Professional Documents

Culture Documents

A Revised Correlation On Downstream Temperature Distribution of Fire-Induced Flow With Mechanical Longitudinal Ventilation

Uploaded by

SEP-PublisherOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

A Revised Correlation On Downstream Temperature Distribution of Fire-Induced Flow With Mechanical Longitudinal Ventilation

Uploaded by

SEP-PublisherCopyright:

Available Formats

www.seipub.

org/fiee

Frontiers in Environmental Engineering (FIEE) Volume 5, 2016

doi: 10.14355/fiee.2016.05.009

A Revised Correlation on Downstream

Temperature Distribution of Fire-Induced

Flow with Mechanical Longitudinal

Ventilation

S.C. Li1,2, Y.H. Zhao1, W. Wang3

1

College of Architecture and Civil Engineering, Beijing University of Technology, Beijing, 100124, China.

Department of Fire Command, The Chinese Peoples Armed Police Force Academy, Lang fang, Hebei, 065000,

China.

2

College of Architecture and Civil Engineering, Beijing University of Technology, Beijing, 100124, China.

lisch@mail.ustc.edu.cn

Abstract

To evaluate the stability of smoke stratification and fire evacuation effectively, the temperature distribution downstream the fire

beneath the ceiling of tunnels with mechanical longitudinal ventilation needs to be estimated. Based on Li model, a revised

correlation is proposed by concerning the effects of the mechanical longitudinal ventilation velocity and the width of the tunnel.

Ten full-scale field test data in three real tunnels from Hu et al. are employed to correlate the revised correlation. The

applicability of the new revised model is validated by comparing with the field test data and previous models. Results indicate

that the new model can agree with the field test data well. The Mean Absolute Percentage Error (MAPE) of the revised model is

found to be 19.99%. Great improvement of the prediction accuracy is achieved as compared with the previous models.

Keywords

Tunnel Fire; Revised Correlation; Maximum Temperature Distribution; Mechanical Longitudinal Ventilation

Introduction

To provide effective fire protection, there is a need for better understanding smoke spreading in tunnels [1]. When

the fire smoke spreads along a tunnel, temperature decay will occur along the tunnel due to the heat loss to the

ceiling [2]. As the buoyancy force is weaker than the inertial force of the longitudinal ventilation air flow at a

distance, the stratification of smoke will be lost [3]. So, knowing the smoke temperature along the tunnel

downstream the fire is very important for evaluation of the stability of the smoke stratification and fire evacuation

effectively.

A correlation for the temperature distribution was given by Delichatsios [4],

T

W 1/3

x W 1/3

=

(

)

0.49 exp{6.67 St (

) }

Tmax 2 H

H 2H

(1)

Where T is excess temperature between T and T0, C; Tmax is excess temperature between T and maximum

temperature Tmax, C; T is smoke temperature, C; T0 is ambient temperature, C; W is tunnel width, m; H is

tunnel height, m; St is Stanton number; x is distance from the fire, m.

Another correlation was proposed by Bailey et al. [5] as

1

T =

T0

2

x /16.7

(2)

Based on the maximum temperature model of Kurioka et al. [6] and the maximum temperature equation of Li et al.

[7], Hu et al [8] proposed a modified empirical correlation by considering tunnel slope. It is expressed as

48

Frontiers in Environmental Engineering (FIEE) Volume 5, 2016

www.seipub.org/fiee

Tx

1+ 0.09 ) Kx

=e (

Tmax

(3)

Where is percentage of the tunnel slope; K is exponential decay coefficient. According to the study of Lee and

Ryou [9], above correlations could not correlate the temperature distribution with various cross-section aspect

ratios. So, a simple correlation was derived for the temperature distribution of the the fire-induced flow along

naturally ventilated tunnels by Li et al. [10].

x xref

T

= exp St

Tref

d

(4)

Where xref is reference position, m; d is hydraulic diameter of the tunnel, m. According to the numerical results by

Li et al. [10], the Stanton number can be obtained. For tunnels with aspect ratio greater than or equal to 1.0, the

Stanton number is 0.00733. For tunnels with aspect ratio smaller than 1.0, the Stanton number is 0.00406 (Aspect

ratio of the tunnel cross section is tunnel height/tunnel width).

