Professional Documents

Culture Documents

CALIB053 - Mathcad 15 Equations

Uploaded by

ilie_vlassaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

CALIB053 - Mathcad 15 Equations

Uploaded by

ilie_vlassaCopyright:

Available Formats

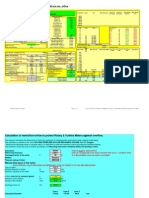

CALIB053 - WET GAS VENTURI FLOW RATE CHECK

Flow Calculations to ISO 5167 Measurement of fluid flow by means of pressure differential devices

Note:- This file carries out the core calculation in strict SI units (Data is entered in 'Oilfield metric')

Calculation Title

CalTitle "Title Here"

Project "Project No here"

CalcRef "enter your Calculation reference"

OPTIONS

Wet Gas correction Method

MC 4

1 = Murdock 1962 (M = 1.26),

2 = Murdock 1977 (M = 1.5),

3 = Chisholm,

4 = De Leew 1994 Standard,

5 = De Leew 1994 Solartron,

6 = Steven 2002 (on hold)

Gas CV

GasCV 2

1 = Mass, 2 = Volumetric

Condensate CV

CondCV 2

1 = Mass, 2 = Volumetric

Methanol Density

RhoCH3OH 2

1 = Keypad, 2 = Calculated

Gas Discharge Coefficient

GDCoeff 1

1 = Fixed, 2 = Table

n 8

n = Number of rows from the table if GDCoeff = 2

Temperature Input

TempInput 1

1 = Upstream, 2= Downstream

Temperature Exponent Type

Texp 1

1 = Keypad, 2 = Calculated (if

TempInput = 2 (Downstream)

Water Density

RhoH2O 2

1 = Keypad, 2 = Calculated

CONFIGURATION PARAMETERS

System Parameters

tcal 20

Calibration Temperature (C)

Dcal.mm 229.92

Meter Tube (mm)

ecs 0.000013

Thermal Expansion

dcal.mm 161.13

Venturi bore (mm)

ess 0.000013

Thermal Expansion

Additional wet gas calculation factors

or

or

The water and methanol standard densities are required only if

RhoCHE3OH and RhoH2O = 1 (Keypad)

Water density equation coefficients

D 0.0001732

Water standard density (kg/m3)

15w.in 1000

Methanol density equation coefficients

G 0.0000713

Methanol standard density (kg/m3)

15m.in 633.6

Condensate density / volume correction

coefficients

K0 1489.067

Condensate standard density (kg/m3)

15c 633.6

Reference and basic configuration parameters

Condensate equilibrium vapour

pressure (PaA)

Pe 1.01325 10

Acceleration due to gravity (m/s2)

g 9.8066

Reference Pressure (PaA)

Pref 1.01325 10

Reference Temperature (C)

tref 15

E 0.1307

F 1040

H 0.3344

J 760

K1 0

K2 0.0018684

Metco Flow Lifecycle Services

Wet Gas Venturi Flow Rate Check

Permanent pressure loss equation

coefficients (required when TempInput = 2

(Downstrean))

A 0.59

Printed at 21/07/2016

Values for A, B, a nd C a re ta ken from eq ua ti on s (a ) o r

(b) in Table 6.4 of the Flow Measurement Engineering

Handbook (2nd Edition).

B 0.86

C 0.436

INPUT PARAMETERS

Gas discharge coefficient

CG.in 0.99735

Liquid discharge coefficient

CL 1.2

This value is used if GDCoeff = 1 (Fixed)

Liquid Properties

Condensate to gas mass ratio

c 0.0110489919

Water to gas mass ratio

w 0.0110489919

Methanol to gas mass ratio

m 0.00526810719

Gas Calorific Value (MJ/kg or MJ/m3)

CVg 70

Condensate Calorific Value (MJ/kg or MJ/m3)

