Professional Documents

Culture Documents

غاز و بتروكيماويات صيف 2012

Uploaded by

Anonymous epd9bzM0 ratings0% found this document useful (0 votes)

26 views19 pagesغاز و بتروكيماويات صيف

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentغاز و بتروكيماويات صيف

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

26 views19 pagesغاز و بتروكيماويات صيف 2012

Uploaded by

Anonymous epd9bzMغاز و بتروكيماويات صيف

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 19

THE GAS AND

PETROCHEMICALS

ENGINEERING

PROGRAM

Cs ee

cr ee re Ss oe Peo

Alexandria University SSP Ay yaisuyl daly,

Faculty of Engineering Auaight Las

Specialized Scientific Programs & Heawedial Ayala! gal

Augest 2012 2012 alan

‘Course title: Numerical Methods Te OE 1g ay hal pal

MP 314

Time allowed: 2 hours pols 2c

Baye Foe B her JTUIY slry

‘Answer the following questions

If is not mention use four decimal points during calculations

1. Given the following data

x 1 2 2.5 4 6 8 8.5,

7 0.4 0.7 0.8 1 12 13 14

Find the best fit for that data using the second order polynomial (8 marks)

2. Use the Newton's method to find the positive root of the function

f(x) = 4X°- 6X? - 8X + 4 near x = - 2 up to four decimal points (use five decimal points

during calculations) (6 marks)

3. Estimated the first derivative of the function f(x) = x* e* + 2x at x = 1 using step

size h = 0.1 by using the forward, backward and central approximation then find the

second derivative approximation by using central approximation (6 marks)

4, By using LU decomposition solve the system of equations (12 marks)

7x+32y + 199.5 2=6.8

32x + 199.5 y + 1430.75 z= 37.3

199.5 x + 1430.75 y + 10924.125 z = 251.75 (use three decimal points during

calculations)

5. Evaluate the following integral | x*e*de where n = 6 by using Trapezoidal rule

and Simpsons rule, find the exact solution, then find R.P.E in each case. (7 marks)

6. By using Euler method, solve the following differential equations

# = -y +x" , given that y(1) = 2, h=0.1 to get y(1.2) .Find the exact

solution and the R.P.E, then use the Runge-Kutta method to find better

approximation for the solution and find the corresponding R.P.E (12 marks)

Good Luck

Exam Committee: Dr. Amr Abdelrazek

qn)

-

rr rr Ss SS STB SS SSeS eS eS ee eS Soe

ALEXANDRIA UNIVERSITY

FACULTY OF ENGINEERING

SSP/GAS & PETROCHEMICAL ENGINEERING

SEPARATION PROCESSES I! SUMMER 2012

FINAL EXAM AUGUST 2012

ANSWER ALL QUESTIONS:

A) Discuss BRIEFLY the following:

B)

1) Types of gases according to partial pressure-concentration

relation

2) Types of drying rates

3) Effect of material porosity on equilibrium moisture content

4) How to use wet-and-dry bulb thermometer to evaluate relative

humidity

5) The idea of mixer-settler arrangement

6) Factors to be considered in selection of a dryer

7) The idea of multiple heating to increase the drying capacity of

the air (as used in shelf dryers and tunnel dryers)

8) Drum dryers and vacuum drum dryers

9) Thermal efficiency of a dryer

10) Examples of 2 different uses of the absorption process

11) _ Fields of application of liquid-liquid extraction

12) How to increase extraction rate in liquid-liquid extraction

13) 2 types of phase diagram (ternary system0 used in liquid-

liquid extraction

(13 x 2 = 26 pts)

Wet sand is dried from 0.6 to 0:33 moisture content (wet basis) in

5 hours. If equilibrium moisture content is 0.02 and critical

moisture content is 0.25 (dry basis), calculate the total drying

time for this sand down to 0.16 (dry basis) under the same

conditions (5 points)

C) An absorption tower is used to remove ammonia from air under

the following conditions: Nog= 7, pure water is used and its flow

rate is 2 kg/m’s, Ye=1.2 X, Kg=0.08 kmol/m?s(atm), initial and final

concentration ratio of ammonia in air are0.06 & 0.012,

respectively, calculate the tower height ( the logarithmic mean of

y-Ve can be taken as the arithmetic mean)

(11 points)

D) Acetaldehyde is to be extracted from its solution in toluene by

fresh water in a co-current 7 stages system fed with a 8% solution

of acetaldehyde in toluene. The equilibrium relation ship is:

kg acetaldehyde/kg water = 2.6 kg acetaldehyde/kg toluene,

Water is fed at the rate of 55 kg/h while toluene solution is fed at

the rate of 125 kg/h, calculate the final concentration of

acetaldehyde in toluene

(8 points)

he gle)

“Life 1

BEST OF LUCK!!!

