Professional Documents

Culture Documents

Hose Burst Valve PDF

Uploaded by

nikhil nagannavarOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Hose Burst Valve PDF

Uploaded by

nikhil nagannavarCopyright:

Available Formats

Hose Burst Valve

Direct-Acting

Flat Seat Valve,

Cartridge 350 bar

RBE 1/4 to 3/4

Up to 150 l/min

Up to 350 bar

FEATURES

FUNCTION

Closing

element

zz Hose burst valves for direct installation in cylinders, lines and control blocks

zz Highly reliable thanks to fast response

zz Unauthorized adjustment not possible once installed

zz Choice of four sizes for optimum adaptability to the system

zz Different flow rate settings available as an option

Consumer

being protected

Valve seat

Spring

E 5.174.11/01.13

SPECIFICATIONS

280

The hose burst valve RBE is a flow

operated flat seat valve which prevents

uncontrolled movement in the consumer in

the event of a hose burst. The hose burst

valve is open in the normal position and

allows flow in both directions. If the pre-set

actuating flow rate is exceeded as a result

of a hose burst, for example, the valve

quickly closes and blocks the flow from

port 1 to port 2.

Caution:

The actuating flow rate should be at least

20% higher than the highest flow rate in the

system, to prevent the valve reacting too

sensitively! Due to the effects of acceleration

and inertia, the valve should be replaced

after a hose burst.

Operating pressure:

max. 350 bar

Nominal flow:

Media operating temperature range:

RBE1/4 up to max. 25 l/min

RBE3/8 up to max. 50 l/min

RBE1/2 up to max. 75 l/min

RBE3/4 up to max. 150 l/min

min. -20 C to max. +100 C

Ambient temperature range:

min. -20 C to max. +100 C

Operating fluid:

Hydraulic oil to DIN 51524 Part 1 and 2

Viscosity range:

min. 2.8 mm/s to max. 800 mm/s

Filtration:

Class 21/19/16 according to ISO 4406 or

cleaner

150 years (see "Conditions and

instructions for valves" in brochure 5.300)

No orientation restrictions, preferably

horizontal

Valve body: steel

RBE1/4 = 0.009 kg

RBE3/8 = 0.016 kg

RBE1/2 = 0.031 kg

RBE3/4 = 0.057 kg

MTTFd:

Installation:

Materials:

Weight:

MODEL CODE

PERFORMANCE

RBE R 1/2 X 75

Basic model

Hose burst valve

Pressure drops, dependent on flow rate at various setting

values, measured at = 34 mm/s and Toil = 46 C

RBER1/4

Size of connection

R 1/4 = RBE R1/4

R 3/8 = RBE R3/8

R 1/2 = RBE R1/2

R 3/4 = RBE R3/4

p [bar]

Series

(determined by manufacturer)

Actuating flow rate

3 25 l/min = RBE R1/4

6 50 l/min = RBE R3/8

12 75 l/min = RBE R1/2

25 150 l/min = RBE R3/4

Setting value = max. flow rate

Other pre-set flow rates on request

Q [l/min]

Model code

Part No.

RBE-R1/4-X-25

710025

RBE-R3/8-X-50

710026

RBE-R1/2-X-75

710028

RBE-R3/4-X-150

710029

Other models on request

RBER3/8

p [bar]

Standard models

Standard in-line bodies

Code

Part No.

Material

Ports

Pressure

Ports: 1x female thread, 1x male thread

XB05520-01X

393215

Steel

G1/4

350 bar

XB08520-01X

393217

Steel

G3/8

350 bar

XB10520-01X

393219

Steel

G1/2

350 bar

XB12520-01X

395061

Steel

G3/4

350 bar

Q [l/min]

RBER1/2

Steel

G1/4

350 bar

Steel

G3/8

350 bar

XX10520-01X

393228

Steel

G1/2

350 bar

XX12520-01X

395063

Steel

G3/4

350 bar

Q [l/min]

RBER3/4

Q [l/min]

E 5.174.11/01.13

393224

393226

p [bar]

XX05520-01X

XX08520-01X

p [bar]

Ports: 2x female thread:

281

DIMENSIONS

Note

The valves are set to the max. actuating flow rate as standard

and can be adjusted by the user. Equally, valves with fixed

settings are also available. The valve is set according to the

setting curves by varying the gap "h" (see diagrams).

Cartridge

setting gauge

setting dimension "h"

Millimeter

Subject to technical modifications

Type

RBE R1/4X...

R1/4

21

11.5

C

3.5

RBE R3/8X...

