Professional Documents

Culture Documents

QSK19G Performance

Uploaded by

troyCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

QSK19G Performance

Uploaded by

troyCopyright:

Available Formats

Engine Performance Data

Power Generation

471 hp (351 kWm) @ 1800 rpm

Cummins Inc

QSK19G-G3

1374 lb-ft (1863 N-m) @ 1800 rpm

Columbus, Indiana 47202-3005

http://www.cummins.com

FR 4704

Configuration

D483002GX03

CPL Code

2113

Compression Ratio:

11.0:1

Displacement:

1150 cu. in. (19 L)

Fuel System:

Natural Gas

Cylinders:

Combustion:

Emission Certification:

Lean Burn

Bore x Stroke:

US EPA Tier 2 Certified and 1g/hp-hr NOx Aspiration:

US EPA NSPS Compliant Capable

Revision

12-Jan-16

6.25 x 6.25 in (159 x 159 mm)

Turbocharged and Aftercooled

Engine Rating:

Engine Speed

Continuous Power

rpm

hp

kWm

1,800

471

351

Engine Fuel Consumption @ 1800 rpm

hp

12000

Fuel Consumption

kWm

BTU/hp-hr

MJ/kWm-hr

Continuous Power

100

471

351

7720

10.9

75

353

263

7998

11.3

50

236

176

8683

12.3

25

118

88

N/A

N/A

Fuel Consumption (BTU/hp-hr)

Output Power

11000

10000

9000

8000

7000

6000

0

100

200

300

400

500

Gross Engine Output (hp)

These guidelines have been formulated to ensure proper application of generator drive engines in A.C. generator set installations. (AEB 26.02)

Reference AEB 10.47 for determining Electrical Output.

STANDBY POWER RATING: Applicable for supplying emergency power for the duration of the utility power outage. No overload capability is

available for this rating. Under no condition is an engine allowed to to operate in parallel with the public utility at the Standby Power rating. This

rating should be applied where reliable utility power is available. A Standby rated engine should be sized for a maximum of an 80% average load

factor and 200 hours of operation per year. This includes less than 25 hours per year at the Standby Power rating. Standby ratings should never be

applied except in true emergency power outages. Negotiated power outages contracted with a utility company are not considered an emergency.

Data shown above represents gross engine performance capabilities obtained and corrected in accordance with ISO-3046 conditions

of 100 kPa (29.53 in-Hg) barometric pressure [110 m (361 ft) altitude], 25 C (77 F) air inlet temperature, and relative humidity of

30% using dry processed gas natural gas fuel with 905 BTU per standard cubic foot lower heating value.

PRIME POWER RATING SPARK IGNITED GAS is applicable for supplying electrical power in place of commercially available power in a variable

load application. The average power output of a prime rating should not exceed the rated power of the associated Continuous Power rating for the

specific engine. If there is no Continuous Power rating associated with this engine, the average power output of a prime rating should not exceed

75% of the Prime Power rating. The total operation time at 100% Prime Power should not exceed 500 hours per year. If a Standby Power rating is

available, an overload capability is available at the Standby Power rating for one out of every 12 hours. The total time at the overload power should

not exceed 25 hours per year. If there is a Continuous Power rating associated with this engine, the Gas Prime rating can be run continuously at the

Continuous Power rating. If there is no Continuous Power rating associated with this engine, the maximum amount of hours of operation is 2500

hours per year.

CONTINUOUS POWER RATING: Applicable for supplying utility power at a constant 100% load for an unlimited number of hours per year. No

overload capability is available for this rating.

Power output curves are based on the engine operating with fuel system, water pump and lubricating oil pump; not included are battery

charging alternator, fan, optional equipment and driven components.

