Professional Documents

Culture Documents

MS Tong Maintenance

Uploaded by

Bahman MatouriCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

MS Tong Maintenance

Uploaded by

Bahman MatouriCopyright:

Available Formats

Page 1

BVM Corporation

TYPE MS TONG

6,500 FT/LBS. TORQUE

Part number:__________________

Serial Number:________________

BVM CORPORATION

TYPE MS TONG

6,500 FT/LBS. TORQUE

WARNING: Manual tongs which have experienced excessive wear or are found to have cracks

should be replaced or repaired by BVM Corp. or designated BVM service station. Failure to do

so can result in serious bodily harm or property damage.

WARNING: To avoid injury do not place hands or any part of your body between pitch point

areas like jaws and pipe, between jaws, between latch and latch jaw and between lever and jaws

can cause sever injury.

WARNING: Only BVM parts should be used. Manual tongs are cast alloy heat treated steel

and should not be welded in the field. Improper welding can cause cracks and brittleness in

heat-affected areas which can result in drastic weakening of the part and possible failure.

Repairs involving welding and/or machining should be performed only by an authorized BVM

repair facility. Using a manual tong that has been improperly welded or repaired can cause

failure which may result in serious bodily injury or property damage.

BVM Document number EN-D005-Rev A

Page 2

BVM Type MS Tong is ideal for light drilling and tubing work. Also used for seismographic,

shot hole and exploration drilling. Like all other BVM Tongs a 3 Jaw design permits the jaws a

uniform contact around the pipe. Jaw sizes range from 1.900 through 6 1/8 OD. All Steel

specifications are certified.

1.

PURPOSE

This technical manual provides operation of and maintenance instructions to the BVM

Type MS Manual Tongs, with assembly drawings and parts breakdown. It provides a

guide for proper field use, disassembly and repairs.

2.

DESCRIPTION

BVM Type MS Manual Tongs are designed in accordance with industry standards and

can handle all kinds of pipe torque from light tubing to heavy wall pipe and drill collars.

All BVM Type MS manual tongs are precision machined from heat treated alloy steel,

with hinge pins made from a special heat treated alloy steel. Interchangeable lug jaw

design permits each tong to handle different sizes of pipe safely and conveniently.

3.

INSTALLATION

BVM Type MS manual tongs are designed for quick installation and easy operation. To

install the manual tong, the tong support line should be connected to the suspension ring.

To prepare the tong for the job at hand, install the right lug jaw to cover the correct size

range. Make sure the tong is capable of handling the torque required. For easy tong

operation, freely suspend tong up to the tong support line as close to the center of the

rotary table as is convenient. This reduces the arc of swing and the distance that the tong

must travel to the table. The pull up line must then be connected to the end of the lever.

A back up line, sized to safely withstand the tong torque rating, should in all cases be

connected to secure safe operation. A BVM tong pull back can be installed to save rig

time as it automatically repositions the tong for another take up.

4.

OPERATION

With the tong positioned and balanced properly, follow four simple steps outlined

below:

Grasp safety handle on lug jaw and safety handle on hanger to move the tong into

position about the pipe.

Press the short jaw firmly around and against the pipe.

Pushing both safety handles simultaneously the manual tong will latch automatically.

Pull both safety handles to break-over the tong and grip the pipe.

5.

MAINTENANCE:

5a ROUTINE FUNCTIONAL TEST

The functional test should be done prior to use or on a regular basis when in use.

Visually inspect the manual tong for loose, worn and missing parts.

Check for worn hinge pins and hinge pin holes by trying to vertically

move jaws from lever.

BVM Document number EN-D005-Rev A

Page 3

Check if all pins are properly locked.

Check for the proper latch engagement on steps of lug jaw. The latch

must not contact any part of the tong when latched and under torque

except the step on lug jaw.

Brush dies clean and check for wear.

5b ROUTINE LUBRICATION

The below lubrication should be done prior to use or on a regular basis when in

use:

Grease hinge pins through grease nipples.

Lubricate regularly during usage and storage to prevent corrosion from

attacking any part of the manual tong operating mechanism.

5c LUBRICATION SPECIFICATION

Use extreme pressure lithium based, multi-purpose grease of no. 1 or 2

consistency and 10 W 30 or 10 W 40 multi-grade motor oil to lubricate BVM

Manual Tongs.