R3/8

23.5

13.5

SW

9.5

12

5

5.5

Dw

dw

2.5/5

10

3.5/6

RBE R1/2X...

R1/2

30.5

17

5.5

14

12

4.5/8

RBE R3/4X...

R3/4

38

23.5

6.5

18

16

6.5/9

Cavity

adjustment nut

RBE-R1/4 and 3/8:

Torque 0.8 Nm

lock nut

RBE-R1/2 and 3/4:

Torque 1.8 nM

To change the setting, loosen the lock nut, measure the gap

using setting gauges, or similar, and then re-tighten lock nut.

setting dimension "h"

in mm

Setting curves

measured at n = 34 mm/s

Q [l/min]

Form tools

Tool

Part No. / Cavity

05520

Millimeter

Subject to technical modifications

Type

t1 0.5

t2 min.

RBE R1/4X...

R1/4

20.5

32

38

RBE R3/8X...

R3/8

22.5

36

44

RBE R1/2X...

R1/2

27

44

53

RBE R3/4X...

R3/4

27.5

51

61

08520

10520

12520

Tap

1002670 1002668 1002667 1002663

Assembly tool

161421

160561

160560

164180

Assembly tool

The installation dimensions (in mm) shown in the tables are minimum values for

threaded pipe connections and male adapters to DIN 3852.

E 5.174.11/01.13

Type

282

Da max.

Dw

Ds

L1min.

L2max.

RBE R1/4X...

11.5

Di

5.8

RBE R3/8X...

15

10

6.5

RBE R1/2X...

18

12

8.2

3.5

11

RBE R3/4X...

24

All dimensions in mm.

16

8.5

12

05520

10520

08520

12520

NOTE

The information in this brochure relates to

the operating conditions and applications

described.

For applications or operating conditions

not described, please contact the relevant

technical department.

Subject to technical modifications.

HYDAC Fluidtechnik GmbH

Justus-von-Liebig-Str.

D-66280 Sulzbach/Saar

Tel: 0 68 97 /509-01

Fax: 0 68 97 /509-598

E-Mail: flutec@hydac.com

E 5.174.11/01.13

CAVITY

283

You might also like

- E5174 RbeDocument4 pagesE5174 RbeVinod YbNo ratings yet

- E5174 10 12 10 - Rbe 1 - 8 3 - 4Document4 pagesE5174 10 12 10 - Rbe 1 - 8 3 - 4romekgzp0% (1)

- Directional Control Valve GuideDocument11 pagesDirectional Control Valve GuideDaniel VillarroelNo ratings yet

- Prince Hydraulics Sectional Body Model SV Offered by PRC Industrial SupplyDocument18 pagesPrince Hydraulics Sectional Body Model SV Offered by PRC Industrial SupplyPRC Industrial SupplyNo ratings yet

- Pressure Relief Valves ARE: Direct Operated, in Line Mounting - G 1/4" and G 1/2" Threaded PortsDocument4 pagesPressure Relief Valves ARE: Direct Operated, in Line Mounting - G 1/4" and G 1/2" Threaded PortsmfbayatNo ratings yet

- Ra 23351Document10 pagesRa 23351GuilhermeGFCNo ratings yet

- Three Way Valve Technical OverviewDocument8 pagesThree Way Valve Technical OverviewWalter JosephNo ratings yet

- Rexroth FDDocument116 pagesRexroth FDIvan GudeljNo ratings yet

- Fedos Rekos KardosDocument34 pagesFedos Rekos KardosIlija RunjajicNo ratings yet

- 14 400E 6DC Final Valvula BermadDocument4 pages14 400E 6DC Final Valvula Bermadmax_powerNo ratings yet

- Leak-free Poppet Solenoid ValvesDocument4 pagesLeak-free Poppet Solenoid ValvesrodrurentNo ratings yet

- FP 730-59 Data Sheet PDFDocument4 pagesFP 730-59 Data Sheet PDFCarlos TarquinoNo ratings yet

- Norgren V51 Solenoid ManualDocument5 pagesNorgren V51 Solenoid ManualjadetorresNo ratings yet

- PRH04-300 FLG PDFDocument5 pagesPRH04-300 FLG PDFengp3077No ratings yet

- Vaa /ru /DL 38: Pressure Relief ValvesDocument2 pagesVaa /ru /DL 38: Pressure Relief ValvesLibinNo ratings yet

- 4/2-And 4/3 - Proportional Directional Valves Direct Operated, Type 4WRA, Series 1XDocument8 pages4/2-And 4/3 - Proportional Directional Valves Direct Operated, Type 4WRA, Series 1XlizbethdiosesNo ratings yet