Data Status: Final (Measured Data)

Data Tolerance: +/- 5%

CHIEF ENGINEER: Kendra Eads (Application)

Lynn Zopff (Base Engine)

Cummins Confidential

FR 4704 (continued) Page: 2

Altitude and Ambient Temperature Derate Curve

LTA Coolant Temperature Derate Curve

Temperature (C)

10.0

16

25

Derate of Rated Power (%)

Derate of Rated Power (%)

30

20

15

10

5

30.0

50.0

14

12

10

8

6

4

2

0

0

2000

4000

6000

8000

10000

0

50

70

90

110

130

150

Temperature (F)

Altitude (Feet)

120 F (49 C)

115 F (46 C)

105 F (41 C)

95 F (35 C)

Operation at Elevated Temperature and Altitude:

For Continuous operation above these conditions, derate by an additional 3.5% per 1000 ft

(305m), and 100 % per 1 F ( 0.6 C) Derates shown are based on 15 in-H2O air intake

restriction and 2 in-Hg exhaust back pressure.

Engine Adjustments for Fuel Methane Index

Derate

Timing Adjustments

40

MI > 51: Timing is 17 degrees BTDC

Derate of Rated Power (%)

35

30

25

20

15

10

Methane index calculated using Cummins Gas Analysis Tool.

Non-standard fuels typically follow the characteristic of high energy content corresponds to low

methane index, or low energy content corresponds to high methane index. Contact G-Drive

Application Engineering if the fuel does not follow this trend.

5

0

30

50

70

90

Methane Index

Engine Adjustments for Fuel Energy Content

Derate

- 2 psig - Fuel Inlet Pressure

Derate of Rated Power (%)

100

- 3 psig - Fuel Inlet Pressure

80

60

This rating should only be operated on 800-1200 BTU/scf fuel.

Operation on fuel outside this range will result in poor engine

40

performance, and is not recommended.

20

0

600

700

800

900

1000

LHV (BTU/scf)

Please refer to the appropriate Operations and Maintenance Manual on Quickserve Online for more information on proper

commissioning procedures and additional ignition timing information.

Cummins Confidential

FR 4704 (continued) Page: 3

ak

e

Te Ma

mp nifo

era ld

tur

e

% Derate Due to Condensation

Int

LT

Te Retu

mp rn

era

tur

e

Condensation Derate Table

86F / 30C

95F / 35C

14

24

34

42

90F / 32C

99F / 37C

15

25

34

42

93F / 34C

102F / 39C

15

25

34

97F / 36C

106F / 41C

16

26

100F / 38C 109F / 43C

17

104F / 40C 113F / 45C

Dewpoint

50

54

57

61

64

68

72

75

79

82

86

10

12

14

16

18

20

22

24

26

28

30

Aftercooler Coolant Pump Restriction Curve

Jacket Water Coolant Pump Restriction Curve

32.5

168

166

164

Coolant Flow (gpm)

Coolant Flow (gpm)

32

31.5

31

30.5

162

160

158

156

154

30

152

0

10

15

External Restriction (psig)

10

External Restriction (psig)

Engine operation is not recommended with an aftercooler external restriction higher than 8

psi (55 kPa). Engine damage may result if run under unapproved conditions.

Engine operation is not recommended with a jacket water external restriction higher than 8 psi

(55 kPa). Engine damage may result if run under unapproved conditions.

Cummins Confidential

FR 4704 (continued) Page: 4

General Engine Data

Type

Aspiration

Compression Ratio

Bore x Stroke

6.25 x 6.25

Displacement

Approximate Engine Weight (Wet)

