Professional Documents

Culture Documents

BLDC Motor Driver

Uploaded by

jpmacabascoCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

BLDC Motor Driver

Uploaded by

jpmacabascoCopyright:

Available Formats

EE197 E-H

5 April 2011

BLDC Motor Driver

Ranbill O. Cadayona, Jan Darell L. Hernandez, Jesse Paulo V. Macabasco

Electrical and Electronics Engineering Institute, University of the Philippines

Diliman, Quezon City, Philippines

ranbillcadayona@yahoo.com

jdhernandez_03@yahoo.com

jpmacabasco@gmail.com

Abstract The brushless DC motor is a motor type gaining

popularity because of its advantages over brushed ones. This

document presents a microcontroller-based driver design for a

BLDC motor.

I. INTRODUCTION

rushless Direct Current (BLDC) motors are one of the

motor types rapidly gaining popularity. BLDC motors

are used in industries such as appliances, automotive,

aerospace, consumer, medical, industrial automation

equipment and instrumentation.

As the name implies, BLDC motors do not use brushes

for commutation; instead, they are electronically commutated.

This is accomplished through a driver designed for the

particular operation of a BLDC motor.

III. BLDC MOTOR DRIVER DESIGN

The BLDC motor driver is both a hardware and software

design, since it will be based on a microcontroller (which

needs to be programmed).

A. Hardware

The hardware design of the driver is based on the threephase bridge, shown in Fig.2. Each drive phase consists of one

motor terminal driven high, one motor terminal driven low,

and one motor terminal left floating; corresponding to the

commutation sequence.

II. BLDC MOTOR THEORY OF OPERATION

The BLDC motor is constructed as such: the rotor is made

of the permanent magnet and the stator contains the windings.

For a three-phase BLDC motor, there are three windings; one

energized positively, another one negatively, and one left

unpowered. This is done at each sequence, alternately

changing between windings; this is called the Six-Step

Commutation. At this commutation, the magnetic field

produced by the windings keeps on changing its position,

causing the permanent magnet in the rotor to follow.

Fig. 2 Three-phase bridge

The field effect transistors used for the driver are IRF9640

and IRF640; power MOSFETs complementary to each other

(P-channel and N-channel respectively). These MOSFETS are,

in turn, driven by power transistors (TIP30 and TIP31)

through a common-emitter amplifier cascaded with a power

amplifier.

2k

R4

Q3

TIP31

IRF9640

1K

470

10k

R3

R2

Q2

TIP31

Q10

TIP30

R5

d1n4004

D1

Q4

2k

R7

Q7

TIP31

Fig. 1 Six-step commutation

470

10k

R16

R8

The BLDC motor will run only if the correct sequence is

followed; otherwise, the motor will run for a certain angle and

stop since commutation did not follow.

IRF640

1K

Q1

TIP31

Q5

TIP30

R6

d1n4004

D2

Q8

Fig. 3 Transistor drive with power amplifier (one phase)

Page 1 of 6

EE197 E-H

5 April 2011

Since a common-emitter amplifier is used, output logic will

be inverted and must be accounted in determining the desired

waveforms for the driver output.

40

V3

ARB3

V(N1)*V(N2)

V10

N1

1K

OUT

ctr=1 frolloff=100k

U1

2k

R4

Q3

TIP31

IRF9640

1K

R1

N2

V7

470

10k

R3

R2

Q2

TIP31

Q10

TIP30

R5

The feedback voltage sensors are used to determine the

state of the windings and voltage levels; for commutation

sequence. Fig.8.a is a virtual ground, since the real neutral

node is not accessible. This virtual ground is formed by

paralleling resistors with each winding and formed in wyeconnection. Fig.8.b is a simple divider to sense the voltage of

the floating winding.

d1n4004

D1

u

U

250k

250k

R2

R1

R1

250k

V_STAR

1K

V4

ctr=1 frolloff=100k

U2

2k

R7

Q7

TIP31

Q1

TIP31

Q5

TIP30

470

10k

R16

R8

R6

d1n4004

D2

Q8

R3

250k

R3

250k

v _u

R4

3.3k

IRF640

1K

R9

Q4

R5

250k

v _v

R2

10k

v _w

R4

10k

R6

10k

Fig. 5 Complete Motor driver (one phase)

Fig. 5 shows the complete design for the motor driver.

Waveform generators are used to simulate the microcontroller.

