Professional Documents

Culture Documents

Saudi Aramco Welding Consumables Checklist

Uploaded by

Ansuman KalidasOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Saudi Aramco Welding Consumables Checklist

Uploaded by

Ansuman KalidasCopyright:

Available Formats

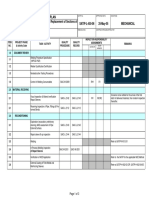

SAUDI ARAMCO ID/PID - 6/29/15 - REV 0 (Standards Cutoff - September 2013)

SAIC NUMBER

SAUDI ARAMCO INSPECTION CHECKLIST

Control of Welding Consumables - Offshore Structures

(Site Storage, Handling, Conditioning & Issuance)

PROJECT TITLE

DATE APPROVED

SAIC-W-2XXX

-11

WBS / BI / JO NUMBER

EQUIPMENT ID NUMBER(S)

EQUIPMENT DESCRIPTION

LAYOUT DRAWING NUMBER

REV. NO.

SCHEDULED INSPECTION DATE & TIME

ACTUAL INSPECTION DATE & TIME

QR NUMBER

WELDCONTRACTOR / SUBCONTRACTOR

EQPT CODE

SYSTEM ID.

PURCHASE ORDER NUMBER

PLANT NO.

EC / PMCC / MCC NO.

QUANTITY INSP.

MH's SPENT

TRAVEL TIME

SAUDI ARAMCO USE ONLY

SAUDI ARAMCO TIP NUMBER

SAUDI ARAMCO ACTIVITY NUMBER

WORK PERMIT REQUIRED?

SATIP-M-005-01 / SATIP-W-013-01

SAUDI ARAMCO INSPECTION LEVEL

CONTRACTOR INSPECTION LEVEL

ITEM

No.

ACCEPTANCE CRITERIA

Storage of Welding Consumables

A1

All consumables shall be stored and dried in accordance with the

requirements of Table 1 for SMAW electrodes and Table 2 for other

consumables. See Attachment 1 & 2

A2

REFERENCE

Shielding gases shall conform to the following requirements:

6.7.1 Carbon dioxide (CO2): Federal Specification BC-C-101, Type B or

Compressed Gas Association (CGA) Specification G-6.2, Type F.

6.7.2 Argon (Ar): Compressed Gas Association (CGA) specification G11.1, Grade A through E. The argon gas purity should be 99.9% minimum

6.7.3 The requirements for other gases and gas mixtures shall be

submitted to CSD for approval.

PASS

FAIL

N/A

RE-INSP DATE

SAES-W-013,

Para. 6.2

SAES-W-013,

Para. 6.7

Handling & Conditioning of Electrodes

B1

All consumables shall be stored and dried in accordance with the

requirements of Table 1 for SMAW electrodes and Table 2 for other

consumables. See Attachment 1 & 2

Control of Electrode Issuance and Return

C1

A project specific procedure or method statement for electrode issuance,

receiving and return was approved by SAPMT and Inspection (PID)

Best Practice

C2

A detailed list of checkpoints are added to this checklist after approval of

the procedure for control of electrode issuance, receiving and return is

approved.

Best Practice

SAES-W-013,

Para. 6.2

NOTES:

1. Item indicated as "Best Practice" requires concurrence among Contractor, SAPMT and PID Inspection Agency. Once accepted by

all parties, it becomes mandatory for implementation.

REMARKS:

REFERENCE DOCUMENTS:

1. SAES-W-013, Welding Requirements for Offshore Structures, (15 December 2009 )

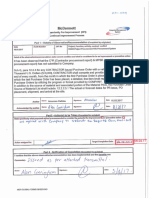

Contractor / Third-Party

Saudi Aramco

Construction Representative*

PMT Representative

Work is Complete and Ready for Inspection:

Name, Initials and Date:

Name, Initials and Date:

QC Inspector

Name, Initials and Date:

T&I Witnessed

QC Record Reviewed

Work Verified

T&I Witnessed

QC Record Reviewed

Work Verified

T&I Witnessed

QC Record Reviewed

Work Verified

PID Representative

Performed Inspection

Work / Rework May Proceed

QC Supervisor

Name, Initials and Date:

Proponent and Others

Quality Record Approved:

Name, Sign and Date:

Name, Organization,

Initials and Date:

*Person Responsible for Completion of Quality Work / Test

Y = YES

Page 1 of 5

N = NO F = FAILED

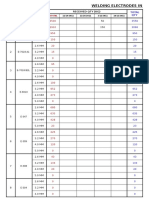

ATTACHMENT 1

Page 2 of 5

ATTACHMENT 1 PAGE 2

Page 3 of 5

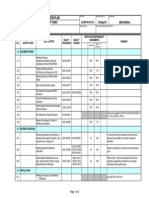

ATTACHMENT 1 PAGE 3

Page 4 of 5

ATTACHMENT 2

Page 5 of 5

You might also like

- Saudi Aramco Inspection Checklist: Inprocess Welding Inspection - Offshore Structures SAIC-W-1313 WeldDocument1 pageSaudi Aramco Inspection Checklist: Inprocess Welding Inspection - Offshore Structures SAIC-W-1313 Weldkartik_harwani4387No ratings yet

- SATIP-L-450-03 Mechanical Ne: Saudi Aramco Typical Inspection Plan Cross Country Above Ground PipeliDocument13 pagesSATIP-L-450-03 Mechanical Ne: Saudi Aramco Typical Inspection Plan Cross Country Above Ground Pipelikarthi51289No ratings yet

- Thickness Qualification Range For PQR and WPQDocument5 pagesThickness Qualification Range For PQR and WPQOuled BladiNo ratings yet

- Saudi Aramco Test Report: 25-May-05 Weld-Weekly Weld Status Report SATR-W-2019Document2 pagesSaudi Aramco Test Report: 25-May-05 Weld-Weekly Weld Status Report SATR-W-2019David RodriguesNo ratings yet

- Repair and Modification ITPDocument8 pagesRepair and Modification ITPShewale PravinNo ratings yet

- NDT Request (Template)Document4 pagesNDT Request (Template)Bethel NdifonNo ratings yet

- Duties of Tank InspectorDocument1 pageDuties of Tank InspectorJawed AlamNo ratings yet

- Wps For Smaw06-001 (Pipe 6g CS)Document10 pagesWps For Smaw06-001 (Pipe 6g CS)walitedisonNo ratings yet

- Weld Matrix Format 1Document7 pagesWeld Matrix Format 1Arslan WaheedNo ratings yet

- SAIC-W-2006 Rev 0Document4 pagesSAIC-W-2006 Rev 0philipyap100% (2)

- SAIC-D-2005 Pressure Vessel Storage, Handling & Preserv PDK-FDocument2 pagesSAIC-D-2005 Pressure Vessel Storage, Handling & Preserv PDK-FAnonymous S9qBDVky100% (1)

- Saudi Aramco welding inspection planDocument12 pagesSaudi Aramco welding inspection planspravin231No ratings yet

- Saudi Aramco Test Report: Welding Rod Oven Calibration/Verification ReportDocument2 pagesSaudi Aramco Test Report: Welding Rod Oven Calibration/Verification ReportJoni Carino Suni100% (1)

- SAUDICHECK - WELD TRACKING DATABASEDocument5 pagesSAUDICHECK - WELD TRACKING DATABASEManoj KumarNo ratings yet

- ITP Heat ExchangerDocument1 pageITP Heat Exchangersarmad009No ratings yet

- QA/QC Engineer-Mechanical (Aramco approvedDocument4 pagesQA/QC Engineer-Mechanical (Aramco approvedshahzad siddiqui0% (1)

- Shaik Yousufuddin (Welding Inspector)Document3 pagesShaik Yousufuddin (Welding Inspector)Mohamed AdelNo ratings yet

- Inspection and Test Plan-Structural Steel C011Document2 pagesInspection and Test Plan-Structural Steel C011FurqanNo ratings yet

- SAEP-379 Quality Issues NotificationDocument4 pagesSAEP-379 Quality Issues NotificationMusic And FunNo ratings yet

- SATR-L-2001 Rev 2 - Flange Joint Tightening Inspection ReportDocument12 pagesSATR-L-2001 Rev 2 - Flange Joint Tightening Inspection Reportdeepa narayan100% (1)