1,150

4,534

Moment of Inertia of Rotating Components Without Flywheel

Center of Gravity

from Rear Face of Block

from Engine Centerline to Left Side of Engine

above Crankshaft Centerline

Maximum Static Loading at Rear Main Bearing

Engine Mounting

Maximum Bending Moment at Rear Face of Block

Maximum Crankshaft Thrust Bearing Load

Four Cycle, Inline, 6 Cylinder

Turbocharged and Aftercooled

11.0:1

in

159 x 159 mm

in3

lbm

18.8

2,057

L

kg

16.1

in-lbf-s2

1.82

kg-m2

23.6

0.0

11.1

N/A

in

in

in

lbm

599

0

282

N/A

mm

mm

mm

kg

1,000

750

lb-ft

lbf

1,356

3,336

N-m

N

Exhaust System

Minimum Back Pressure

Maximum Back Pressure

N/A

2.00

in-Hg

in-Hg

N/A

6.8

kPa

kPa

Air Induction System

Maximum Intake Air Restriction

with Dirty Filter Element

with Normal Duty Air Cleaner and Clean Filter Element

with Heavy Duty Air Cleaner and Clean Filter Element

15

N/A

N/A

in-H2O

in-H2O

in-H2O

3.7

N/A

N/A

kPa

kPa

kPa

36

5

7

60

quarts

quarts

psi

ft

34.1

4.7

48

18.3

L

L

kPa

m

Cooling System

Coolant Capacity

Engine

Aftercoolers

Minimum Pressure Cap Rating at Sea Level

Maximum Static Head of Coolant Above Crankshaft Centerline

Acceptable Types of Deaeration System

Jacket Water Circuit Requirements

Maximum Coolant Friction Head External to Engine

Maximum Coolant Temperature (Maximum Top Tank Temp)

Thermostat (Modulating) Range

Positive

8

203

180 - 202

psi

F

F

55

95.0

82 - 94

kPa

C

C

Aftercooler Circuit Requirements

Maximum Coolant Friction Head External to Engine

psi

55

kPa

Maximum Coolant Temperature Into the Aftercooler

130

54

104

40

Thermostat (Modulating) Range

90 - 110

32 - 43

Lubrication System

Oil Pressure

@ Minimum Low Idle

@ Governed Speed

Maximum Oil Temperature

Oil System Capacity (Including Filter)

20

50 - 70

250

33

psi

psi

F

gal

138

345 - 483

121

125

kPa

kPa

C

L

1

5

psi

psi

7

34

kPa

kPa

without Power Derate

Fuel System

Minimum Fuel Inlet Pressure @ Inlet of GMF Sensor Housing

Maximum Fuel Inlet Pressure @ Inlet of GMF Sensor Housing

Maximum Fuel Pressure Variation

Acceptable Fuel

Minimum Fuel Methane Number*

+/-3 %

Pipeline Quality Natural Gas, 800-1200 BTU/scf

77 MN

Minimum Fuel Energy Content*

845

* when equipped with original fuel system hardware and original ignition timing, at

3 psig fuel inlet pressure at full load

Additional fuel quality and derate information is located on Page 2.

BTU/scf

Cummins Confidential

31.5

MJ/scm

FR 4704 (continued) Page: 5

Electrical System

System Voltage

Minimum Battery Capacity: Cold Soak at -18 C (0 F) or Above

Engine Only Cold Cranking Amps

Engine Only Reserve Capacity

Maximum Starting Circuit Resistance

24

900

320

0.002

Cold Start Capability

Unaided Cold Start

Minimum Cranking Speed

Minimum Ambient Temperature for Unaided Cold Start

Minimum Ambient Temperature for NFPA 110 Cold Start (90 F Minimum

Coolant Temperature)

Cranking Torque at Minimum Unaided Cold Start Temperature

V

CCA

min

Ohm

N/A

45

rpm

F

7.2

N/A

N/A

F

lb-ft

N/A

N/A

C

N-m

Performance Data

All data is based on:

-Engine operating with fuel system, water pump, lubricating oil pump, air cleaner and exhaust silencer; not included are

battery charging alternator, fan, and optional driven components

-Engine operating with 905 BTU/scf fuel

-ISO 3046, Part 1, Standard Reference Conditions of:

Barometric Pressure: 100 kPa (29.53 in-Hg)

Air Temperature:

25 C (77 F)

Altitude:

110 m (361 ft)

Relative Humidity:

30%

Estimated Free Field Sound Pressure Level: 1800 RPM, @ 7.5 m from Engine (ISO-3744)

Exhaust Noise at Rated: 1 m Horizontally From Centerline of Exhaust Pipe Outlet,

Upwards at 45: 1800 RPM

Steady State Speed Stability at Any Constant Load

Governed Engine Speed

Engine Idle Speed

83.8

dBa

101.9

+/- 0.75

1,800

900

dBa

%

rpm

rpm

Continuous Power

75% Load

353 (263)

135 (929)

hp (kWm)

psi (kPa)

100% Load

471 (351)

