Professional Documents

Culture Documents

23 Power Quality

Uploaded by

nambaccucCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

23 Power Quality

Uploaded by

nambaccucCopyright:

Available Formats

Chap23 exe

20/06/02

16:21

Page 410

23

Power Quality

Introduction

23.1

Power Quality classification

23.2

Causes and impact of Power

Quality problems

23.3

Power Quality monitoring

23.4

Remedial measures

23.5

Examples

23.6

Chap23 exe

20/06/02

16:21

Page 411

23 Power Quality

23.1 INTRODUCTION

Over the last thirty years or so, the amount of equipment

containing electronics has increased dramatically. Such

equipment can both cause and be affected by

electromagnetic disturbances. A disturbance that

affects a process control computer in a large industrial

complex could easily result in shutdown of the process.

The lost production and product loss/recycling during

start-up represents a large cost to the business.

Similarly, a protection relay affected by a disturbance

through conduction or radiation from nearby conductors

could trip a feeder or substation, causing loss of supply

to a large number of consumers. At the other end of the

scale, a domestic user of a PC has to re-boot the PC due

to a transient voltage dip, causing annoyance to that

and other similarly affected users.

Therefore,

transporters and users of electrical energy have become

much more interested in the nature and frequency of

disturbances in the power supply. The topic has become

known by the title of Power Quality.

23.2 CLASSIFICATION OF POWER SYSTEM

DISTURBANCES

To make the study of Power Quality problems useful, the

various types of disturbances need to be classified by

magnitude and duration. This is especially important for

manufacturers and users of equipment that may be at

risk. Manufacturers need to know what is expected of

their equipment, and users, through monitoring, can

determine if an equipment malfunction is due to a

disturbance or problems within the equipment itself.

Not surprisingly, standards have been introduced to

cover this field. They define the types and sizes of

disturbance, and the tolerance of various types of

equipment to the possible disturbances that may be

encountered.

The principal standards in this field are IEC 61000, EN

50160, and IEEE 1159. Standards are essential for

manufacturers and users alike, to define what is

Network Protection & Automation Guide

411

Chap23 exe

20/06/02

16:21

Page 412

reasonable in terms of disturbances that might occur and

what equipment should withstand.

Table 23.2 lists the limits given in Standard EN 50160

and notes where other standards have similar limits.

Table 23.1 provides a broad classification of the

disturbances that may occur on a power system, some

typical causes of them and the potential impact on

equipment. From this Table, it will be evident that the

electricity supply waveform, often thought of as

composed of pure sinusoidal quantities, can suffer a wide

variety of disturbances. The following sections of this

Chapter describe the causes in more detail, along with

methods of measurement and possible remedial

measures.

Causes

Voltage dips

Local and remote faults

Inductive loading

Switch on of large loads

Power Quality

Voltage surges

23

Capacitor switching

Switch off of large loads

Phase faults

Short

Interruptions

Long

Interruptions

Transient

Overvoltage

Voltage

unbalance

Undervoltage

Impacts

Tripping of sensitive

equipment

Resetting of control

systems

Motor stalling/tripping

Tripping of sensitive

equipment

Damage to insulation

and windings

Damage to power

supplies for electronic

equipment

Overvoltage

Load switching

Capacitor switching

System voltage regulation

Problems with equipment

that requires constant

steady-state voltage

Harmonics

Industrial furnaces

Non-linear loads

Transformers/generators

Rectifier equipment

Mal-operation of sensitive

equipment and relays

Capacitor fuse or

capacitor failures

Telephone interference

Loss of generation

Extreme loading

conditions

Negligible most of time

Motors run slower

De-tuning of harmonic

filters

Voltage

fluctuation

AC motor drives

Inter-harmonic current

components

Welding and arc furnaces

Flicker in:

Fluorescent lamps

Incandescent lamps

Rapid voltage

change

Motor starting

Transformer tap

changing

Light flicker

Tripping of

equipment

Voltage

imbalance

Unbalanced loads

Unbalanced

impedances

Overheating in

motors/generators

Interruption of 3-phase

operation

Short and long

voltage

interruptions

Power system faults

Equipment failures

Control malfunctions

CB tripping

Loss of supply

to customer equipment

Computer shutdowns

Motor tripping

Undervoltage

Heavy network loading

Loss of generation

Poor power factor

Lack of var support

All equipment

without backup

supply facilities

Transients

Lightning

Capacitive switching

Non linear switching loads

System voltage regulation

Control system resetting

Damage to sensitive

electronic components

Damage to insulation

Power frequency

variation

Rapid voltage

changes

Voltage surge

Voltage

fluctuations

Frequency

variation

Harmonics

Limits from

EN50160

+/- 10%

230V

5% to 10%

1kV-35kV

<6%

230V

>99%

230V

>99%

230V

Generally

<6kV

Measurement

Typical Other applicable

period

duration

standards

95% of

1 week

10-1000/year 10ms 1sec

IEEE 1159

Several

Short

per day

duration

Short

Per day

IEEE 1159

duration

20-200

Up to 3 mins EN61000-4-11

per year

10-50

>3 mins

IEEE 1159

per year

Not specified

<1ms

IEEE 1159

<-10%

Not specified

<150%

of

230V nominal voltage Not specified

>1 min

IEEE 1159

>200ms

IEEE 1159

230V

<200ms

IEC 60827

230V

230V

3%

10 min

+/- 1%

+4%, -6%

THD<8% up

to 40th

95% of 1 week Not specified Measured over 10s

100% of 1 week Not specified Measured over 10s

95% of

Not specified

1 week

Table 23.2: Power system disturbance

classification to EN 50160

For computer equipment, a common standard that

manufacturers use is the ITI (Information Technology

Industry) curve, illustrated in Figure 23.1. Voltage

disturbances that lie in the area indicated as safe

should not cause a malfunction in any way.