The driver is isolated by 4N25 optocouplers in the input side

to ensure protection for the microcontroller.

The simulated waveforms of the driver are shown in Fig. 6.

PWM signals are used to control the input voltage. By

averaging the voltages from the PWM signals, an effective

input voltage is achieved. For a PWM signal with 10% duty

cycle, 10% of the input voltage is fed to the driver.

Fig. 8.a) Virtual ground and b) feedback voltage sensors

These sensed voltages are then fed into a comparator; used

as a zero-crossing detector. If a zero-crossing is detected, the

transistor will output a logic high (3.3V) which the

microcontroller polls. This will serve as markers, and signal

the microcontroller to make the required adjustments for

correct commutation sequence. This will now correspond to

the closed loop control of the motor.

3.3

V2

7

V1

R2

3.3k

u_u

X1

v_u

250k

v_STAR

R1

Q1

Q2N3904

LF353

3.3

V4

7

V3

R4

3.3k

u_v

X2

v_v

250k

v_STAR

R3

Q2

Q2N3904

LF353

3.3

V6

7

V5

Fig. 6 Simulated driver output waveforms (one phase)

The waveforms are based on the logic shown in Fig. 7.

When A2 (green waveform in Fig. 6) is logic high and A1

(blue waveform) is logic low, the output logic (red waveform)

should be float or open circuit; in the case of the simulation,

20V is the set float voltage since float cannot be really

simulated. When A2 and A1 is both logic high, the output

logic is high; low when both inputs are low. When A2 is low

and A1 is high, it would mean that the voltage supply is

shorted to ground; so this final case should not be encountered

in producing the PWM signals.

Fig. 7 PWM Logic

R6

3.3k

u_w

X3

v_w

250k

v_STAR

R5

Q3

Q2N3904

LF353

Fig. 9 Feedback Voltage Comparators

For current limiting of the driver, a simple metal clip (with

approximately 18m resistance) is used; sensing the voltage

across it and feeding it into the ADC of the microcontroller.

Initially, when there is no load, supply voltage is equal to 40%

of the DC input voltage (48V). After applying a load, the back

emf decreases, making the current high, which is undesirable

for the system. The microcontroller lowers the duty cycle of

the PWM signal if a high current is detected.

Fig. 10 Current sensing

Page 2 of 6

EE197 E-H

5 April 2011

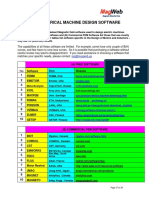

B. Software

The microcontroller used for this motor driver is the

Z8F6421 Flash Microcontroller (packaged in the IRC

slimboard). The language used for programming the

microcontroller is C.

Since the commutation sequence for the BLDC motor is

divided into six, a unique set of codes will correspond to each

stage.Timers are operated in PWM mode to produce the inputs

to the three-phase bridge. Fig. 11 shows the microcontroller

output waveforms for an open loop system (six-step

commutation). This program applies when the system is at its

starting condition. The output coming from the

microcontroller is fed directly to the motor, making it rotate at

low speed.

Fig. 12 b) Microcontroller Waveforms for a Closed Loop System

IV. LIMITATIONS OF THE DESIGN

The configuration for speed control is not working properly;

it should change the speed of the commutation by changing

the reload values in the microcontroller program. In testing it,

the motor would only enter dynamic breaking, and then

proceed back to normal commutation sequence. A problem

with this scheme is that the change is sudden, a more reliable

control configuration (preferably with a potentiometer) is

recommended for the driver.

Fig. 11 Microcontroller Waveforms for an Open Loop System

After some time, the motor will start to rotate faster,

turning the system to a closed loop. At this point, the part of

the program following the scheme shown in Fig.12 will be

applied. For commutation purposes with the back emf signals,

the phase voltage should be determined whether it has crossed

zero with respect to the neutral (zero crossing detector). As

this happens, when one phase is crossing neutral, the other

two phases are at equal and opposite voltages, thus, a zero

crossing of one phase is detected.

V. CONCLUSION

The design presented in this paper is able to drive the

BLDC motor with a rating of 48V; from low starting speed to

a certain high speed. The right commutation sequence is

followed by the driver; hence a smoother running of the

BLDC motor.

The driver also implements both open and closed loop

control; open loop is for starting sequences and then

transitions into the closed loop control for the motor. This is

done through correct voltage feedback sensing and use of

comparators. The driver also includes a current limiting

scheme to protect the design from damage due to high

currents caused by loading.

