Professional Documents

Culture Documents

Organotin Compound

Uploaded by

Atsar Leswara NinditaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Organotin Compound

Uploaded by

Atsar Leswara NinditaCopyright:

Available Formats

Determination of Organotin

Compounds in Toy Materials by

Agilent 5977A GC/MSD to Meet

European Regulation EN71-3: 2013,

Migration of Certain Elements

Application Note

Consumer Products, Materials

Authors

Abstract

Shuang Feng and Yufeng Zhang

The EU approved Directive 2009/48/EC bans certain organotin compounds in toy

Agilent Technologies Co. Ltd

material for public safety. This application note used the Agilent 5977A Series

Unit 08, 66/F,CITIC Plaza,

GC/MSD system to analyze 11 organotin compounds with excellent sensitivity and

233 Tian He Bei Road

linearity. Additionally, good reproducibility and recovery were achieved through the

Guangzhou 510613, China

analysis of three categories of toy materials. The 5977A Series GC/MSD provides a

Wenjie Yu

Toy testing technology center of

Shenazhen CIQ

15/F, CIQ bldg, 1011 Fuqiang Road,

Shenzhen 518045, China

complete instrument solution to meet European regulation EN71-3: 2013.

Toy materials and parts of toys are divided into three

categories:

Introduction

Organotin compounds are chemical compounds based on tin

with hydrocarbon substitutions. They are used in the toy

industry as disinfectants due to their antibacterial and

fungicidal properties. The triorganotin compounds are very

toxic, and partly degrade to di- and monoalkyltin derivatives.

These compounds may have a harmful effect on living beings,

and can disrupt the normal growth of children. Due to their

toxicity, certain organotin compounds have been banned or

severely restricted for health or environmental reasons.

Category I: Dry, brittle, powder-like, or pliable materials

Category II: Liquid or sticky materials

Category III: Coatings and scraped-off materials

EN71-3 specifies migration limits for 17 elements: aluminum,

antimony, arsenic, barium, boron, cadmium, chromium, cobalt,

copper, lead, manganese, mercury, nickel, selenium,

strontium, tin (and organic tin compounds), and zinc. There

are two migration limits for tin and organic tin specified for

each category (Table 1). Toy materials in Category II (liquid

products that may easily be swallowed) must meet the lowest

limit of 0.2 mg/kg for total amount of organic tin compounds.

The sample preparation method specified in EN71-3 (Figure 1)

applies a total dilution factor of 20x. This means that the

detection limit of a single organic tin compound in the

samples as measured is 1 ppb; therefore, this application

needs a very sensitive method for organic tin.

The EU Toy Safety Directive (2009/48/EC) seeks to ensure the

safety of children by minimizing their exposure to potentially

hazardous or toxic toy products. The European Standard on

the safety of toys (EN71) supports the requirements of EU

Directive 2009/48/EC, and Part 3 of the standard (EN71-3)

covers the migration of certain elements from various

categories of toy products. The most recent (2013) revision of

EN71-3 has been published, supporting the new chemical

requirements of the EU Toys Safety Directive, which take

effect from 20 July 2013.

Table 1.

The Agilent 5977A Series GC/MSD has an extractor ion

source, which provides greater ion throughput, higher

abundance signals, and better sensitivity. This application

note describes a method of determining organic tin

compounds at the low level required in three categories toy

materials. Calibration, limit-of-detection (LOD), reproducibility,

and sample spike recovery are addressed.

Categories of Toy Materials and the Respective Migration Limits of Tin and Organic Tin

Toy material

Category 1

Category 2

Category 3

Tin

15,000

3,750

180,000

Organic tin

0.9

0.2

12

Coatings of paints, varnishes, lacquers, printing inks, polymers, foams and similar coatings

Polymeric and similar materials, including laminates, whether textile reinforced or not,

but excluding other textiles

Paper and paper board

Textiles, whether natural or synthetic

Glass, ceramic, metallic materials

Other materials whether mass colored or not

Compressed paint tablets, materials intended to leave a trace or similar materials in solid form

appearing as such in the toy

Pliable modeling materials, including modeling clays and plaster

Liquid paints, including finger paints, varnishes, lacquers, liquid ink in pens and

similar materials in liquid form appearing as such in the toy

Glue sticks

Migration limits from toy materials (mg/kg)

Working Solution B*: Dilute stock Solution A 100 times with

methanol to prepare the 10 mg/L organic tin working

solution.

> 100 mg of the toy material (< 6 mm)

Mix the test piece with 50 times its mass of

0.07 mol/L HCl0.1 g/5 mL (pH should be 1.01.5)

* If the method needs a lower LOD, make 1 mg/L working

Solution B instead.

Agitate the mixture at 37 2 C for 1 hour

IS stock Solution C: Weigh 100 mg of Tributyl-d27-tin

chloride, 100 mg of tetrabutyl-d36-tin, and 100 mg of

Triphenyl-d15-tin chloride, to the nearest 0.1 mg, into a

100-mL volumetric flask, and dissolve with methanol to

prepare the 1,000 mg/L IS mix stock solution. (The solution is

stable for up to 1 year when stored in the dark at 4 C.)