However, some disturbances at LV levels that lie within

the boundaries defined by EN50160 might cause a

malfunction because they do not lie in the safe area of

the ITI curve. It may be necessary to check carefully

which standards are applicable when considering

equipment susceptibility.

Percentage of nominal voltage (r.m.s.)

Category

Type of

Voltage

disturbance Level

Voltage

230V

Variation

Voltage Dips 230V

500

450

400

350

300

250

200

Affected by disturbance

Withstand

disturbance

150

100

50

0

0.001 0.01 0.1

Affected by disturbance

1

10

100 1000 10000 100000

Duration of disturbance (ms)

Figure 23.1: ITI curve for equipment

susceptibility

Table 23.1: Power Quality issues

412

Network Protection & Automation Guide

Page 413

23.3 CAUSES AND IMPACT OF POWER

QUALITY PROBLEMS

Each of the Power Quality disturbance categories

detailed in Table 23.1 is now examined in more detail as

to the possible causes and the impact on consumers.

23.3.1 Voltage Dips

Figure 23.2 shows the profile of a voltage dip, together

with the associated definitions. The major cause of

voltage dips on a supply system is a fault on the system,

that is sufficiently remote electrically that a voltage

interruption does not occur. Other sources are the starting

of large loads (especially common in industrial systems),

and, occasionally, the supply of large inductive loads.

insulator flashover, collisions due to birds, and

excavations damaging cables. Multiple voltage dips, as

illustrated in Figure 23.3, cause more problems for

equipment than a single isolated dip.

The impact on consumers may range from the annoying

(non-periodic light flicker) to the serious (tripping of

sensitive loads and stalling of motors). Where repeated

dips occur over a period of several hours, the repeated

shutdowns of equipment can give rise to serious

production problems. Figure 23.4 shows an actual

voltage dip, as captured by a Power Quality recorder.

100

80

60

40

20

0

-20

-40

-60

-80

-100

Vrms

Nom. High

PQ Standards

Figure 23.4: Recording of a voltage dip

User defined setpoints

Retained voltage

61-70%

0-10%

81-90%

41-50%

91-100%

51-60%

Number of undervoltage disturbances recorded

Vrms

Nom. High

Nom. Low

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

0

<0.5ms

PQ Standards

User defined setpoints

Retained Voltage

Duration of disturbance

Interruption

91-100%

71-80%

51-60%

31-40%

11-20%

Retained voltage

Time

Figure 23.5: Undervoltage disturbance histogram

Figure 23.3: Multiple voltage dip

Other network-related fault causes are weatherrelated

(such as snow, ice, wind, salt spray, dust) causing

Network Protection & Automation Guide

Power Quality

Voltage dips due to the latter are usually due to poor design

of the network feeding the consumer. A voltage dip is the

most common supply disturbance causing interruption of

production in an industrial plant. Faults on a supply

network will always occur, and in industrial systems, it is

often practice to specify equipment to ride-through

voltage dips of up to 0.2s. The most common exception is

contactors, which may well drop out if the voltage dips

below 80% of rated voltage for more than 50-100ms.

Motor protection relays that have an undervoltage element

setting that is too sensitive is another cause. Since

contactors are commonly used in circuits supplying motors,

the impact of voltage dips on motor drives, and hence the

process concerned, requires consideration.

>10s

Figure 23.2: Voltage dip profile

Typical data for undervoltage disturbances on power

systems during evolving faults are shown in Figure 23.5.

Disturbances that lie in the front right-hand portion of

the histogram are the ones that cause most problems,

but fortunately these are quite rare.

1-5s

5-10s

Time

0.5-1s

Retained Voltage

Number of incidents/yr

Interruption

100-500ms

Nom. Low

x % below nominal

o a

Time

10-50ms

50-100ms

16:21

1-5ms

5-10ms

20/06/02

0.5-1ms

Chap23 exe

23.3.2 Voltage Surges/Spikes

Voltage surges/spikes are the opposite of dips a rise

413

23

Chap23 exe

20/06/02

16:21

Page 414

that may be nearly instantaneous (spike) or takes place

over a longer duration (surge). These are most often

caused by lightning strikes and arcing during switching

operations on circuit breakers/contactors (fault

clearance, circuit switching, especially switch-off of

inductive loads). Figure 23.6 shows the profile of a

voltage surge.

are sufficiently high enough, protective devices may shut

the equipment down to avoid damage. Some equipment,

such as certain protection devices, may maloperate and

cause unnecessary shutdowns.

150

100

50

Vrms

Nom. High

User defined setpoints

Time

-50

Nom. Low

PQ Standards

-100

-150

Figure 23.7: Supply waveform distorted

due to the presence of harmonics

Interruption

Equipment may suffer serious damage from these causes,

ranging from insulation damage to destruction of

sensitive electronic devices. The damage may be

immediate and obvious by the fact that equipment stops

working, through to failure at a much later date from

deterioration initiated from a surge or spike of voltage.

These latter failures are very difficult to distinguish from

random failures due to age, minor manufacturing

defects, etc.

Special provision may have to be made to filter

harmonics from the measured signals in these

circumstances.

Interference may be caused to

communication systems.

