Professional Documents

Culture Documents

Chuong2 Vatlieu Polymer

Uploaded by

hien3sphhCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Chuong2 Vatlieu Polymer

Uploaded by

hien3sphhCopyright:

Available Formats

9/27/2012

KHOA CNG NGH

B MN K THUT C KH

BI GING

CHNG 2

CNG NGH CH TO

VT LIU POLYMER (NHA)

KHUN MU

Tin s Nguyn Vn Cng

nvcuong@ctu.edu.vn

CHNG 2: VT LIU POLYMER

2.1. PHN LOI VT LIU K THUT

VT LIU K THUT

NI DUNG

2.1. PHN LOI VT LIU K THUT

KIM LOI

2.2. POLYMER

2.2.1. KHI NIM V POLYMER

Cha st

2.2.2. LCH S PHT TRIN POLYMER

- Thp (iron)

- Gang (cast iron)

2.2.3. U NHC IM CA POLYMER

Khng cha st

2.2.4. NG DNG CA POLYMER

- Al, Mg, Cu, Ti,

Ni, Zn, etc.

- Cc hp kim.

Kim loi qu

2.3. CHT DO

2.3.1. KHI NIM PHN LOI CHT DO

2.3.2. NG DNG

2.3.3. NHN BIT CHT DO

2.3.4. CHN VT LIU NHA

2.4. MT S LOI NHA THNG DNG

2.1. PHN LOI VT LIU K THUT

- Thp (iron)

- Gang (cast

iron)

Hp kim c bit

POLYMERS

Nhit do

(thermoplastic)

- Nylons

- Polystyrene

- Polypropylene

- etc.

Nhit rn (thermoset)

- Epoxy, polyesters.

- Cc hp kim.

n hi (Elastomer)

- Cao su lu ha

CERAMICS

Truyn thng

- t st (Clays)

- Thch anh (Silica)

- Khong cht

(Feldspar)

Cao

- Oxydes, Nitrides,

Carbides,

Ferrides,

Titanates.

HN HP

Composites

Electronics

Magnetic

Construction

Thy tinh

2.1. PHN LOI VT LIU K THUT

POLYMERS

KIM LOI

c: cha st v khng cha st

T nhin: protein, polysacarides, gum resin, cao su

Rn: cha st v khng cha st

thin nhin, cotton, protein ng vt, g, etc.

Cht n hi

Tng hp:

c tnh la chn: Tnh bn (nn, ct, un, etc.), modun n

hi, gin, gii hn ko nn, mt , tnh dn nhit, dn in,

h s dn nhit v in.

1. Cht do: cht nha nhit do (thermoplastic), nha

nhit rn (thermo setting).

2. Vt liu n hi.

9/27/2012

2.1. PHN LOI VT LIU K THUT

2.1. PHN LOI VT LIU K THUT

COMPOSITES

GM (CERAMICS)

L loi vt liu tng hp c t hai hay nhiu vt liu ha

hc khc nhau, hai yu t cu thnh composite l si gia c

v matrix.

Cng, bn nhit cao, chu mi mn tt, cch

in v nhit tt.

C tnh kim loi v phi kim loi

Si gia c: l thy tinh, graphite, aramids, borons hoc cc

cht khc.

S dng chng mi mn, trong xy dng, thy

tinh, chu la, trong cc ngnh k thut nh t,

hng khng, in t, ch to my, y khoa, ...

Matrix: l nha nhit rn (epoxy, polyester, phenolics, etc.),

nha nhit do (polysulfon, polyetherimide, etc.), kim loi, gm

v carbon.

7

2.1. PHN LOI VT LIU K THUT

2.2. POLYMER

2.2.1. KHI NIM POLYMER

SO SNH CC C TNH C HC CA VT LIU K THUT

Polymer l g? What is polymer?

2.2. POLYMER

10

2.2. POLYMER

2.2.1. KHI NIM POLYMER

2.2.1. KHI NIM POLYMER

Polymer l g? What is polymer?