Recently, a correlation of the fire flow temperature along mechanically ventilated tunnels is proposed by Li et al.

[11] based on Eq. (5).

exp[0.0086( x xmax ) / d ], 0 < ( x xmax ) / d 50

T

=

0.43

Tmax 3.5 [ ( x xmax ) / d ] ,50 < ( x xmax ) / d

(5)

Some studies [2, 10] indicate that longitudinal ventilation velocity has a major influence on the temperature

distribution downstream the tunnel.

Based on theoretical analysis by Li et al. [10] and experimental studies by Hu et al. [2], this paper proposes a new

revised model to correlate the temperature distribution downstream the tunnel fire with mechanical ventilation.

The applicability of the new revised model is validated by comparing with the experiment work [2] and previous

models [4, 5, 10, 11].

Theoretical Analysis

For rectangular tunnel, the correlation of the temperature decay with mechanical ventilation is [11]

h

T

= exp[ c ( 2f + 20.3f 1 ) ( x xref ) / H ]

Tref

rC pu

(6)

Where Tref is excess temperature between Tref and T0, C; hc is heat transfer coefficient, W m-2C-1; is density

of the air, kg m-3; Cp is specific heat, Jkg-1C-1; u is longitudinal ventilation velocity, m s-1; f is aspect ratio of the

tunnel cross section, f=H/W.

For arch tunnel, the correlation of the temperature decay with mechanical ventilation is [10]

h

T

= exp[ c ( 2 + 20.3(f 0.11) 2 ) ( x xref ) / W ]

Tref

rC pu

(7)

As arch tunnel is the common type, the paper mainly investigates the Eq. (7). Thus, for mechanically ventilated

tunnels, Eq. (7) is expressed as

x xref

T

c

= exp

Tref

a

V

+

b

W

Where

T T

T

= x 0

Tref Tref T0

(8)

(9)

The excess temperature is the temperature difference between T and T0. The smoke temperature Tx is measured by

the thermocouple and the thermal resistors at distance x from the fire; and Tref is the temperature at the reference

position downstream the fire as shown in Figure 1.

49

www.seipub.org/fiee

Frontiers in Environmental Engineering (FIEE) Volume 5, 2016

FIG. 1 SCHEMATIC DIAGRAM OF SMOKE MOVEMENT IN A TUNNEL FIRE

Experimental Examination

Test data by Hu et al. [2] are used to examine the revised correlations. The tests were carried out in three full-scale

road tunnels by Hu et al..

Three fire tests were conducted in YangZong Road Tunnel and there were three fire tests and four fire tests which

were conducted in DaFengYaKou Road Tunnel and YuanJiang1# Road tunnel respectively. Ten fire tests were

summarized in Table 1.

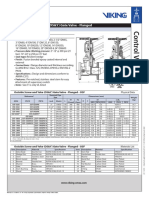

TABLE 1 SUMMARY OF THE FULL-SCALE TESTS USED BY HU ET AL.[2]

Tunnel name

YangZongTun

nel

DaFengYaKo

u Tunnel

YuanJiang

1# tunnel

Test

number

Pool

size

Fuel(liters used)

Heat

release

rates

(MW)

Height of the

pool fire source

above the

floor(m)

Test 1

1 m2

Gasoline/12

1.8

0.2

2.5

20

Test 2

2 m2

Diesel oil/30

3.2

0.2

0.5

20

Test 3

2 m2

Diesel oil/9

+Gasoline /8

2.5

0.2

4.5

20

Test 4

1 m2

Gasoline /20

1.8

1.7

0.5

17.5

Test 5

1 m2

Gasoline /20

1.8

0.2

1.9

17.5

Test 6

2 m2

Gasoline /40

3.2

0.2

0.8

17.5

Test 7

1 m2

Gasoline /20

1.8

1.7

1.0

21.5

Test 8

1 m2

Gasoline /15

1.8

0.2

0.6

22

Test 9

2m2

Gasoline /30

3.2

0.2

0.5

25

Test 10

2 m2

Gasoline /30

3.2

0.2

0.9

24

Longitudinal

Ventilation

velocity(m s-1)

Ambient

temperature(C

)

Revised Model Correlation and Validation

Correlation

Test data in Table 1 are used to correlate the Eq. (8). The reference positions are +20m or +60m from the fire source.