- Pressue CompensatorDocument2 pagesPressue CompensatorMahmud MaherNo ratings yet

- External Gear Pumps Technical SpecificationsDocument4 pagesExternal Gear Pumps Technical SpecificationsAnton Feny SaputraNo ratings yet

- Flow Switches BarksdaleDocument20 pagesFlow Switches BarksdaleDian PramadiNo ratings yet

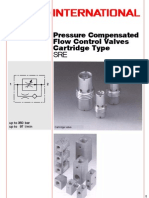

- Flow Control Valves Pressure Compensated Cartridge TypeDocument6 pagesFlow Control Valves Pressure Compensated Cartridge TypevrgohilNo ratings yet

- Re21468 2005-07Document8 pagesRe21468 2005-07LuHa1No ratings yet

- Valvula de Alivio de PresionDocument4 pagesValvula de Alivio de PresioneselcosacNo ratings yet

- 43 430 UF Final PDFDocument4 pages43 430 UF Final PDFCarlos TarquinoNo ratings yet

- 11 042Document2 pages11 042toha82No ratings yet

- Re 22049Document16 pagesRe 22049ShortcutterNo ratings yet

- All About HidrolicDocument7 pagesAll About Hidrolicpiteng1945100% (3)

- RE 22 371/03.98 - 4/3 and 4/2 directional control valves with hand lever Type WMMDocument8 pagesRE 22 371/03.98 - 4/3 and 4/2 directional control valves with hand lever Type WMMAhmed Abd ElhakeemNo ratings yet

- DM931 Variable Orifice Double Regulating Valve: PN16 Cast Iron Balancing Valve (VODRV), Flanged To BSEN 1092-2Document10 pagesDM931 Variable Orifice Double Regulating Valve: PN16 Cast Iron Balancing Valve (VODRV), Flanged To BSEN 1092-2Mohamed AdelNo ratings yet

- GiacominiDocument2 pagesGiacominiflorahope4No ratings yet

- Rotametro ABBDocument10 pagesRotametro ABBjoticamario123No ratings yet

- ATOSs Valves DHI-0711Document4 pagesATOSs Valves DHI-0711Cardoso MalacaoNo ratings yet

- Valvula Reductora de Presion Bermad Area 675 720-ULDocument4 pagesValvula Reductora de Presion Bermad Area 675 720-ULChristian FherNo ratings yet

- Valvulas Sole No Ides IsDocument12 pagesValvulas Sole No Ides Isaaa3131No ratings yet

- Valve configuration and solenoid directional valvesDocument8 pagesValve configuration and solenoid directional valvesFabinhoTowerNo ratings yet

- Valvulas Mariposa EclipseDocument12 pagesValvulas Mariposa EclipseFernando GiadansNo ratings yet

- Bermad: Fire ProtectionDocument4 pagesBermad: Fire ProtectionalbertoNo ratings yet

- Valvula ASCO Falcon SB2500Document2 pagesValvula ASCO Falcon SB2500Elmer HuashuayoNo ratings yet

- Speader Valves Hk66b102Document12 pagesSpeader Valves Hk66b102seaqu3stNo ratings yet

- FunctionalSafety V7666Document12 pagesFunctionalSafety V7666rufino.perea.2No ratings yet

- Cartridgevalves PDFDocument15 pagesCartridgevalves PDFÂnderson Silva BrasilNo ratings yet

- SD 14 eDocument12 pagesSD 14 eseaqu3stNo ratings yet

- Rexroth PumpsDocument24 pagesRexroth PumpsAmanda SmithNo ratings yet

- Armstrong Automatic Air Vent ValveDocument2 pagesArmstrong Automatic Air Vent ValveT. LimNo ratings yet

- Series 825Y Specification SheetDocument2 pagesSeries 825Y Specification SheetFEBCONo ratings yet

- Moog ServovalvesDocument8 pagesMoog Servovalvesdylan_dearing@hotmail.com100% (1)

- Re29564 2007-011Document12 pagesRe29564 2007-011engineer86No ratings yet

- VDLSE502 - VRB2-3 - Danfoss VentiliDocument8 pagesVDLSE502 - VRB2-3 - Danfoss VentilizigicsasaNo ratings yet

- Relay Relayair StartAirDocument8 pagesRelay Relayair StartAirLuis Eduardo Albarracin RugelesNo ratings yet

- Directional Valve Spec SheetDocument4 pagesDirectional Valve Spec SheetRFIGUEROACNo ratings yet

