo ratings yet

- Eos Materials Table Overview M en WebDocument3 pagesEos Materials Table Overview M en WebutkuNo ratings yet

- CNC Laser Cutting Machine: The SpeedmasterDocument10 pagesCNC Laser Cutting Machine: The SpeedmasterKaast Machine ToolsNo ratings yet

- Material Data Sheet: Description, ApplicationDocument5 pagesMaterial Data Sheet: Description, ApplicationCharles SedilloNo ratings yet

- OE AN41280 ARL EasySpark Iron 0316Document4 pagesOE AN41280 ARL EasySpark Iron 0316María Lizeth Mandón GNo ratings yet

- Pmi Master Smart Brochure en UsDocument4 pagesPmi Master Smart Brochure en UsJuanm ManuelNo ratings yet

- Aisi 409Document1 pageAisi 409sheinilaNo ratings yet

- Portfolio Overview: EOS Materials MetalDocument3 pagesPortfolio Overview: EOS Materials MetalRaj RajeshNo ratings yet

- L-Dens 427F Ex Density Sensor SpecificationsDocument6 pagesL-Dens 427F Ex Density Sensor Specificationsd1arsenovskiNo ratings yet

- Eos Materials Overview Metal enDocument3 pagesEos Materials Overview Metal enPali BigBeat SinnemiaNo ratings yet

- Summary ISO TR 15608 Metallic Materials Grouping SystemDocument3 pagesSummary ISO TR 15608 Metallic Materials Grouping SystemharikrishnanNo ratings yet

- Electromagnetic Buzzers Pin Terminal SD Series: Conformity To Rohs DirectiveDocument4 pagesElectromagnetic Buzzers Pin Terminal SD Series: Conformity To Rohs DirectiveYugi Abdul LathifNo ratings yet

- AISI 410 / UNS S41000 / DIN 1.4006: Industrial Piping ProductsDocument3 pagesAISI 410 / UNS S41000 / DIN 1.4006: Industrial Piping Productsbhanu.kiranNo ratings yet

- Aisi 431 Stainless SteelDocument3 pagesAisi 431 Stainless SteeldhaneshquilonNo ratings yet

- EosDocument33 pagesEosIonut TodericNo ratings yet

- Pages From SIMABUS Tubular Busbar Accesories-444Document1 pagePages From SIMABUS Tubular Busbar Accesories-444asi midobarNo ratings yet

- Ancorsteel® 4300 PDFDocument3 pagesAncorsteel® 4300 PDFJoydip JoydipNo ratings yet

- Material Data Sheet - Flexline: Eos Stainlesssteel CXDocument4 pagesMaterial Data Sheet - Flexline: Eos Stainlesssteel CXRaj RajeshNo ratings yet

- ThyssenKrupp - XAR PLUSDocument3 pagesThyssenKrupp - XAR PLUSParametric EngineeringNo ratings yet

- Data EC309 LDocument1 pageData EC309 LbabakjooonNo ratings yet

- Aerospace Material Specification: Titanium Alloy Tubing, Seamless, Hydraulic 3.0al - 2.5V Cold Worked, Stress RelievedDocument9 pagesAerospace Material Specification: Titanium Alloy Tubing, Seamless, Hydraulic 3.0al - 2.5V Cold Worked, Stress Relievedvsraju2No ratings yet

- Industrial Combustion Gas & Emissions AnalyzerDocument3 pagesIndustrial Combustion Gas & Emissions AnalyzerPeterNo ratings yet

- Stabilized Ferritic Stainless Steel: General CharacteristicsDocument37 pagesStabilized Ferritic Stainless Steel: General CharacteristicsBina Niaga MultiusahaNo ratings yet

- Stabilized Ferritic Stainless Steel for Automotive Exhaust SystemsDocument37 pagesStabilized Ferritic Stainless Steel for Automotive Exhaust SystemsShashank SaxenaNo ratings yet

- En 1.4301Document1 pageEn 1.4301sheinilaNo ratings yet

- Stainless Steel 304 Product InfoDocument1 pageStainless Steel 304 Product Infoarunava001No ratings yet

- Data FlowchartDocument1 pageData FlowchartMiguel A. ChávezNo ratings yet

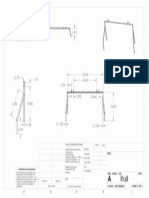

- RailDocument1 pageRailMiguel A. ChávezNo ratings yet

- Process Software PSW - Basics: 9.9.6 Calculation of X-/Y-scaling ValuesDocument2 pagesProcess Software PSW - Basics: 9.9.6 Calculation of X-/Y-scaling ValuesMiguel A. ChávezNo ratings yet

- Trig. Sheet For Right TrianglesDocument3 pagesTrig. Sheet For Right TrianglesMiguel A. ChávezNo ratings yet

- Chem 400 Prereq RVW KeyDocument9 pagesChem 400 Prereq RVW KeyMiguel A. ChávezNo ratings yet

