Professional Documents

Culture Documents

Ishikawa Diagram - Wikipedia, The Free Encyclopedia

Uploaded by

Sachin SaxenaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ishikawa Diagram - Wikipedia, The Free Encyclopedia

Uploaded by

Sachin SaxenaCopyright:

Available Formats

Ishikawa diagram - Wikipedia, the free encyclopedia

1 of 3

https://en.wikipedia.org/wiki/Ishikawa_diagram

Ishikawa diagram

From Wikipedia, the free encyclopedia

Ishikawa diagrams (also called fishbone diagrams,

herringbone diagrams, cause-and-effect diagrams, or

Fishikawa) are causal diagrams created by Kaoru Ishikawa

(1968) that show the causes of a specific event.[1][2] Common

uses of the Ishikawa diagram are product design and quality

defect prevention, to identify potential factors causing an

overall effect. Each cause or reason for imperfection is a

source of variation. Causes are usually grouped into major

categories to identify these sources of variation. The

categories typically include

People: Anyone involved with the process

Methods: How the process is performed and the

specific requirements for doing it, such as policies,

procedures, rules, regulations and laws

Machines: Any equipment, computers, tools, etc.

required to accomplish the job

Materials: Raw materials, parts, pens, paper, etc. used

to produce the final product

Measurements: Data generated from the process that

are used to evaluate its quality

Environment: The conditions, such as location, time,

temperature, and culture in which the process operates

Ishikawa diagram

One of the Seven Basic Tools of Quality

First

Kaoru Ishikawa

described

by

Purpose

To break down (in successive layers of

detail) root causes that potentially

contribute to a particular effect

Contents

1 Overview

2 Causes

2.1 The 5 M's (used in manufacturing industry)

2.2 The 7 P's (used in marketing industry)

2.3 The 5 S's (used in service industry)

3 See also

4 References

4.1 Further reading

5 External links

Overview

Ishikawa diagrams were popularized in the 1960s by Kaoru Ishikawa,[3] who pioneered quality management

processes in the Kawasaki shipyards, and in the process became one of the founding fathers of modern

management.

The basic concept was first used in the 1920s, and is considered one of the seven basic tools of quality control.[4]

8/15/2015 11:33 PM

Ishikawa diagram - Wikipedia, the free encyclopedia

2 of 3

https://en.wikipedia.org/wiki/Ishikawa_diagram

It is known as a fishbone diagram because of its shape, similar

to the side view of a fish skeleton.

Ishikawa diagram, in fishbone shape, showing

factors of Equipment, Process, People, Materials,

Environment and Management, all affecting the

overall problem. Smaller arrows connect the

sub-causes to major causes.

Mazda Motors famously used an Ishikawa diagram in the

development of the Miata sports car, where the required result

was "Jinba Ittai" (Horse and Rider as One jap. ).

The main causes included such aspects as "touch" and

"braking" with the lesser causes including highly granular

factors such as "50/50 weight distribution" and "able to rest

elbow on top of driver's door". Every factor identified in the

diagram was included in the final design.

Causes

Causes in the diagram are often categorized, such as to the 5

M's, described below. Cause-and-effect diagrams can reveal key

relationships among various variables, and the possible causes provide additional insight into process behavior.

Causes can be derived from brainstorming sessions. These groups can then be labeled as categories of the

fishbone. They will typically be one of the traditional categories mentioned above but may be something unique

to the application in a specific case. Causes can be traced back to root causes with the 5 Whys technique.

Typical categories are

The 5 M's (used in manufacturing industry)

Machine (technology)

Method (process)

Material (Includes Raw Material, Consumables and Information.)

Man Power (physical work)/Mind Power (brain work): Kaizens, Suggestions

Measurement (Inspection)

The original 5 M's used by the Toyota Production System have been expanded by some to include the following

and are referred to as the 8 Ms. However, this is not globally recognized. It has been suggested to return to the

roots of the tools and to keep the teaching simple while recognizing the original intent; most programs do not

address the 8M's.