Overloading of neutral

conductors in LV systems has also occurred (the

harmonics in each phase summing in the neutral

conductor, not cancelling) leading to failure due to

overheating. This is a particular risk in buildings that

have a large number of PCs, etc., and in such cases a

neutral conductor rated at up to 150% of the phase

conductors has been known to be required. Busbar risers

in buildings are also at risk, due to harmonic-induced

vibration causing joint securing bolts, etc. to work loose.

23.3.3 Overvoltages

23.3.5 Frequency Variations

Sustained overvoltages are not common. The most likely

causes are maladjusted voltage regulators on generators

or on-load tap changers, or incorrectly set taps on fixedtap transformers. Equipment failures may immediately

result in the case of severe overvoltages, but more likely

is accelerated degradation leading to premature failure

without obvious cause. Some equipment that is

particularly sensitive to overvoltages may have to be

shut down by protective devices.

Frequency variations that are large enough to cause

problems are most often encountered in small isolated

networks, due to faulty or maladjusted governors. Other

causes are serious overloads on a network, or governor

failures, though on an interconnected network, a single

governor failure will not cause widespread disturbances

of this nature. Network overloads are most common in

areas with a developing electrical infrastructure, where a

reduction in frequency may be a deliberate policy to

alleviate overloading. Serious network faults leading to

islanding of part of an interconnected network can also

lead to frequency problems.

Time

Power Quality

Figure 23.6: Voltage surge profile

23

23.3.4 Harmonics

This is a very common problem in the field of Power

Quality. The main causes are Power Electronic Devices,

such as rectifiers, inverters, UPS systems, static var

compensators, etc. Other sources are electric discharge

lamps, arc furnaces and arc welders. In fact, any nonlinear load will be a source of harmonics. Figure 23.7

illustrates a supply waveform that is distorted due to the

presence of harmonics. Harmonics usually lead to

heating in rotating equipment (generators and motors),

and transformers, leading to possible shutdown.

Capacitors may be similarly affected. If harmonic levels

Few problems are normally caused by this problem.

Processes where product quality depends on motor speed

control may be at risk but such processes will normally

have closed-loop speed controllers. Motor drives will

suffer output changes, but process control mechanisms

will normally take care of this.

Extreme under- or overfrequency may require the

tripping of generators, leading to the possibility of

progressive network collapse through network

overloading/underfrequency causes.

414

Network Protection & Automation Guide

20/06/02

16:21

Page 415

23.3.6 Voltage Fluctuations

23.3.9 Undervoltage

These are mainly caused by load variations, especially

large rapid ones such as are likely to occur in arc and

induction heating furnaces, rolling mills, mine winders,

and resistance welders.

Excessive network loading, loss of generation, incorrectly

set transformer taps and voltage regulator malfunctions,

cause undervoltage. Loads with a poor power factor (see

Chapter 18 for Power Factor Correction) or a general lack

of reactive power support on a network also contribute.

The location of power factor correction devices is often

important, incorrect location resulting in little or no

improvement.

Flicker in incandescent lamps is the most usual effect of

voltage fluctuations. It is a serious problem, with the

human eye being particularly sensitive to light flicker in

the frequency range of 5-15Hz. Because of the wide use

of such lamps, the effects are widespread and inevitably

give rise to a large number of complaints. Fluorescent

lamps are also affected, though to a lesser extent.

23.3.7 Voltage Unbalance

Unbalanced loading of the network normally causes

voltage unbalance. However, parts of the supply network

with unbalanced impedances (such as untransposed

overhead transmission lines) will also cause voltage

unbalance, though the effect of this is normally small.

Overheating of rotating equipment results from voltage

unbalance. In serious cases, tripping of the equipment

occurs to protect it from damage, leading to

generation/load imbalance or loss of production.

23.3.8 Supply Interruptions

Faults on the power system are the most common cause,

irrespective of duration. Other causes are failures in

equipment, and control and protection malfunctions.

Electrical equipment ceases to function under such

conditions, with undervoltage protection devices leading

to tripping of some loads.

Short interruptions may be no more than an

inconvenience to some consumers (e.g. domestic

consumers), but for commercial and industrial

consumers (e.g. semiconductor manufacture) may lead

to lengthy serious production losses with large financial

impact. Longer interruptions will cause production loss

in most industries, as induction and synchronous motors

cannot tolerate more than 1-2 seconds interruption

without having to be tripped, if only to prevent excessive

current surges and resulting large voltage dips on supply

restoration.

On the other hand, vital computer systems are often fed

via a UPS supply that may be capable of supplying power

from batteries for several hours in the event of a mains

supply failure. More modern devices such as Dynamic

Voltage Restorers can also be used to provide continuity

of supply due to a supply interruption. For interruptions

lasting some time, a standby generator can be provide a

limited supply to essential loads, but cannot be started in

time to prevent an interruption occurring.

Network Protection & Automation Guide

The symptoms of undervoltage problems are tripping of

equipment through undervoltage trips. Lighting will run

at reduced output. Undervoltage can also indirectly lead

to overloading problems as equipment takes an increased

current to maintain power output (e.g. motor loads).

Such loads may then trip on overcurrent or thermal

protection.

23.3.10 Transients

Transients on the supply network are due to faults,

control and protection malfunctions, lightning strikes,

etc.

Voltage-sensitive devices and insulation of electrical

equipment may be damaged, as noted above for

voltage surges/spikes. Control systems may reset.

Semiconductor manufacture can be seriously affected

unless the supplies to critical process plant are suitably

protected.

Power Quality

Chap23 exe

23.4 POWER QUALITY MONITORING

If an installation or network is thought to be suffering

from problems related to Power Quality, suitable

measurements should to be taken to confirm the initial

diagnosis. These measurements will also help quantify

the extent of the problem(s) and provide assistance in

determining the most suitable solutions. Finally, followup measurements after installation will confirm the

effectiveness of the remedial measures taken.