REFERENCES

[1]

[2]

[3]

[4]

(2011) Permanent Magnet Synchronous Machine on MathWorks

[Online].

Available:

http://www.mathworks.com/help/toolbox/

physmod/powersys/ref/permanentmagnetsynchronousmachine.html

R. Condit, Sensorless BLDC Control With Back-EMF Filtering,

Microchip Technology Inc., c2007.

P. Yedamale, Brushless DC (BLDC) Motor Fundamentals, Microchip

Technology Inc., c2003.

J.R. Mevey, Sensorless Field Oriented Control of Brushless Permanent

Magnet Synchronous Motors, Dept. of Electrical and Computer

Engineering, College of Engineering, Kansas State University,

Manhattan, Kansas, USA, c2009.

Fig. 12 a) Microcontroller Waveforms for a Closed Loop System

Page 3 of 6

EE197 E-H

5 April 2011

APPENDIX

T1RL = (RELOAD & 0xFF);

IRQ0ENH &= ~0x40;

// disable timer1 interrupt T3I

IRQ0ENL &= ~0x40;

IRQ0 &= ~0x40;

// clear timer3 interrupt flag

T1CTL1 |= 0x80;

// Enable timer3

Source Code

#include <sio.h>

#include <stdio.h>

#include <ez8.h>

#define CHANNEL 0x00

#define MODE 0x00

#define VREF 0x00

#define ENABLE 0x80

#define RELOADPWM 144

void delay(void);

void Init_ADC(void);

int Poll_ADC(void);

void InitTimerDelay0(void);

void InitTimerDelay1(void);

void InitTimerDelay2(void);

void InitTimer0(void);

void InitTimer1(void);

void InitTimer2(void);

void stage_1(void);

void stage_2(void);

void stage_3(void);

void stage_4(void);

void stage_5(void);

void stage_6(void);

void sense_current(void);

int RELOAD=24001;

int PWM;

void delay ()

{

char a;

for(a = 0; a < (0x0F); a++);

}

void Init_ADC (void)

{

PBAF = 0x01;

ACTL = (CHANNEL | VREF | MODE);

}

int Poll_ADC (void)

{

ACTL |= ENABLE;

while(ACTL & ENABLE);

return (int)((ADHR<<2)|(ADLR>>6));

}

void InitTimerDelay0(void)

{

T1CTL1 = 0x28; // disable T3,one shot mode, prescaler 32

T1H = 0x00; T1L = 0x01;

// T3 start = 0x0001

T1RH = (RELOAD >> 8);

}

void InitTimer0(void)

{

PAAF |= 0x02;

//T0OUT --> PA1

T0CTL1 = 0x2B;

//PWM mode, prescaler = 32,

low first per period, disable T0

T0H = 0x00;

//T0 start = 0x0001

T0L = 0x01;

T0RH = (RELOADPWM>>8); //T0 reload value

T0RL = (RELOADPWM & 0xFF);

T0PWMH = (PWM>>8);

//T0 PWM value

T0PWML = (PWM & 0xFF);

IRQ0ENH &= ~0x02; //disable timer interrupt T0I

IRQ0ENL &= ~0x02;

IRQ0 &= ~0x02;

//clear timer0 interrupt flag

T0CTL1 |= 0x80;

//enable timer 0

}

void InitTimerDelay1(void)

{

T2CTL1 = 0x28; // disable T3,one shot mode, prescaler 32

T2H = 0x00; T2L = 0x01;

// T3 start = 0x0001

T2RH = (RELOAD >> 8);

T2RL = (RELOAD & 0xFF);

IRQ0ENH &= ~0x80;

// disable timer1 interrupt T3I

IRQ0ENL &= ~0x80;

IRQ0 &= ~0x80;

// clear timer3 interrupt flag

T2CTL1 |= 0x80;

// Enable timer3

}

void InitTimer1(void)

{

PCAF |= 0x02;

T1CTL1 = 0x2B;

//T1OUT --> PC1

//PWM mode, prescaler = 32,

low first per period, disable T1

//T1 start = 0x0001

T1H = 0x00;

T1L = 0x01;

T1RH = (RELOADPWM>>8); //T1 reload value

T1RL = (RELOADPWM & 0xFF);

T1PWMH = (PWM>>8);

//T1 PWM value

T1PWML = (PWM & 0xFF);

IRQ0ENH &= ~0x40; //disable timer interrupt T1I

IRQ0ENL &= ~0x40;