Stand for 1 hour at 37 2 C

Separate solid from solution by filtration < 0.45 m

Migration solution

Figure 1.

IS working Solution D: Pipette 0.2 mL of the IS stock

Solution C into a 100-mL volumetric flask. Adjust to the mark

with methanol to prepare the 2 mg/L IS working solution.

Sample migration flow.

Reagents

Hydrochloric acid solution: Add 5.8 mL of 37 % hydrochloric

acid and 250 mL of water to a 500-mL volumetric flask. Adjust

to the mark with water to prepare the 0.07 0.005 mol/L HCl

solution.

The organic tin chloride compounds listed in Table 2 were

purchased from Dr. Ehrenstorfer, Augsburg, Germany.

Tributyl-d27-tin chloride, tetrabutyl-d36-tin, and

triphenyl-d15-tin chloride were used as the internal standards

(IS).

Acetate buffer solution: Dissolve 16.6 g sodium acetate with

250 mL of water into a 500-mL volumetric flask. Add 1.2 mL of

glacial acetic acid to reach a pH of 5.4 and adjust to the mark

with water.

Experimental

Derivatization agent (2 % mass concentration): Weigh

approximately 200 mg of sodium tetraethylborate into a 10-mL

volumetric flask, and adjust to the mark with water. (This

solution is not stable, and must be prepared daily.)

Stock Solution A: Weigh the specified amount (Table 2), to

the nearest 0.1 mg, of the organic tin chloride into a 100-mL

volumetric flask, and dissolve with methanol to prepare the

1,000 mg/L organic tin stock solution. (The solution is stable

for up to 1 year when stored in the dark at 4 C.)

Table 2.

Required Weighed Portions of Organic Tin Compounds, and Their Weighing Factors, Corresponding to 100 mg of Organic

Tin Cations (Expressed as Tributyltin Cation)

Substance (OTClx)

CAS#

Weighed portion (mg)

MW OTClx

MW OC

Weighing factor*

Relative MW

Dimethyltin dichloride

753-73-1

75.8

219.7

148.7

0.677

1.948

Methyltin trichloride

993-16-8

82.8

240.1

133.7

0.557

2.167

Di-n-propyltin dichloride

867-36-7

94.2

273.6

202.7

0.743

1.429

Butyltin trichloride

1118-46-3

97.4

282.2

175.8

0.623

1.648

Dibutyltin dichloride

683-18-1

104.7

303.6

232.7

0.767

1.245

Tributyltin chloride

1461-22-9

112.2

325.2

289.7

0.891

1.000

n-octyltin trichloride

3091-25-6

116.6

338.1

231.7

0.686

1.250

Di-n-octyltin dichloride

3542-36-7

143.4

415.6

344.7

0.830

0.840

Tetrabutyltin

1461-25-2

119.6

346.7

346.7

1.000

0.836

Diphenyltin dichloride

1135-99-5

118.6

343.6

272.7

0.794

1.062

Triphenyltin chloride

639-58-7

138.0

385.2

349.7

0.875

0.828

*Weighing factor = molar mass (organic tin cation)/molar mass (organic tin chloride)

Sample migration and derivatization procedure

Table 3.

The sample preparation procedure is given in Figure 1. The

procedure follows EN71-3, which simulates gastric digestion

as would occur in the case when a child swallows toy

material.

GC conditions

Pipette 5 mL of the above migration solution to a 22-mL glass

tube. Then add 0.1 mL of IS Solution D and 5 mL acetate

buffer solution to adjust the pH to 4.7. Subsequently, add

0.5 mL of 2% sodium tetraethylborate and 2 mL of hexane.

Vortex for 30 minutes and allow to stand until the phase

separation is complete. The hexane fraction is then ready to

be analyzed by GC/MS.

Gas Chromatograph and Mass Spectrometer Conditions

Column

Agilent J&W DB-5ms Ultra Inert capillary

column, 30 m 0.25 mm, 0.25 m

(p/n 122-5532UI)

Injection volume

2 L

Injection mode

Pulsed splitless, 25 psi until 0.75 minutes

Inlet temperature

275 C

Carrier gas

Helium, constant flow, 1.0 mL/min

Oven program

50 C for 1 minute, 20 C/min to 280 C,

280 C hold 1 minute

Post run

300 C for 2 minutes

MS conditions

Calibration standards

Solvent delay

3 minutes

Source temperature

250 C

Insert 5.0 mL of 0.07 mol/L HCl into each of seven 22-mL

glass tubes. Then pipette 0, 20 L, 50 L, 100 L, 0.2 mL,

0.5 mL, and 1.5 mL of working solution B, respectively. Add

0.1 mL of IS working solution D and 5 mL of acetate buffer

solution to adjust the pH to 4.7. Then add 0.5 mL of 2 %

sodium tetraethylborate and 2 mL of hexane. Vortex the

mixture for 30 minutes and allow to stand until the phase

separation is complete. Then, analyze the hexane fraction by

GC/MS.

Table 4.

Instrumentation

No.

Compound

RT (min)

Quantifier ion

I.S.