CVc 70

Water density (kg/m3)

w.in 1000

Methanol density (kg/m3)

m.in 633.6

Units depends on the option selected for GasCV and

CondCV: 1 = Mass, 2 = Volumetric

The water and methanol line densities are required

only if RhoCHE3OH and RhoH2O = 1 (Keypad)

Gas Properties

Gas Isentropic exponent

1.30873

Gas Dynamic viscosity (Pa*s)

cp 0.012132

Temperature Exponent

KTe 0.2359

Fixed Base Density (kg/m3)

b 0.774972911

Used in calculation if Temperature Exponent Type

Texp = 1 (keypad)

Process Conditions

Upstream Pressure (bar.g)

pop 25

Upstream / Downstream Temperature (C)

tf.in 18

Differential Pressure (mbar)

pmbar 721

Gas Density Upstream (kg/m3)

f 20.6810271

According to the Temperature Input option selected

Gas Discharge Coefficient Table, if GDCoeff = Table

DCLTable

Reynolds

Number at D

Discharge

Coefficient C

92972.00000

0.99751

8004183.95420

0.99617

12613500.71600

1.00018

20938522.39857

0.99581

21084325.29000

0.99523

25914898.81200

1.00007

30746226.64400

1.00187

44714447.81400

0.99931

48714447.81400

0.99800

10

50714447.81400

0.99850

Reynolds submatrix( DCLTable 1 n 1 1 )

CALIB053

Values for gas discharge coefficient are obtained

by linear interpolation between look-up table

values from venturi calibration results.

DischargeCoeff submatrix( DCLTable 1 n 2 2)

Page 2 of 8

Metco Flow Lifecycle Services

Wet Gas Venturi Flow Rate Check

Printed at 21/07/2016

1.002

1

DischargeCoeff 0.998

0.996

0.994

0

10000000

20000000

30000000

40000000

50000000

Reynolds

Unit Conversion: Oilfield to SI & 'conventional' to Absolute

Reference and basic definitions

Tref tref 273.15 288.15

Convert Dimensions to SI

Dcal

dcal

D cal.mm

0.22992

1000

d cal.mm

1000

0.16113

Convert viscosity from Cp to Pa*s

cp 10

Convert mbar to Pa

dp pmbar 100 72100

Beta Ratio

D cal

metre

Pf pf 1.01325 10

Tf.in tf.in 273.15 291.15

dcal

metre

pf p op 10

Convert to SI & absolute

PaA

0.000012132

0.700808977035

Since the venturi throat and pipe diameters

apply to the same body material, Beta does

not vary with temperature and can thus be

calculated as d cal/Dcal (instead of d t/Dt), so the

calculation of Beta does not require iteration.

Equation for calculation of permanent pressure loss

taken from Flow Measurement Engineering Handbook

(RW Miller), 2nd Edition, Table 6.4 (15o or 7 o exit cone)

Permanent Pressure Loss

A B C dp 8873.554713081878

(Pascal)

Throat Tapping Pressure

P2 Pf dp 2529225

(Pascal)

Fully Recovered Downstream Pressure

P3 Pf 2592451.445286918

(Pascal)

Pf 2601325

Upstream Temperature

Temperature Exponent

Te

if Texp = 2

0.2359

KTe otherwise

Tf

Te

P3

Tf.in P

if TempInput = 2

291.15

(K)

tf Tf 273.15 18

(degC)

Tf.in otherwise

Throat Diameter Temperature Correction

dop d cal 1 ess tf tcal 0.16112581062

(metre)

Pipe Diameter Temperature Correction

Dop D cal 1 ecs tf tcal 0.22991402208

(metre)

Liquid to Gas Mass Ratio (from liquid component to gas mass ratios)

L c w m 0.02736609099

Gas Mass Fraction

CALIB053

Condensate Mass Fraction

Page 3 of 8

Metco Flow Lifecycle Services

g

1

1 L

Wet Gas Venturi Flow Rate Check

0.973362863316

Printed at 21/07/2016

c c g 0.010754678393

Water Mass Fraction

w w g 0.010754678393

Methanol Mass Fraction

m m g 0.005127779899

Condensate Line Density

15

K0 K1 15c

2

K2 0.001840831181

t tf 15 3

(deg C)