23.4.1 Type of Installation

Monitoring equipment for Power Quality may be suitable

for either temporary or permanent installation on a

supply network. Permanent installation is most likely to

be used by Utilities for routine monitoring of parts of

their networks to ensure that regulatory limits are being

complied with and to monitor general trends in respect

of power quality issues. Consumers with sensitive loads

may also install permanent monitoring devices in order

to monitor Power Quality and provide supporting

evidence in the event of a claim for compensation being

made against the supplier if loss occurs due to a power

quality problem whose source is in the Utility network.

415

23

Chap23 exe

20/06/02

16:21

Page 416

The performance of any devices installed to improve

Power Quality can also be monitored.

Such devices may have a data link to a DCS or data

logger in order to provide historical data recording and

data processing/presentation facilities. They are quite

small and are fitted in a suitable cubicle forming part of

a switchboard line-up. The data link may be hard-wired,

use a modem connection to a telephone line, or in the

case of a utility with many geographically-dispersed

substations, radio links for data transmission may be

used. Internal data storage will be provided to ensure

effective use of the data link. The units may be self- or

auxiliary supply powered, and in the case of important

Utility substations may have battery-backed supplies to

ensure capture of voltage interruptions.

Time

synchronisation may be required to ensure accurate

identification of events.

Power Quality

For investigation of particular problems, a portable

instrument is more suitable. The same range of Power

Quality measurement capabilities is provided as for

permanent instrumentation. The instrument may have

built-in analysis/data storage capabilities, but external

storage in the form of floppy discs or a data link to a

laptop or desktop PC is commonplace. Analysis/report

writing software running on a PC is often available,

which may be more comprehensive than that provide in

the instrument itself.

Figure 23.8 illustrates a Power Quality meter that is

available (MiCOM M720 range).

23.4.2 Connection to the Supply

Connection to the supply being monitored may present

problems. For LV supplies, the voltage inputs are usually

taken directly to the instrument in single-phase or threephase form as required. Monitoring of currents may be

through a current shunt or suitable CT, depending on

circuit rating. At higher voltages, VTs and CTs already

fitted for instrumentation/protection purposes are used.

In general, the conventional electromagnetic voltage or

current transformer is suitable for use without special

considerations being required, but capacitor voltage

transformers often have a low-pass filter on the output

that has the potential to seriously affect readings of

harmonics and transient phenomena. In such cases, the

input to the monitoring device must be taken prior to

filtering, or the filter characteristics must be determined

and the measured signals processed to take account of

the filtering prior to analysis being undertaken. In

addition, the CVT itself may have a non-linear transfer

function with respect to frequency, though the variety of

types of CVT and difficulties of testing make

confirmation of this point virtually impossible at present.

Where harmonics or high-frequency phenomena are

being measured, suitable connecting leads between the

transducers and the measuring instrument are required to

avoid signal distortion. This is especially important if long

cable runs are used; this may be the case if the measuring

instruments are centralised but measurements are being

made at a number of switchboards.

23.4.3 Types of Power Quality Measurements

Instruments for power quality monitoring may not offer

the full range of measurements for all Power Quality

issues. Care is therefore required that the instrument

chosen is suited for the purpose. Most instruments will

provide provide measurements of current and voltage

harmonics, and capture of voltage dips and frequency

excursions (Figure 23.9).

23

Measurements to the commonly encountered standards

may be built-in. For capture of surges, spikes and

interruptions, more specialised instrumentation may be

required as transient high-speed waveform capture is

required. This requires a high sampling rate and large

memory storage.

Figure 23.8: MiCOM M720 Power Quality meter

Most instruments designed for Power Quality use A/D

conversion of the input waveforms. The raw waveform is

stored and either transferred to a computer for analysis,

or the instrument contains built-in software to carry out

analysis of power quality in line with accepted standards.

Often the software will have a choice of standards for

user selection. Figure 23.10 shows the capture of data

and analysis for a period of one week to determine

compliance with EN 50160.

416

Network Protection & Automation Guide

Chap23 exe

20/06/02

16:21

Page 417

More detailed analysis using the same instrument can

show directly how the results compare with this

standard, as shown in Figure 23.11.

To facilitate the interchange of data between locations

and/or users, the public-domain PQDIF data interchange

format for Power Quality may be used and facilities

provided for in the software.

23.4.4 Instrument Location

The location of the measuring instrument also requires

consideration. By careful placement and observing the

relative polarities, it is possible to deduce if the source of

the disturbance is on the source or load side of the

monitoring device.

23.5 REMEDIAL MEASURES

Equipment

UPS

Earthing practices

Filters (Active/Passive)

Energy Storage Devices

Application

Voltage variations

Supply interruptions

Frequency variations

Harmonics

Harmonics

Voltage variations

Supply interruptions

Power Quality

Figure 23.9: Transient voltage

disturbance capture

There are many methods available for correcting Power

Quality problems. The most common are given in Table

23.3. Brief details of each method are given below, but

it is emphasised that the solution adopted will be

tailored specifically to the problem and site.