Tributyl tin-D27

8.529

217

281

318

Dimethyl tin

3.450

179

177

151

135

Methyl tin

4.358

193

165

191

163

Di-n-propyl tin

6.492

235

193

233

191

Butyl tin

6.557

235

177

179

233

Di-butyl tin

7.691

263

207

205

261

Tri-butyl tin

8.643

291

289

205

207

I.S.

Tetra-butyl tin-D36

9.314

190

254

318

n-Octyl tin

9.130

291

177

179

289

Tetra-butyl tin

9.452

291

177

179

235

Di-phenyl tin

10.853

301

275

195

305

I.S.

Tri-phenyl tin-D15

12.874

366

364

10

Di-n-octyl tin

11.821

375

261

179

263

11

Tri-phenyl tin

12.910

351

349

347

197

The experiments are performed on an Agilent 7890B Gas

Chromatograph System with split/splitless capillary inlet, an

Agilent 5977A Series Mass Spectrometer with Extractor Ion

source, and an Agilent 7697A Automatic Liquid Sampler

equipped with a 10-L syringe. The instrumental configuration

and analytical conditions are summarized in Table 3. Table 4

presents the selected target ion and three qualifying ions for

SIM method.

Quadrupole temperature

150 C

Transfer line temperature

280 C

EM gain factor

Mass mode

SIM

Retention Time and SIM Ions for 11 Organic Tin Compounds and

Internal Standards

Qualifier ion (s)

Results and Discussion

Table 5.

Calibration solutions

Compound

Range of

linearity (g/L)

Correlation

coefficient (R2)

A six-level 11-component organic tin compounds calibration

curve was evaluated over the concentration range 1.0 to

200 g/L. Figure 2 shows the SIM overlay total ion

chromatogram of six levels. As indicated in Table 5, all of the

organic tin compounds achieved excellent linearity, with a

linear coefficient R2 greater than 0.996.

Diethyl tin

1 ~ 282

0.9962

Methyl tin

1 ~ 200

0.9997

Di-n-propyl tin

2 ~ 279

0.9999

Butyl tin

2 ~ 259

0.9999

Di-butyl tin

2 ~ 236

0.9999

Tri-butyl tin

2 ~ 234

0.9999

n-Octyl tin

1 ~ 187

0.9999

Tetra-butyl tin

2 ~ 262

0.9998

Di-phenyl tin

1 ~ 206

0.9999

Di-n-octyl tin

1 ~ 159

0.9996

Tri-phenyl tin

1 ~ 198

0.9998

10 5

7.6

Calibration Results of Organic Tin Compounds

+ TIC SIM TSD6-1.D

* 12.874

7.2

* 12.910

6.8

6.4

* 9.314

6.0

* 9.130

5.6

* 9.452

5.2

4.8

Counts

4.4

* 11.821

* 6.557

4.0

3.6

* 6.487

3.2

2.8 * 3.444

* 8.529

* 4.353

* 10.853

2.4

* 7.686

2.0

1.6

1.2

0.8

0.4

0

3.4

Figure 2.

3.8

4.2

4.6

5.0

5.4

5.8

6.2

6.6

7.0

7.4

7.8 8.2 8.6 9.0

Acquisition time (min)

SIM Ions overlay chromatogram of six levels for organic tin compounds.

9.4

9.8

10.2 10.6 11.0

11.4

11.8 12.2 12.6 13.0

The instrument sensitivity is excellent. Figure 3 shows the

SIM ion chromatogram of 11 organic tin compounds for the

lowest calibration level (~ 1 g/L).

Each calibration level was injected seven times for evaluation.

The RSD under six different calibration levels is shown in

Table 6. Most of the RSD results were below 5 %, even at an

extremely low concentration level of 1.5 g/L, illustrating

satisfactory reproducibility.

Table 6.

RSD% Result of Organic Tin Compounds for Six Calibration Levels (n = 7)

Compounds

Std 1

(~ 1.5 g/L)

Std 2

(~ 6.0 g/L)

Std 3

(~ 15 g/L)

Std 4

(~ 30 g/L)

Std 5

(~ 75 g/L)

Std 6

(~ 225 g/L)

Diethyl tin

7.29

4.39

3.00

0.68

0.54

0.68

Methyl tin

1.28

0.88

1.62

0.63

0.76

0.5

Di-n-propyl tin

4.44

1.26

1.73

0.53

1.01

1.04

Butyl tin

3.20

1.08

1.69

0.63

0.85

1.03

Di-butyl tin

2.49

0.85

1.98

0.57

1.01

0.98

Tri-butyl tin

4.49

1.68

1.88

0.44

1.28

1.21

n-Octyl tin

1.50

1.70

2.00

0.83

0.85

1.20

Tetra-butyl tin

6.94

1.85

1.80

0.71

1.17

0.94

Di-phenyl tin

4.08

1.16

2.08

0.46

0.87

0.85

Di-n-octyl tin

3.10

1.15

2.20

0.83

1.27

1.55

Tri-phenyl tin

4.58

1.04

2.24

0.67

0.94

1.17

10 3

TSD1 [Dimethyltin]

179.0

6

5

4

3

2

1

4.1

3.3 3.4 3.5 3.6 3.7 3.8 3.9

10 2

TSD1 [Di-butyl tin]

263.0

10 2

3.2

4.0

3.5

3.0

2.5

2.0

1.5

4.2

4.4

4.3

4.5

4.6

TSD1 [Tri-butyl tin]

291.0

6.3

10 2

6

2.8

TSD1 [Diphenyl tin]

301.0

10.7

Figure 3.