5d TORQUE TEST

BVM Type MS manual tongs are torque tested after manufacture or repair to 1

times their torque rating.

6. Assembly Drawing and List of Parts see attachment.

Inspection

Daily Inspection (when tool is in use)

Category I.

This category involves observing the equipment during operation for indications of inadequate performance. When in

use, equipment shall be visually inspected on a daily basis for cracks, loose fits or connections, elongation of parts,

and other signs of wear, corrosion or overloading. Any equipment found to show cracks, excessive wear, etc., shall

be removed from service for further examination. The equipment shall be visually inspected by a person

knowledgeable in that equipment and its function.

Category II.

This is Category I inspection plus further inspection for corrosion, deformation, loose or missing components,

deterioration, proper lubrication, visible external cracks, and adjustment.

Procedure

Observe and repair when needed (cat I + II)

Observe the functioning of the tong as follows:

1) Check for proper latch engagement on lugs of lug jaw. The latch must not contact any part of the tong when

latched and under torque except the lug on lug jaw.

OK

2) Check for worn hinge pins and hinge pin bores by trying to vertically move jaws from lever

OK

Procedure

Visually inspect and repair when needed (cat I + II)

1. Check for worn and damaged parts

OK

2. Check for loose and missing parts

OK

3. Check all pins are properly locked

OK

4. Brush dies clean and check for wear

OK

BVM Document number EN-D005-Rev A

Page 4

5. Check the proper locking of:

Bolts and nuts OK

Slotted nuts & cotter pins OK

Lock tabs & lock bars OK

Roll pins and dowel pins OK

Snap rings OK

Cotter pins OK

6 Monthly Inspection (when tool is in use)

Category III

This is Category II inspection plus further inspection, which should include NDT of critical areas and may

involve some disassembly to access specific components and to identify wear that exceeds the

manufacturer's allowable tolerances.

Annual (1 year) Inspection (when tool is in use)

Category IV

This is Category III inspection plus further inspection for which the equipment is disassembled to the

extent necessary to conduct NDT of all primary-load-carrying components as defined by manufacturer.

Equipment shall be:

Disassembled in a suitably-equipped facility to the extent necessary to permit full inspection of all

primary-load-carrying components and other components that are critical to the equipment & Inspected

for excessive wear, cracks, flaws and deformations.

Corrections shall be made in accordance with the manufacturer's recommendations. Prior to Category III

and Category IV inspections, all foreign material such as dirt, paint, grease, oil, scale, etc. shall be

removed from the concerned parts by a suitable method (e.g. paint-stripping, steam-cleaning, gritblasting).

Procedure 6 Monthly Inspection

Procedure on rig (cat III) ;

Disassemble the following parts of the tong for dimensional check according to max. allowable wear (see this

chapter):

Hinge pins

Latch pins

Hinge pin holes

Latch pin holes

Jaws/Latches

Procedure Annual (1 year) Inspection

Annual (1 year) Inspection (cat IV)

MPI tong major load bearing components critical areas as per MPI-procedure, using the Critical Area Drawings.

Major load bearing components are:

Latch lug jaw (CA-222)

Latch jaw (CA-223)

Short jaw (CA-224)

Lever & Tubing tong lever (CA-225)

Long jaw (CA-226)

Manual tong hinge jaw (CA-227)

Latch (CA-228)

Hinge

BVM Document number EN-D005-Rev A

Page 5

Magnetic Particle Inspection

The BMV critical area drawings will indicate which areas are considered as to be critical or noncritical.

In general; for load bearing components, in case no critical area drawing exists, the complete component

is considered critical. Carry out MPI according to ASME BPVC sub section V, subsection A, article 7 and

subsection B, article 25 or ASTM E709 or an equivalent standard.

Machined surfaces shall be examined by the wet fluorescent method, other surfaces shall be examined

by wet or dry method. In case of inspecting a used product the only types of indications one need to

consider are cracks with size bigger as 1.6 mm (1/16 inch). All other types of indications have been

reviewed when the part was produced and found to be acceptable. In case the defect was not

acceptable it must have developed a crack during use and shall be considered relevant.

Evaluations of indications

Qualifications and certification

All personnel performing and interpreting MPI shall be qualified in accordance with the guidelines of

ASNT SNT-TC-1A (latest edition) or an equivalent standard and shall be trained in the use of the

reference photographs and the interpretation of the MPI with regard to the acceptance criteria and ASTM

E125 reference photographs.