The relevant parameters concluded from the fitting to Eq. (8) are that a=-1.05, b=3.81 and c=0.2, with a correlation

coefficient R2 =0.9737. The new correlation is expressed as

x xref

T

0.2

= exp

Tref

V

+

W

1

.

05

3

.

81

(10)

Validation

Comparison of the new model with test data is presented in Figure 2. It is shown that Eq. (10) can reasonably

correlate the temperature distribution for all test data involved.

As shown in Figure 2, approximately 87% of the predicted excess temperature is consistent with the experimental

data within a relative deviation of 15% . The revised correlation presents a good agreement with the experimental

data.

50

Frontiers in Environmental Engineering (FIEE) Volume 5, 2016

1.2

1.1

Test 4 Q=1.8MW u=0.5m s-1

Test 7 Q=1.8MW u=1.0m s-1

Test 9 Q=3.2MW u=0.5m s-1

The line of y=x

1.0

Delichatsios model Equation (1)

Bailey model Equation (2)

Li model Equation (4)

Li model Equation (5)

This model Equation (10)

Test 4 Q=1.8MW u=0.5m s-1

Test 9 Q=3.2MW u=0.5m s-1

0.9

0.8

+15%

0.7

0.8

T/Tref

T/Tref (predicted)

1.0

Test 2 Q=3.2MW u=0.5m s-1

Test 6 Q=3.2MW u=0.8m s-1

Test 8 Q=1.8MW u=0.6m s-1

Test 10 Q=3.2MW u=0.9m s-1

Upper and Lower 85% Error Limit

www.seipub.org/fiee

-15%

0.6

0.6

0.5

0.4

0.3

0.4

0.2

0.2

0.1

0.0

0.0

-0.1

0.0

0.2

0.4

0.6

0.8

1.0

T/Tref (measured)

1.2

100

200

300

400

500

600

700

800

x-xref

FIG. 2 VALIDATED BY THE TEST DATA

FIG. 3 COMPARISON WITH OTHER MODELS

The correlation is further verified by comparing the predicted excess temperature with other models, Delichatsios

model, Bailey model, Li model and the new revised model. It is shown in Figure 3 that the temperature decay for

Delichatsios model, Bailey model and Li model is much faster than the new revised model.

The parameter of Mean Absolute Percentage Error (MAPE) is used to evaluate the accuracy of the revised model

with the previous models. MAPE is the mean absolute percentage error in prediction. It indicates the forecast

accuracy of a model. The equation of MAPE is expressed as

1 n Yi Y i

=

100%

MAPE

n i =1 Yi

(11)

The results of the comparison are shown in Figure 4. The new revised model presents an agreeable MAPE value of

19.99%. Great improvement is clearly indicated by comparing with the other models.

Revised model

Eq.(10)

19.99

Li model

Eq.(5)

36.61

Li model

Eq.(4)

89.41

Bailey model

Eq.(2)

93.45

Delichatsios

model

Eq.(1)

0.00

96.79

20.00

40.00

60.00

80.00

100.00

MAPE%

FIG. 4 COMPARISON OF MAPE WITH OTHER MODELS

Conclusions

Base on Li model and test data conducted by Hu et al., a revised correlation of temperature distribution along the

tunnel with mechanical ventilation including both the tunnel width and longitudinal ventilation velocity is further

developed. The MAPE of the revised new model is 19.99%. Great improvement is found by comparing with the

previous models. The results indicate that the revised model can be utilized to predict the temperature distribution

of the fire with acceptable accuracy.