LDPE Low Density PolyEthylene

Polymer c ngun gc t Hy Lp, c ngha l gm nhiu units. Polymer c

ngha l l phn t c lp li nhiu ln t cc n phn t (monomer)

nh lin kt cng ha tr, s cc monomer c th ln n hng ngn thm

ch hng triu, kt qu to ra cht cao phn t.

Polymer bao gm cht do v cao su (plastics v rubber), cc phn t ca

chng c mch di.

Polymer thng bao gm carbon, oxygen v hydrogen, ngoi ra cn c Si,

F, Cl, S. Polymer ch gm c carbon v hydrogen l cht hu c.

11

12

9/27/2012

2.2. POLYMER

2.2. POLYMER

2.2.1. KHI NIM POLYMER

2.2.1. KHI NIM POLYMER

Nha PE PolyEthylene

Nha PE PolyEthylene

13

2.2. POLYMER

14

2.2. POLYMER

2.2.1. KHI NIM POLYMER

2.2.1. KHI NIM POLYMER

15

2.2. POLYMER

16

2.2. POLYMER

2.2.1. KHI NIM POLYMER

2.2.1. KHI NIM POLYMER

17

18

9/27/2012

2.2. POLYMER

2.2. POLYMER

2.2.2. LCH S PHT TRIN CA POLYMER

2.2.1. KHI NIM POLYMER

19

1838 Bn quyn u tin v phn ng trng hp

c vit thnh sch bi Victor Regnault (Php).

1839 Charles Goodyear (ngi M) pht minh

bin php x l ha rn ca cao su thin nhin,

ng gi l qu trnh lu ha.

1860s J.W. Hyatt (ngi M) pht minh ra celluloid

-mt loi cht do. Qu bng bida c ch to t cht do ny

thay cho ng voi.

1899 Arthur Smith (Anh) s dng bn quyn v nha phenolformaldehyde

to ra vt liu cch in.

1910 Leo Baekeland (B) thng mi ha nha tng hp Bakelite.

1920s phn ng trng ha thnh cng trong cng nghip.

1930s thng mi ha PVC, PE mt thp, PS, PMMA.

1939 DuPont W.H. Carothers to ra sn phm Nylon 6/6 thng mi.

1945 1970: thng mi ha nhiu loi polymer, pht trin nhiu thit b, si tng

hp c s dng.

1970 nay: cht do c si gia c (composite) dn thay th cc vt truyn thng, 20

cht do k thut c pht trin.

2.2. POLYMER

2.2. POLYMER

2.2.3. U - NHC IM CA POLYMER

2.2.3. U - NHC IM CA POLYMER

NHC IM

U IM

C th to sn phm sc nt m khng cn nguyn cng tinh, c th to

c hnh dng phc tp mt cch d dng,

C bn, cng thp hn kim loi, modun n hi thp

Mt thp hn kim loi hoc gm, tnh dn nhit v dn in km (thp

hn 3 ln so vi kim loi),

H s gin n nhit cao (gp 5 ln so vi kim loi, 10 ln so vi gm),

Trng lng ring nh: polymer ~ 1.2 (gm ~ 2.5, kim loi ~ 7.0),

Nhit nng chy thp, nhit dung ring ln gp 2 v 4 ln so vi kim loi

v gm,

Chu n mn v ha cht, c dng rng ri trong vt liu composite,

C tnh cht vt tri so vi kim loi: gim ting n, kh nng to mu d

dng, trong sut cao,

Phm vi s dng nhit thp

n nh kch thc theo thi gian km

D bc chy

Kh sa cha

C tnh c hi nguy him (mi hoc khi trong qu trnh hnh thnh sn

phm)

Ht m

Mt s polymer c th b phn hy di nh nng mt tri hoc tia bc x.

Gi thnh tng i thp.

21

2.2. POLYMER

22

2.2. POLYMER

2.2.4. NG DNG CA POLYMER

2.2.4. NG DNG CA POLYMER

Polymer ng dng trong

Polymer ng dng u? Gm nhng sn phm g?

Trao i cng nhm 2 3 ngi, thi gian 2 + 3 pht.