15c

Ctl exp 15 t 1 0.8 15 t 0.994468463709

4

Fc 10

Cpl

870960

2

15c

exp 1.6208 0.00021592 tf

4209.2 tf

2

15c

1.005274634893

0.000209878364

(/bar)

c C tl C pl 15c 633.418740831676

1 Pf Pe Fc 10

(kg/m3)

Water Line Density

w

D tf2 E tf F

if RhoH2O = 2

w 1037.5912832

(kg/m3)

if RhoCH3OH = 2

m 754.0039012

(kg/m3)

15w 1038.00053

(kg/m3)

15m 755.0000425

(kg/m3)

w.in otherwise

Methanol Line Density

m

G tf2 H tf J

m.in otherwise

Water Standard Density

15w ( 225 D 15 E F) if RhoH2O = 2

15w.in otherwise

Methanol Standard Density

15m

( 225 G 15 H J) if RhoCH3OH = 2

15m.in otherwise

Liquid Line Density

L

L

c

c

w

w

780.128308508431

(kg/m3)

m

m

Dry Gas Expansion Factor

2

1

Pf dp

Pf dp

Pf

1

Pf

2

1

Pf dp

1 4 Pf dp

Pf

Pf

0.5

0.977494961548354

Gas Discharge Coefficient Linearisation

CALIB053

Page 4 of 8

Metco Flow Lifecycle Services

qmcalc

Wet Gas Venturi Flow Rate Check

Printed at 21/07/2016

Cd 1

for k 1 20

Re

Cd

Cd

qmutable

dop

2 dp f

4 qmutable

Dop

DCLTable1 2 if Re DCLTable1 1

1

1

2

1

DCLTable DCLTable 1 1 if Re max DCLTable

lookup max DCLTable

1

2

linterp submatrix( DCLTable 1 n 1 2) submatrix( DCLTable 1 n 1 2 ) Re otherwise

kk1

qmutable

Re Cd

qmutable

Re C d qmcalc

qmutable

Re C d

39.40889 17988978.67585

CG

Gas Discharge Coefficent

Cd if GDCoeff = 2

3

0.99736

CG 0.99735

CG.in otherwise

Uncorrected Mixture Mass Flow Rate

qmu

qmu 39.408566841053

qmutable if GDCoeff = 2

d 2 C

op

G

4

1

1

Pipe Reynolds Number

ReD Re if GDCoeff = 2

4 q mu

D op

(kg/s)

2 dp f otherwise

Re 17988978.675846118

17988829.242673423

otherwise

Mass Flowrate Calculations

This Sub-Routine Iterates the De Leew Wet Gas Correction Factor

Define Froude index selection

PIF( Frg) if Frg 1.5 0.41 0.606 1 e

0.746 Frg

Define Sub-Routine

CALIB053

Page 5 of 8

Metco Flow Lifecycle Services

DeLew

qgov.lew

Ylew

Wet Gas Venturi Flow Rate Check

Printed at 21/07/2016

q mu

f

1 g Cd

f

if MC = 5

g

L

CL

1 g f

otherwise

g L

for run 1 15

lew qgov.lew

2

D

op

lew

f

Fr

g Dop L f

frd PIF( Fr)