Milieu/Mother Nature(Environment)

Management/Money Power

Maintenance

The 7 P's (used in marketing industry)

Product/Service

Price

Place

Promotion

People/personnel

Process

Physical Evidence

8/15/2015 11:33 PM

Ishikawa diagram - Wikipedia, the free encyclopedia

3 of 3

https://en.wikipedia.org/wiki/Ishikawa_diagram

The 7 P's are primarily used in service marketing.

The 5 S's (used in service industry)

Surroundings

Suppliers

Systems

Skills

Safety

See also

Seven Basic Tools of Quality

Five whys

Ishikawa Diagram Examples (http://creately.com/blog/examples/fishbone-diagram-templates/)

References

1.

2.

3.

4.

Ishikawa, Kaoru (1968). Guide to Quality Control. Tokyo: JUSE.

Ishikawa, Kaoru (1976). Guide to Quality Control. Asian Productivity Organization. ISBN 92-833-1036-5.

Hankins, Judy (2001). Infusion Therapy in Clinical Practice. p. 42.

Tague, Nancy R. (2004). "Seven Basic Quality Tools" (http://www.asq.org/learn-about-quality/seven-basic-qualitytools/overview/overview.html). The Quality Toolbox. Milwaukee, Wisconsin: American Society for Quality. p. 15.

Retrieved 2010-02-05.

Further reading

Ishikawa, Kaoru (1990); (Translator: J. H. Loftus); Introduction to Quality Control; 448 p; ISBN

4-906224-61-X OCLC 61341428 (https://www.worldcat.org/oclc/61341428)

Dale, Barrie G. et al. (2007); Managing Quality 5th ed; ISBN 978-1-4051-4279-3 OCLC 288977828

(https://www.worldcat.org/oclc/288977828)

External links

Retrieved from "https://en.wikipedia.org

/w/index.php?title=Ishikawa_diagram&oldid=675430251"

Wikimedia Commons has

media related to Ishikawa

diagrams.

Categories: Causal diagrams Causality Knowledge representation

Quality control tools

This page was last modified on 10 August 2015, at 14:57.

Text is available under the Creative Commons Attribution-ShareAlike License; additional terms may

apply. By using this site, you agree to the Terms of Use and Privacy Policy. Wikipedia is a registered

trademark of the Wikimedia Foundation, Inc., a non-profit organization.

8/15/2015 11:33 PM

You might also like

- Ishikawa DiagramsDocument2 pagesIshikawa Diagramsabhi_003No ratings yet

- Fishbone IshikawaDocument4 pagesFishbone IshikawaHarusiNo ratings yet

- A New Model of Ishikawa DiagraDocument7 pagesA New Model of Ishikawa Diagrastagfire17No ratings yet

- Ishikawa Diagram - WikipediaDocument18 pagesIshikawa Diagram - WikipediaramandinipNo ratings yet

- Fishbone Diagram Causes and UsesDocument2 pagesFishbone Diagram Causes and UsesbahjahturahmahNo ratings yet

- Ishikawa MethodDocument6 pagesIshikawa MethodneddylalolaNo ratings yet

- A New Model of Ishikawa Diagram For Quality AssessDocument7 pagesA New Model of Ishikawa Diagram For Quality AssessWildan Abdul SaidNo ratings yet

- Ishikawa DiagramDocument4 pagesIshikawa Diagramisabella343No ratings yet

- Kaoru IshikawaDocument4 pagesKaoru IshikawapearlsugarfairyNo ratings yet

- 1) Ishikawa Diagram: 7 Basic Tools of QualityDocument6 pages1) Ishikawa Diagram: 7 Basic Tools of QualityRob WillestoneNo ratings yet

- 7 Basic Qualty Tools Root Cause Analysis PDFDocument42 pages7 Basic Qualty Tools Root Cause Analysis PDFgabao123100% (1)

- Root Cause Analysis Using Fishbone DiagramDocument6 pagesRoot Cause Analysis Using Fishbone DiagramRose Mae TecsonNo ratings yet