Table 23.3: Power system disturbance

classification to EN 50160

23.5.1 UPS Systems

Figure 23.10: Data capture for analysis

of data to EN50160

A UPS system consists of the following:

a. an energy storage device normally a battery

b. a rectifier and inverter

c. transfer switches

Figure 23.11: THD analysis to EN50160

Network Protection & Automation Guide

The UPS may be on-line (continuously in operation) or

offline (switched in when a disturbance occurs). The

former eliminates all problems due to voltage

surges/spikes/dips and interruptions (within the capacity

of the storage device) while the latter passes some of the

disturbance through, until the supply is transferred from

the normal source to the UPS. Harmonics originating in

the source may be reduced, but not eliminated in the

load, because the UPS itself is a source of harmonics, as

it contains Power Electronic Devices. Thus it may

increase harmonic distortion on the source side.

417

23

Chap23 exe

20/06/02

16:21

Page 418

Rectifier/

Inverter

Supply

Load

Energy

storage

Figure 23.12: UPS system

The main disadvantages of UPS systems are cost and

efficiency. An on-line UPS incurs continuous losses, while

both types require energy storage devices that can be

expensive. Fast-acting switches to transfer load to the

energy storage device are required for offline devices, while

transfer switches to bypass the rectifier/inverter when

these are undergoing maintenance may also be required.

Figure 23.12 illustrates conceptually both types of UPS.

(voltage source converter) technologies are possible.

Passive filters may take up significant space, depending

on the harmonics being filtered and the connection

voltage. A voltage source converter may be used instead

to provide a reduced footprint. It can filter several

frequencies simultaneously and track changes in the

frequencies of the harmonics as the fundamental

frequency changes. It can be expensive when used solely

as an active filter, but be viable where space is at a

premium. Figure 23.14 shows the concept of an active

harmonic filter. A danger with filters is the possibility of

resonance with part of the power system at some

frequency, giving rise to problems that would not

otherwise occur.

Load

Network

Coupling

inductance

23.5.2 Dynamic Voltage Restorer (DVR)

Energy

storage

system

23

IGBT

power section

DC-link capacitor

Figure 23.14: Active harmonic filter concept

23.5.5 Static Var Compensator (SVC)

D.C.-D.C.

D.C.-D.C.

Modular 3-phase power

electronic inverters

A.C.-D.C.

Disturbance free supply

Disturbed incoming supply

A.C.-D.C.

Power Quality

This is a voltage source converter and energy store,

connected in series (either directly or via an injection

transformer) that controls the voltage downstream

directly by injection of suitable voltage in series with the

source. Ratings of up to several MW are possible at

voltages up to 11kV. Figure 23.13 illustrates the concept.

D.C.-D.C.

Figure 23.13: Dynamic Voltage Restorer concept

23.5.3 Earthing Practices

A site that suffers from problems with harmonics may

need to investigate the earthing of equipment. The high

neutral currents that result can give rise to

overheating/failure of neutral/earth connections, while

high neutral-earth impedances can give rise to commonmode voltage problems.

All neutral and earth

connections need to be checked to ensure they are

adequately sized and have sound joints.

This is a shunt-connected assembly of capacitors, and

possibly reactors, which provides reactive power to a

network during disturbances to minimise them. It is

normally applied to transmission networks to counter

voltage dips/surges during faults and enhance power

transmission capacity on long transmission circuits. The

devices are switched either in discrete steps or made

continuously variable through the use of PEDs. It works

by providing reactive power (leading/lagging as required)

to assist in keeping the voltage at the point of

connection constant. Voltage variations at that point are

reflected in var variations, so provision of reactive power

of appropriate sign can reduce the voltage fluctuations.

The STATCOM is a SVC comprised of a self commutated

static converter and capacitor energy storage. The

switching of the converter is controlled to supply

reactive power of appropriate sign to the network.

23.5.6 Ferro-resonant Transformer

23.5.4 Filters

These are shunt-connected devices used to eliminate

harmonics. Either passive (LC or RLC) networks or active

This is a transformer that is designed to run highly

saturated. Thus, input voltage dips and surges have little

effect on the output voltage. Voltage interruptions of

very short duration result in the magnetic stored energy

418

Network Protection & Automation Guide

Chap23 exe

20/06/02

16:21

Page 419

being used up in maintaining output voltage and current.

The transformer is normally of 1:1 ratio, although taps

may be provided for fine adjustment of output voltage.

Appropriate shielding of the windings enables the impact

of voltage spikes to be reduced. It is used in LV systems,

with a power output of up to a few tens of kVA.

23.6 EXAMPLES

The dips can also be seen using the graphical viewing

facilities of the instrument. Figure 23.16(a) shows the

display of the envelope of the r.m.s. voltage, and Figure

23.16(b), the same data magnified. The number,

magnitude and frequency of the dips can be clearly seen.

A detailed view of one dip shows clearly that the dips are

only just outside the normal supply voltage limits (Figure

23.17).

The following sections show some examples of the

measurement of Power Quality problems, using an

ALSTOM M720 Power Quality meter.

23.6.1 Flicker Detection on a LV network,

using Power Quality Monitoring Instruments

Figure 23.17: Detailed analysis

on a single voltage dip

Using the waveform capture facility, the problem can be

viewed in great detail, as shown in Figure 23.18.

Power Quality

In a network known to have a high incidence of

disturbances, some local industries were identified as the

source of pollution of the electrical network, reducing

the level of Power Quality at LV voltages. Measurements

using a Power Quality meter show many voltage dips to

about 88% of the nominal voltage, as illustrated in

Figure 23.15. The voltage dips were found to occur at

frequencies of up to 8 dips/second.

Figure 23.15: Voltage dip recording

Figure 23.18: Detailed view of

voltage dip waveform

Using this information, and knowledge of the operating

cycle of the industries causing the dip, the particular

equipment responsible for causing the voltage dip can be

identified and remedial measures implemented.