Klew

L frd f frd

f L

Flew

1 Klew Ylew Ylew

qmu

qm.lew

Flew

qgov.lew

Fr

frd

F

lew

Ylew

Fr

frd

F

lew

Ylew

q m.lew

f

lew

Klew

Fr

frd

F

lew

lew DeLew

Klew

Ylew

lew

Klew

4.949569680023

0.004455698537

0.590902925176

45.037281362282

1.019120579237

8.660123985453

Flew 1.019120579237104

Murdock (Dickinson/Jamieson) Correction Factor

M

Murdock equation constant

1.5 if MC = 2

1.26

1.26 otherwise

1 g Cd

g CL

Fdj 1 M

Lockhart Martinelli Parameter

f

L

1.004561112938649

Ydj

Chisholm Correction Factor

Lockhart Martinelli Parameter

CALIB053

Ych

1 g Cd

g CL

1 g

g

f

L

f

L

0.003619931

0.004455698537

Page 6 of 8

Metco Flow Lifecycle Services

L

Kch

f

Fchm

0.25

f

L

Wet Gas Venturi Flow Rate Check

Printed at 21/07/2016

0.25

2.881776634396

1 Kch Ych Ych 1.00640955

Interim Results

Throat Tapping Pressure, Pa

P2 2529225

Fully Recovered Downstream Pressure, Pa

P3 2592451.445286918

Upstream temperature, deg C

tf 18

Throat Diameter, m

dop 0.16112581062

Liquid to gas Mass Ratio

L 0.02736609099

Epsilon Dry Gas

0.977494961548354

Wet Gas Correction Factor

Fwg

Fdj if MC = 1 MC = 2

Fwg 1.019120579237104

Fchm if MC = 3

1 = Murdock 1962 (M = 1.26),

2 = Murdock 1977 (M = 1.5),

3 = Chisholm,

4 = De Leew 1994 Standard,

5 = De Leew 1994 Solartron

Flew if MC = 4 MC = 5

0 otherwise

Dry Gas Gross Volume Flow Rate, m3/s

qvgG

Liquid Mass Flow Rate, kg/s

qmL

qmu

Fwg f

qmu

Fwg

1.869790574301

1 g

1.058224559419

Beta Ratio

0.700808977035

Pipe Reynolds Number

ReD 17988829.24

Gas Discharge Coefficent

Cd 0.9973582849846854

Results

Uncorrected Mixture Mass Flow Rate (kg/s)

qmu 39.40856684

Dry Gas Mass Flow Rate (kg/s)

qmG

Dry Gas Standard Volume Flow Rate (Sm3/s)

Dry Gas Energy Flow Rate (MJ/s)

qvsG

qeG

qmu

Fwg

qmG

b

38.66918954

49.897472530429

CVg qmG

CVg qvsG

if GasCV = 1

otherwise

Wet Gas Mass Flow Rate (kg/s)

qm qmG qmL 39.727414097868

Condensate Mass Flow Rate (kg/s)

qmc c qm 0.42725556199

Condensate SVol Flow Rate (Sm3/s)

qvsc

Condensate Energy Flow Rate (MJ/s)

Hydrocarbon Mass Flow Rate (kg/s)

CALIB053

qec

qmc

15c

3492.823077130001

0.000674330117

CVc qmc

CVc qvsc

if CondCV = 1

0.047203108174

otherwise

qmhc q mG q mc 39.096445100439

Page 7 of 8

Metco Flow Lifecycle Services

Wet Gas Venturi Flow Rate Check

Hydrocarbon SVol Flow Rate (Sm3/s)

qvshc q vsG q vsc 49.898146860545

Hydrocarbon Energy Flow Rate (MJ/s)

qehc qeG q ec 3492.870280238176

Methanol Mass Flow Rate (kg/s)

qmm m q m 0.203713435439

Methanol SVol Flow Rate (Sm3/s)

qvsm

q mm

0.000269819105

15m

Water Mass Flow Rate

qmw w qm 0.42725556199

Water Standard Volume Flow Rate (Sm3/s)

qvsw

Liquid Standard Volume Flow Rate

(Sm3/s)

Mixture Standard Volume Flow Rate

(Sm3/s)

Printed at 21/07/2016

qmw

0.000411614011

15w

qvsL qvsc q vsw qvsm 0.0013557632

Not displayed in Metrology

qvs qvsG qvsL 49.898828293661

Not displayed in Metrology

Mass Flow rate in Oilfield Terms

Hydrocarbon Mass Flowrate (t/hr)