23

24

9/27/2012

2.3. CHT DO

2.3. CHT DO

2.3.1. KHI NIM PHN LOI CHT DO

2.3.1. KHI NIM PHN LOI CHT DO

Phn loi theo cu trc mch phn t ca cht do

Phn loi theo cu trc ha hc ca cht do

25

26

2.3. CHT DO

2.3. CHT DO

2.3.1. KHI NIM PHN LOI CHT DO

2.3.1. KHI NIM PHN LOI CHT DO

Cu trc mch ca polymer khi gia nhit

Phn loi theo cu trc mch phn t ca cht do

27

28

2.3. CHT DO

2.3. CHT DO

2.3.1. KHI NIM PHN LOI CHT DO

2.3.1. KHI NIM PHN LOI CHT DO

Nha lm hng tiu dng v cc chi tit mi mn thp:

Nha k thut: chu mi mn, chng va p, bn chc

PP PolyPropylene

PC PolyCarbonate

PS PolyStyrene (trong sut, dai, bn cao, chu va p, chu

nhit, d gia cng, d pha mu. L tng SX hp

cassette, video, v CD, v TV, t lnh,)

PA PolyAmide (Nylon) [PA6: Nylon 6, PA6,6: Nylon 6,6]: dng

trong cng nghip t v in t.

ABS Styrene Co-Polymers

PE PolyEthylene

PPO PolyPhenylene Oxide

LDPE Low Density PolyEthylene

HDPE High Density PolyEthylene

PVC PolyVinyl Chlorid

29

30

9/27/2012

2.3. CHT DO

2.3. CHT DO

2.3.1. KHI NIM PHN LOI CHT DO

2.3.1. KHI NIM PHN LOI CHT DO

Cu trc ha hc ca polymer bn tinh th

Cht nhit do n hi (Elastomer thermoplastic): dng

trong cng nghip v gia dng.

TPU PolyUrethanes

SBS Styrene Butadiene Sityrene

31

2.3. CHT DO

32

2.3. CHT DO

2.3.2. NG DNG CHT DO

2.3.2. NG DNG CHT DO

33

2.3. CHT DO

34

2.3. CHT DO

2.3.2. NG DNG CHT DO

2.3.2. NG DNG CHT DO

35

36

9/27/2012

2.3. CHT DO

2.3. CHT DO

2.3.2. NG DNG CHT DO

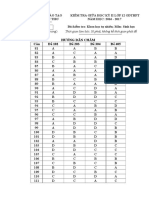

2.3.3. NHN BIT CC CHT DO

Ch : Cc sn phm lm t PVC, thc cht lm t hn hp:

Phng php th nung nng

a.

b.

1. Nha PVC

Cht nhit do s tr nn mm trc khi t 200C

Cht do t nhit s si bt v bt u ra nt trc khi mm ra

2. Cht n nh

TT

Nha

Mm ra?

Bt la

Mu la

Chy tip?

Khi

Mi

Du hiu khc

3. Cht do ha

ABS

Vng b hng

B hng

Hng

Mi gn ging

cao su

4. Ph gia bn va p

PA

Khng

Kh

Xanh l, nh vng

Khng

Si bt khi bt

la

PP

Vng, xanh l y

Du nng

Mm nhit

cao

PVC

Kh

Vng, xanh lc y

Khng

Trng

Hng

D hn gn

PS

Da cam

B hng

Du

Khi bn

PF

Khng

Kh

Vng

Khng

Kht

La si

5. Mu pha

6. Cht hp th UV

7. Cht chng khi, chng chy,

37

38

2.3. CHT DO

2.3. CHT DO

Nhit gia cng ca vt liu nhit do

TT

Nha Tn y

Nhit gia cng ca cht do nhit rn

Nhit khun (C)

Nhit cui piston-vit (C)

PP

Polypropylene

10 80

220 235

TT

Nhit khun (C)

Nhit cui piston-vit (C)

PS

Polystyrene

10 75

200 280

Nha Tn y

PF

Phenolic resins GP

170 190

60 80

ABS

Styrene co-polymers

10 80

220 270

MF

Melamine resins GP

150 165

70 80

PVC

Polyvinyle chloride

20 60

170 200

PMMA

Polymethyl Metacrilate

30 70

190 240

MPF

Melamine phenolic

160 180

60 80

PA6

Polyamide (nylon 6)