10.8

7.9

10.9

11.0

6.35

10 2

7

6.45

6.55

6.65

6.75

9.55

9.65

TSD1 [Tetrabutyl tin]

291.0

4

3

2

8.45

10 3

1.4

1.3

1.2

1.1

1.0

0.9

0.8

0.7

0.6

0.5

6.7

1.2

7.8

6.6

TSD1 [Butyl tin]

235.0

1.6

7.7

6.5

TSD1 [n-Octyl tin]

291.0

2.0

7.6

6.4

10 3

1.0

0.9

0.8

0.7

0.6

0.5

0.4

0.3

2.4

7.5

10 3

1.2

1.1

1.0

0.9

0.8

0.7

0.6

0.5

TSD1 [Di-n-propyl tin]

10 3 235.0

1.0

0.9

0.8

0.7

0.6

0.5

0.4

0.3

TSD1 [Methyl tin]

10 3 193.0

2.0

1.8

1.6

1.4

1.2

1.0

0.8

0.6

8.55

8.65

8.75

8.85

TSD1 [Di-n-octyl tin]

375.0

11.6

11.7

11.8

10 3

2.6

2.4

2.2

2.0

1.8

1.6

1.4

1.2

1.0

0.8

11.9

2

8.95

12.0

9.05

9.25

9.35

TSD1 [Triphenyl tin]

351.0

12.7

12.8

SIM ion chromatogram of 11 organic tin compounds for the lowest calibration level.

9.15

12.9

13.0

13.1

9.25

9.35

9.45

Instrument detection limits (SNR > 3) of each organic tin

compound is calculated by signal-to-noise ratio (S/N) of

lowest concentration (Table 7). For all the organic tin

compounds, the instrument detection limits are below

1.0 g/L, which meets the EN 71-3 regulation requirement.

Table 7.

S/N at the Lowest Calibration Level and Instrument Detection Limit

Compound

Lowest

concentration ( g/L)

S/N

(peak-to-peak)

Instrument

detection limit (g/L)

Diethyl tin

1.88

19

0.30

Methyl tin

1.33

91

0.04

Di-n-propyl tin

1.86

29

0.19

Butyl tin

1.73

40

0.13

Di-butyl tin

1.57

27

0.17

Tri-butyl tin

1.56

0.78

n-Octyl tin

1.25

30

0.13

Tetra-butyl tin

1.75

19

0.28

Di-phenyl tin

1.38

16

0.26

Di-n-octyl tin

1.06

12

0.27

Tri-phenyl tin

1.32

29

0.13

Toy material sample analysis:

Spike recovery and reproducibility

Three types of toy materials, representing three categories of

EN71-3 were analyzed. Each category had two different toy

samples (Figure 4): Category I: crayon (Sample A) and

plasticene (Sample B) , Category II: bubble solution

(Sample A) and paint (Sample B), Category III: soft plastic

(Sample A) and cloth (Sample B). All of the samples were

prepared by the migration and dervatization procedure

described above and then analyzed by GC/MS.

Category I

Sample A

Crayon

Figure 4.

Sample B

Plasticene

Category II

Sample A

Bubble solution

Category III

Sample B

Paint

Sample A

Soft plastic

Six toy materials for recovery test represent three categories into EN71-3.

Sample B

Cloth

The spike recovery test of organic tin compound was using

the migration solutions. Category I and Category III toy

samples were spiked at two concentration levels of 20 g/L

and 40 g/L. Category II samples were spiked at three

concentration levels of 4 g/L, 20 g/L, and 40 g/L. The

lowest migration solution spike level of 4 g/L for Category II

and 20 g/L for Categories I and III just meet the migration

limits from toy material in EN 71-3 (0.2 mg/kg for Category II,

0.9 mg/kg for Category I ). The method evaluated six parallel

spike samples for each level. The result of the spike recovery

and reproducibility is shown in Table 8.

As indicated in these tables, with the exception of paint and

plasticene which contain trace amounts of methyl tin and

dimethyl tin, good recoveries were obtained for all the other

investigated organic tin compounds, ranging from 80 to 120 %,

and relative standard deviation (RSD) less than 10 % for more

than 96 % of the parallel spike samples. All of the results

demonstrated the excellent recovery and reproducibility of the

method, especially at limit concentration level.