180 (1240)

Intake Air Flow

Turbocharger Compressor Outlet Abs. Pressure

Turbocharger Compressor Outlet Temperature

Intake Manifold Abs. Pressure

Exhaust Gas Temp - Dry Stack

ft3/min (L/s)

in-Hg (kPa)

F (C)

in-Hg (kPa)

F (C)

1021 (482)

91 (308)

368 (187)

73 (247)

993 (534)

Exhaust Gas Flow

Air to Fuel Ratio (Mass Basis)

Heat Rejection to Ambient

Heat Rejection to Exhaust

Heat Rejection to Jacket Coolant

Engine Jacket Water Flow at:

5 psi External Friction Head

Maximum Friction Head

Heat Rejection to Aftercooler Coolant

Engine Aftercooler Water Flow at:

5 psi External Friction Head

Maximum External Friction Head

Ignition Timing (BTDC)

O2

ft3/min (L/s)

BTU/min (kW)

BTU/min (kW)

BTU/min (kW)

2903 (1370)

26.5:1

1821 (32)

20377 (358)

12408 (218)

2196 (1036)

25.6:1

1423 (25)

15653 (275)

10587 (186)

1535 (724)

24.6:1

1025 (18)

10815 (190)

9506 (167)

gpm (L/min)

gpm (L/min)

BTU/min (kW)

167 (632)

156 (591)

4895 (86)

167 (632)

156 (591)

3529 (62)

167 (632)

156 (591)

1992 (35)

gpm (L/min)

gpm (L/min)

deg

%

31 (117)

27 (102)

17

8.7

31 (117)

27 (102)

17

8.4

31 (117)

27 (102)

17

8.1

Gross Engine Power Output

Brake Mean Effective Pressure

Additional Notes:

End of Report

Cummins Confidential

762

88

349

55

979

(360)

(298)

(176)

(186)

(526)

50% Load

236 (176)

90 (622)

537 (253)

73 (247)

303 (151)

39 (132)

968 (520)

You might also like

- Engine Data SheetEngine Data SheetEngine Data SheetEngine Data SheetDocument3 pagesEngine Data SheetEngine Data SheetEngine Data SheetEngine Data SheetHumayun Nawaz100% (1)

- BE2000E BrochureDocument4 pagesBE2000E BrochureOrlando VeladoNo ratings yet

- TBG 620 Work Shop ManualDocument146 pagesTBG 620 Work Shop Manualubaldo caraballoNo ratings yet

- PandarosDocument9 pagesPandarosTempest_LNo ratings yet

- QSK60 G6 PDFDocument2 pagesQSK60 G6 PDFShahzad Ali100% (2)

- Tank Type Engine Heater Installation GuideDocument4 pagesTank Type Engine Heater Installation GuideJosë Rodríguez100% (1)

- 2206a-E13tag3 Electropak Pn1881Document2 pages2206a-E13tag3 Electropak Pn1881ibrahemNo ratings yet

- C450N6 A042j403 G-01Document5 pagesC450N6 A042j403 G-01JoseLuisAramayoNo ratings yet

- Tecjet™ 110 Gas Regulation and Metering Valve / Actuator SystemDocument54 pagesTecjet™ 110 Gas Regulation and Metering Valve / Actuator SystemAnonymous LfeGI2hMNo ratings yet

- Model QRNG 325 Model QRNG 325 Model QRNG 325 Model QRNG 325 Model QRNG 325Document26 pagesModel QRNG 325 Model QRNG 325 Model QRNG 325 Model QRNG 325 Model QRNG 325roalcalo_uanNo ratings yet

- Mitsubishi Diesel Engine - S16R-Y2PTAW2Document2 pagesMitsubishi Diesel Engine - S16R-Y2PTAW2Christian Rivera FloverNo ratings yet

- Cummins Onan 175HDKBRDocument4 pagesCummins Onan 175HDKBRpetey100% (1)

- MEC20-902 Controlador Gran Plaza PDFDocument101 pagesMEC20-902 Controlador Gran Plaza PDFCesar AmloNo ratings yet