- Solidworks Simulation 2011 TutorialDocument8 pagesSolidworks Simulation 2011 TutorialCarlos GonzálezNo ratings yet

- Berkeley GuideDocument22 pagesBerkeley Guideapi-295642195No ratings yet

- Solution: (A) A B C DDocument8 pagesSolution: (A) A B C DMiguel A. ChávezNo ratings yet

- Solution: (A) A B C DDocument8 pagesSolution: (A) A B C DMiguel A. ChávezNo ratings yet

- Dynamics ch1Document104 pagesDynamics ch1Miguel A. ChávezNo ratings yet

- Fermacell Orange BookDocument138 pagesFermacell Orange BookabudabeejajaNo ratings yet

- Ficha Tecnica CableDocument2 pagesFicha Tecnica CableAriel HerreraNo ratings yet

- WWT6 - Colection and Conveyance of SewageDocument37 pagesWWT6 - Colection and Conveyance of SewageHelder MbidiNo ratings yet

- Water & Waste Solutions Complete Turnkey CapabilitiesDocument6 pagesWater & Waste Solutions Complete Turnkey CapabilitiesAquasoul CoNo ratings yet

- ASTM - STP 425 - Stress Corrosion Testing 1967 PDFDocument390 pagesASTM - STP 425 - Stress Corrosion Testing 1967 PDFnarmathaNo ratings yet

- Spectacle Blind FlangeDocument3 pagesSpectacle Blind Flangemaniastur365No ratings yet

- Piping Latest Aramco QuestionsDocument2 pagesPiping Latest Aramco Questionschandu666creator0% (1)

- Pile Testing - State of The ArtDocument17 pagesPile Testing - State of The ArtNader MehdawiNo ratings yet

- Gate DesignDocument2 pagesGate DesignDineshkumar SNo ratings yet

- Armoured Cables - Types, Standards and Uses ExplainedDocument2 pagesArmoured Cables - Types, Standards and Uses Explaineddaniel_silabanNo ratings yet

- JIS G3101 SS 400 Steel Plate StandardDocument6 pagesJIS G3101 SS 400 Steel Plate StandardArun kumarNo ratings yet

- ADWEA I&C InstallationDocument32 pagesADWEA I&C InstallationAyman Termanini100% (2)

- True G4SM-23PT MerchandiserDocument2 pagesTrue G4SM-23PT Merchandiserwsfc-ebayNo ratings yet

- AISC DG 37 - Hybrid Steel Frames With CLTDocument116 pagesAISC DG 37 - Hybrid Steel Frames With CLTpeacers100% (1)

- Introduction To Geothermal Comfort Systems Dave Buss GAOI Northern Meeting 10 30 13Document83 pagesIntroduction To Geothermal Comfort Systems Dave Buss GAOI Northern Meeting 10 30 13Md Shane KarimiNo ratings yet

- ESC Steel Philippines Brochure - Oct 2019 PDFDocument12 pagesESC Steel Philippines Brochure - Oct 2019 PDFCarlos_CriticaNo ratings yet

- 07Document32 pages07SERGIO CARDENAS CASTILLONo ratings yet

- Largest Brick Structure in The World JetavanaramayaDocument7 pagesLargest Brick Structure in The World JetavanaramayaTharindu Edirisinghe100% (1)

- Roll Up Door DesignDocument1 pageRoll Up Door DesignLester Neil LomodNo ratings yet

- PCXPDS14 60Hz Ducted Split B-SeriesDocument2 pagesPCXPDS14 60Hz Ducted Split B-SeriesDesmondiceNo ratings yet

- Design of FRC Tunnel Segments Considering The Ductility Requirements of The Model Code 2010Document23 pagesDesign of FRC Tunnel Segments Considering The Ductility Requirements of The Model Code 2010Freddie KooNo ratings yet

- V-STEEL J-TRACTION OFF-THE-ROAD TIRESDocument2 pagesV-STEEL J-TRACTION OFF-THE-ROAD TIRESJAVIER BERMUDEZNo ratings yet

- Lecture 4 Columns DesignDocument33 pagesLecture 4 Columns DesignOlesea NesterencoNo ratings yet

- General Requirements For ValvesDocument16 pagesGeneral Requirements For ValvesKrishna Prasad R100% (1)

- CONTRACT OF SERVICEDocument4 pagesCONTRACT OF SERVICER13 PENRO Surigao Del NorteNo ratings yet

- FLYER 127A/4127A SERIES Viking PumpsDocument2 pagesFLYER 127A/4127A SERIES Viking PumpsMarcosNo ratings yet

- What Is Urban DesignDocument18 pagesWhat Is Urban DesignArun RajNo ratings yet

- Name of Project: Structure Parcel OfficeDocument31 pagesName of Project: Structure Parcel Officemohan sundarNo ratings yet

- Hansen PSV'S PDFDocument4 pagesHansen PSV'S PDF9082888lcNo ratings yet

- 0132497468-Ch13 ISMDocument48 pages0132497468-Ch13 ISMJeison Rincón Garzón100% (2)