Examination

BVM tongs should be MPI examined according to the maintenance procedures. The areas subject to

inspection shall be inspected according to the procedures developed by the user or, alternatively, as per

API RP 8B.

Table 1: Acceptance criteria for API 7k equipment

Grey area NOT applicable for MPI for equipment in service.

NOTE: If any relevant indications are found, contact BVM to determine the next course of action.

Preferably an inspection report (with photograph or sketch) detailing the serial number of the equipment

and the type, length and location of the indication should be presented. BVM will be able to advise the

proper and most efficient repair.

Linear indication: An indication, revealed by NDE, having a length at least three times its width

Rounded indication: An indication, revealed by NDE, with a circular or elliptical shape and having a

length less than three times its width. (pay special attention to the weld joint area

Grey area NOT applicable for MPI for equipment in service.

NOTE: If any relevant indications are found, contact BVM to determine the next course of action.

Preferably an inspection report (with photograph or sketch) detailing the serial number of the equipment

and the type, length and location of the indication should be presented. BVM will be able to advise the

proper and most efficient repair.

Linear indication: An indication, revealed by NDE, having a length at least three times its width

Rounded indication: An indication, revealed by NDE, with a circular or elliptical shape and having a

length less than three times its width.

BVM Document number EN-D005-Rev A

Page 6

Type

Discontinuity description

Max. permitted

degree critical areas

Max. permitted degree

non-critical areas

Linear discontinuities (hot tears, cracks)

None, see note Degree

II Shrinkage

III Inclusions

IV Internal chills and chaplets

V Porosity

Degree II

Degree II

Degree I

Degree I

Degree I

Degree II

Degree II

Degree I

Degree II

Table 2: Acceptance criteria for welds

No relevant linear indications ( 1.6 mm (1/16)

No rounded indications with a major dimension 3.2 mm ( 1/8 inch) for welds whose depth is 16 mm (

5/8 inch) or less

No rounded indications with major dimension greater than 5 mm ( 3/16) for welds whose depth is

greater than 16 mm ( 5/8 inch)

No more than 3 relevant indications in a line separated by less than 1.6mm (1/16 inch)

Table 3: Acceptance Criteria for wrought material

No relevant indications with a major dimension equal or greater than 3/16

No more than ten relevant indications in any continuous 6 in

No more than 3 relevant indications in a line separated by less than 1/16 edge to edge

No relevant indications in pressure sealing areas, in the root area of rotary threads or in stress-relief

features of threaded joints.

Tests

BVM Manual tongs are torque tested after manufacture or repair to 1.5 times their torque rating.

NOTE: Only a BVM authorized repair facility is allowed to remanufacture BVM Manual tongs which have

indications outside the acceptance criteria.

WARNING: BVM Manual tongs which have experienced wear or are found to have cracks must be

replaced or repaired by a BVM authorized repair facility.

WARNING: Only original BVM-OEM parts must be used. BVM Manual tongs are produced from

cast alloy heat treated steel and must not be welded in the field. Improper welding can cause

cracks and brittleness in heat-affected areas which can result in dramatic weakening of the part

and possible failure. Repairs involving welding and/or machining should be performed only by an

BVM authorized repair facility. Using a HT tong that has been improperly welded or repaired is

dangerous.

BVM Document number EN-D005-Rev A

Page 7

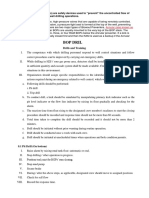

Maximum allowable wear to maintain 100% torque rating

B

A

A

A

A

A

Tong Type

Dimension A

Maximum

clearance (inch)

Dimension B

Maximum

clearance (inch)

SDD

DB

B

C

LF

MS

0.035

0.035

0.025

0.030

0.030

0.025

0.035

0.035

0.035

0.035

0.035

0.035

Shop repairs

Changing dies/inserts

1. Remove the cotter pin and take out the retaining pin

2. After replacing the inserts, the retaining pins with the cotter pins shall be reinstalled.

CAUTION: Wear eye protection when removing or replacing inserts to protect against chip

fragments

BVM Document number EN-D005-Rev A

You might also like

- How To Draw ChibiDocument13 pagesHow To Draw ChibiNurzaria Zakaria100% (1)