IRQ0 &= ~0x40;

//clear timer1 interrupt flag

T1CTL1 |= 0x80;

//enable timer 1

}

void InitTimerDelay2(void)

{

T0CTL1 = 0x28; // disable T3,one shot mode, prescaler 32

T0H = 0x00; T0L = 0x01;

// T3 start = 0x0001

T0RH = (RELOAD >> 8);

Page 4 of 6

EE197 E-H

5 April 2011

T0RL = (RELOAD & 0xFF);

IRQ0ENH &= ~0x20;

// disable timer1 interrupt T3I

IRQ0ENL &= ~0x20;

IRQ0 &= ~0x20;

// clear timer3 interrupt flag

T0CTL1 |= 0x80;

// Enable timer3

PCOUT |= 0x04;

InitTimerDelay0();

while(!(IRQ0&0x40))

{

sense_current();

}

IRQ0 &= ~0x40;

return;

}

void InitTimer2(void)

{

PCAF |= 0x80;

T2CTL1 = 0x2B;

//T2OUT --> PC7

//PWM mode, prescaler = 32,

low first per period, disable T2

//T2 start = 0x0001

T2H = 0x00;

T2L = 0x01;

T2RH = (RELOADPWM>>8); //T2 reload value

T2RL = (RELOADPWM & 0xFF);

T2PWMH = (PWM>>8); //T2 PWM value

T2PWML = (PWM & 0xFF);

IRQ0ENH &= ~0x80; //disable timer interrupt T2I

IRQ0ENL &= ~0x80;

IRQ0 &= ~0x80;

//clear timer2 interrupt flag

T2CTL1 |= 0x80; //enable timer 2

}

void stage_3(void)

{

PAAF &= ~0x02;

PADD &= ~0x02;

PAOUT &= ~0x02;

if(RELOAD<=4001)

{

while(1)

{

if(PAIN&0x10)break;

}

}

void stage_1(void)

{

//cancel alt func of PC7

//set PC7 as output

//set PC7 low

//set PA2 high

//set PC6 high

if(RELOAD>4001)InitTimerDelay1();

while(!(IRQ0&0x80))

{

sense_current();

}

IRQ0 &= ~0x80;

return;

InitTimer0();

if(RELOAD<=4001)

{

while(1)

{

if(PAIN&0x80)break;

}

}

}

void stage_4(void)

{

PAOUT &= ~0x04;

PCOUT |= 0x40;

if(RELOAD>4001)InitTimerDelay0();

while(!(IRQ0&0x40))

{

sense_current();

}

IRQ0 &= ~0x40;

return;

//set PA2 low

//set PC6 high

InitTimerDelay1();

while(!(IRQ0&0x80))

{

sense_current();

}

IRQ0 &= ~0x80;

return;

}

void stage_2(void)

{

PCOUT &= ~0xC2;

//cancel alt func of PA1

//set PA1 as output

//set PA1 low

InitTimer1();

PCAF &= ~0x80;

PCDD &= ~0x80;

PCOUT &= ~0x80;

PAOUT |= 0x04;

PCOUT |= 0x40;

//set PC2 high

//set PC1,PC6,and PC7 low

void stage_5(void)

{

Page 5 of 6

EE197 E-H

PCAF &= ~0x02;

PCDD &= ~0x02;

PCOUT &= ~0x02;

5 April 2011

//cancel alt func of PC1

//set PC1 as output

//set PC1 low

InitTimer2();

if(RELOAD<=4001)

{

while(1)

{

if(PAIN&0x40)break;

}

}

PCDD &= ~0xC6; //set PC1,PC2,PC6, and PC7 as

output

//----------------------dynamic breaking-------------------------PAOUT &= ~0x02;

//set PA1 low

PCOUT &= ~0x82;

//set PC1 and PC7 low

delay();

PAOUT &= ~0x04;

//set PA2 low

PCOUT &= ~0x44;

//set PC2 and PC6 low

//-----------------------------------------------------------------while(1)

{

if(!(PDIN&0x40))break;

}

if(RELOAD>4001)InitTimerDelay2();

while(!(IRQ0&0x20))

{

sense_current();

}

IRQ0 &= ~0x20;

return;

}

sense_current();

while(1)

{

stage_1();

sense_current();

stage_2();

sense_current();

stage_3();

sense_current();

stage_4();

sense_current();

stage_5();

sense_current();

stage_6();

sense_current();

if(RELOAD>3001)