ACKNOWLEDGEMENT

This work was supported by the National Science Foundation of China under Grant No. 51178015.

51

www.seipub.org/fiee

Frontiers in Environmental Engineering (FIEE) Volume 5, 2016

REFERENCES

[1]

Alan Beard and Richard Carvel. Handbook of tunnel fire safety. Thomas Telford, 2012.

[2]

L.H. Hu, R. Huo, H.B. Wang, Experimental and numerical studies on longitudinal smoke temperature distribution

upstream and downstream from the fire in a road tunnel, J. Fire Sci., 2007, 25, 2343.

[3]

D. Yang, L.H. Hu, R. Huo, Y.Q. Jiang, S. Liu, F. Tang, Experimental study on buoyant flow stratification induced by a fire in

a horizontal tunnel, Appl. Therm. Eng., 2010, 30, 872878.

[4]

Delichatsios MA. The Flow of Fire Gases under a Beamed Ceiling, Combustion and Flame, 1981,43:110.

[5]

Bailey JL, Forney GP, Tatem PA, et al. Development and validation of corridor flow submodel for CFAST. J Fire Protect

Eng.,2002, 12 (3) (2002), 139161.

[6]

H. Kurioka, Y. Oka, H. Satoh, O. Sugawa, Fire properties in near field of square fire source with longitudinal ventilation in

tunnels, Fire Saf. J., 2003, 38 (4), 319340.

[7]

Y.Z. Li, B. Lei, H. Ingason, The maximum temperature of buoyancy-driven smoke flow beneath the ceiling in tunnel fires,

Fire Saf. J., 2011, 46 , 204210.

[8]

Hu L H, Chen L F, Wu L, et al. An experimental investigation and correlation on buoyant gas temperature below ceiling in

a slopping tunnel fire. Appl. Therm. Eng., 2013, 51, 246254.

[9]

Lee SR and Ryou HS. An experimental study of the effect of the aspect ratio on the critical velocity in longitudinal

ventilation tunnel fires. J Fire Sci.,2005, 23 (2), 119138.

[10] Li, L., Cheng, X., Wang, X., Zhang, H., Temperature distribution of fire-induced flow along tunnels under natural

ventilation. J. Fire Sci., 2012, 30 (2), 122137.

[11] Li L, Li S, Wang X, et al. Fire-induced flow temperature along tunnels with longitudinal ventilation. Tunn. Undergr. Sp.

Technol.,2012, 32 , 4451.

52

You might also like

- Microstructure and Wear Properties of Laser Clad NiCrBSi-MoS2 CoatingDocument5 pagesMicrostructure and Wear Properties of Laser Clad NiCrBSi-MoS2 CoatingSEP-PublisherNo ratings yet

- Mill's Critique of Bentham's UtilitarianismDocument9 pagesMill's Critique of Bentham's UtilitarianismSEP-PublisherNo ratings yet

- Quantum Meditation: The Self-Spirit ProjectionDocument8 pagesQuantum Meditation: The Self-Spirit ProjectionSEP-PublisherNo ratings yet

- Mindfulness and Happiness: The Empirical FoundationDocument7 pagesMindfulness and Happiness: The Empirical FoundationSEP-PublisherNo ratings yet

- Cold Mind: The Released Suffering StabilityDocument3 pagesCold Mind: The Released Suffering StabilitySEP-PublisherNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Stelzer Catalog PDFDocument12 pagesStelzer Catalog PDFlhphong021191No ratings yet

- Jadual 6 MpobDocument11 pagesJadual 6 MpobTipah HafizahNo ratings yet

- Toshiba 42pw33q - S Ch. Pw33 SchematicsDocument18 pagesToshiba 42pw33q - S Ch. Pw33 SchematicstodorloncarskiNo ratings yet

- Refining Mechanical PulpingDocument12 pagesRefining Mechanical PulpingMahdia MahmudNo ratings yet