Table 8A. Recovery Data for Category I Toy Material Spiked with Organotins

Category I

Sample A: Crayon

20 g/L

Sample B: Plasticene

40 g/L

20 g/L

40 g/L

Compound

Recovery %

RSD %

Recovery %

RSD %

Recovery %

RSD %

Recovery %

RSD %

Diethyl tin

106

2.09

106

2.20

130

2.21

128

2.62

Methyl tin

122

4.57

110

7.22

171

13.2

152

4.10

Di-n-propyl tin

110

1.59

105

1.44

105

0.91

103

0.84

Butyl tin

123

2.26

112

7.2

128

9.61

118

3.00

Di-butyl tin

110

1.63

105

1.38

108

1.37

104

1.39

Tri-butyl tin

109

1.00

104

1.43

108

1.51

104

0.64

n-Octyl tin

111

1.49

106

3.71

90

4.96

84

1.98

Tetra-butyl tin

106

2.16

106

5.99

98

3.23

90

1.53

Di-phenyl tin

106

0.40

105

0.94

110

1.73

107

0.47

Di-n-octyl tin

110

1.70

109

2.41

104

2.75

103

1.66

Tri-phenyl tin

107

0.52

103

0.69

108

2.1

104

0.73

Table 8B. Recovery Data for Category II Toy Material Spiked with Organotins

Category II

Sample A: Bubble solution

4 g/L

20 g/L

Sample B: Paint

40 g/L

4 g/L

20 g/L

40 g/L

Compound

Recovery % RSD % Recovery % RSD % Recovery % RSD % Recovery % RSD % Recovery % RSD % Recovery % RSD %

Diethyl tin

96

5.43

106

3.68

111

3.71

155

3.25

154

2.22

145

6.57

Methyl tin

88

13.6

79

10.3

115

8.62

122

5.37

135

4.33

102

13.39

Di-n-propyl tin

76

7.01

85

2.32

90

3.21

79

1.78

79

2.72

80

5.23

Butyl tin

73

9.37

73

5.24

95

3.80

80

3.63

82

4.22

69

6.76

Di-butyl tin

84

5.81

93

1.36

94

2.21

90

1.55

87

0.73

87

3.89

Tri-butyl tin

82

4.77

92

1.42

95

1.60

100

1.22

97

0.96

95

1.54

n-Octyl tin

93

4.46

95

1.12

99

1.77

87

3.47

83

1.56

73

2.18

Tetra-butyl tin

99

3.43

94

5.42

100

1.70

117

11.7

108

8.17

123

36.6

Di-phenyl tin

102

3.19

102

1.27

105

1.51

116

3.31

113

2.33

106

3.67

Di-n-octyl tin

72

3.44

82

3.35

82

3.14

113

5.11

116

6.38

110

2.34

Tri-phenyl tin

88

4.87

93

1.00

96

1.59

98

1.35

95

0.89

93

1.10

Table 8C.

Recovery Data for Category III Toy Material Spiked with Organotins

Category III

Sample A: Soft plastic

20 g/L

Sample B: Cloth

40 g/L

20 g/L

40 g/L

Compound

Recovery %

RSD %

Recovery %

RSD %

Recovery %

RSD %

Recovery %

RSD %

Diethyl tin

96

2.42

94

2.24

113

1.81

105

1.48

Methyl tin

125

5.30

109

2.89

130

2.94

111

2.33

Di-n-propyl tin

97

1.78

94

2.52

97

2.11

94

1.36

Butyl tin

115

3.84

105

2.56

106

2.31

97

2.21

Di-butyl tin

97

1.40

96

3.87

97

2.14

95

1.48

Tri-butyl tin

97

0.67

96

1.35

97

1.74

95

1.60

n-Octyl tin

98

3.77

97

2.62

93

1.05

88

1.86

Tetra-butyl tin

90

9.46

94

6.06

91

3.43

90

6.72

Di-phenyl tin

96

4.43

97

4.08

104

2.95

95

1.23

Di-n-octyl tin

94

7.23

103

10.5

97

6.35

88

1.64

Tri-phenyl tin

95

1.74

96

1.09

95

1.52

95

1.55

Conclusion

References

The use of the Extractor EI source in an Agilent 5977A Series

GC/MSD can provide excellent sensitivity and stability for the

analysis of organotin compounds in toy materials. Instrument

detection limits were lower than 1 g/L for all the

compounds. Calibration from 1.0 to 200 g/L showed

excellent linearity, as measured by coefficient R2 > 0.996.

Moreover, good recovery and reproducibility were also

achieved for the analysis of organotin compounds in three

categories toy materials. As a result, the 5977A Series

GC/MSD was demonstrated to meet the requirements of EN

71-3: 2013 for the determination of organic tin compounds in

toys.

1.

Official Journal of the European Communities, Toy Safety

Directive 2009/48/EC.

2.

EN 71-3 2013 Safety of toys-Part 3: Migration of certain

elements.

3.

F. David, P. Sandra, and P.L. Wylie, Improving the

analysis of organotin compounds using retention time

locked methods and retention time database Agilent

Technologies, publication number 5988-9256EN.

4.

K. Sakai, J. Song, D. Yan, and X.C. Zeng, LC-ICP-MS

method for the determination of trivalent and hexavalent

chromium in toy materials to meet European regulation

EN71-3:2012 Migration of certain elements Agilent

Technologies, publication number 5991-2878EN.

For More Information

These data represent typical results. For more information on

our products and services, visit our Web site at

www.agilent.com/chem.

www.agilent.com/chem

Agilent shall not be liable for errors contained herein or for incidental or consequential

damages in connection with the furnishing, performance, or use of this material.