- Kta38-G5 2Document4 pagesKta38-G5 2Ali AmirNo ratings yet

- QST30 G5Document2 pagesQST30 G5Hoang Minh Hung75% (4)

- CG260 16Document8 pagesCG260 16erick_fer_b0% (2)

- Datasheet G3516 1200 RPMDocument4 pagesDatasheet G3516 1200 RPMVerita SanjuánNo ratings yet

- RENR7941 - CDVR SpecificationDocument4 pagesRENR7941 - CDVR SpecificationХусниддин ГаниевNo ratings yet

- 1800reozm Specification KohlerDocument4 pages1800reozm Specification KohlerTrần Quang TuyênNo ratings yet

- 001a HM02316 - 00 Engine SpecificationsDocument92 pages001a HM02316 - 00 Engine SpecificationsBruno VenturaNo ratings yet

- ACS Analogue Control Systems eDocument12 pagesACS Analogue Control Systems eKhaled KamelNo ratings yet

- Four Stroke Diesel Engine PresentationDocument29 pagesFour Stroke Diesel Engine Presentationfaizan997No ratings yet

- Eq Generacion Electrica Iluminacion Olympian GEP150Document5 pagesEq Generacion Electrica Iluminacion Olympian GEP150Gianni EscalanteNo ratings yet

- For Your Information! Anymore!: Safety Solenoid Valve Nominal Width RP 1/2 - RP 2 SV SV-D Sv-DleDocument8 pagesFor Your Information! Anymore!: Safety Solenoid Valve Nominal Width RP 1/2 - RP 2 SV SV-D Sv-DleRomly MechNo ratings yet

- Ot Iii 962-0512Document142 pagesOt Iii 962-0512Kien TranNo ratings yet

- 4008TAG2 Electro Unit PN2199Document2 pages4008TAG2 Electro Unit PN2199RioNo ratings yet

- X20CM0985 1 Eng - V1.42Document72 pagesX20CM0985 1 Eng - V1.42rushaNo ratings yet

- Test and repair exciter rectifier bridgeDocument54 pagesTest and repair exciter rectifier bridgeedgar luis100% (1)

- Wizard2 LEXF4916 03Document2 pagesWizard2 LEXF4916 03Rolando ChanisNo ratings yet

- Transformadores de Sensado CaterpillarDocument1 pageTransformadores de Sensado CaterpillarRoberto EspinNo ratings yet

- Altronic DD20 Annunciator and TachmotersDocument31 pagesAltronic DD20 Annunciator and TachmotersVladimirNo ratings yet

- Ecp-4083935oampmecpg PDFDocument100 pagesEcp-4083935oampmecpg PDFP.p. Arul Ilancheeran100% (1)

- (نسخة) JB-WD-DSE 6120 MKIII - 12.5-200 (1106)Document1 page(نسخة) JB-WD-DSE 6120 MKIII - 12.5-200 (1106)Mahmood NabilNo ratings yet

- 3012Tag3A 3000 Series: Diesel Engine - ElectropakDocument2 pages3012Tag3A 3000 Series: Diesel Engine - ElectropakMounir Yousfi100% (1)

- 3306 164-200KW PRDocument4 pages3306 164-200KW PRvanaselvan vpNo ratings yet

- MX-321Document6 pagesMX-321Akun BackupNo ratings yet

- GVSP Governor Spec ReportDocument2 pagesGVSP Governor Spec ReportJohn100% (1)

- SEDEMAC B12 Rotary Actuator PDSDocument2 pagesSEDEMAC B12 Rotary Actuator PDSSamir Khan100% (1)

- AUTO MAINS FAILURE MODULEDocument2 pagesAUTO MAINS FAILURE MODULESOSNo ratings yet

- B2-Lehe4748-01 - Emcp3.3Document8 pagesB2-Lehe4748-01 - Emcp3.3Ali H. Al-ZowayedNo ratings yet

- Wartsila W28SG 1Document5 pagesWartsila W28SG 1hadNo ratings yet

- 4016T 61TRG32250kVA For 50Hz PDFDocument13 pages4016T 61TRG32250kVA For 50Hz PDFParinya100% (1)