RELOAD=RELOAD-1000;

}

void stage_6(void)

{

PAOUT |= 0x04;

PCOUT &= ~0x04;

//set PA2 high

//set PC2 low

InitTimerDelay2();

while(!(IRQ0&0x20))

{

sense_current();

}

IRQ0 &= ~0x20;

return;

}

void sense_current(void)

{

float volts;

Init_ADC();

volts=(float)(Poll_ADC())/512.0;

PWM=RELOADPWM*(0.7+(0.1*volts));

}

void main(void)

{

PWM=RELOADPWM*0.6;

PADD |= 0xD0;

//set PA4,PA6, and PA7 as input

PDDD |= 0x4C;

//set PD2,PD3, and PD6 as input

PADD &= ~0x06; //set PA1 and PA2 as output

/*

while(1)

{

stage_1();

sense_current();

stage_2();

sense_current();

stage_3();

sense_current();

stage_4();

sense_current();

stage_5();

sense_current();

stage_6();

sense_current();

}

*/

}

*/End of Code*/

Page 6 of 6

You might also like

- The Occult WorldDocument256 pagesThe Occult WorldJewell Elliott100% (1)

- Hell On Earth Reloaded AdventureDocument16 pagesHell On Earth Reloaded AdventureKurt Garwood100% (1)

- Direct Back EMF Detection Method for Sensorless BLDC DrivesDocument91 pagesDirect Back EMF Detection Method for Sensorless BLDC DrivesnicoletabytaxNo ratings yet

- Electronic Code Locking Using GSMDocument63 pagesElectronic Code Locking Using GSMSumanth MatamNo ratings yet

- Feminist Philosophy of Religion (Stanford)Document35 pagesFeminist Philosophy of Religion (Stanford)Jagad-Guru DasNo ratings yet

- Electrical Correcting Elements in Automatic Control and Regulation CircuitsFrom EverandElectrical Correcting Elements in Automatic Control and Regulation CircuitsNo ratings yet

- RF Based Pick-And-place-robot Use ZigbeeDocument66 pagesRF Based Pick-And-place-robot Use Zigbeesumit_saNo ratings yet

- Developing A Mechanical Trading SystemDocument4 pagesDeveloping A Mechanical Trading SystemKathiravan R100% (1)

- Tektronix 576 Curve Tracer Operation and Service ManualDocument251 pagesTektronix 576 Curve Tracer Operation and Service Manualmunnizza64100% (3)

- Arduino 101: Timers and Interrupts GuideDocument10 pagesArduino 101: Timers and Interrupts GuideFabian Monteleone100% (1)

- Cell Phone DetectorDocument51 pagesCell Phone DetectorAnonymous L9fB0XU0% (1)

- Speed Control for BLDC Motors Using PID Algorithm WhitepaperDocument14 pagesSpeed Control for BLDC Motors Using PID Algorithm Whitepapertoufani95No ratings yet

- VMware Virtual SANDocument24 pagesVMware Virtual SANUjjwal LanjewarNo ratings yet

- Delay 1.0K Millis 2.3K Micros 1.0K Delaymicroseconds 359 Analogwrite 274 Tone 1.4K Notone 76 Servo Library 1.6KDocument11 pagesDelay 1.0K Millis 2.3K Micros 1.0K Delaymicroseconds 359 Analogwrite 274 Tone 1.4K Notone 76 Servo Library 1.6KOthmane Bouzarzar100% (1)

- 555 Ignition Coil DriverDocument3 pages555 Ignition Coil Drivertim schroderNo ratings yet

- of BLDCDocument45 pagesof BLDCsmhbNo ratings yet

- PML Manual PDFDocument178 pagesPML Manual PDFChandrashekar R100% (1)

- Programming 16 Bit Timer On Atmega328Document9 pagesProgramming 16 Bit Timer On Atmega328VisitOn.T.witte.r100% (1)

- CH 02Document20 pagesCH 02Pauline Nguyen100% (1)

- Hall Effect Sensors PDFDocument171 pagesHall Effect Sensors PDFjotagea100% (1)

- 2.review of Literature and Statement of ProblemDocument6 pages2.review of Literature and Statement of ProblemsheriabhiNo ratings yet

- Direct Conversion ReceiversDocument6 pagesDirect Conversion ReceiversAmir ChishtiNo ratings yet