(a)

(b)

Figure 23.16: Graphical view of voltage dip data

Network Protection & Automation Guide

23.6.2 Investigation of Harmonic Pollution

Problems on an Industrial Plant

An industrial plant was suffering Power Quality

problems, and harmonic pollution was suspected as the

cause. A Power Quality meter was installed at various

parts of the network to determine the extent of the

problem and the equipment causing the problem.

Confirmation of the pollution as being due to harmonics

was readily obtained. This can be seen in Figure 23.19,

for the equipment identified as the source of the

disturbance. The graphics enable rapid and clear

identification of the frequency and amount by which the

generated harmonics exceed the permitted limit. A

Power System Analysis of the network was then

419

23

Chap23 exe

20/06/02

16:22

Page 420

conducted to replicate the measured results, and then

used for testing the effectiveness of harmonic filter

designs. The most cost-effective filter design and

location can then be selected for implementation.

Power Quality

Figure 23.19: Harmonic pollution

measurement

23

420

Network Protection & Automation Guide

You might also like

- Protection FundamentalsDocument12 pagesProtection FundamentalsGeorge AsuncionNo ratings yet

- Protection FundamentalsDocument12 pagesProtection FundamentalsGeorge AsuncionNo ratings yet

- 09-Overcurrent ProtectionDocument30 pages09-Overcurrent ProtectionSristick83% (6)

- 21-Relay Testing and CommissioningDocument28 pages21-Relay Testing and CommissioningSristick100% (4)

- 21-Relay Testing and CommissioningDocument28 pages21-Relay Testing and CommissioningSristick100% (4)

- 17-Generator and Generator Transf ProtDocument35 pages17-Generator and Generator Transf ProtSristick100% (7)

- 08-Protection Signalling and TrippingDocument10 pages08-Protection Signalling and TrippingSristick100% (2)

- 08-Protection Signalling and TrippingDocument10 pages08-Protection Signalling and TrippingSristick100% (2)

- 06-Current and VoltageDocument19 pages06-Current and VoltageSristick100% (2)

- 06-Current and VoltageDocument19 pages06-Current and VoltageSristick100% (2)

- 15 Busbar ProtectionDocument21 pages15 Busbar ProtectionSristick100% (8)

- 15 Busbar ProtectionDocument21 pages15 Busbar ProtectionSristick100% (8)

- 13-Protection of Complex TransmissionDocument16 pages13-Protection of Complex TransmissionSristick100% (2)

- 13-Protection of Complex TransmissionDocument16 pages13-Protection of Complex TransmissionSristick100% (2)

- 12-Distance Protection SchemesDocument9 pages12-Distance Protection SchemesSristick100% (1)

- 12-Distance Protection SchemesDocument9 pages12-Distance Protection SchemesSristick100% (1)

- Design of Transient Protection Systems: Including Supercapacitor Based Design Approaches for Surge ProtectorsFrom EverandDesign of Transient Protection Systems: Including Supercapacitor Based Design Approaches for Surge ProtectorsNo ratings yet

- Harajuku: Rebels On The BridgeDocument31 pagesHarajuku: Rebels On The BridgeChristian Perry100% (41)

- 25-Distribution System AutomationDocument12 pages25-Distribution System AutomationSristick100% (3)

- Monitoring and Control of Electrical Power Systems using Machine Learning TechniquesFrom EverandMonitoring and Control of Electrical Power Systems using Machine Learning TechniquesEmilio Barocio EspejoNo ratings yet

- Power AmplifierDocument37 pagesPower AmplifierSristick100% (6)

- Power System Control and ProtectionFrom EverandPower System Control and ProtectionB. Don RussellRating: 4 out of 5 stars4/5 (11)

- 20-Protection of AC Elec RailDocument18 pages20-Protection of AC Elec RailSristick100% (3)

- 20-Protection of AC Elec RailDocument18 pages20-Protection of AC Elec RailSristick100% (3)

- Symmetrical Components: The Commonwealth and International Library: Applied Electricity and Electronics DivisionFrom EverandSymmetrical Components: The Commonwealth and International Library: Applied Electricity and Electronics DivisionRating: 4 out of 5 stars4/5 (2)

- Auto-Transformer Design - A Practical Handbook for Manufacturers, Contractors and WiremenFrom EverandAuto-Transformer Design - A Practical Handbook for Manufacturers, Contractors and WiremenRating: 4 out of 5 stars4/5 (2)

- 24-Substation Control and AutomationDocument20 pages24-Substation Control and AutomationSristick90% (10)

- 24-Substation Control and AutomationDocument20 pages24-Substation Control and AutomationSristick90% (10)

- 14 Auto ReclosingDocument14 pages14 Auto ReclosingSristick100% (6)

- 10 Unit ProtectionDocument18 pages10 Unit ProtectionSristick100% (1)

- 10 Unit ProtectionDocument18 pages10 Unit ProtectionSristick100% (1)

- 19-AC Motor ProtectionDocument16 pages19-AC Motor ProtectionSristick100% (7)

- Voltage Sags.... 2020Document13 pagesVoltage Sags.... 2020Dr Hafiz Mudassir Munir - Assistant ProfessorNo ratings yet

- 11 Distance ProtectionDocument22 pages11 Distance ProtectionSristick100% (1)

- 11 Distance ProtectionDocument22 pages11 Distance ProtectionSristick100% (1)

- Power System Fault Diagnosis: A Wide Area Measurement Based Intelligent ApproachFrom EverandPower System Fault Diagnosis: A Wide Area Measurement Based Intelligent ApproachNo ratings yet