- 545 ELP-ES-2011 - Catálogo de DisipadoresDocument24 pages545 ELP-ES-2011 - Catálogo de DisipadoresrichkidNo ratings yet

- Outside Screw and Yoke (OS&Y) Gate Valve - Flanged: Technical FeaturesDocument2 pagesOutside Screw and Yoke (OS&Y) Gate Valve - Flanged: Technical FeaturesMark Louie GuintoNo ratings yet

- MS275 10 Inch Compound Miter Saw MB4B2ADocument4 pagesMS275 10 Inch Compound Miter Saw MB4B2ArightoutacontrolNo ratings yet

- AKSML 230 - 33 KV - Sheet1Document2 pagesAKSML 230 - 33 KV - Sheet1Arif HossenNo ratings yet

- Sample Electrical LayoutDocument1 pageSample Electrical LayoutBentesais Bente UnoNo ratings yet

- SAX Brochure - Web ReadyDocument4 pagesSAX Brochure - Web ReadyEng-Ahmad Abo-AledousNo ratings yet

- Earned Schedule - Walt LipkeDocument27 pagesEarned Schedule - Walt LipkeKatie BensonNo ratings yet

- Scenario of Shale Gas Exploration in IndiaDocument24 pagesScenario of Shale Gas Exploration in IndiaManish TiwariNo ratings yet

- Recommendation Handling of Norit GL 50Document9 pagesRecommendation Handling of Norit GL 50Mátyás DalnokiNo ratings yet

- Chapter 6 PDFDocument59 pagesChapter 6 PDFSyarif HidayatNo ratings yet

- Ncomputing VSpace Server Management Console User ManualDocument34 pagesNcomputing VSpace Server Management Console User ManualJeff IvanNo ratings yet

- Engineering Department ProcedureDocument29 pagesEngineering Department ProcedureOmar Ahmed Elkhalil100% (1)

- Lectures - Mass TransferDocument36 pagesLectures - Mass TransferaaaNo ratings yet

- Civil Engineering PDFDocument3 pagesCivil Engineering PDFchetan c patilNo ratings yet

- Fracture in Concrete and Reinforced ConcreteDocument23 pagesFracture in Concrete and Reinforced ConcreteNilay GandhiNo ratings yet

- 006R5-WMS-JI-MI-MAU-ACS-II-23 Working Method - Pile CapDocument20 pages006R5-WMS-JI-MI-MAU-ACS-II-23 Working Method - Pile CapEko Budi HartantoNo ratings yet

- Graco Pumps Catalog 300435EN MDocument76 pagesGraco Pumps Catalog 300435EN MAlbu MihaiNo ratings yet

- Tpa3110D2-Q1 15-W Filter-Free Stereo Class-D Audio Power Amplifier With Speakerguard™Document37 pagesTpa3110D2-Q1 15-W Filter-Free Stereo Class-D Audio Power Amplifier With Speakerguard™tran anh tuanNo ratings yet

- 91 194 DCDocument57 pages91 194 DCGusdeluxeNo ratings yet

- 2014 Summer Model Answer PaperDocument20 pages2014 Summer Model Answer Papercivil gpkpNo ratings yet

- Kalzip - Vapour Layer FR 0822 PDFDocument2 pagesKalzip - Vapour Layer FR 0822 PDFBerat CakmakliNo ratings yet

- DUNAN Fan Coil UnitDocument14 pagesDUNAN Fan Coil UnitDjordjeNo ratings yet

- Cable TrenchDocument57 pagesCable TrenchHari Krishna AaryanNo ratings yet

- Jaybird Bluebuds X ManualDocument1 pageJaybird Bluebuds X Manualeduardi7720No ratings yet

- Basic Electronics - AC - DC PDFDocument20 pagesBasic Electronics - AC - DC PDFRowena ResurreccionNo ratings yet

- Kohler 14 20 RES Parts Manual TP 6806 2016 06Document76 pagesKohler 14 20 RES Parts Manual TP 6806 2016 06peleniusNo ratings yet