PROF DR HASSAN FARAG

-

cr rT ST eS SI eS SI eae ese US ee eS eS eS

Alexandria University = Aytyt Healy

Faculty of Engincering ays as

Specialized Scientific Programs Lewes hated gal)

August 2012 . —= 2012 valud i

‘Cours ie Ramer: Kis sd Reactions Engiesbg Tis det ae

aa

‘Tine lone Tro hours gio: Oost

wer all questions

1) The dimerization of the butadiene (CsHe) colorless gas was carried out in a

laboratory reactor at 25°C. Butadiene dimerizes to yield hexahydropentalene

(CeHny) in an irreversible reaction.

The concentration-time data were obtained in a batch reactor as follows

Time (min) 50 100 140 200 250

Concentration of

Cailefmov'dem’) | 2238 | ° 0306 | 0.0256 | 0.0200 | 0.0170

At t=0, C canc=0.05M.

i) Determine the reaction order with respect to butadiene. (12 marks)

ii) Determine the half life time of butadiene. G marks)

2) Calculate the pressure drop in a 18 m length pipe packed with catalyst pellets 0.6 om

in diameter; the pipe diameter is 7 cm. Air passes through the bed at 25 cm/s. The

temperature is constant throughout the pipe at 250°C, the solid fraction is 40% and

the entering pressure is 10 atm. (12 marks)

3) Find the time required for the concentration of the reactant, A, to drop to one third

ofits initial value (ti) in the irreversible reaction: A—rProducts. (5 marks)

4) Put (\) or (X) and correct the wrong sentences if any. (13 marks)

i) The specific reaction rate tells us how fast a number of moles of one chemical

species are being consumed to form another chemical species.

ii) Homogeneous catalysis concerns processes in which a catalyst is in solution with

at least one of the reactants,

‘The half-life of a reaction is defined as the time it takes for the concentration of

the reactant to fall to half of its initial value.

iv) In the integral method used to confirm the reaction rate, a series of experiments is

carried out at different initial concentrations, Co.

1/3

5)

¥) There’s only one common type of reactors used to

reaction order.

vi) In the gas phase reactions, the concent

the total pressure.

Vii) The overall conversion of plug flow reactors in seri

conversion of a single PFR.

viii) For most liquid phase reactions th

insignificant.

ix) For reversible reactions the maximum conversio;

%) The type of catalyst influences the rate of reaction.

xi) In the tubular reactor there is no mixin

flow.

xii) One of the advantages of the semi batch

phase reactions.

xiii) One of the advantages of the tubular reactors th

maintain,

obtain data rate to obtain the

ration of reacting species is proportional to

ies is the same as the

ie change in the solution density is

ig in the axial direction, ie, the direction of

eactors that they can be used for two

at they are easy to

A mixture of n-CsHo gas (75% by volume) and inert gas at 830 kPa enters a reactor

with a volumetric flow rate of 0.2 m?/s at 600K. Calculate the entering concentration

of n-CaHhio , the n-C.Ho entering molar flow rate and the final concentration of n-

C4Ho at a conversion of 78%,

(5 marks)

Best Wishes

Dr. Yasmine Ossama

2/3

er re SS eS eS eee SPSS LS eS eS

Additional Information

j (1+ &x)ax 1

[BAe romy-e

a

fQ+exdx O+0x 1

nea cn

(i-x)? ~ 1=x 1-x

aren = 260 +)Ind—y sere GEO's

R=8.314 Pa.m’/mol.K

Three po ferenti mn formulas:

Initial point (4C4/At)u=(-3Crst4Cyn-CraV2At

Interior point (ACw/dd)—(Cagr-Can)/2At

Final point (AC/at)e=(Caeay4Caeayt3Cai/2At

Molecular weight of hexahydropentalene=108

o 2Bo

** A= gp eR.

GA-9) 1501 -p)e

Serer errr ee ee

7a92D,9° | By :

‘At 250°C and 10 atm: [40.0673 Ibp/ft.h, MWac=29;

1 f= 30.48 em Uba= 454 g,

ge= Ikg.m/N.s"; 1 atm= 1.013*10°Pa

Bo

3/3

or rr Ss SS See eee

Student Name: Student Number:

Alexandria University SSP Ayala Fal

Faculty of Engineering usaigh Ais

Specialized Scientific Programs y Aanadiad yalell gal yl)

August 2012 2012 (abut!

