Professional Documents

Culture Documents

Lesson 10 - 1

Uploaded by

crysCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Lesson 10 - 1

Uploaded by

crysCopyright:

Available Formats

Lesson 10 - Reliability of Welding Filler Metals

1 dari 1

Lesson 1

The Basics of Arc

Welding

Lesson 2

Common Electric

Arc Welding

Processes

Lesson 3

Covered Electrodes

for Welding

Mild Steels

Lesson 4

Covered Electrodes

for Welding Low

Alloy Steels

Lesson 5

Welding Filler Metals

for Stainless Steels

http://www.esabna.com/euweb/AWTC/Lesson10_3.htm

LESSON X

RELIABILITY OF WELDING FILLER METALS

10.1

INTRODUCTION

Producing a weld by the arc welding process has often been compared to steelmaking on a

very small scale. The weld puddle is molten for a very short time and during that time, a

number of reactions must take place between the base plate, the filler metal, and the

Lesson 7

Flux Cored Arc

Electrodes Carbon

Low Alloy Steels

Lesson 8

Hardsurfacing

Electrodes

Lesson 9

Estimating &

Comparing Weld

Metal Costs

Go To Test

Print

electrode coating or shielding gas ingredients. These reactions must result in predictable

mechanical properties and chemical composition of the weld metal produced by each of

the great number of filler materials available. Reliable welding filler metals are the result of

Glossary

the proper formulation, adherence to certain codes and specifications, and the result of a

good quality assurance program.

10.2

CODES, SPECIFICATIONS AND STANDARDS

The wide use of welding as a fabricating method requires that certain controls be exercised

to assure the safety and protection of persons and property exposed to structures and

Lesson 6

Carbon & Low Alloy

Steel Filler Metals GMAW,GTAW,SAW

Current

Chapter

Table of

Contents

Turn Pages

equipment utilizing welded joints. As a result, various codes, specifications and standards

have been established by technical societies and professional organizations to assure safe,

sound welds. Among other things, these groups specify or recommend the base metal

requirements, joint design, filler metal, welding procedures, operator qualifications, required

weld tests, testing methods, and inspection of welds.

10.2.0.1

The professional technical societies or organizations have no way of enforcing

the codes, specifications or standards that they prepare. However, in many instances,

governing bodies of municipalities, counties, states or federal agencies may adopt all or

part of these documents as law. Private industry may require that work performed under

contract will conform to one or more of these codes or specifications, and therefore, they

become part of a legal document. Lastly, purchase orders issued for welding materials

Search

Chapter

(Faster

Download)

Search

Document

(Slower

Download)

may state that the terms are to meet a particular code or specification, and as such, these

purchase orders have legal implications.

10.2.0.2

The following is a description of the major societies and organizations whose

specifications and codes are widely used in the welding filler metals industry.

Lesson 10

Reliability of Welding

Filler Metals

COPYRIGHT 2000 THE ESAB GROUP, INC.

09/12/2013 14:27

You might also like

- Pt. Intan Anugrah PersadaDocument1 pagePt. Intan Anugrah PersadacrysNo ratings yet

- Pt. Intan Anugrah PersadaDocument1 pagePt. Intan Anugrah PersadacrysNo ratings yet

- Installation of Stop Contact, Cable Tray and Panel Location on Level 3 & 5Document1 pageInstallation of Stop Contact, Cable Tray and Panel Location on Level 3 & 5crysNo ratings yet

- Vac 105 PDFDocument1 pageVac 105 PDFcrysNo ratings yet

- Vac 113 PDFDocument1 pageVac 113 PDFcrysNo ratings yet

- Pt. Intan Anugrah Persada: Void VoidDocument1 pagePt. Intan Anugrah Persada: Void VoidcrysNo ratings yet

- 328 PDFDocument1 page328 PDFcrysNo ratings yet

- Sound system installation plans for Treepark City CikokolDocument1 pageSound system installation plans for Treepark City CikokolcrysNo ratings yet

- Pt. Intan Anugrah PersadaDocument1 pagePt. Intan Anugrah PersadacrysNo ratings yet

- Sdb-Atap Tower A Db-Fire Atap Tower A Pp-Lift.2A Pp-Lift.1A: Pt. Intan Anugrah PersadaDocument1 pageSdb-Atap Tower A Db-Fire Atap Tower A Pp-Lift.2A Pp-Lift.1A: Pt. Intan Anugrah PersadacrysNo ratings yet

- Cipta Sukses, PT.: Pt. Intan Anugrah PersadaDocument1 pageCipta Sukses, PT.: Pt. Intan Anugrah PersadacrysNo ratings yet

- Vac 110 PDFDocument1 pageVac 110 PDFcrysNo ratings yet

- Asme31 3Document1 pageAsme31 3crysNo ratings yet

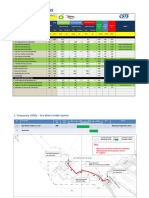

- Summary Progress & Status Piping Work-Cut of Date 16 Des 2017Document16 pagesSummary Progress & Status Piping Work-Cut of Date 16 Des 2017crysNo ratings yet

- Vac 112 PDFDocument1 pageVac 112 PDFcrysNo ratings yet

- PT Alphacon's Single V Butt Joint WPSDocument20 pagesPT Alphacon's Single V Butt Joint WPScrys0% (1)

- Lift Dan Gondola 06-11-2015Document8 pagesLift Dan Gondola 06-11-2015crysNo ratings yet

- Assembling Flanged Joints Procedure1 PDFDocument34 pagesAssembling Flanged Joints Procedure1 PDFcrysNo ratings yet