- 18-Industrial and CommercialDocument20 pages18-Industrial and CommercialSristick100% (3)

- UHV Transmission TechnologyFrom EverandUHV Transmission TechnologyChina Electric Power Research InstituteNo ratings yet

- 16-Transformer and Transformer Feeder ProtDocument26 pages16-Transformer and Transformer Feeder ProtSristick100% (4)

- 16-Transformer and Transformer Feeder ProtDocument26 pages16-Transformer and Transformer Feeder ProtSristick100% (4)

- 05 Equivalent CircuitsDocument32 pages05 Equivalent CircuitsSristick100% (1)

- 114 Handy Formulae For Quantitative Aptitude ProblemsDocument12 pages114 Handy Formulae For Quantitative Aptitude ProblemsRaju.Konduru91% (69)

- Case Study No. 11 - Hydroelectric Power Plant in The PhilippinesDocument26 pagesCase Study No. 11 - Hydroelectric Power Plant in The PhilippinespicefeatiNo ratings yet

- Introduction to Power System ProtectionFrom EverandIntroduction to Power System ProtectionRating: 5 out of 5 stars5/5 (1)

- Rules & Guidelines of Elliott WaveDocument12 pagesRules & Guidelines of Elliott WaveNd Reyes100% (2)

- Pyrolysis ProjectDocument122 pagesPyrolysis ProjectSohel Bangi100% (1)

- Chich The ChickenDocument23 pagesChich The ChickenSil100% (4)

- Release emotions with simple questionsDocument10 pagesRelease emotions with simple questionsDubravko ThorNo ratings yet

- Non-Intrusive Condition Assessment of MV SwitchgearDocument4 pagesNon-Intrusive Condition Assessment of MV SwitchgearAries dNo ratings yet

- Transient Phenomena in Electrical Power Systems: International Series of Monographs on Electronics and Instrumentation, Vol. 24From EverandTransient Phenomena in Electrical Power Systems: International Series of Monographs on Electronics and Instrumentation, Vol. 24No ratings yet

- The Technology of Instrument Transformers: Current and Voltage Measurement and Insulation SystemsFrom EverandThe Technology of Instrument Transformers: Current and Voltage Measurement and Insulation SystemsNo ratings yet

- Openstack Deployment Ops Guide PDFDocument197 pagesOpenstack Deployment Ops Guide PDFBinank PatelNo ratings yet

- 07-Relay TechnologyDocument13 pages07-Relay Technologyapi-3769988No ratings yet

- 01 IntroductionDocument1 page01 Introductionapi-3697422No ratings yet

- Article JEEET 2Document8 pagesArticle JEEET 2tariqqureshitariqqureshi49No ratings yet

- Overview of Voltage Sag MitigationDocument7 pagesOverview of Voltage Sag MitigationJjjjpfNo ratings yet

- Solutions Voltage Sags - InteruptionsDocument6 pagesSolutions Voltage Sags - Interuptionsnikkoelbao96No ratings yet

- Overview of Voltage Sag MitigationDocument7 pagesOverview of Voltage Sag MitigationEduardo BerlesiNo ratings yet

- PSQ, Chapt 1.1Document57 pagesPSQ, Chapt 1.1Seid EndrisNo ratings yet

- High Voltage Circuit Breaker and Power Transformer Failure Modes and Their DetectionDocument6 pagesHigh Voltage Circuit Breaker and Power Transformer Failure Modes and Their Detectiondavid23281dNo ratings yet

- Article JEEET 2Document9 pagesArticle JEEET 2ElemaNo ratings yet

- Cahier Technique No. 199 Page 7 - 12Document6 pagesCahier Technique No. 199 Page 7 - 12Muklis AhmadNo ratings yet

- Zhang Isei 08 01Document5 pagesZhang Isei 08 01JorgeNo ratings yet

- Article JEEET 2Document9 pagesArticle JEEET 2sissi tata hNo ratings yet

- CIRED2009 0112 PaperDocument4 pagesCIRED2009 0112 PaperkotiniNo ratings yet

- Sensitivity of Low Voltage Consumer Equipment To Voltage SagsDocument7 pagesSensitivity of Low Voltage Consumer Equipment To Voltage Sagsharri8026No ratings yet

- Electric Power Quality: Types, and Measurements: M. A. GolkarDocument7 pagesElectric Power Quality: Types, and Measurements: M. A. GolkarJohn Renzo Mesa CerdaNo ratings yet

- More Papers and Presentations Available On Above Site: Santosh Bharadwaj ReddyDocument10 pagesMore Papers and Presentations Available On Above Site: Santosh Bharadwaj ReddyS Bharadwaj ReddyNo ratings yet

- Diagnosis of Technical Condition of Power Transformers Based On The Analysis of Vibroacoustic Signals Measured in Transient Operating ConditionsDocument7 pagesDiagnosis of Technical Condition of Power Transformers Based On The Analysis of Vibroacoustic Signals Measured in Transient Operating Conditionsdibyaranjan barikNo ratings yet

- Technical Methods For The Prevention and Correction of Voltage Sags and Short Interruptions Inside The Industrial Plants and in The Distribution NetworksDocument8 pagesTechnical Methods For The Prevention and Correction of Voltage Sags and Short Interruptions Inside The Industrial Plants and in The Distribution NetworksNaga AnanthNo ratings yet

- Guide Efficiency PowerQualityDocument57 pagesGuide Efficiency PowerQualityKevin GurungNo ratings yet

- Power Quality and Enhancement Techniques: Research Gaps and Current TrendsDocument7 pagesPower Quality and Enhancement Techniques: Research Gaps and Current TrendsSohrab JunaidNo ratings yet