GPE 523 Process Design a

Time allowed: 2 Hours

CLOSED BOOK SECTION

Define the following :

HAZOPS study - FTA - LFL - UFL - AIT

List the major factors to be considered in selection of plant site

(10 Marks )

(3 Marks )

er Tr rr eer SPS TS eS SS eS SS eS oe

OPEN BOOK SECTION

3.. The three isomers of xylene (0 ,m & p ) are being produced according to the

equation :

CoH + 2C3 He (CoH, (CH3 2 +2 C2 Ha

The reaction is being carried out in the gaseous phase in a tubular continuous flow

reactor 3 m long and 0.6 m in diameter. The residence time of the gaseous stream in

the reactor is 20 seconds. The reactants are fed from their storage tanks, from where

pure benzene is passed through a vaporizer followed by a mixing feed blower. In this,

blower, both benzene vapor and propylene gas are mixed in the required ratio and

then the gaseous mixture is delivered to a pre heater. After the pre heater, the mixture

is fed to the reactor by another blower. The mixture enters the reactor at 500 K and

2 atmosphere. The reaction is only 70% complete. Reactor conditions favor the

formation of p-xylene, so that 60% mole of the xylene isomers produced are

p-xylene , where the rest is equally divided between the two other isomers.

‘The effluent stream from the reactor is fed to a cooler condenser, where all of the

components ( products and unreacted material), except the produced ethylene and

unreacted propylene, are condensed. The liquid mixture of the three isomers,is,

therefore fed to a distillation column, operating continuously at a reflux ratio of 2:1,

where all the unreacted benzene is separated. The mixture of the three isomers is,

therefore fed to a fractional crystallizer, where 95% of one of the isomers is

crystallized out . The remaining liquid mixture is fed to a pre heater followed by a

distillation column, that separates 90% Of the second isomer as a pure overhead

product.

All unreacted benzene & propylene are not recycled to the reactor, but are fed back

to their storage tanks.

Draw a qualitative flow sheet showing the main units of this process and other

necessary subsidiary equipment, identifying the different streams in the flow

sheet.

(7 Marks )

cer rr Fr FT FS FP SS SSeS eee eee

4. A plant produces evaporators at the rate of N evaporators per day.. The variable costs

per evaporator are SR 1200 +0,6N’. The total daily fixed charges are SR 25,000 and all

other expenses are constant SR. 44,000 per day. Economical analysis have shown that the

maximum daily profit can be attained on operating at a production rate 42.86 % higher than

the production rate giving the maximum cost per evaporator. Calculate:

‘a. The selling price

b. The daily profit at a (production rate giving the minimum cost per evaporator

¢. The daily profit at a production rate giving the maximum profit per day

4d. The daily production rate at the break even point

(10 Marks )

ee ee ee ee ee ee ee ee ee ee ee

5. A Dryer has an original value of SR 50,000 and a scrap value of SR 2,000. According to

local regulations, depreciation cost per year should not exceed SR 2,000 for this dryer.

Itis allowed to use either straight line method or declining balance method for depreciation

calculations.

What method would give a longer service life?. Calculate the ratio between both service lifes

(10 Marks )

cr FS FST ST SE ae ae eSErthlCcaeeEUhlUcraesertlUCcaeetmeaeste eee

6.A multiple — effect evaporator is used to raise the concentration of sodium sulfate

solution from 2% to 25% wt. ‘The feed rate of dilute solution is 10 tons per 24 hour

day. The total initial cost of the first effect is SR 6000 and each additional effect

cost SR 4500. The service life of the effects is estimated to be 6 years and the scrap

value of each effect at the end of service life is estimated to be SR 200. The straight

line depreciation method is used. Fixed charges minus depreciation are 20% yearly,

based on the first cost of the equipment. Steam costs SR_3.5 per ton. Annual

maintenance charges are 5% of the initial equipment cost. All other costs are

independent on the number of effects. The unit will operate 300 days per year.

If kgs of water evaporated per kg of steam equals 0.7 x No of effects ,

determine the optimum number of effects for minimum annual costs.

