Professional Documents

Culture Documents

Cable Pulling & Installation Guide

Uploaded by

Reginald D. De GuzmanCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Cable Pulling & Installation Guide

Uploaded by

Reginald D. De GuzmanCopyright:

Available Formats

5 PULLING & INSTALLATION

In order to reduce pulling and installation time, Nexans

has designed a cable range which offers:

time saving on connexions by easy sheath and

insulation stripping

reduced weight, diameter and volume

easier drawing due to low friction coefficient of

polyolefin outer sheath compound.

Nexans decides to distinguish main cable circuits by

different outer sheath colours:

red for medium voltage cables (from 1.8/3 kV up to

12/20 kV)

black for power and control cables rated 0.6/1 kV

grey for instrumentation and control cables rated

150/250 V

orange for all types fire resistant cables

blue for intrinsic circuit cables

In order to avoid unwanted effects of electromagnetic

interference (EMI) as far as possible, Nexans recommends to separate on different cable trays, power

circuits from control, instrumentation or communication

circuits.

5-1 Pulling

The process of pulling electrical cables on board of

marine vessels is relatively a usual procedure.

Nevertheless, Nexans would suggest some following

rules to avoid any cable degradation and damage.

Prior to start, care must be taken to ensure that the

pulling equipment directly attached to the cable is

tightly fitted over the complete cable and not only to

one cable element such as the outer sheath, armour or

conductors.

The maximum pulling force exerted on the cable must

not exceed 50 N/mm2 (of nominal cross section area

of the conductors) whether the cable is being manually

pulled or with a winch or other mechanical equipment.

If the cable link is pre-cut before pulling, the cable has

to be correctly coiled to avoid any over twist.

Pre-cut cable ends, in waiting position before final

installation and connexion must be protected.

All cable runs must be smooth and clean or covered

with a complementary protection to prevent any outer

sheath damage.

When several cables are pulled together, talcum is

recommended to limit friction and abrasion between

cables and to ease the pulling process with better

cables sliding.

20

Where cables have to be pulled perpendicularly to

other cables already installed, it is advised to protect

them to avoid abrasion damage.

Cables have to be pulled with a slow and regular

speed about 20 m/minute, and with a minimum outer

temperature of -15C. It is always necessary, to store

cables in warmed premises at an ambient temperature

of + 10C for 12 hours. A longer period might be

necessary for large drums.

5-2 Installation

Cables installation must be in accordance with certification Bodies rules, and also with IEC 60092-352 or

IEC 61892-4.

Some recommendations are given as follow about:

special precautions for single-core cables for A.C.

wiring

minimum bending radius

parallel cable links.

5-2-1 Precautions for single-core cables:

In order to reduce electro-dynamic forces when a short

circuit appears, symmetric method for cable installation

is recommended as is shown in the following table (L1, L2

and L3 indicates the location of the respective phase

conductor).

See 1st template on opposite page.

5-2-2 Minimum bending radius:

To limit the stress (elongation/compression) on insulation

and sheath materials when cable are bent, rules about

minimum internal bending radius have to be respected:

in fixed installations

during pulling and installation

Values for these MBR stated in IEC 60092-352 and IEC

61892-4 are given in the following table.

See 2nd template on opposite page.

Number of conductors per

phase

Number of single core

cables

L1 L2 L3 L3 L2 L1

or L1 L2 L3

L3 L2 L1

L1 L2 L3

L2 L3 L1

L3 L1 L2

12

L1 L2 L3 L3 L2 L1

L3 L2 L1 L1 L2 L3 or

L3 L1 L2 L3

L2 L3 L1 L2

L1 L2 L3 L1

Cables Type up to 1.8/3 kV

Recommended cable positionning

Minimum internal bending radius

Unarmoured Cables

Armoured Cables

outer diameter < 25 mm

4D

6D

outer diameter > 25 mm

6D

6D

Cables with sector shaped class 2 conductors

8D

8D

FLEXISHIP cable with class 5 conductors

(round or sector shaped conductors)

4D

5D

Cables with circular class 2 conductors:

Cables Type from 3.6/6 kV to 12/20 kV

Single core cables

- class 2 conductors

- FLEXISHIP

12D

10D

3 cores cables

- class 2 conductors

- FLEXISHIP

9D

7.5D

All these bending radius values must be multiplied by 2, during pulling and installation of the cables.

Copyright April 2009 - Nexans

5-2-3 Parallel cables link:

According to certification society rules, several cables

can be installed in parallel if certain conditions are

respected:

cables type must be the same (same design)

cables must be rated for the same temperature class

cables must have the same nominal cross section areas

conductor cross section area > 10 mm2

cables must have equal lengths.