- Weld Summary: SATIP-W-011-01 SATR-W-2008 30/apr/13 19/04/2020Document3 pagesWeld Summary: SATIP-W-011-01 SATR-W-2008 30/apr/13 19/04/2020bishalNo ratings yet

- Offshore Marinetech PVT - LTD: Electrode Baking RegisterDocument3 pagesOffshore Marinetech PVT - LTD: Electrode Baking RegisterPrathamesh OmtechNo ratings yet

- Mechanical and Piping Inspector HDocument3 pagesMechanical and Piping Inspector HHafiz Shabbir HussainNo ratings yet

- GRE/GRP Piping QA/QC InspectorDocument1 pageGRE/GRP Piping QA/QC Inspectoransar100% (1)

- Saudi Aramco Inspection ChecklistDocument5 pagesSaudi Aramco Inspection ChecklistManoj Kumar100% (1)

- INSPECTION REPORT TITLEDocument7 pagesINSPECTION REPORT TITLEABEC Trombay siteNo ratings yet

- Welding Inspector Job and ResponsilbilitiesDocument5 pagesWelding Inspector Job and ResponsilbilitiesFelix GomintongNo ratings yet

- Saudi Aramco Typical Inspection PlanDocument3 pagesSaudi Aramco Typical Inspection PlanAnonymous S9qBDVkyNo ratings yet

- Received Qty (KG) : SL# Electrode SizeDocument34 pagesReceived Qty (KG) : SL# Electrode Sizepadinharethil50% (2)

- AES-W-016 welding filler metalsDocument2 pagesAES-W-016 welding filler metalsmalika_00No ratings yet

- Asif CVDocument6 pagesAsif CVRaghu KumarNo ratings yet

- Saic L 2008 PDFDocument4 pagesSaic L 2008 PDFHesham HelalNo ratings yet

- Juba Export Refinery Piping Quality ProcedureDocument15 pagesJuba Export Refinery Piping Quality ProcedureMd ShariqueNo ratings yet

- (Painting Works) : Inspection and Test PlanDocument2 pages(Painting Works) : Inspection and Test Planrize1159No ratings yet

- Form Attchment - RFI PICTURE-2Document2 pagesForm Attchment - RFI PICTURE-2Echik Kici100% (1)

- Field Welding Inspection Checklist: Wisconsin Department of TransportationDocument1 pageField Welding Inspection Checklist: Wisconsin Department of Transportationandreafaith biatingoNo ratings yet

- Saic L 2007 PDFDocument7 pagesSaic L 2007 PDFHesham HelalNo ratings yet

- Welding Quality Control Plan (WQCP) Requirements in Accordance With "Welding Quality Control"Document2 pagesWelding Quality Control Plan (WQCP) Requirements in Accordance With "Welding Quality Control"Go MocNo ratings yet

- Project Quality RequirementsDocument8 pagesProject Quality RequirementsSIVANo ratings yet

- Weld Log PDFDocument1 pageWeld Log PDFDeniz Aydin100% (1)

- 00 Saip 10aDocument1 page00 Saip 10amalika_00No ratings yet

- Painting Inspector CVDocument2 pagesPainting Inspector CVGodwin A.udo-akanNo ratings yet

- 1 Imran Piping QC CVDocument4 pages1 Imran Piping QC CVkazim MirzaNo ratings yet

- Visual Inspection ReportDocument2 pagesVisual Inspection ReportAlfian ImaduddinNo ratings yet

- Painting & Inspection FormatDocument1 pagePainting & Inspection FormatABEC Trombay siteNo ratings yet

- Welding Consumables Control RegisterDocument5 pagesWelding Consumables Control RegisterAli Mhaskar100% (2)

- Inspection and Test Plan - In-Situ Puf Insulation To Valvesflanges Froth PakDocument2 pagesInspection and Test Plan - In-Situ Puf Insulation To Valvesflanges Froth PakDinesh100% (1)

- AWS D1.1 (2020) - Essential Variable For WPS & WeldersDocument7 pagesAWS D1.1 (2020) - Essential Variable For WPS & WeldersFouad OudinaNo ratings yet