- TM 120 Daily and Weekly Inspection and Maintenance TasksDocument23 pagesTM 120 Daily and Weekly Inspection and Maintenance TasksAlejandra Noguera GiraldoNo ratings yet

- Procedure de Test BOPDocument12 pagesProcedure de Test BOPkhireddineboulifaNo ratings yet

- Parallel Structure ExercisesDocument2 pagesParallel Structure Exercisesadi sp0% (1)

- Hoist Equipment Inspection ProcedureDocument5 pagesHoist Equipment Inspection ProcedureAhmed Imtiaz Rao100% (1)

- BOP Choke Man Inspection ProcedureDocument13 pagesBOP Choke Man Inspection ProcedureAhmed Imtiaz Rao100% (2)

- Compressed Catalog 2Document95 pagesCompressed Catalog 2ask101No ratings yet

- SLX SX Elevator Maintenance ManualDocument7 pagesSLX SX Elevator Maintenance ManualBahman MatouriNo ratings yet

- Blohm + Voss Pipe Handling Equipment ManualDocument72 pagesBlohm + Voss Pipe Handling Equipment ManualDaniel TostaNo ratings yet

- Inspection Side Door ElevatorDocument22 pagesInspection Side Door ElevatorAnthony WaaliaNo ratings yet

- Tower Climbing ProcedureDocument33 pagesTower Climbing ProcedurePyara Kamboj50% (2)

- Rig Superintendent ExamDocument30 pagesRig Superintendent ExamAboZaidNo ratings yet

- NOV - Rotary Slips ManualDocument7 pagesNOV - Rotary Slips ManualbenkaouhaNo ratings yet

- Canrig torque wrench specificationsDocument16 pagesCanrig torque wrench specificationsaris4silveyraNo ratings yet

- Honeywell India-Full Catalogue PDFDocument152 pagesHoneywell India-Full Catalogue PDFInyamul hasanNo ratings yet

- Directive 036Document206 pagesDirective 036drilling moneytreeNo ratings yet

- SD-010404-01 - Test Stump Operating ManualDocument15 pagesSD-010404-01 - Test Stump Operating ManualFam Escalante OnofreNo ratings yet

- BVM TONG TORQUE WARNINGSDocument7 pagesBVM TONG TORQUE WARNINGSBahman MatouriNo ratings yet

- Temporary Pipe Installation GuideDocument17 pagesTemporary Pipe Installation GuideTeguh Setiono100% (1)

- 10 Driller Module Admin ManualDocument80 pages10 Driller Module Admin Manualcpb dwo100% (2)

- B+V Manual - CLS 100-150 - 621100-Y-BC-D Rev 005Document30 pagesB+V Manual - CLS 100-150 - 621100-Y-BC-D Rev 005Leonardo Rachen RodriguezNo ratings yet

- Derrick-Mast Inspection ProcedureDocument3 pagesDerrick-Mast Inspection ProcedureChandrasekhar Sonar100% (3)

- Rutong DH 吊环使用说明书(ZY)2013 links - 1Document3 pagesRutong DH 吊环使用说明书(ZY)2013 links - 1QAMAR ALI KHANNo ratings yet

- BVM elevator manualDocument8 pagesBVM elevator manualBahman MatouriNo ratings yet

- Texas International Oilfield ToolsDocument16 pagesTexas International Oilfield ToolssepehrccNo ratings yet

- Slip Type ElevatorDocument15 pagesSlip Type ElevatorJohn Jairo SimancaNo ratings yet

- Blohm + Voss Pipe Handling Equipment ManualDocument38 pagesBlohm + Voss Pipe Handling Equipment ManualWaleed Barakat Maria100% (1)

- Bop Dril: Drills and TrainingDocument3 pagesBop Dril: Drills and TrainingNazrul AminNo ratings yet

- H Tong Maintenance ManualDocument8 pagesH Tong Maintenance ManualBahman MatouriNo ratings yet

- 611520-Y-BC-D Rev 009 - B+V Manual CL 150-1000Document56 pages611520-Y-BC-D Rev 009 - B+V Manual CL 150-1000Imed Hammouda100% (2)

- Manual Spider VarcoDocument45 pagesManual Spider VarcoJAVIER EDUARDO MANTILLA BUITRAGONo ratings yet