- Product Specifications for FOXTOP Control Valve System PSS 4-24A1 FDocument0 pagesProduct Specifications for FOXTOP Control Valve System PSS 4-24A1 Fcico_ctNo ratings yet

- 70PCVBA Air BoosterDocument20 pages70PCVBA Air BoosterWirote DewilaiNo ratings yet

- Re17047 2003-11Document8 pagesRe17047 2003-11Oscar CruzNo ratings yet

- Econ Gate ValvesDocument22 pagesEcon Gate ValvesRiyas Udheen100% (1)

- NIMCO CV3000sDocument16 pagesNIMCO CV3000sBruno SamaeianNo ratings yet

- Valvula WW-820Document4 pagesValvula WW-820Anonymous Iic1fi49uENo ratings yet

- Boost pressure up to 4 times with no-power air boosterDocument20 pagesBoost pressure up to 4 times with no-power air boosterCarlos Andres Rodriguez SolarteNo ratings yet

- SD 16 eDocument20 pagesSD 16 eseaqu3stNo ratings yet

- PSI PumpsDocument12 pagesPSI PumpsagiacomuzoNo ratings yet

- Accelerated Life Test Principles and Applications in Power SolutionsDocument8 pagesAccelerated Life Test Principles and Applications in Power Solutionsnikhil nagannavarNo ratings yet

- Weld Analysis Research Paper Variomat 34272Document33 pagesWeld Analysis Research Paper Variomat 34272nikhil nagannavarNo ratings yet

- Accelerated Test Paper: Recipient Name ContactDocument1 pageAccelerated Test Paper: Recipient Name Contactnikhil nagannavarNo ratings yet

- Accelerated Test Paper: Recipient Name ContactDocument1 pageAccelerated Test Paper: Recipient Name Contactnikhil nagannavarNo ratings yet

- Weld Analysis Research Paper Variomat 34272Document33 pagesWeld Analysis Research Paper Variomat 34272nikhil nagannavarNo ratings yet

- Weld Analysis Research Paper Variomat 34272Document33 pagesWeld Analysis Research Paper Variomat 34272nikhil nagannavarNo ratings yet

- Weld Analysis Research Paper Variomat 34272Document33 pagesWeld Analysis Research Paper Variomat 34272nikhil nagannavarNo ratings yet

- Weld Analysis Research Paper Variomat 34272Document33 pagesWeld Analysis Research Paper Variomat 34272nikhil nagannavarNo ratings yet

- Accelerated Test Paper: Recipient Name ContactDocument1 pageAccelerated Test Paper: Recipient Name Contactnikhil nagannavarNo ratings yet

- Weld Analysis Research Paper Variomat 34272Document33 pagesWeld Analysis Research Paper Variomat 34272nikhil nagannavarNo ratings yet

- Spline DesignDocument5 pagesSpline DesignRuchira Chanda Indu100% (2)

- MSRTC - Rest AllDocument1 pageMSRTC - Rest Allnikhil nagannavarNo ratings yet

- En 24Document1 pageEn 24nikhil nagannavarNo ratings yet

- Dana Te27 Powershift Transmission MaintananceDocument186 pagesDana Te27 Powershift Transmission Maintanancenikhil nagannavar100% (5)

- Spline DesignDocument5 pagesSpline DesignRuchira Chanda Indu100% (2)

- Introduction to Vehicle Transmission ComponentsDocument21 pagesIntroduction to Vehicle Transmission ComponentsManohara ErlaNo ratings yet

- Bhagwan Shri Krishna MarathiDocument1 pageBhagwan Shri Krishna Marathinikhil nagannavarNo ratings yet

- Bhagwan Shri Krishna Marathi PDFDocument60 pagesBhagwan Shri Krishna Marathi PDFnikhil nagannavar75% (4)

- Manufacturing TolerancesDocument13 pagesManufacturing TolerancesHarsh100% (1)

- Potensi Energi Listrik Yang Dihasilkan Dari Emisi Gas Metana Di Tpa Suwung Provinsi BaliDocument8 pagesPotensi Energi Listrik Yang Dihasilkan Dari Emisi Gas Metana Di Tpa Suwung Provinsi BaliNuyul FaizahNo ratings yet

- PWC Verbal Past Question and Answer 1Document130 pagesPWC Verbal Past Question and Answer 1Anton PermanaNo ratings yet

- Oral Hygiene: Presented By: Anis Anis Andreas KyriakidisDocument60 pagesOral Hygiene: Presented By: Anis Anis Andreas Kyriakidislenami_91No ratings yet