- Weekly Welder ReportDocument2 pagesWeekly Welder Reportkarthi51289No ratings yet

- SAIC-W-OFFSHORE STRUCTURAL 2 In-Process Weld InspectionDocument5 pagesSAIC-W-OFFSHORE STRUCTURAL 2 In-Process Weld Inspectionاحمد حسنNo ratings yet

- OCS Engineering & Construction Visual Inspection ReportDocument1 pageOCS Engineering & Construction Visual Inspection ReportvinothNo ratings yet

- Welding Procedure Specification For GTAWDocument9 pagesWelding Procedure Specification For GTAWraja reyhanNo ratings yet

- Saudi Aramco Test ReportDocument7 pagesSaudi Aramco Test ReportziaNo ratings yet

- Corrective and Preventive Action On High Rejection RateDocument1 pageCorrective and Preventive Action On High Rejection RateRakeshNo ratings yet

- Saudi Aramco Inspection Checklist: Structural Re-Instatement Punchlisting SAIC-M-1074 18-May-05 CivilDocument5 pagesSaudi Aramco Inspection Checklist: Structural Re-Instatement Punchlisting SAIC-M-1074 18-May-05 Civil(*KaT*)No ratings yet

- Typical Inspection Plan (TIP) Index: Project Inspection Division / IAGDocument5 pagesTypical Inspection Plan (TIP) Index: Project Inspection Division / IAGvajidqcNo ratings yet

- Saudi Aramco Inspection Checklist: Review of Radiographic Testing Procedure SAIC-RT-2001 25-May-05 NdeDocument1 pageSaudi Aramco Inspection Checklist: Review of Radiographic Testing Procedure SAIC-RT-2001 25-May-05 NdephilipyapNo ratings yet

- 1 SATIP-W-017-01 Welding of API Tanks-Rev 1Document4 pages1 SATIP-W-017-01 Welding of API Tanks-Rev 1khalid764No ratings yet

- 1 SATIP-D-109-01 Shop Fab Storage Tank PDFDocument4 pages1 SATIP-D-109-01 Shop Fab Storage Tank PDFJithuJohnNo ratings yet

- First Article InspectionDocument1 pageFirst Article InspectionAnsuman KalidasNo ratings yet

- Acb enDocument48 pagesAcb enM Refaat FathNo ratings yet

- 5L E45 Purch Guidelines R0 201306Document1 page5L E45 Purch Guidelines R0 201306Ansuman KalidasNo ratings yet

- 5L E45 Purch Guidelines R0 201306 PDFDocument4 pages5L E45 Purch Guidelines R0 201306 PDFAnsuman KalidasNo ratings yet

- TBT - Key Changes To Material Receiving Inspection ProcedureDocument1 pageTBT - Key Changes To Material Receiving Inspection ProcedureAnsuman KalidasNo ratings yet

- Data Sheet Width Flange BeamDocument32 pagesData Sheet Width Flange BeamIrvan IskandarNo ratings yet

- Risk Based Thinking and The Digital Transformation of QualityDocument32 pagesRisk Based Thinking and The Digital Transformation of QualityAnsuman KalidasNo ratings yet

- The Effect of Multiple Postweld Heat Treatment Cycles On The Weldability of Waspaloy®Document6 pagesThe Effect of Multiple Postweld Heat Treatment Cycles On The Weldability of Waspaloy®Aliakbar GhaderiNo ratings yet

- PDFDocument2 pagesPDFAnsuman KalidasNo ratings yet

- PSL 2 Pipe for sour serviceDocument6 pagesPSL 2 Pipe for sour serviceAnsuman KalidasNo ratings yet

- Saic-W-2xxx-15 Pre Welding & Joint Fit-Up InspectionDocument4 pagesSaic-W-2xxx-15 Pre Welding & Joint Fit-Up InspectionAnsuman Kalidas100% (1)

- Welding Inspection Level-1: Presented By: M.IlyasDocument34 pagesWelding Inspection Level-1: Presented By: M.IlyasRizwan BangashNo ratings yet

- AGA Fume Gases Facts About UKDocument20 pagesAGA Fume Gases Facts About UKPeter's KitchenNo ratings yet