- Rotary InformationDocument14 pagesRotary InformationMohammad UsmanNo ratings yet

- Manual: CDQ (S) Sucker Rod ElevatorsDocument5 pagesManual: CDQ (S) Sucker Rod ElevatorsDarshan MakwanaNo ratings yet

- HH-Travling BlockDocument3 pagesHH-Travling Blockabdi rachman100% (2)

- BOP Checklist IPMDocument8 pagesBOP Checklist IPMEmre CengizNo ratings yet

- Manual Drill Collar S-R-LDocument6 pagesManual Drill Collar S-R-LJAVIER EDUARDO MANTILLA BUITRAGONo ratings yet

- Derrickman Module Admin ManualDocument35 pagesDerrickman Module Admin Manualاحمد ابوبكر اشقيفهNo ratings yet

- Down HoleDocument14 pagesDown HoleGhinet Teodor-ioanNo ratings yet

- Safety Clamp: Operation ManualDocument21 pagesSafety Clamp: Operation ManualDavid Venegas AndradeNo ratings yet

- Slips Maintenance, Inspection, & Wear Data PDFDocument3 pagesSlips Maintenance, Inspection, & Wear Data PDFcorsini999100% (1)

- BV Elevator Links ManualDocument54 pagesBV Elevator Links ManualMikeCao1384No ratings yet

- Certificate of Inspection for Sucker Rod ElevatorDocument2 pagesCertificate of Inspection for Sucker Rod Elevatorteodorescu MARIUSNo ratings yet

- Well Control Drills and Exercises WIPER TRIPDocument3 pagesWell Control Drills and Exercises WIPER TRIPmanuelperdomotNo ratings yet

- Mrs - Tittlemouse, Beatrix Potter, AutoPlayDocument66 pagesMrs - Tittlemouse, Beatrix Potter, AutoPlayKen KunzNo ratings yet

- Drilling Rig Technical Audit ChecklistDocument113 pagesDrilling Rig Technical Audit Checklistmarwan khalilNo ratings yet

- BVM Corporation Maintenance Manual: Series "S" ElevatorDocument11 pagesBVM Corporation Maintenance Manual: Series "S" ElevatorAnang SakraniNo ratings yet

- Manual-18 Rotary Side Door ElevatorDocument12 pagesManual-18 Rotary Side Door ElevatorYesid Cruz Yesid CruzNo ratings yet

- 20 1703YSeriesElevatorManualDocument27 pages20 1703YSeriesElevatorManualnjava1978No ratings yet

- Maintenance Y SERIESDocument10 pagesMaintenance Y SERIESStowartNo ratings yet

- Placement Test BDocument8 pagesPlacement Test BGunay HasanovaNo ratings yet

- RA Elevator ManualDocument8 pagesRA Elevator ManualBahman MatouriNo ratings yet

- Slip Type Elevator PDFDocument22 pagesSlip Type Elevator PDFسہۣۗفيہۣۗانشہۣۗينہۣۗويNo ratings yet

- Repositorio de Autorretrato en en La Historia Del ArteDocument107 pagesRepositorio de Autorretrato en en La Historia Del ArteAlessandro RiveraNo ratings yet

- 20-1718 Rig Tongs AOTDocument10 pages20-1718 Rig Tongs AOTRahul M.R100% (1)

- DEN-CON TOOL ELEVATOR MAINTENANCE INSPECTION DATADocument2 pagesDEN-CON TOOL ELEVATOR MAINTENANCE INSPECTION DATAHector BarriosNo ratings yet

- Rigging Amp Lifting Handbook NSLDocument7 pagesRigging Amp Lifting Handbook NSLAkram BadranNo ratings yet

- Safe Man Riding LiftsDocument2 pagesSafe Man Riding Liftsreda mesbahNo ratings yet

- Shock Sub Tool: Impact and Vibration Reduction ToolDocument4 pagesShock Sub Tool: Impact and Vibration Reduction ToolLeonardo Barrios0% (1)

- Drillpipe and Bottom Hole Assembly StandardsDocument2 pagesDrillpipe and Bottom Hole Assembly StandardsSasan Abbasi100% (1)

- IADC Drilling Manual 11th Edition DetailsDocument4 pagesIADC Drilling Manual 11th Edition DetailshustlerNo ratings yet