(10 Marks )

rer re SS See ete lee tlle leer terete ee

SSP

Alexandria University Ayaitap daa

Faculty of Engineering Lasigh As

Specialized Scientific Programs Tacit Ayah Gal

‘Angest, 2012 2012 used

‘Course tite Wamber Nawal Gas Lepecion 7 PRE FID nen

‘Tine alowed: Two hours eke: Oost

1) Compare between: (15 marks)

a) The Simple Cascade Process and the Optimized Cascade Process.

b) ExxonMobil Dual Multicomponent process and DMR Process.

©) APCI-C3 MR and APCI AP-X.

4) The spiral wound heat exchanger and the PFHE.

©) Air cooling and sea water cooling.

2) Give reason: (13 marks)

2) The main condenser size in the Linde process is smaller than the condenser size in

the Optimized Philips Cascade process.

b) For LNG processes with lower precooling temperatures a greater requirement for

LPG recovery is needed.

©) _ Inthe process cycle development a design basis is needed.

4) The compressor size is limited in case of using pure propane refrigerant.

©) _Exergy analysis are useful in the process cycle development

f) __ Ifthenew LNG charge is lighter than the existing liquid in the storage tank, it

‘g0€s in at the bottom of the tank.

2) Safety codes require that storage LNG tanks have vent sizes many times larger

than the normal boil-off rate.

h) The PFHE has an advantage over the spiral wound heat exchanger.

i) The final loop added to the APCI AP-X process uses pure nitrogen.

J) Inground LNG storage has some advantages.

Kk) _ Inthe CO» Precooled Linde Process, the carbon dioxide is used in the precooling

stage only.

1) The air cooling has an advantage over the sea water cooling.

m) _ Large offload storage facilities are less subjected to rollover than peak shaving facilities.

3) Complete the following sentences: (9 marks)

i. The three basic types of LNG aboveground storage vessels in use are: .

and...

ii. The most widely used metal for large LNG tanks is .

iii, ‘The role of the electrical heating element at the bottom of the LNG storage tanks is.

Page 1 of 3

d

The .........+-+ storage tanks may actually be the most economical choice of all the steel

above ground tanks,

The three basic types of LNG in ground storage are:

and.

‘A design basis used for the process development contains key project requirements such as

and.

The first step after the design basis is established is

The overall change in exergy ofthe steams flowing in and out ofan equipment unit (e.g

heat exchanger, compressor) is ..

‘The comparison of different processes fora specifi case must be done with cre, takin into

account all parameters such as: and ..,

Among the processes that uses proprietary heat exchangers are.

Define: (8 marks)

a)

b)

°)

d

°)

f

2)

h)

Reliability

Exergy

‘Temperature approach

Mach Number

CAPEX

Stratification

LNG weathering

Rollover

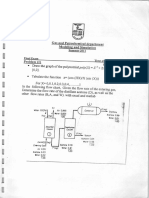

‘Methane is to be liquefied in a Joule-Thomson cycle (as in the given figure). The methane enters the

heat exchanger at 80°F and 1,500 psia and expands to 14.7 psia.

1. Calculate the fraction of methane entering the system that is liquefied.

2. Estimate the % decrease in production if a heat leak of 15 Btu/lb of methane

centering is present and if a temperature approach of 5°C is obtained at the warm

end of the exchanger.

3. Calculate the fraction liquefied if the pressure is 2,000 psia. (S marks)

Page 2 of 3

rr TT SF ST SS ae aeeEtaeeUeeeeeeeeeeeeeee e C

Methane make-up

os

Air-cooled

beat exchanger

— “Thermodynamic

. ‘boundary

1 YY

3

Heat

Jexchange|

+

a

vabe

“—. s

«

Ligeid

recelver

1 =350 Btu/lb (80°F, 1500 psia)

18 = 392 Btuflb (80°F, 14.7 psia)

12.=0 Btu/lb = (-259°F, 14.7 psia, liquid)

h= 337 Btu/lb = (80°F, 2,000 psia)

Best of Luck

Dr. Yasmine Ossama

Page 3 of 3

crm rr FP FP FP YS FT ST SSS SSS eS eS es

Student Name: Student Number:

Alexandria University SSP Hy yaigaty deat

Faculty of Engineering Huaaigh 3s

Specialized Scientific Programs Hawai Ayla Gal

August 2012 2012 qulauél

GPE 337 GaN ass

Combustion Technology

Time allowed: 2 Hours Chel toa j

1)

‘a. Calculate the stoichiometric mass air-fuel ratio ( A/F ) for combustion of

ethane ( C2H6)

b. A natural gas operates with an oxygen concentration of 4 mole percent in the

flue gas (wet basis ). Determine the operating air ~ fuel ratio and the

equivalence ratio.