- Chewale2019 PDFDocument7 pagesChewale2019 PDFOppo k 13No ratings yet

- A Survey of Voltage Sags and Voltage Swells Phenomena in Power Quality ProblemsDocument5 pagesA Survey of Voltage Sags and Voltage Swells Phenomena in Power Quality ProblemsDwikiNo ratings yet

- Condition Monitoring A Decade of Proposed TechniquesDocument15 pagesCondition Monitoring A Decade of Proposed TechniquesOsman T.No ratings yet

- Curso AvrDocument41 pagesCurso AvrGeneracion ELPNo ratings yet

- Transients Part 1Document4 pagesTransients Part 1Earl Jenn AbellaNo ratings yet

- Power Quality and The Need For Compensation: International Journal of Recent Development in Engineering and TechnologyDocument6 pagesPower Quality and The Need For Compensation: International Journal of Recent Development in Engineering and TechnologyDeepak DasNo ratings yet

- MosfetDocument13 pagesMosfetSristick100% (3)

- Electrical Machine DrawingDocument4 pagesElectrical Machine DrawingSristickNo ratings yet

- 22-Power Systems MeasurementsDocument11 pages22-Power Systems Measurementsapi-3769988No ratings yet

- Frequncy SpectrumDocument2 pagesFrequncy SpectrumSristick100% (1)

- 07-Relay TechnologyDocument13 pages07-Relay Technologyapi-3769988No ratings yet

- 01 IntroductionDocument1 page01 Introductionapi-3697422No ratings yet

- Freq SpecDocument2 pagesFreq SpecSristickNo ratings yet

- ThyristorDocument10 pagesThyristorSristick100% (2)

- JNTUA Mechanical Engineering (R09) Syllabus BookDocument147 pagesJNTUA Mechanical Engineering (R09) Syllabus Bookslv_prasaad0% (1)

- No-Till For Micro Farms: The Deep-Mulch Method (Lean Micro Farm)Document20 pagesNo-Till For Micro Farms: The Deep-Mulch Method (Lean Micro Farm)Chelsea Green PublishingNo ratings yet

- Oposa vs. Factoran 224 Scra 792Document28 pagesOposa vs. Factoran 224 Scra 792albemartNo ratings yet

- Silyzer 300 - Next Generation PEM ElectrolysisDocument2 pagesSilyzer 300 - Next Generation PEM ElectrolysisSaul Villalba100% (1)

- Advisory Circular: Aircraft Maintenance Engineer Licence - Examination Subject 2 Aircraft Engineering KnowledgeDocument44 pagesAdvisory Circular: Aircraft Maintenance Engineer Licence - Examination Subject 2 Aircraft Engineering KnowledgejashkahhNo ratings yet

- KENDRIYA VIDYALAYA Biology Investigatory ProjectDocument28 pagesKENDRIYA VIDYALAYA Biology Investigatory Projectvishali GNo ratings yet

- CANAVAN' and VESCOVI - 2004 - CMJ X SJ Evaluation of Power Prediction Equations Peak Vertical Jumping Power in WomenDocument6 pagesCANAVAN' and VESCOVI - 2004 - CMJ X SJ Evaluation of Power Prediction Equations Peak Vertical Jumping Power in WomenIsmenia HelenaNo ratings yet

- G10 - Math - Q1 - Module 7 Grade 10Document12 pagesG10 - Math - Q1 - Module 7 Grade 10Shua HongNo ratings yet

- Aemses Sof Be LCP 2021 2022Document16 pagesAemses Sof Be LCP 2021 2022ROMEO SANTILLANNo ratings yet

- User Manual: C43J890DK C43J892DK C49J890DK C49J892DKDocument58 pagesUser Manual: C43J890DK C43J892DK C49J890DK C49J892DKGeorge FiruțăNo ratings yet

- Beuys Begleitheft en ScreenDocument18 pagesBeuys Begleitheft en Screensofijawt0% (1)

- DX DiagDocument42 pagesDX DiagVinvin PatrimonioNo ratings yet

- NotesTransl 108 (1985) Larsen, Who Is This GenerationDocument20 pagesNotesTransl 108 (1985) Larsen, Who Is This GenerationluzuNo ratings yet

- Ezequiel Reyes CV EngDocument1 pageEzequiel Reyes CV Engezequiel.rdNo ratings yet

- Jensen-English I SyllabusDocument6 pagesJensen-English I Syllabusapi-284900455No ratings yet

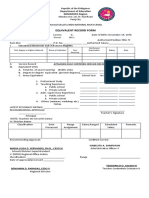

- Equivalent Record Form: Department of Education MIMAROPA RegionDocument1 pageEquivalent Record Form: Department of Education MIMAROPA RegionEnerita AllegoNo ratings yet

- EAPP Module 5Document10 pagesEAPP Module 5Ma. Khulyn AlvarezNo ratings yet

- Hope 03 21 22Document3 pagesHope 03 21 22Shaina AgravanteNo ratings yet

- TG KPWKPDocument8 pagesTG KPWKPDanmar CamilotNo ratings yet

- Nurses Week Program InvitationDocument2 pagesNurses Week Program InvitationBenilda TuanoNo ratings yet

- KOREADocument124 pagesKOREAchilla himmudNo ratings yet

- Final Exam IN Sample QuestionsDocument27 pagesFinal Exam IN Sample QuestionsJI TEN100% (1)

- Limit Switch 1LX7001-J AZBILDocument8 pagesLimit Switch 1LX7001-J AZBILHoàng Sơn PhạmNo ratings yet