- Analysis of Axial Flux MotorDocument4 pagesAnalysis of Axial Flux MotorAvi GuptaNo ratings yet

- Total Productive MaintenanceDocument41 pagesTotal Productive Maintenancejeff090288No ratings yet

- Control of BLDC MotorDocument55 pagesControl of BLDC MotorankitNo ratings yet

- How Brushless Motors Work (BLDC Motors)Document41 pagesHow Brushless Motors Work (BLDC Motors)Chandrashekar ReddyNo ratings yet

- ML4425 Sensor Less BLDC Motor ControllerDocument17 pagesML4425 Sensor Less BLDC Motor Controllerfrazier8553No ratings yet

- Design Software 1Document2 pagesDesign Software 1anbarasuval84No ratings yet

- BLDC MotorDocument46 pagesBLDC MotorShafira AuliaNo ratings yet

- PIC-EK User Manual PDFDocument91 pagesPIC-EK User Manual PDFDjura CurugNo ratings yet

- OBD applications for Abarth 500 modelsDocument2,680 pagesOBD applications for Abarth 500 modelsSadam RexhepiNo ratings yet

- ZRP Catalog 2019 PDFDocument68 pagesZRP Catalog 2019 PDFMichaelNo ratings yet

- BLDC Product GuideDocument36 pagesBLDC Product GuidemjtbbhrmNo ratings yet

- Design of Three Phase Inverter Fed Induction Motor Drive Using Neural Network Predictive ControlDocument5 pagesDesign of Three Phase Inverter Fed Induction Motor Drive Using Neural Network Predictive Controlesatjournals100% (1)

- Permanent Magnet Motor GuideDocument36 pagesPermanent Magnet Motor GuidekkarthiksNo ratings yet

- BLDC DriverDocument8 pagesBLDC DriverRich ManNo ratings yet

- How To Make Sodium PerchlorateDocument17 pagesHow To Make Sodium PerchlorateKing90No ratings yet

- Application of Brushless DC Motor in MilitaryDocument10 pagesApplication of Brushless DC Motor in Militarymighty_heart100% (1)

- Design of Quarter-Wave Compact Impedance Transformers Using Coupled Transmission LinesDocument1 pageDesign of Quarter-Wave Compact Impedance Transformers Using Coupled Transmission LinesBruno Koch SchmittNo ratings yet

- Introduction To mc68hc11Document35 pagesIntroduction To mc68hc11SHRIYAM MALVIYANo ratings yet

- Iraudamp1 PDFDocument22 pagesIraudamp1 PDFamijoski6051No ratings yet

- Modeling and Simulation of Reluctance Motor Using Digital ComputerDocument5 pagesModeling and Simulation of Reluctance Motor Using Digital ComputerroyourboatNo ratings yet

- Design and Development of Three Phase Permanent Magnet BrushlessDocument11 pagesDesign and Development of Three Phase Permanent Magnet BrushlessteomondoNo ratings yet

- Reduction of Power MOSFET Losses in Hard-Switched ConvertersDocument2 pagesReduction of Power MOSFET Losses in Hard-Switched ConvertersWesley de PaulaNo ratings yet

- Ignition Systems For Gasoline EnginesDocument27 pagesIgnition Systems For Gasoline Enginesanon_53273932No ratings yet

- BLDC SimulationDocument4 pagesBLDC SimulationSiva GuruNo ratings yet

- BLDCDocument4 pagesBLDCmechtex Pvt LtdNo ratings yet

- Catalog CureleDocument0 pagesCatalog CureleCristi CryyNo ratings yet

- PG Embedded Systems Embedded Projects TitleDocument19 pagesPG Embedded Systems Embedded Projects TitlePGEmbedded systemsNo ratings yet

- Engine Knock Sensors - Part TwoDocument4 pagesEngine Knock Sensors - Part TwoFabricio LimaNo ratings yet

- ZVS Full BridgeDocument20 pagesZVS Full Bridgejameschall1No ratings yet

- MotorsDocument18 pagesMotorsAmado CamachoNo ratings yet

- 650 To 400V, 100kW Buck ConverterDocument13 pages650 To 400V, 100kW Buck ConverterCataNo ratings yet

- Brushless DC MotorDocument6 pagesBrushless DC Motorpsksiva13No ratings yet

- Temperature SensorsDocument14 pagesTemperature SensorsViktor -stNo ratings yet

- Mo at Source PDFDocument2 pagesMo at Source PDFcavcicNo ratings yet

- EFI Engine Management Manual PDFDocument58 pagesEFI Engine Management Manual PDFAbhijit BiswasNo ratings yet