- Natural gas and biogas generator frequency and emissionsDocument2 pagesNatural gas and biogas generator frequency and emissionsjosuelino2002No ratings yet

- L36GL Data Sheet PDFDocument2 pagesL36GL Data Sheet PDFManuel ValdiviesoNo ratings yet

- AGC 100 Operator's Manual 4189340753 UKDocument17 pagesAGC 100 Operator's Manual 4189340753 UKRicardo JúniorNo ratings yet

- DVR 2400 and DVR 2500 Digital Voltage Regulator: Installation, Operation and Maintenance ManualDocument68 pagesDVR 2400 and DVR 2500 Digital Voltage Regulator: Installation, Operation and Maintenance Manualalexel_unamNo ratings yet

- Spark Plugs GuideDocument22 pagesSpark Plugs GuidenachoNo ratings yet

- Operation Maintenance Manual 2206-E13 SEBU8337-00 May 08Document88 pagesOperation Maintenance Manual 2206-E13 SEBU8337-00 May 08Kornelius David Pattiselanno100% (1)

- Operation Maintenance G-3500 3rcDocument116 pagesOperation Maintenance G-3500 3rcJorge Enrique Fuentes MarinNo ratings yet

- QSV 81/91 Gas Engine Routine Maintenance CourseDocument53 pagesQSV 81/91 Gas Engine Routine Maintenance CourseWilliam Ruiz100% (1)

- Dse7420 Installation InstructionsDocument2 pagesDse7420 Installation Instructionspj_chaudhary3796100% (1)

- CURSOR TIER 3 SERIES Industrial Application C87 CURSOR 87 TE XDocument24 pagesCURSOR TIER 3 SERIES Industrial Application C87 CURSOR 87 TE XAminadavNo ratings yet

- Cummins Gta1710g Natural Gas EngineDocument2 pagesCummins Gta1710g Natural Gas EngineAbhi Karmyal100% (1)

- CEM 7CEA 7CEC 7CEM7 + CEC7Manual start•xx•Manual stop•xx•Automatic start••x•Automatic stop••x•Remote startx•xxRemote stopx•xxCEM 7CEA 7CEC 7CEM7 + CEC7Mains failureDocument13 pagesCEM 7CEA 7CEC 7CEM7 + CEC7Manual start•xx•Manual stop•xx•Automatic start••x•Automatic stop••x•Remote startx•xxRemote stopx•xxCEM 7CEA 7CEC 7CEM7 + CEC7Mains failureMd MoniruzzamanNo ratings yet

- Woodward GovernorDocument5 pagesWoodward Governorveer_s100% (2)

- (REHS0371) Installation and Initial Start Up Procedures For G3300 and G3400 EnginesDocument16 pages(REHS0371) Installation and Initial Start Up Procedures For G3300 and G3400 Enginesvictor.cipriani100% (1)

- Cummins QSK78-G7 Engine Performance DataDocument4 pagesCummins QSK78-G7 Engine Performance Dataacere18100% (1)

- Cummins QSK78 Engine Performance DataDocument4 pagesCummins QSK78 Engine Performance DataBidonsBidonsNo ratings yet

- Tad730ge 111797s01Document8 pagesTad730ge 111797s01roozbehxoxNo ratings yet

- AE Running HoursDocument1 pageAE Running HoursIhwan AsrulNo ratings yet

- Part Catalogue Mitsubishi Engine L3E SeriesDocument130 pagesPart Catalogue Mitsubishi Engine L3E SeriesDesta 77No ratings yet

- Fuel Filter PartsDocument20 pagesFuel Filter PartsNaimahSulistianingsih100% (1)

- Installation of Injection Pump: Downloaded From Manuals Search EngineDocument6 pagesInstallation of Injection Pump: Downloaded From Manuals Search EngineDavid QuispeNo ratings yet

- Snowmobile Maintenance GuideDocument643 pagesSnowmobile Maintenance GuideSteven Antonio100% (5)

- TNT25 250-15 - Euro - IV - Service - Manual - ABS - EN - 20181031A 2Document440 pagesTNT25 250-15 - Euro - IV - Service - Manual - ABS - EN - 20181031A 2Edward BlowNo ratings yet