Information, descriptions, and specifications in this publication are subject to change

without notice.

Agilent Technologies, Inc., 2014

Printed in the USA

May 29, 2014

5991-4658EN

You might also like

- 4 - Odd Hours - Dean KoontzDocument261 pages4 - Odd Hours - Dean KoontzJustinSnow80% (5)

- 0001 CatDocument108 pages0001 CatJorge CabreraNo ratings yet

- Dr. Berg's Favorite HEALTHY JUNK FOODS & Other AlternativesDocument23 pagesDr. Berg's Favorite HEALTHY JUNK FOODS & Other Alternativesprashant_padte100% (8)

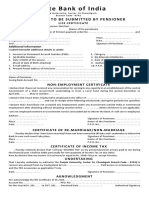

- SBI - Certificate To Be Submitted by Pensioner - ChandigarhDocument1 pageSBI - Certificate To Be Submitted by Pensioner - ChandigarhMsinghNo ratings yet

- OHIO Methylene BlueDocument2 pagesOHIO Methylene BlueLynn MailNo ratings yet

- D1208Document3 pagesD1208Ненад КнежевићNo ratings yet

- Age Discrimination PDFDocument20 pagesAge Discrimination PDFMd. Rezoan ShoranNo ratings yet

- Astm D 4603-2003 PDFDocument4 pagesAstm D 4603-2003 PDFb_afrinaldiNo ratings yet

- ASTM IndexDocument34 pagesASTM IndexJimmy Chan67% (3)

- Healthcare Financing in IndiADocument86 pagesHealthcare Financing in IndiAGeet Sheil67% (3)

- Presentation On Data Integrity in PharmaDocument80 pagesPresentation On Data Integrity in Pharmaskvemula67% (3)

- Accredited Meat Processing Plant (MPP) PDFDocument14 pagesAccredited Meat Processing Plant (MPP) PDFClayton PanghulanNo ratings yet

- 9.2.27 AOAC Official Method 988.11 Mercury (Methyl) in Fish and ShellfishDocument2 pages9.2.27 AOAC Official Method 988.11 Mercury (Methyl) in Fish and ShellfishLêXuânThắngNo ratings yet

- Lycopene Extract From TomatoDocument7 pagesLycopene Extract From TomatoShayne PalalayNo ratings yet

- Jurnal Analitik Jahlela Sari Kimia Bahasa InggrisDocument14 pagesJurnal Analitik Jahlela Sari Kimia Bahasa InggriskhairiyatiNo ratings yet

- EurlSrm Observation CS2 Hydrolysis Version3 240119Document12 pagesEurlSrm Observation CS2 Hydrolysis Version3 240119Andres RestrepoNo ratings yet

- C993 03 PDFDocument7 pagesC993 03 PDFdanzan1No ratings yet

- Chemical recycling of PET waste for environmental sustainabilityDocument5 pagesChemical recycling of PET waste for environmental sustainabilityفؤاد مهندسNo ratings yet

- Simethicone Test MethodDocument8 pagesSimethicone Test MethodCesar Hernández RamírezNo ratings yet

- (+) - (7as) - 7a-METHYL-2,3,7,7a-TETRAHYDRO-1 H-INDENE-1,5 - (6H-DIONEDocument7 pages(+) - (7as) - 7a-METHYL-2,3,7,7a-TETRAHYDRO-1 H-INDENE-1,5 - (6H-DIONEAlex CumbaNo ratings yet

- Automated Determination of The Hydroxyl Number (HN) According To ASTM E 1899-08 and DIN 53240-2Document13 pagesAutomated Determination of The Hydroxyl Number (HN) According To ASTM E 1899-08 and DIN 53240-2DIENLUU150489100% (1)

- Research ArticleDocument9 pagesResearch ArticleSyamsir RusdinNo ratings yet

- HYDROXYPROPYLMETHYL CELLULOSE SPECIFICATIONSDocument7 pagesHYDROXYPROPYLMETHYL CELLULOSE SPECIFICATIONSAndrea Sanchez AbarcaNo ratings yet

- Evans Auxiliary ProcedureDocument6 pagesEvans Auxiliary Procedureacmkim05No ratings yet

- Chapter 3Document9 pagesChapter 3Noor ZarifNo ratings yet

- Usp31nf26s1 - c211, General Chapters - 211 - ARSENICDocument2 pagesUsp31nf26s1 - c211, General Chapters - 211 - ARSENICEfsha KhanNo ratings yet

- Science - Adh1853 SMDocument44 pagesScience - Adh1853 SMgetahun esubalewNo ratings yet

- Α-Allenic Esters From Α-Phosphoranylidene Esters And Acid ChloridesDocument5 pagesΑ-Allenic Esters From Α-Phosphoranylidene Esters And Acid ChloridesJarrett RobinsonNo ratings yet

- Air Oxidation of Primary Alcohols Catalyzed by Copper (I) /TEMPO. Preparation of 2-Amino-5-Bromo-BenzaldehydeDocument15 pagesAir Oxidation of Primary Alcohols Catalyzed by Copper (I) /TEMPO. Preparation of 2-Amino-5-Bromo-BenzaldehydeCarlos GonzalezNo ratings yet