- CPDACA 200 ManualDocument48 pagesCPDACA 200 ManualsunhuynhNo ratings yet

- Boehler CN 23 12 PW-FDDocument1 pageBoehler CN 23 12 PW-FDbrayanNo ratings yet

- GS 118-10 Welding of Transmission Pipelines: Supplementary To BS 4515: 1996 December 1998 (Amended February 2000)Document40 pagesGS 118-10 Welding of Transmission Pipelines: Supplementary To BS 4515: 1996 December 1998 (Amended February 2000)Mohd KhairulNo ratings yet

- ISO 15609 1 2004 Specification and Qualification of WeldingDocument16 pagesISO 15609 1 2004 Specification and Qualification of WeldingVanwynsberghe FredericNo ratings yet

- Consumeables Catalog - Lincoln Electric PDFDocument356 pagesConsumeables Catalog - Lincoln Electric PDFr0m14r100% (1)

- Welding Procedure Specification (WPS) FormDocument2 pagesWelding Procedure Specification (WPS) FormEarl Harbert0% (1)

- Aws B2.1-1 8-010-02Document18 pagesAws B2.1-1 8-010-02udomNo ratings yet

- TN f140 10Document6 pagesTN f140 10Kourosh KhalpariNo ratings yet

- AWS 2007 standards library color codesDocument12 pagesAWS 2007 standards library color codesWagnerTarossiNo ratings yet

- AWS C5.2-01 Plasma Arc CuttingDocument53 pagesAWS C5.2-01 Plasma Arc CuttingvenkateshNo ratings yet

- FroniusDocument156 pagesFroniuskbreisscribdNo ratings yet

- Manual Puk 04 - EnglishDocument22 pagesManual Puk 04 - EnglishJuan Antonio PérezNo ratings yet

- Book FrictionStir WeldingDocument239 pagesBook FrictionStir WeldingKaushik SenguptaNo ratings yet

- STT Lincoln ElectricDocument30 pagesSTT Lincoln ElectricElias KapaNo ratings yet

- Information About WeldingDocument16 pagesInformation About Weldingdav.id.stNo ratings yet

- Structural Steel Welds PDFDocument28 pagesStructural Steel Welds PDFshekhar2681No ratings yet

- 4 ESAB Solid Wires Nov 06Document84 pages4 ESAB Solid Wires Nov 06ananth84No ratings yet

- Oxygen Equivalent Effects On The Mechanical Properties of Titanium WeldsDocument12 pagesOxygen Equivalent Effects On The Mechanical Properties of Titanium WeldsGiustNo ratings yet

- Fabricating of Hastelloy Corrosion Resistant Alloys of HaynesDocument40 pagesFabricating of Hastelloy Corrosion Resistant Alloys of HayneszuudeeNo ratings yet

- Types of Arc WeldingDocument20 pagesTypes of Arc WeldingEhigiator JosephNo ratings yet

- Power Wave R500: Operator's ManualDocument42 pagesPower Wave R500: Operator's ManualJohan ZraghozNo ratings yet

- cswip 시험 문제 자료 PDFDocument185 pagescswip 시험 문제 자료 PDFkyeong cheol lee100% (1)

- High-strength flux-cored wire for welding high-strength steelsDocument2 pagesHigh-strength flux-cored wire for welding high-strength steelsjimmy_wdNo ratings yet

- Power Wave455m 10942 10957Document165 pagesPower Wave455m 10942 10957Jaime ArreolaNo ratings yet

- The purpose of welding procedure specification (WPS) and Procedure Qualification Record (PQRDocument68 pagesThe purpose of welding procedure specification (WPS) and Procedure Qualification Record (PQRParvee K Nakwal100% (1)

- Sec 3 Welding Imperfections (Defects)Document31 pagesSec 3 Welding Imperfections (Defects)Abdullah100% (1)

- Plasma Cutting and Welding GuideDocument83 pagesPlasma Cutting and Welding GuideTarek SatiNo ratings yet

- The Technology of Mounting and Joining Elements in Case of Metallic Structures Beijing National Stadium (Bird's Nest)Document12 pagesThe Technology of Mounting and Joining Elements in Case of Metallic Structures Beijing National Stadium (Bird's Nest)Matei SilviuNo ratings yet