- Ishikawa Diagram: Learn To Make Diagrams, The Ishikawa WayDocument45 pagesIshikawa Diagram: Learn To Make Diagrams, The Ishikawa Wayjuliet moises100% (2)

- Causeff Rev ColDocument5 pagesCauseff Rev ColwhatisnameNo ratings yet

- Cause and Effect Fishbone Ishikawa DiagramDocument11 pagesCause and Effect Fishbone Ishikawa Diagramtush_joshiNo ratings yet

- Ishikawa DiagramDocument2 pagesIshikawa DiagramBrahim KaddafiNo ratings yet

- Assignment Fish Bone DiagramDocument7 pagesAssignment Fish Bone DiagramshahenshahNo ratings yet

- Decision Making ToolsDocument26 pagesDecision Making ToolsRafael SoroNo ratings yet

- 7 Tool of TQMDocument69 pages7 Tool of TQMMuhammad Ali AkbarNo ratings yet

- Ishikawa Diagram: Anticipate and solve problems within your businessFrom EverandIshikawa Diagram: Anticipate and solve problems within your businessRating: 5 out of 5 stars5/5 (3)

- الأداوات السبعة للجودةDocument69 pagesالأداوات السبعة للجودةHamada AhmedNo ratings yet

- Ishikawa Diagram FinalDocument9 pagesIshikawa Diagram Finalpurvangi_r5661No ratings yet

- Approaches To Problem-Solving Techniques: Fishbone AnalysisDocument23 pagesApproaches To Problem-Solving Techniques: Fishbone AnalysisMahmood KhanNo ratings yet

- The 7 Quality Tools - PpsDocument13 pagesThe 7 Quality Tools - PpsRobert GonzalezNo ratings yet

- Qcfi Que Set 4 Theory & Questions by JudgesDocument12 pagesQcfi Que Set 4 Theory & Questions by JudgesSaurabh Choudhari100% (1)

- The Application of Cause and Effect Diagram in The Oil Industry in Iran: The Case of Four Liter Oil Canning Process of Sepahan Oil CompanyDocument8 pagesThe Application of Cause and Effect Diagram in The Oil Industry in Iran: The Case of Four Liter Oil Canning Process of Sepahan Oil CompanyFatimahAhmatNo ratings yet

- Training Facility Norms and Standard Equipment Lists: Volume 1---Precision Engineering or MachiningFrom EverandTraining Facility Norms and Standard Equipment Lists: Volume 1---Precision Engineering or MachiningNo ratings yet

- QUALITY MANAGEMENT - Assgnment1Document12 pagesQUALITY MANAGEMENT - Assgnment1Nain TikaryaNo ratings yet

- Country Safeguard Systems: Second Regional Workshop Proceedings: Towards Common Approaches and Better ResultsFrom EverandCountry Safeguard Systems: Second Regional Workshop Proceedings: Towards Common Approaches and Better ResultsNo ratings yet

- Lecture 02Document17 pagesLecture 02hasindu rathnayekeNo ratings yet

- Mathematical Optimization Terminology: A Comprehensive Glossary of TermsFrom EverandMathematical Optimization Terminology: A Comprehensive Glossary of TermsNo ratings yet

- Cause and Effect DiagramsDocument4 pagesCause and Effect DiagramsMohammad Jaid AlamNo ratings yet

- BAB II Kajian Pustaka PPMDocument14 pagesBAB II Kajian Pustaka PPMDavidjuan SebastianNo ratings yet

- Handbook on Construction Techniques: A Practical Field Review of Environmental Impacts in Power Transmission/Distribution, Run-of-River Hydropower and Solar Photovoltaic Power Generation ProjectsFrom EverandHandbook on Construction Techniques: A Practical Field Review of Environmental Impacts in Power Transmission/Distribution, Run-of-River Hydropower and Solar Photovoltaic Power Generation ProjectsRating: 2 out of 5 stars2/5 (1)