21

You might also like

- 20A SINGLE SWITCH MANUFACTURERS AND SUPPLIERSDocument2 pages20A SINGLE SWITCH MANUFACTURERS AND SUPPLIERSReginald D. De GuzmanNo ratings yet

- Exterior Door Light FixtureDocument1 pageExterior Door Light FixtureReginald D. De GuzmanNo ratings yet

- Eaton UpsDocument2 pagesEaton UpsReginald D. De GuzmanNo ratings yet

- Max889 PDFDocument8 pagesMax889 PDFameer_jaburNo ratings yet

- Atex 2 PDFDocument2 pagesAtex 2 PDFzainahmedscribdNo ratings yet

- Cadweld 2007Document123 pagesCadweld 2007zaga76No ratings yet

- ThermoweldDocument276 pagesThermoweldReginald D. De GuzmanNo ratings yet

- Ecm Final 2019Document49 pagesEcm Final 2019Reginald D. De GuzmanNo ratings yet

- LM 7805 RegulatorDocument12 pagesLM 7805 RegulatorFadel BairuniNo ratings yet

- TL 7705 BDocument25 pagesTL 7705 BBogdan NegrutiuNo ratings yet

- Principles of Explosion Protection 30080001258 PDFDocument68 pagesPrinciples of Explosion Protection 30080001258 PDFlorytechNo ratings yet

- Enec Services Service TermsDocument4 pagesEnec Services Service TermsReginald D. De GuzmanNo ratings yet

- MAX7400/MAX7403/MAX7404/MAX7407Document12 pagesMAX7400/MAX7403/MAX7404/MAX7407xyalfaxyzNo ratings yet

- 4.thermoweld - Lightning and GroundingDocument88 pages4.thermoweld - Lightning and GroundingNurul Fyzi FauziahNo ratings yet

- GVT0244 008a PDFDocument56 pagesGVT0244 008a PDFReginald D. De GuzmanNo ratings yet

- Cable Lug - 120mm - Sq.Document2 pagesCable Lug - 120mm - Sq.Reginald D. De GuzmanNo ratings yet

- 5789: : Ÿ ?8: : Ÿ 4@9 Abc:D: !!ÿ E!%! F# Ÿ %G $F (%ÿ G Ÿ E % (%hÿ F%ÿ I% (%hÿ J ($!%Document2 pages5789: : Ÿ ?8: : Ÿ 4@9 Abc:D: !!ÿ E!%! F# Ÿ %G $F (%ÿ G Ÿ E % (%hÿ F%ÿ I% (%hÿ J ($!%Reginald D. De GuzmanNo ratings yet

- Atex 2 PDFDocument2 pagesAtex 2 PDFzainahmedscribdNo ratings yet

- Cable Lug - 120mm - Sq.Document2 pagesCable Lug - 120mm - Sq.Reginald D. De GuzmanNo ratings yet

- 52 Feam Pap EngDocument2 pages52 Feam Pap EngReginald D. De GuzmanNo ratings yet

- 52 Feam Pap EngDocument2 pages52 Feam Pap EngReginald D. De GuzmanNo ratings yet

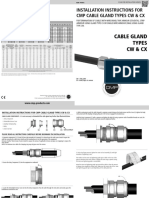

- Install cable glands CW and CXDocument2 pagesInstall cable glands CW and CXReginald D. De GuzmanNo ratings yet

- Spacial CRN Nsycrn54150Document2 pagesSpacial CRN Nsycrn54150Reginald D. De GuzmanNo ratings yet

- 52 Feam Pap EngDocument2 pages52 Feam Pap EngReginald D. De GuzmanNo ratings yet

- HubbellDocument68 pagesHubbellReginald D. De GuzmanNo ratings yet

- Understanding GFCIs: How They Operate and Prevent Electrical ShockDocument37 pagesUnderstanding GFCIs: How They Operate and Prevent Electrical ShockReginald D. De GuzmanNo ratings yet

- 0L1428Document6 pages0L1428Reginald D. De GuzmanNo ratings yet

- ZAC Products Brochure 2010sDocument15 pagesZAC Products Brochure 2010sReginald D. De GuzmanNo ratings yet

- Bwy IomDocument17 pagesBwy IomReginald D. De GuzmanNo ratings yet

- Greenlee Cable Pulling Equipment SystemDocument12 pagesGreenlee Cable Pulling Equipment SystemReginald D. De GuzmanNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5783)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- C5-2015-03-24T22 29 11Document2 pagesC5-2015-03-24T22 29 11BekNo ratings yet

- 4340 Fracture Toughness PDFDocument22 pages4340 Fracture Toughness PDFGrafton Montgomery0% (1)

- Making A StandDocument22 pagesMaking A StandQueens Nallic Cillan100% (2)