- 10.1.02 AOAC Official Method 985.22 Organochlorine and Organophosphorus Pesticide ResiduesDocument0 pages10.1.02 AOAC Official Method 985.22 Organochlorine and Organophosphorus Pesticide ResiduesTruong Hoai ThanhNo ratings yet

- 4.5 The Iodoform Test: How Can Methanol Be Distinguished From Ethanol?Document17 pages4.5 The Iodoform Test: How Can Methanol Be Distinguished From Ethanol?Aparna KandaNo ratings yet

- 4.5 The Iodoform Test: How Can Methanol Be Distinguished From Ethanol?Document17 pages4.5 The Iodoform Test: How Can Methanol Be Distinguished From Ethanol?Aparna KandaNo ratings yet

- MDI PurityDocument6 pagesMDI PuritycgrigorasNo ratings yet

- EU Pharmacopea 30103EDocument4 pagesEU Pharmacopea 30103EPascal MosnierNo ratings yet

- Journal of Environmental Chemical Engineering: Carla Albertina Demarchi, Mayara Campos, Clo Vis Antonio RodriguesDocument9 pagesJournal of Environmental Chemical Engineering: Carla Albertina Demarchi, Mayara Campos, Clo Vis Antonio RodriguesdiyanaNo ratings yet

- Determination of Formaldehyde Content in Toys Using UV/Vis SpectrometryDocument4 pagesDetermination of Formaldehyde Content in Toys Using UV/Vis SpectrometryLadymarry MputNo ratings yet

- IDF 86 e IDF 81 - 2 MetodosDocument9 pagesIDF 86 e IDF 81 - 2 MetodosJocilene DantasNo ratings yet

- Organic Carbon Total HR TNT 10128Document8 pagesOrganic Carbon Total HR TNT 10128okgnosasNo ratings yet

- Plastic Cutlery Alternative Case Study With Biodegradable SpoonsDocument8 pagesPlastic Cutlery Alternative Case Study With Biodegradable SpoonsMarlon James TobiasNo ratings yet

- LArge Volume Injection of Organochlorine Pesticide Extracts Using A Programmable Temperature Vaporizer in The Solvent Split ModeDocument6 pagesLArge Volume Injection of Organochlorine Pesticide Extracts Using A Programmable Temperature Vaporizer in The Solvent Split ModeDiego BermudezNo ratings yet

- Delfino CastelanDocument9 pagesDelfino CastelanJoseBuendiaNo ratings yet

- Chem 101 Exp3 Limiting Reagent Fall 2015Document6 pagesChem 101 Exp3 Limiting Reagent Fall 2015Nahyan Akhtar MemonNo ratings yet

- EPA Method 8015DDocument5 pagesEPA Method 8015DBrenda AcuñaNo ratings yet

- STM - Re - French Bpa Ban Being Enforced 01 01 2015Document13 pagesSTM - Re - French Bpa Ban Being Enforced 01 01 2015olivierNo ratings yet

- Additive-068 BHA JEFCADocument4 pagesAdditive-068 BHA JEFCASartika MutiarasaniNo ratings yet

- ArsenicDocument2 pagesArsenicVanNo ratings yet

- PH Euro 3.1.1Document30 pagesPH Euro 3.1.1ryad bmzaNo ratings yet

- Additive 241 PDFDocument5 pagesAdditive 241 PDFmargaretasuprajogiNo ratings yet

- Determination of Total Inorganic BromideDocument5 pagesDetermination of Total Inorganic BromidemcosicNo ratings yet

- ASTM D 1396 - 92 (Reapproved 1998) Chemical Analysis of Poly (Vinyl Butyral)Document2 pagesASTM D 1396 - 92 (Reapproved 1998) Chemical Analysis of Poly (Vinyl Butyral)alin2005No ratings yet

- 〈211〉 ARSENICDocument2 pages〈211〉 ARSENICSiska Rotua Uli SihombingNo ratings yet

- Determination of BisphenolDocument1 pageDetermination of BisphenolLiana DinicaNo ratings yet

- 2008 Bioprocess Biosys Eng A. Mosquera 31-6-535-540Document6 pages2008 Bioprocess Biosys Eng A. Mosquera 31-6-535-540monica2061No ratings yet

- Omega-3 EPA & DHA MonographDocument6 pagesOmega-3 EPA & DHA MonographCarla Sánchez GallardoNo ratings yet

- PH Euro 3.1.3 PolyolefinesDocument9 pagesPH Euro 3.1.3 Polyolefinesryad bmzaNo ratings yet

- Working With Hazardous Chemicals: A Publication of Reliable Methods For The Preparation of Organic CompoundsDocument16 pagesWorking With Hazardous Chemicals: A Publication of Reliable Methods For The Preparation of Organic CompoundsIgennel Zeref Acnologia ErriugaNo ratings yet

- Aniline, O-Toluidine, and Nitrobenzene 2017Document6 pagesAniline, O-Toluidine, and Nitrobenzene 2017HyuReaperNo ratings yet