Treat the natural gas as C1.08 H4.17

(10 Marks )

Tt)

a, Differentiate between :

i) Proximate analysis and ultimate analysis of coal:

ii) Fuel lean mixture and fuel rich mixture.

iii) The higher heating value of a fuel (HHV ) and the lower heating value (LHV)

iv) Lignite and anthracite.

b. A coal with a dry, ash — free composition of 86% C , 9% H2 ,1% S and 4%02

is burned with 25% excess air. The as — fired ash and moisture contents are

4 and 5% respectively. What are the stoichiometric and actual air — fuel ratios

(12 Marks)

IM) Determine the upper and lower heating values at 298 K for gaseous n-decane ~

C10 H22 per kmole and per kilogram of fuel. Given :

he c1oH22 = - 249659 kj/kmol

hf — Co2 = - 393546 ki/kmol

hr = RO @ = - 285857 kj/kmol

hr = H20(@) = = 241847 kjdkmol

(6 Marks )

cr rT FFF SSS SS RS SO

IV) Calculate the theoretical flame temperature when methane at 25 C is burned

with 15% excess air. The pressure is I atm.

Assume complete combustion. T adiabatic is gussed to be about 2100 K

Species Enthalpy of formation Specific heats at 1200K

At 298 K (kj/Kmol) (Kj/Kmol K )

cH4 - 74831 -

coz - 393546 56.21

#20 ~ 241845 43.87

N2 0 33.71

02 0 37.00

(9 Marks )

'V) Write short notes on : Unburnrd fuel - CO - NOx and Sox emissions

In combustion processes

(13 Marks)

H=1,C=12,0=16,8=32,N=14

cr cP eS er Fe] SS FS PS eso ors

Alexandria University

Faculty of Engineering

Gas and Petrochemical Engineering Department

Environmental Impact Assessment

Summer 2012

‘Time Allowed: 2 hours

Final Exam

Answer ALL the following questions

QI. Decide whether each statement is TRUE or FALSE, Then correct the FALSE,

statements [10 marks]

1. itis most acceptable that any method of assessment will satisfactorily characterize

environmental quality ( )

2. escape of heavy metal contaminated dust from a factory on vehicle tyres, arising from

poor dust control and wheel washing arrangements can be considered as planned

emission of pollutant ( )

3. Environmental standard is set in relation to impacts upon public health or upon natural

ecosystems at a level of medium risk. Cc)

4, Environmental Quality Standards are the national standards adopted by the country.(_)

5, Septum is a constant temperature heating zone inside injection port of GC C )

6. thermionic detector is a universal detector cy

7. Inside the GC- packed column, tube is densely packed with a solid support material onto

which it represents the stationary phase in the column. Cc )

8. Propane -air mixture is suitable for the determination of most of the common metals. (_

9. Random errors are due to causes over which the analyst can control ( )

10. Impingement is one of the methods used for the collection of atmospheric gaseous

samples ( )

Q2. Give Reason(s) for each of the following [10 marks ]

1. Urban rivers are usually ranked higher in chemi

are classified by biological means.

| quality than if the same water-courses

2 pages Best Wishes Dr. Ola Abdelwahab

?

nor rT aS SS SS SS SS

“

2. heli

is preferred as a carrier gas when thermal conductivity detectors are employed

3._ stream-splitting device is employed when further examination, other than FID, of the

elute is necessary

4, large numbers of soil and sediment samples may be required to characterize a relatively

small area

5. liquid samples are preserved by acidification to pH 2 and refrigeration to 4°C

Q3. Mention the role of each of the following [10 marks]

1. nebuliser-bumer system in AAS

2. Adsorption systems

3. Environmental Impact Assessment

4. Column in GC

5. Environmental Standard

Q4. Discus each of the following [20 marks]

(a) How do Environmental Quality Standards reliably set emission limits of pollutants?

(b) Grab sampling

(©) The FID has a wide linear response range, which made it the most popular detector in

current use

Case Studies

(a) How did the textile finishing industries in North-West England reduce the PCP in their

discharge

Answer either (e) or (f)

(©) How can pollution load generated from leather industry reduced?

(8) How do the problem of pollution caused from ballast water was solved?