- BVM Elevator Maintenance and Inspection GuideDocument9 pagesBVM Elevator Maintenance and Inspection Guideyury1102No ratings yet

- NOV Elevator Link CompatibilityDocument2 pagesNOV Elevator Link CompatibilityisamelgqNo ratings yet

- Power Slip Lifter Systems CatalogDocument36 pagesPower Slip Lifter Systems CatalogAdrian Cantaragiu100% (1)

- FY-50Y BOP Handling System Maintenance ManualDocument15 pagesFY-50Y BOP Handling System Maintenance ManualJosé Manuel100% (1)

- Doc. 20-1715 Rev D (9/12/1005) Pneumatic Spider Operating Procedure ManualDocument12 pagesDoc. 20-1715 Rev D (9/12/1005) Pneumatic Spider Operating Procedure ManualGregory StewartNo ratings yet

- Intermediate Inspection CriteriaDocument2 pagesIntermediate Inspection CriteriaKaleem UllahNo ratings yet

- BVM Corporation Maintenance Manual: "C", "T", & "MP" Series Safety ClampsDocument8 pagesBVM Corporation Maintenance Manual: "C", "T", & "MP" Series Safety ClampsRakefsNo ratings yet

- Permeabilities and Po-ItiesDocument12 pagesPermeabilities and Po-ItiesBahman MatouriNo ratings yet

- Proper Selection OF Drill Bits AND Their USE: Sent To The Society ofDocument12 pagesProper Selection OF Drill Bits AND Their USE: Sent To The Society ofBahman MatouriNo ratings yet

- 00000787Document24 pages00000787Bahman MatouriNo ratings yet

- 00000800Document13 pages00000800Bahman MatouriNo ratings yet

- 00000774Document31 pages00000774Bahman MatouriNo ratings yet

- 00000681Document5 pages00000681Bahman MatouriNo ratings yet

- Underground Combustion 01L-Rec0Ver% Experiment in The Venango First Sand, Warren County, PaDocument47 pagesUnderground Combustion 01L-Rec0Ver% Experiment in The Venango First Sand, Warren County, PaBahman MatouriNo ratings yet

- 00000768Document50 pages00000768Bahman MatouriNo ratings yet

- 00000613Document13 pages00000613Bahman MatouriNo ratings yet

- 00000768Document50 pages00000768Bahman MatouriNo ratings yet

- 00000667Document7 pages00000667Bahman MatouriNo ratings yet

- 00000705Document9 pages00000705Bahman MatouriNo ratings yet

- Su. Ts In: M R12s VDocument20 pagesSu. Ts In: M R12s VBahman MatouriNo ratings yet

- Su. Ts In: M R12s VDocument20 pagesSu. Ts In: M R12s VBahman MatouriNo ratings yet

- 00000613Document13 pages00000613Bahman MatouriNo ratings yet

- A. and M. DivisionDocument17 pagesA. and M. DivisionBahman MatouriNo ratings yet

- Evaluation of Scale-Up Laws For Two-Phase Flow (Through Porous MediaDocument13 pagesEvaluation of Scale-Up Laws For Two-Phase Flow (Through Porous MediaBahman MatouriNo ratings yet

- 00000569Document12 pages00000569Bahman MatouriNo ratings yet

- !pedmical I'?Ote: Some LmlmowDocument19 pages!pedmical I'?Ote: Some LmlmowBahman MatouriNo ratings yet

- Reservoirs With Gas and Walter: SimpleDocument6 pagesReservoirs With Gas and Walter: SimpleBahman MatouriNo ratings yet

- 00000569Document12 pages00000569Bahman MatouriNo ratings yet

- A Review of Diffusion and Dispersion in Porous MediaDocument15 pagesA Review of Diffusion and Dispersion in Porous MediaBahman MatouriNo ratings yet

- A Mathematical Model For Dispersion in The Direction of Flow in Porous MediaDocument4 pagesA Mathematical Model For Dispersion in The Direction of Flow in Porous MediaBahman MatouriNo ratings yet

- Pressure Build-Up Analysis, Variable-Rate Case: S+?s - RX' """Document5 pagesPressure Build-Up Analysis, Variable-Rate Case: S+?s - RX' """Bahman MatouriNo ratings yet