- ISO Common Name Chemical Name Empirical Formula RMM M.P. V.P. SolubilityDocument6 pagesISO Common Name Chemical Name Empirical Formula RMM M.P. V.P. Solubilityjessica montielNo ratings yet

- Potenciometria Minoxidil PDFDocument5 pagesPotenciometria Minoxidil PDFJ C Torres FormalabNo ratings yet

- Post Lab 2Document9 pagesPost Lab 2Chin RamosNo ratings yet

- Influence of Alternative Polymeric PlastDocument10 pagesInfluence of Alternative Polymeric Plastkatarzyna.stacharskaNo ratings yet

- Total Nitrogen DeterminationDocument9 pagesTotal Nitrogen DeterminationEnvironmental Toxicology And Risk AssessmentNo ratings yet

- BHT in Food by HS Trap - GCMSDocument4 pagesBHT in Food by HS Trap - GCMSazambhabibNo ratings yet

- International Journal of Green and Herbal Chemistry: Decolorization of Textile Waste Water Using Low Cost AdsorbentDocument6 pagesInternational Journal of Green and Herbal Chemistry: Decolorization of Textile Waste Water Using Low Cost AdsorbentFarrukh JamilNo ratings yet

- Lutein From Tagetes Erecta: SynonymsDocument4 pagesLutein From Tagetes Erecta: SynonymsKrrliveNo ratings yet

- Transition Metal-Catalyzed Pyridine Synthesis: Transition Metal-Catalyzed Heterocycle Synthesis SeriesFrom EverandTransition Metal-Catalyzed Pyridine Synthesis: Transition Metal-Catalyzed Heterocycle Synthesis SeriesNo ratings yet

- Sustainable synthesis of ciclopentene derivatives through multicomponent reactions in continuous flow regimeFrom EverandSustainable synthesis of ciclopentene derivatives through multicomponent reactions in continuous flow regimeNo ratings yet

- SK Accessories - ENYAQ - Unpriced - JAN 2023 ART V2Document30 pagesSK Accessories - ENYAQ - Unpriced - JAN 2023 ART V2Viktor RégerNo ratings yet

- Practical Research 1 Quarter 1 - Module 10: Through The SlateDocument10 pagesPractical Research 1 Quarter 1 - Module 10: Through The SlateMark Allen Labasan100% (1)

- Khatr Khola ISP District RatesDocument56 pagesKhatr Khola ISP District RatesCivil EngineeringNo ratings yet

- Acute Coronary Syndrome Guidelines 2020Document79 pagesAcute Coronary Syndrome Guidelines 2020Γιώργος ΕλευθεριάδηςNo ratings yet

- Understanding Anxiety Disorders and Abnormal PsychologyDocument7 pagesUnderstanding Anxiety Disorders and Abnormal PsychologyLeonardo YsaiahNo ratings yet

- Mole Concept: Chemfile Mini-Guide To Problem SolvingDocument18 pagesMole Concept: Chemfile Mini-Guide To Problem SolvingNaren ParasharNo ratings yet

- Cell Biology & BiochemistryDocument320 pagesCell Biology & BiochemistryVai SanNo ratings yet

- Liquid - Liquid ExtractionDocument19 pagesLiquid - Liquid ExtractionApurba Sarker ApuNo ratings yet

- Fluvial Erosion Processes ExplainedDocument20 pagesFluvial Erosion Processes ExplainedPARAN, DIOSCURANo ratings yet

- Baileys in 2009: Case Study Reference No 509-050-1Document17 pagesBaileys in 2009: Case Study Reference No 509-050-1Ernesto KulasinNo ratings yet

- Pakistan List of Approved Panel PhysicianssDocument5 pagesPakistan List of Approved Panel PhysicianssGulzar Ahmad RawnNo ratings yet

- To 1 BUMN 2023 Bahasa Inggris StructureDocument5 pagesTo 1 BUMN 2023 Bahasa Inggris StructureKukuh Perkasa WirayudaNo ratings yet

- Final Project Report 2Document8 pagesFinal Project Report 2Mallesh MaranurNo ratings yet

- Human Diseases A Systemic Approach 8th Edition-Páginas-15-26Document12 pagesHuman Diseases A Systemic Approach 8th Edition-Páginas-15-26Karime LopezNo ratings yet

- SafewayDocument70 pagesSafewayhampshireiiiNo ratings yet

- Yanagiba Sharpening: Everything You Need To KnowDocument16 pagesYanagiba Sharpening: Everything You Need To KnowT ChenNo ratings yet

- Olpers MilkDocument4 pagesOlpers MilkARAAJ YOUSUFNo ratings yet

- MTD CalculationsDocument50 pagesMTD CalculationsLeny HrNo ratings yet

- Catálogo SEDIVERDocument32 pagesCatálogo SEDIVEREnver Rojas DiazNo ratings yet

- 3-O FaultDocument15 pages3-O FaultJaved Ahmed LaghariNo ratings yet

- Risk Management in Educational InstitutionsDocument8 pagesRisk Management in Educational InstitutionsBhoxszKurtjusticePascualNo ratings yet