- CV FreasmanDocument2 pagesCV FreasmancrysNo ratings yet

- Indonesia LNGDocument22 pagesIndonesia LNGcrys100% (1)

- RFCC-T-PJ-GS-0900 Project Quality Plan (B) PDFDocument23 pagesRFCC-T-PJ-GS-0900 Project Quality Plan (B) PDFcrysNo ratings yet

- RFCC T PJ GS 0900 Project Quality Plan (B)Document44 pagesRFCC T PJ GS 0900 Project Quality Plan (B)crysNo ratings yet

- PASCAL Check Valves CatalogueDocument19 pagesPASCAL Check Valves Cataloguecrys100% (1)

- ITP Installation of Boiler - R1Document14 pagesITP Installation of Boiler - R1crys100% (4)

- Clarification 17Document1 pageClarification 17crysNo ratings yet

- Spark Arrestor Safety GuideDocument6 pagesSpark Arrestor Safety GuidecrysNo ratings yet

- 72957d3bb1659d7c77dbf6b6c550abeeDocument41 pages72957d3bb1659d7c77dbf6b6c550abeerasheedillikkalNo ratings yet

- GENERATOR SET CSTS INSTALLATION STATUS AND PROGRESS REPORTDocument1 pageGENERATOR SET CSTS INSTALLATION STATUS AND PROGRESS REPORTcrysNo ratings yet

- Spec PDFDocument1 pageSpec PDFcrysNo ratings yet

- Aluminium Valve FinalDocument5 pagesAluminium Valve FinalcrysNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5783)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Mining LawDocument199 pagesMining LawDr Tabrez ahmadNo ratings yet

- CH 4Document40 pagesCH 4stephanie_berroaNo ratings yet

- Chemistry Mock Test 12: ExamraceDocument9 pagesChemistry Mock Test 12: ExamracepremkumarNo ratings yet

- Flouch BrochureDocument4 pagesFlouch Brochuremuhammad abidinNo ratings yet

- 10 1113 02 4RP AFP tcm143-520229Document20 pages10 1113 02 4RP AFP tcm143-520229FauziaNabeelNo ratings yet

- Separating mixtures using chromatography and distillationDocument5 pagesSeparating mixtures using chromatography and distillationFatema KhatunNo ratings yet

- Effect of Welding Current On The Mechanical and StructuralDocument8 pagesEffect of Welding Current On The Mechanical and StructuralBhramandhikaNalendraGhuptaNo ratings yet

- Design and DetailingDocument87 pagesDesign and DetailingFashmina MohamedNo ratings yet

- SCC of Ss in NAOHDocument9 pagesSCC of Ss in NAOHKarna2504No ratings yet

- Hanger CatalogueDocument4 pagesHanger CatalogueDnyaneshwar100% (1)

- Electrochemical SeriesDocument10 pagesElectrochemical SeriesLiixyz LingNo ratings yet

- Silicon Compound Manufacturing (O'mara)Document32 pagesSilicon Compound Manufacturing (O'mara)Arens Ong100% (1)

- Handrail and Flooring September 2016Document168 pagesHandrail and Flooring September 2016Peter DavidsonNo ratings yet

- EarthScience12 Q1 Mod3 MineralsandItsImportance v3Document50 pagesEarthScience12 Q1 Mod3 MineralsandItsImportance v3Berlyn AmanoNo ratings yet

- AFM ER308 Afm Er308LDocument9 pagesAFM ER308 Afm Er308LKH NgNo ratings yet

- 5070 w11 QP 12Document12 pages5070 w11 QP 12mstudy123456No ratings yet

- RCABC Roof Curb Pentrations and OpeningsDocument13 pagesRCABC Roof Curb Pentrations and OpeningsdomcristiniNo ratings yet

- Surkhi 2Document7 pagesSurkhi 2Syed Showkath AliNo ratings yet

- Heat Treatment Training ManualDocument118 pagesHeat Treatment Training Manualkumarvizayin100% (4)

- August Test Paper 1 Chemistry Form 6Document16 pagesAugust Test Paper 1 Chemistry Form 6sharifahNo ratings yet

- Astm A588-A588m-05Document3 pagesAstm A588-A588m-05Hoang Kien100% (1)

- Nitric Acid: Dictionary Sci-Tech Encycl. Dental Dictionary Britannica Concise Columbia Ency. Wikipedia CitationsDocument13 pagesNitric Acid: Dictionary Sci-Tech Encycl. Dental Dictionary Britannica Concise Columbia Ency. Wikipedia CitationsmusmanafzalNo ratings yet

- GCSE Chemistry - Making Salts GameDocument46 pagesGCSE Chemistry - Making Salts GameSumi VjNo ratings yet

- SCTE Best Practices For Proactively Maintaining Your Return Paths v10 PDFDocument172 pagesSCTE Best Practices For Proactively Maintaining Your Return Paths v10 PDFGil HaleNo ratings yet

- Material Standard: IPS-M-PI-150Document30 pagesMaterial Standard: IPS-M-PI-150gurugovindanNo ratings yet

- Bonding Brackets PDFDocument40 pagesBonding Brackets PDFMaria Yael75% (4)

- K2o & P2o5Document8 pagesK2o & P2o5Elwathig BakhietNo ratings yet

- Deposits, Minerals and Plants: Non Ferrous Metal OresDocument270 pagesDeposits, Minerals and Plants: Non Ferrous Metal Oreseheimlich7223No ratings yet

- Karakterisasi Material PDFDocument40 pagesKarakterisasi Material PDFmiftakhurNo ratings yet

- Chemical Quality of TMT Bars: View Previous Topic View Next TopicDocument6 pagesChemical Quality of TMT Bars: View Previous Topic View Next Topicpatrik710No ratings yet