50 80

250 280

UP

Polyester resins

150 170

40 60

PA6,6

Polyamide (nylon 6,6)

50 80

250 280

FP

Epoxy resins

160 170

70

PPO

Polyphenylene oxide

40 80

300 330

PC

PolyCarbonate

70 115

300 350

10

POM

60 90

190 210

11

Poly Acetatic resins

Elastomer

(nha n hi cao su)

T lu ha

75 110

12

LDPE

Low density polyethylene

50 70

160 260

13

HDPE

High density polyethylene

30 70

75 110

39

40

2.3. CHT DO

2.3. CHT DO

co ca mt s vt liu do

Sn phm nha nhit do s b ph hy, ra nt nu gp nhit cao

TT

Nha

TT

Nha

co (%)

Mt (g/cm3)

TT

Nha

co (%)

Mt (g/cm3)

PS

0,3 0,6

1,05

10

PPO

0,5 0,7

1,06

ABS

0,4 0,7

1,06

11

PC

0,8

1,2

LDPE

1,5 5,0

0,954

12

PA6

0,5 2,2

1,14

HDPE

1,5 3,0

0,92

13

PA6,6

0,5 2,5

1,15

PP

1,0 2,5

1,15

14

PF

1,2

1,4

PVC

mm

> 0,5

1,38

15

MF

1,2 2,0

1,5

PVC

cng

0,5

1,38

16

MPF

0,8 1,8

1,6

PMMA

0,1 0,8

1,18

17

UP

0,5 0,8

2,0 2,1

POM

1,9 2,3

1,42

18

EP

0,2

1,9

Nhit ph hy (C)

ABS

310

PA6,6

320 330

PS

250

PP

280

PVC

180 220

41

42

9/27/2012

2.3. CHT DO

2.3. CHT DO

2.3.4. Chn vt liu nha

Chiu dy thnh sn phm nha nhit do

Cho bit nn chn vt liu nha c tnh cht nh th no?

Nha

Chiu dy min

(mm)

PA

0,38

1,6

PC

1,0

2,4

9,5

LDPE

0,5

1,6

6,4

HDPE

0,9

1,6

6,4

PP

0,63

2,0

7,6

PS

0,76

1,6

6,4

PVC

1,0

2,4

9,5

TT

Chiu dy trung bnh

(mm)

Chiu dy max

(mm)

3,2

43

2.4. MT S LOI NHA THNG DNG

45

44

2.4. MT S LOI NHA THNG DNG

46

HT CHNG 2

47

You might also like

- Chuyen de 7 Dai Cuong Kim LoaiDocument40 pagesChuyen de 7 Dai Cuong Kim Loaihien3sphhNo ratings yet

- On Tap HKI Hoa 10tu LuanDocument8 pagesOn Tap HKI Hoa 10tu Luanhien3sphhNo ratings yet

- Chuyen de Ly Thuyet Va Bai Tap Dai Cuong Kim LoaiDocument14 pagesChuyen de Ly Thuyet Va Bai Tap Dai Cuong Kim Loaihien3sphhNo ratings yet

- Kim Lo IDocument24 pagesKim Lo Ivianhconyeu7124119No ratings yet

- NgtoDocument3 pagesNgtoNguyen ThangNo ratings yet

- DAI CUONG HOA HUU CO Ly Thuyettrac Nghiem Co Dap AnDocument13 pagesDAI CUONG HOA HUU CO Ly Thuyettrac Nghiem Co Dap Anhien3sphhNo ratings yet

- Cac Dang Bai Tap Chuong 5 Dai Cuong Kim LoaiPhuyquangDocument16 pagesCac Dang Bai Tap Chuong 5 Dai Cuong Kim LoaiPhuyquanghien3sphhNo ratings yet

- Chuyen de Dai Cuong Kim Loai Phan LoaiDocument22 pagesChuyen de Dai Cuong Kim Loai Phan Loaihien3sphhNo ratings yet

- Trac Nghiem Chuong Dai Cuong Kim LoaiDocument10 pagesTrac Nghiem Chuong Dai Cuong Kim LoaingngtrongNo ratings yet