- Conduct of Operations and Operational Discipline: For Improving Process Safety in IndustryFrom EverandConduct of Operations and Operational Discipline: For Improving Process Safety in IndustryRating: 5 out of 5 stars5/5 (1)

- DasicP1 Electrical 2007Document11 pagesDasicP1 Electrical 2007Adhe MartiyaNo ratings yet

- QE - 7QC - Cause and Effect DiagramDocument11 pagesQE - 7QC - Cause and Effect Diagrammovies comNo ratings yet

- 7 QCDocument5 pages7 QCAMIT THAKKARNo ratings yet

- QE - 7QC - FLOW PROCESS CHART and Cause and Effect DiagramDocument18 pagesQE - 7QC - FLOW PROCESS CHART and Cause and Effect Diagrammovies comNo ratings yet

- Root Cause Analysis: What Is A Fishbone Diagram?Document7 pagesRoot Cause Analysis: What Is A Fishbone Diagram?kriskan2509No ratings yet

- Fishbone DiagramDocument3 pagesFishbone DiagramMuhammad ArhamNo ratings yet

- Gorostiza Research 2Document6 pagesGorostiza Research 2John Vincent GorostizaNo ratings yet

- Ishikawa MethodDocument32 pagesIshikawa MethodNur Azira FauziNo ratings yet

- Seven Tools of QualityDocument23 pagesSeven Tools of QualityhimanshuNo ratings yet

- Presentación Diagrama IshikawaDocument13 pagesPresentación Diagrama IshikawaAgustin GalvanNo ratings yet

- Life Cycle Inventory Analysis: Methods and DataFrom EverandLife Cycle Inventory Analysis: Methods and DataAndreas CirothNo ratings yet

- Taking the LEAP: The Methods and Tools of the Linked Engineering and Manufacturing Platform (LEAP)From EverandTaking the LEAP: The Methods and Tools of the Linked Engineering and Manufacturing Platform (LEAP)Dimitris KiritsisNo ratings yet

- Research 1Document11 pagesResearch 1Cristiano Jr.No ratings yet

- RCM3: Risk-Based Reliability Centered MaintenanceFrom EverandRCM3: Risk-Based Reliability Centered MaintenanceRating: 1 out of 5 stars1/5 (1)

- cc2005 March06final4444Document62 pagescc2005 March06final4444José Segundo Pedro AvilaNo ratings yet

- Industrial Agents: Emerging Applications of Software Agents in IndustryFrom EverandIndustrial Agents: Emerging Applications of Software Agents in IndustryPaulo LeitãoNo ratings yet

- Improve Productivity Using Industrial Engineering ToolsDocument7 pagesImprove Productivity Using Industrial Engineering ToolsMahesh JadhavNo ratings yet

- 7 Basic Qualty Tools & Root Cause AnalysisDocument42 pages7 Basic Qualty Tools & Root Cause AnalysisRamonS.FernandezOrozco100% (1)

- 2007 GoodDocument155 pages2007 Goodpooyeh_rNo ratings yet

- Total Quality Management: Seven Basic Quality ToolsDocument31 pagesTotal Quality Management: Seven Basic Quality ToolsAditya vatsyayanNo ratings yet

- Pareto Chart - Wikipedia, The Free EncyclopediaDocument2 pagesPareto Chart - Wikipedia, The Free EncyclopediaSachin SaxenaNo ratings yet

- Schedule - Training For Trainers PDFDocument2 pagesSchedule - Training For Trainers PDFSachin SaxenaNo ratings yet

- Application 45Document8 pagesApplication 45SMBEAUTYNo ratings yet

- 18 Fundamental Waveguide Theory PDFDocument35 pages18 Fundamental Waveguide Theory PDFanilNo ratings yet

- Higher Algebra - Hall & KnightDocument593 pagesHigher Algebra - Hall & KnightRam Gollamudi100% (2)

- Schedule - Training For Trainers PDFDocument2 pagesSchedule - Training For Trainers PDFSachin SaxenaNo ratings yet