- Greek MathemaDocument6 pagesGreek MathemaSebastian GhermanNo ratings yet

- Technical Manual: Package Air Conditioner Rooftop - Cooling Only (50Hz)Document56 pagesTechnical Manual: Package Air Conditioner Rooftop - Cooling Only (50Hz)Im Chinith100% (1)

- Esquematicos CaterpillarDocument9 pagesEsquematicos Caterpillarluis alberto rodriguez100% (1)

- Winbond Elec W25q128jvfiq c111478Document75 pagesWinbond Elec W25q128jvfiq c111478Guilherme El KadriNo ratings yet

- 72 Names of God in HasidimDocument16 pages72 Names of God in HasidimFrancesco VinciguerraNo ratings yet

- (MITSUBISHI) Manual de Taller Mitsubishi Montero 2002Document21 pages(MITSUBISHI) Manual de Taller Mitsubishi Montero 2002wnsdNo ratings yet

- Incorrect Fuel Level Indication RepairDocument3 pagesIncorrect Fuel Level Indication RepairBogdan StefanNo ratings yet

- Surface-Based Transport Model For Mixed-Size Sediment: Peter R. Wilcock, M.ASCE, and Joanna C. CroweDocument9 pagesSurface-Based Transport Model For Mixed-Size Sediment: Peter R. Wilcock, M.ASCE, and Joanna C. CroweEdwinNo ratings yet

- AWWA Bacterial Regrowth in Distr Sys PDFDocument368 pagesAWWA Bacterial Regrowth in Distr Sys PDFsaishankarlNo ratings yet

- Lectures On Quadratic FormsDocument170 pagesLectures On Quadratic FormsyusamengNo ratings yet

- PHD Call - TCD - Micha Ruhl - PHD Project Short DescriptionDocument2 pagesPHD Call - TCD - Micha Ruhl - PHD Project Short DescriptionabuzarNo ratings yet

- In Situ Combustion: Amit Kumar Singh R270307004 Integrated (Ape) +mba (Uam) Semester: VIIIDocument17 pagesIn Situ Combustion: Amit Kumar Singh R270307004 Integrated (Ape) +mba (Uam) Semester: VIIISmita SharmaNo ratings yet

- Final StereogramDocument16 pagesFinal StereogramsimNo ratings yet

- Case CX210B Mine Crawler Excavator Tier 3 Parts Manual PDFDocument701 pagesCase CX210B Mine Crawler Excavator Tier 3 Parts Manual PDFJorge Martinez100% (3)

- Astm F477-08Document4 pagesAstm F477-08ALARCONISTANo ratings yet

- Op-Amp Comparator: Astable (Or Free-Running) Multivibrators Monostable MultivibratorsDocument5 pagesOp-Amp Comparator: Astable (Or Free-Running) Multivibrators Monostable MultivibratorsYuvaraj ShanNo ratings yet

- Strategic Capacity ManagementDocument36 pagesStrategic Capacity ManagementRahul KhannaNo ratings yet

- STC PDFDocument34 pagesSTC PDFМиша ШаулаNo ratings yet

- Balance of Payment (BoP) Definition, Importance and ComponentsDocument21 pagesBalance of Payment (BoP) Definition, Importance and ComponentsAnkita Sharma PandeyNo ratings yet

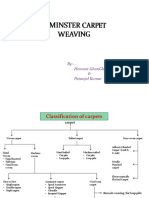

- Axminster CarpetDocument19 pagesAxminster Carpetrohit sinhaNo ratings yet

- TOPFLYtech Product - April 2023 - 4GDocument56 pagesTOPFLYtech Product - April 2023 - 4GmosorioNo ratings yet

- Zip Grade 100 Question V2Document1 pageZip Grade 100 Question V2Jesus Daniel Anaya AlvaradoNo ratings yet

- AmadeusDocument3 pagesAmadeusCleofe Mae Piñero AseñasNo ratings yet

- Danniel Martinez Gonzalez - Gizmo: Seasons: Earth, Moon and Sun Activity B Due 2.3 Deadline 3.1Document3 pagesDanniel Martinez Gonzalez - Gizmo: Seasons: Earth, Moon and Sun Activity B Due 2.3 Deadline 3.1dannielNo ratings yet

- Network FYPDocument3 pagesNetwork FYPla tahzanNo ratings yet

- Countable UncountableDocument4 pagesCountable UncountablePaoLo Mena la TorreNo ratings yet

- Diversification in Flavoured Milk: A ReviewDocument6 pagesDiversification in Flavoured Milk: A ReviewInternational Journal of Clinical and Biomedical Research (IJCBR)No ratings yet