- G3406 Specifications (4FD, 5NW) SENR3863-01 (Oct 2000)Document39 pagesG3406 Specifications (4FD, 5NW) SENR3863-01 (Oct 2000)caterpillar etNo ratings yet

- Gear Group (Front) - Time: Pruebas y AjustesDocument10 pagesGear Group (Front) - Time: Pruebas y Ajustesluismf14No ratings yet

- Continental Parts CatalogueDocument29 pagesContinental Parts Cataloguedomdum372No ratings yet

- MODEL COLOR OPTIONSDocument91 pagesMODEL COLOR OPTIONSPoe TamNo ratings yet

- Wartsila New X Series EnginesDocument48 pagesWartsila New X Series Enginesvran7775% (4)

- Working Principle of 2 Stroke EngineDocument3 pagesWorking Principle of 2 Stroke EngineSean GreeneNo ratings yet

- PDF Isuzu Truck Fault Codes List PDF - CompressDocument1 pagePDF Isuzu Truck Fault Codes List PDF - CompressRodrigo Almanza NNo ratings yet

- PMS InstructionsDocument44 pagesPMS InstructionsDamien DrakeNo ratings yet

- Model: C100 D6 (6B) Frequency: 60 Fuel Type: Diesel: Generator Set Data SheetDocument3 pagesModel: C100 D6 (6B) Frequency: 60 Fuel Type: Diesel: Generator Set Data SheetIng Victor MendezNo ratings yet

- Estimate: Hammer PerformanceDocument5 pagesEstimate: Hammer PerformanceTravis NineLivesNo ratings yet

- Data Sheet-Cummins 6CTA8.3-GM175 Marine Generators EngineDocument4 pagesData Sheet-Cummins 6CTA8.3-GM175 Marine Generators EngineabdullahaljafarieNo ratings yet

- Cat Electronic Technician 2017B v1.0 Status ReportDocument2 pagesCat Electronic Technician 2017B v1.0 Status ReportPILAR MARTINEZNo ratings yet

- Parts Manual: CMP15/18/20s L FX15/18 L-2Document157 pagesParts Manual: CMP15/18/20s L FX15/18 L-2Marcio50% (2)

- Why Is It That ImportantDocument2 pagesWhy Is It That Importantkozaro 678No ratings yet

- Parts Book Generator Diesel Engine DA1146, D1146T, PO86TI - ENGLISHDocument61 pagesParts Book Generator Diesel Engine DA1146, D1146T, PO86TI - ENGLISHracso92% (12)

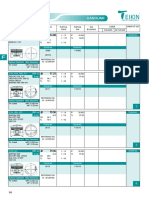

- Teikin Catalog Vol 18-Automotive FordDocument6 pagesTeikin Catalog Vol 18-Automotive FordBolívar FuentesNo ratings yet

- Manual Reparación Motores Yanmar TNE SeriesDocument136 pagesManual Reparación Motores Yanmar TNE SeriesRectificadora JS , sccl93% (43)

- MBE4000 Engine Harness PDFDocument1 pageMBE4000 Engine Harness PDFalejandro sanchezNo ratings yet

- Chapter5 EFI SYSTEM PDFDocument74 pagesChapter5 EFI SYSTEM PDFHillan VieiraNo ratings yet

- Test Data Sheets For DPCN Pumps PDFDocument78 pagesTest Data Sheets For DPCN Pumps PDFUliAlejandroRodriguezCorianga100% (4)

- SI 1037T Approved Pistons Rings and CylindersDocument13 pagesSI 1037T Approved Pistons Rings and CylindersKamal Jit DhimanNo ratings yet

- Isuzu N-Series 4HK1 5.2L (2014-15)Document16 pagesIsuzu N-Series 4HK1 5.2L (2014-15)Robert Callahan100% (2)

- Technical Terms Chapter 47Document5 pagesTechnical Terms Chapter 47thena MartinNo ratings yet

- Volvo PentaDocument250 pagesVolvo PentaRuben Antonio Huaranca Cruz86% (22)