- Advanced Topics in Power ElectronicsDocument1 pageAdvanced Topics in Power Electronicsdileepk1989No ratings yet

- Arduino Based Sensorless Speed Control of BLDC Motor Using GSMDocument6 pagesArduino Based Sensorless Speed Control of BLDC Motor Using GSMRaja Ramesh DNo ratings yet

- Bistable MultivibratorsDocument9 pagesBistable MultivibratorsihtishamuddNo ratings yet

- FEKO. User's ManualDocument2,142 pagesFEKO. User's ManualLaz GsodfjxNo ratings yet

- STEPPER MOTOR CONTROL USING INFERA REDMinor ProjectDocument22 pagesSTEPPER MOTOR CONTROL USING INFERA REDMinor ProjectJet's100% (2)

- 1000W AC Motor Speed ControllerDocument4 pages1000W AC Motor Speed ControllerAntonio José Montaña Pérez de CristoNo ratings yet

- Codigo Hexadecimal para EepromDocument3 pagesCodigo Hexadecimal para EepromFranciss Jr. Velasco HernandezNo ratings yet

- Distribution Transformer Manufacturing Process ManualDocument29 pagesDistribution Transformer Manufacturing Process ManualAnonymous Jf6X8nNo ratings yet

- Final QuestionDocument5 pagesFinal QuestionrahulNo ratings yet

- Itp 8Document5 pagesItp 8Arung IdNo ratings yet

- Form II Biology respiration study guideDocument2 pagesForm II Biology respiration study guideedwinmasaiNo ratings yet

- Model 9200-2123: 1 RS-422 Input/3 RS-422 Output ModuleDocument2 pagesModel 9200-2123: 1 RS-422 Input/3 RS-422 Output ModuleNisar AhmedNo ratings yet

- Accelerating research insightsDocument13 pagesAccelerating research insightsViệt Dũng NgôNo ratings yet

- Syl LB Hms 240809Document102 pagesSyl LB Hms 240809sharma_anand73No ratings yet

- TheImpactofEmployeeEngagementonOrganizationsProductivity PDFDocument10 pagesTheImpactofEmployeeEngagementonOrganizationsProductivity PDFSapna SharmaNo ratings yet

- Thermodynamic of Polymer Blends PDFDocument34 pagesThermodynamic of Polymer Blends PDFSyam RizalNo ratings yet

- MCQ With AnswersDocument4 pagesMCQ With AnswersAkai OakNo ratings yet

- NAHRIM - Institut Penyelidikan Hidraulik Kebangsaan Malaysia - Rainwater Harvesting SystemDocument4 pagesNAHRIM - Institut Penyelidikan Hidraulik Kebangsaan Malaysia - Rainwater Harvesting SystemAnonymous e1j2F5Ge0No ratings yet

- Enviro Engineering General Trading CatalogueDocument112 pagesEnviro Engineering General Trading CatalogueEnviroEngineeringGTNo ratings yet

- Payment For Building PermitDocument1 pagePayment For Building PermitSterben ShouchiNo ratings yet

- In The Bedroom Missing Letters in Words Esl WorksheetDocument2 pagesIn The Bedroom Missing Letters in Words Esl Worksheetgirl_blueeyes89No ratings yet

- Ap Art CrashcourseDocument19 pagesAp Art Crashcourseapi-298825724No ratings yet

- Annals of Medicine and Surgery: Bliss J. ChangDocument2 pagesAnnals of Medicine and Surgery: Bliss J. ChangroromutiaraNo ratings yet

- Lesson PlanDocument7 pagesLesson Planapi-357536453No ratings yet

- Kajo 5 PDFDocument3 pagesKajo 5 PDFJonathan ChauNo ratings yet

- Resume Michal SzalonekDocument2 pagesResume Michal Szalonekszalonek4330No ratings yet

- 02 V3 2016 CFA二级强化班 Quantitative MethodsDocument79 pages02 V3 2016 CFA二级强化班 Quantitative MethodsCarey CaiNo ratings yet

- ETHOSUXIMIDEDocument14 pagesETHOSUXIMIDEAfrizal MahadiNo ratings yet

- Mcqs Pa OrignalDocument55 pagesMcqs Pa OrignalMuhammad Youneeb100% (1)