- Q & A Set 1Document9 pagesQ & A Set 1aminchhipa6892No ratings yet

- Recommended Reading List For Operation ManagementDocument1 pageRecommended Reading List For Operation ManagementHakanNo ratings yet

- US Economics Digest: The 2014 FOMC: A New Cast of CharactersDocument10 pagesUS Economics Digest: The 2014 FOMC: A New Cast of CharactersGlenn ViklundNo ratings yet

- Accounting Edexcel FINALDocument6 pagesAccounting Edexcel FINALClifford PeraltaNo ratings yet

- Ripple CryptocurrencyDocument5 pagesRipple CryptocurrencyRipple Coin NewsNo ratings yet

- Paper Express SalesDocument1 pagePaper Express Salesapi-6506215No ratings yet

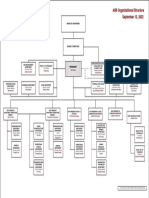

- AIIB Organizational StructureDocument1 pageAIIB Organizational StructureHenintsoa RaNo ratings yet

- Cheniere Energy Valuation ModelDocument11 pagesCheniere Energy Valuation Modelngarritson1520100% (1)

- Maintainance Contract FormatDocument3 pagesMaintainance Contract Formatnauaf101No ratings yet

- Monografia Edificios VerdesDocument56 pagesMonografia Edificios VerdesKa VaNo ratings yet

- Rotisserie Affair Deli Marketing PlanDocument41 pagesRotisserie Affair Deli Marketing PlanAri EngberNo ratings yet

- Edmonton Commerce News June-July 2010Document28 pagesEdmonton Commerce News June-July 2010Venture PublishingNo ratings yet

- Fabric Test ReportDocument4 pagesFabric Test ReportHasan MustafaNo ratings yet

- Chapter 5 Questions V1Document6 pagesChapter 5 Questions V1prashantgargindia_930% (1)

- Amazon Service Marketing Case StudyDocument36 pagesAmazon Service Marketing Case StudyAbhiNo ratings yet

- Oranjolt - Rasn-WPS OfficeDocument3 pagesOranjolt - Rasn-WPS OfficeKaviya SkNo ratings yet

- Integration and Responsiveness MatrixDocument9 pagesIntegration and Responsiveness MatrixVishalNo ratings yet

- Aud589 (Pya 2019 Dec)Document7 pagesAud589 (Pya 2019 Dec)amirah zahidahNo ratings yet

- Denali Investors Partner Letter - 2014 Q2Document6 pagesDenali Investors Partner Letter - 2014 Q2ValueInvestingGuy100% (1)

- Marketing Manager Coordinator Programs in Dallas FT Worth TX Resume KeJaun DuBoseDocument2 pagesMarketing Manager Coordinator Programs in Dallas FT Worth TX Resume KeJaun DuBoseKeJuanDuBoseNo ratings yet

- CRM of HardeesDocument6 pagesCRM of Hardeeshamza_butt88No ratings yet

- Flavia CymbalistaDocument3 pagesFlavia Cymbalistadodona7772494No ratings yet

- Analyzing Risks and Controls in Information SystemsDocument42 pagesAnalyzing Risks and Controls in Information SystemsHongNo ratings yet

- Entrepreneurship by Hisrich, Shepherd, Peters Chapter 1 MCQs and QuestionsDocument6 pagesEntrepreneurship by Hisrich, Shepherd, Peters Chapter 1 MCQs and QuestionsTooba100% (5)

- Sample of Application Letter and CVDocument4 pagesSample of Application Letter and CVSaleh Al ArifinNo ratings yet

- Auditing bank reconciliation proceduresDocument2 pagesAuditing bank reconciliation procedureshsjhsNo ratings yet

- Fundamental RulesDocument18 pagesFundamental RulesrakeshNo ratings yet

- Finance Class 04 - New With TestDocument23 pagesFinance Class 04 - New With TestMM Fakhrul IslamNo ratings yet

- Ryan M Scharetg TMobile BillDocument3 pagesRyan M Scharetg TMobile BillJonathan Seagull LivingstonNo ratings yet