- 00000545Document8 pages00000545Bahman MatouriNo ratings yet

- 00000542Document25 pages00000542Bahman MatouriNo ratings yet

- 00000532Document52 pages00000532Bahman MatouriNo ratings yet

- Experimental Study of Crater Formation in Plastically Deforming Synthetic RocksDocument6 pagesExperimental Study of Crater Formation in Plastically Deforming Synthetic RocksBahman MatouriNo ratings yet

- PDFDocument6 pagesPDFBahman MatouriNo ratings yet

- Spes - : Some Experiments On The Flow of Miscible Fluids of Unequal Density Through Porous MediaDocument4 pagesSpes - : Some Experiments On The Flow of Miscible Fluids of Unequal Density Through Porous MediaBahman MatouriNo ratings yet

- Improving Belt Conveyor Safety With Better Procedures and TrainingDocument6 pagesImproving Belt Conveyor Safety With Better Procedures and TrainingcdkueaNo ratings yet

- Install Mechanical Seal GuideDocument2 pagesInstall Mechanical Seal GuideAnees Ud DinNo ratings yet

- In The Court of The Yellow King PDFDocument15 pagesIn The Court of The Yellow King PDFLuis G. AbbadieNo ratings yet

- Irregular VerbsDocument6 pagesIrregular VerbsYeansys Lara VelasquezNo ratings yet

- KIZUNA (Bond) Project 2012Document35 pagesKIZUNA (Bond) Project 2012Jonathan PhanNo ratings yet

- Exercício de Interpretação de Texto em Inglês (Com Gabarito)Document5 pagesExercício de Interpretação de Texto em Inglês (Com Gabarito)Marcelo AfonsoNo ratings yet

- Ip4 M3uDocument10 pagesIp4 M3uMNo ratings yet

- Necvol 1Document1,169 pagesNecvol 1Abd ZouhierNo ratings yet

- Everything You Need to Know About Fully Fashioned KnittingDocument4 pagesEverything You Need to Know About Fully Fashioned KnittingMuhammad Rafiqul IslamNo ratings yet

- Submitted To: Md. Emdad Sarker Lecturer Department of TextileDocument38 pagesSubmitted To: Md. Emdad Sarker Lecturer Department of TextileMd Golam Kibria100% (1)

- GT. Tieng Anh Co SoDocument97 pagesGT. Tieng Anh Co SoNguyễn Chí TâmNo ratings yet

- Fundamentals of Yarn Technology: Learning ObjectivesDocument16 pagesFundamentals of Yarn Technology: Learning Objectivesdwidha100% (1)

- Making Copy Shine With Editing: Sabrina Schmitz, CJE, Walsworth YearbooksDocument48 pagesMaking Copy Shine With Editing: Sabrina Schmitz, CJE, Walsworth YearbooksSaybara DelacruzNo ratings yet

- Tourist at C Commoda Tion Regulations AppendixDocument202 pagesTourist at C Commoda Tion Regulations AppendixMuhanadNo ratings yet

- Use and Application of Engineering ComponentsDocument3 pagesUse and Application of Engineering ComponentsRossDuttonNo ratings yet

- Potential Sources of Wear Metals in Used Lubricating Oil AnalysisDocument4 pagesPotential Sources of Wear Metals in Used Lubricating Oil Analysismaruf amaludinNo ratings yet

- The Lost Spring Summary: Deprived Children Forced into LaborDocument25 pagesThe Lost Spring Summary: Deprived Children Forced into LaborDev TrivediNo ratings yet

- Karnali Blues - Buddhisagar Michael HuttDocument376 pagesKarnali Blues - Buddhisagar Michael Huttpanta.shrisha500No ratings yet

- EPP Festival of Talents GuidelinesDocument9 pagesEPP Festival of Talents GuidelinesJason GranadaNo ratings yet

- Emma Routine 1Document3 pagesEmma Routine 1Silvia amaroNo ratings yet

- CRAB RatingDocument62 pagesCRAB RatingRashed MahmudNo ratings yet

- Q4 W5 DAY 1 - SCIENCE - Safety Precautions - Beverly SantiagoDocument45 pagesQ4 W5 DAY 1 - SCIENCE - Safety Precautions - Beverly Santiagobeverly v santiagoNo ratings yet

- CommasDocument19 pagesCommasSafia Haroon Rasheed50% (2)