- Registration Form: National Hospital Insurance FundDocument5 pagesRegistration Form: National Hospital Insurance FundOgweno OgwenoNo ratings yet

- (JPP-1) - (Indefinite Integration) - 11th SepDocument52 pages(JPP-1) - (Indefinite Integration) - 11th Sepfunnyvideos. comNo ratings yet

- SH BSC Hons Pre Registration Nursing PDFDocument104 pagesSH BSC Hons Pre Registration Nursing PDFJogendra Singh PatelNo ratings yet

- Latifa's Thesis PDFDocument182 pagesLatifa's Thesis PDFنذير امحمديNo ratings yet

- OOADDocument21 pagesOOADNamelessNo ratings yet

- Reading Process Theories: Bottom-Up Model Interactive Model Top-Down ModelDocument2 pagesReading Process Theories: Bottom-Up Model Interactive Model Top-Down ModelBeverly Panganiban CadacioNo ratings yet

- Type AKP20 MICRO-Axial Piston Pumps: Up To 300 Bar 0,012 CM /revDocument6 pagesType AKP20 MICRO-Axial Piston Pumps: Up To 300 Bar 0,012 CM /revpeterNo ratings yet

- Dogtooth Film ReviewDocument6 pagesDogtooth Film ReviewAstrid JohnsonNo ratings yet

- 5-Engine CharacteristicsDocument22 pages5-Engine CharacteristicsAli ŞENERNo ratings yet

- Scenario Pack 3048-3050 - Operational Turning Points - REVIVAL TrialsDocument41 pagesScenario Pack 3048-3050 - Operational Turning Points - REVIVAL TrialsSly MantisNo ratings yet

- 8 State Based or Graph Based TestingDocument4 pages8 State Based or Graph Based TestingZINNIA MAZUMDER 19BIT0155No ratings yet

- Altamirov DishniDocument95 pagesAltamirov DishniEmersonJParedes100% (1)

- Global Economics 13th Edition by Carbaugh ISBN Solution ManualDocument5 pagesGlobal Economics 13th Edition by Carbaugh ISBN Solution Manualdorothy100% (31)

- MATH 10 Test Questions SY 2022-2023 QIIIDocument4 pagesMATH 10 Test Questions SY 2022-2023 QIIIRYAN C. ENRIQUEZNo ratings yet

- Leadership Styles - Types of Leadership Styles - BBA - MantraDocument5 pagesLeadership Styles - Types of Leadership Styles - BBA - Mantrakarthik sarangNo ratings yet

- Rutherford Gate Condominiums BLDG C Feature SheetDocument2 pagesRutherford Gate Condominiums BLDG C Feature SheetCarringtonNo ratings yet

- Circuits 4 Name & SetDocument2 pagesCircuits 4 Name & SetMUhammad Saqib Naveed ShahNo ratings yet

- Analysis, Design and Implementation of Zero-Current-Switching Resonant Converter DC-DC Buck ConverterDocument12 pagesAnalysis, Design and Implementation of Zero-Current-Switching Resonant Converter DC-DC Buck Converterdaber_huny20No ratings yet

- Rt380T 230/400 PCB Rohs: Analog Three-Phase Thyristor Trigger ModuleDocument3 pagesRt380T 230/400 PCB Rohs: Analog Three-Phase Thyristor Trigger ModuleFelipe CasasNo ratings yet

- Blind / Switch Actuator REG-K/12x/24x/10 With Manual Mode, Light GreyDocument2 pagesBlind / Switch Actuator REG-K/12x/24x/10 With Manual Mode, Light GreyRazvan RazNo ratings yet

- Macro To Roll Exalted 3e Die in Foundry VTTDocument5 pagesMacro To Roll Exalted 3e Die in Foundry VTTtcherban100% (1)

- 5.2 PWM 7 Mac 2017Document34 pages5.2 PWM 7 Mac 2017Elawarasi Nadarajan100% (1)

- Guidelines For The Operation of Digital FM Radio BroadcastDocument3 pagesGuidelines For The Operation of Digital FM Radio BroadcastmiyumiNo ratings yet

- 120.anti Theft Alerting System For Vehicle (2 Wheeler)Document3 pages120.anti Theft Alerting System For Vehicle (2 Wheeler)Basha BashaNo ratings yet

- Design No. X772: BXUV.X772 Fire Resistance Ratings ANSI/UL 263Document7 pagesDesign No. X772: BXUV.X772 Fire Resistance Ratings ANSI/UL 263Ing. RECALNo ratings yet

- Section 05120 Structural Steel Part 1Document43 pagesSection 05120 Structural Steel Part 1jacksondcplNo ratings yet

- BS 812-110-1990 Testing AggregatesDocument12 pagesBS 812-110-1990 Testing Aggregatesbatara2007No ratings yet