2 pages Best Wishes Dr. Ola Abdelwahab

You might also like

- غاز و بتروكيماويات ربيع 2012-2013Document41 pagesغاز و بتروكيماويات ربيع 2012-2013Anonymous epd9bzMNo ratings yet

- كمبيوتر صيف 2011Document15 pagesكمبيوتر صيف 2011Anonymous epd9bzMNo ratings yet

- بتروكيماويات ربيع2009Document34 pagesبتروكيماويات ربيع2009Anonymous epd9bzMNo ratings yet

- Alex Eng DraftDocument1 pageAlex Eng DraftAnonymous epd9bzMNo ratings yet

- غاز و بتروكيماويات خريف 2013Document63 pagesغاز و بتروكيماويات خريف 2013Anonymous epd9bzMNo ratings yet

- عمارة و تشييد ربيع 2013Document53 pagesعمارة و تشييد ربيع 2013Anonymous epd9bzMNo ratings yet

- الغاز و البتروكيماويات خريف2010Document50 pagesالغاز و البتروكيماويات خريف2010Anonymous epd9bzMNo ratings yet

- غاز و بتروكيماويات خريف2012-2013Document52 pagesغاز و بتروكيماويات خريف2012-2013Anonymous epd9bzMNo ratings yet

- عماره و تشييد 2010 خريفDocument9 pagesعماره و تشييد 2010 خريفAnonymous epd9bzMNo ratings yet

- غاز و بتروكيماويات صيف2011Document23 pagesغاز و بتروكيماويات صيف2011Anonymous epd9bzMNo ratings yet

- عمارة و تشييد صيف2012Document3 pagesعمارة و تشييد صيف2012Anonymous epd9bzMNo ratings yet

- غاز وبتروكيماويات 2009 خريفDocument40 pagesغاز وبتروكيماويات 2009 خريفAnonymous epd9bzMNo ratings yet

- Medtermعماره و تشييد خريف 2010Document5 pagesMedtermعماره و تشييد خريف 2010Anonymous epd9bzMNo ratings yet

- غاز و بتروكيماويات خريف2012-2013Document52 pagesغاز و بتروكيماويات خريف2012-2013Anonymous epd9bzMNo ratings yet

- برنامج العمارة و التشيد خريف2013Document49 pagesبرنامج العمارة و التشيد خريف2013Anonymous epd9bzMNo ratings yet

- غاز و بتروكيماويات خريف 2013Document63 pagesغاز و بتروكيماويات خريف 2013Anonymous epd9bzMNo ratings yet

- أولى ترم ثانى 2013Document16 pagesأولى ترم ثانى 2013Anonymous epd9bzM0% (1)

- عمارة و تشييد خريف 2012-2013Document27 pagesعمارة و تشييد خريف 2012-2013Anonymous epd9bzMNo ratings yet

- الحاسبات و الاتصالات خريف 2013 PDFDocument51 pagesالحاسبات و الاتصالات خريف 2013 PDFAnonymous epd9bzMNo ratings yet

- حاسبات و اتصالات خريف2012-2013Document55 pagesحاسبات و اتصالات خريف2012-2013Anonymous epd9bzMNo ratings yet

- حاسبات و اتصالات خريف 2011Document28 pagesحاسبات و اتصالات خريف 2011Anonymous epd9bzMNo ratings yet

- ثالثة ترم ثانى 2013Document12 pagesثالثة ترم ثانى 2013Anonymous epd9bzMNo ratings yet

- رابعة ترم أول 2013Document11 pagesرابعة ترم أول 2013Anonymous epd9bzMNo ratings yet

- الحاسبات و الاتصالات خريف 2013 PDFDocument51 pagesالحاسبات و الاتصالات خريف 2013 PDFAnonymous epd9bzMNo ratings yet

- Day 2 Training-13-11-2014Document84 pagesDay 2 Training-13-11-2014Anonymous epd9bzMNo ratings yet

- ثانية ترم ثانى 2013Document22 pagesثانية ترم ثانى 2013Anonymous epd9bzMNo ratings yet

- Day 1 Training-13-11-2014Document183 pagesDay 1 Training-13-11-2014Anonymous epd9bzMNo ratings yet

- ثالثة ترم أول 2013Document21 pagesثالثة ترم أول 2013Anonymous epd9bzMNo ratings yet

- ثانية ترم أول 2013Document10 pagesثانية ترم أول 2013Anonymous epd9bzMNo ratings yet