- Dap An Bai Tap Trac Nghiem Ve Hidrocacbon NoDocument5 pagesDap An Bai Tap Trac Nghiem Ve Hidrocacbon NorainbowsujuNo ratings yet

- Chuyen de DAI CUONG KIM LOAI Co Dap AnDocument7 pagesChuyen de DAI CUONG KIM LOAI Co Dap Anhien3sphhNo ratings yet

- Bia Ga Hoa 11 Tang TietDocument1 pageBia Ga Hoa 11 Tang Tiethien3sphhNo ratings yet

- Ly Thuyet Va Bai Tap Dai Cuong KIM LOAI LTDHDocument17 pagesLy Thuyet Va Bai Tap Dai Cuong KIM LOAI LTDHhien3sphhNo ratings yet

- Dap An Bai Tap Trac Nghiem Ve Hidrocacbon NoDocument17 pagesDap An Bai Tap Trac Nghiem Ve Hidrocacbon Nohien3sphhNo ratings yet

- Luyen Tap Phan Ung Oxi Hoa KhuDocument3 pagesLuyen Tap Phan Ung Oxi Hoa Khuhien3sphhNo ratings yet

- Trac Nghiem Cau Tao Nguyen Tu Hay Co Dap AnDocument8 pagesTrac Nghiem Cau Tao Nguyen Tu Hay Co Dap Anhien3sphh100% (1)

- Bai Tap Hoa 12 Day Du Cac ChuongDocument69 pagesBai Tap Hoa 12 Day Du Cac Chuonghien3sphhNo ratings yet

- Phan Loai Bai Tap Chuong 2 Hoa Hoc 10Document12 pagesPhan Loai Bai Tap Chuong 2 Hoa Hoc 10hien3sphhNo ratings yet

- HDC KHTN Sinh THPT - Chinh ThucDocument2 pagesHDC KHTN Sinh THPT - Chinh Thuchien3sphhNo ratings yet

- Dai Cuong Ve Kim Loai Rat HayDocument34 pagesDai Cuong Ve Kim Loai Rat HayVandai MaiNo ratings yet

- Bài tập hóa lýDocument60 pagesBài tập hóa lýJoshep Petrus Copper50% (2)

- Bia Ga Hoa 10Document1 pageBia Ga Hoa 10hien3sphhNo ratings yet

- BÀI TẬP KIM LOẠI KIỀM - KIỀM THỔ - NHÔMDocument37 pagesBÀI TẬP KIM LOẠI KIỀM - KIỀM THỔ - NHÔMTạp Chí Hóa Học - www.hoahoc.org100% (3)

- ĐỀ CƯƠNG ÔN TẬP GIỮA HKII 2016Document18 pagesĐỀ CƯƠNG ÔN TẬP GIỮA HKII 2016hien3sphhNo ratings yet

- Dai Cuong Kim LoaiCo Dap AnDocument19 pagesDai Cuong Kim LoaiCo Dap AnPhạm Đình VũNo ratings yet

- Gửi - nhập điểm giữa HKII - K12 - 2016-2017Document24 pagesGửi - nhập điểm giữa HKII - K12 - 2016-2017hien3sphhNo ratings yet

- HDC KHTN Ly12 PT Giuahk2-1617Document1 pageHDC KHTN Ly12 PT Giuahk2-1617hien3sphhNo ratings yet

- Cac Dang Bai Tap Ve Kim Loai Kiem Kiem Tho Va NhomDocument8 pagesCac Dang Bai Tap Ve Kim Loai Kiem Kiem Tho Va Nhomhien3sphhNo ratings yet

- Chuong 6kloai Kiemkiem Tho NhomDocument10 pagesChuong 6kloai Kiemkiem Tho Nhomhien3sphhNo ratings yet

- BÀI TẬP KIM LOẠI KIỀM - KIỀM THỔ - NHÔMDocument37 pagesBÀI TẬP KIM LOẠI KIỀM - KIỀM THỔ - NHÔMTạp Chí Hóa Học - www.hoahoc.org100% (3)