Dry Gas Mass Flowrate (t/hr)

Condensate Mass Flowrate (t/hr)

qmhcThr qmhc

qmGThr q mG

qmuThr q mu

3600

1000

3600

1000

3600

1000

140.747202361579

139.209082338416

141.870840627792

Energy Flow rates in Oilfield Terms

Dry Gas Energy Flow Rate (TJ/hr)

Condensate Energy Flow Rate (TJ/hr)

Hydrocarbon Energy Flow Rate (TJ/hr)

qeG.hr q eG

qec.hr qec

3600

6

12.574163077668

10

3600

0.000169931189

6

10

3600

qehc.hr qehc

12.574333008857

6

10

Standard Volume Flow rates in Oilfield Terms

Dry Gas Std Vol Flow Rate (m3/hr)

qvsGhr q vsG.3600 17.963090110954

Condensate Std Vol Flow Rate (m3/hr)

qvschr qvsc.3600 0.000242758842

Hydrocarbon Std Vol Flow Rate (m3/hr)

qvshchr qvshc .3600 17.963332869796

CALIB053

Page 8 of 8

You might also like

- LEGO Today I Feel Visual Emotions Chart - Updated PDFDocument3 pagesLEGO Today I Feel Visual Emotions Chart - Updated PDFilie_vlassaNo ratings yet

- Gas Cylinder RulesDocument30 pagesGas Cylinder RulesRishabhNo ratings yet

- Harmonies of The World by KeplerDocument61 pagesHarmonies of The World by Keplerfundik8100% (2)

- RELIEF FORCESDocument2 pagesRELIEF FORCESChris DENo ratings yet

- How To Read Body LanguageDocument6 pagesHow To Read Body LanguageSyed Ather Ali Shah100% (5)

- PSV 0600B Well Test Separator - L03Document6 pagesPSV 0600B Well Test Separator - L03Ebby OnyekweNo ratings yet

- Calculation SpreadsheetDocument50 pagesCalculation SpreadsheetYoussef RadefNo ratings yet

- Gas Line SizingDocument7 pagesGas Line SizingTun Naing WinNo ratings yet

- NaturalConvectionHeatTransferCoefficients SI Units Final ProtectedDocument44 pagesNaturalConvectionHeatTransferCoefficients SI Units Final ProtectedFabio MiguelNo ratings yet

- Small Bore Orifice For Gas Flow PDFDocument4 pagesSmall Bore Orifice For Gas Flow PDFManufacturer VerifyNo ratings yet

- Cone Layout ToolDocument1 pageCone Layout ToolSaravanan ManiNo ratings yet

- Yale & Sentry 2010 Closure Catalog - R&MDocument16 pagesYale & Sentry 2010 Closure Catalog - R&MAlfredo OrellanaNo ratings yet

- Double FdexchangerDocument8 pagesDouble FdexchangerBoško IvanovićNo ratings yet

- 01 - Fluid FlowDocument76 pages01 - Fluid FlowMubarak AhmadNo ratings yet

- CALCULATING COMPRESSIBILITY FACTOR z FOR GASESDocument3 pagesCALCULATING COMPRESSIBILITY FACTOR z FOR GASESSrihari KodimelaNo ratings yet

- Meter Selection Rev 031Document5 pagesMeter Selection Rev 031andrew_c_potocki902No ratings yet

- VALVE SPECSDocument3 pagesVALVE SPECSazitaggNo ratings yet

- Section 7Document64 pagesSection 7WlopezaNo ratings yet

- HORIZONTAL THREE-PHASE SEPARATORDocument16 pagesHORIZONTAL THREE-PHASE SEPARATORDhanny MiharjaNo ratings yet

- Weymouth Gas Flow CalculationsDocument44 pagesWeymouth Gas Flow CalculationsPierre GermaineNo ratings yet

- Finite Element Analysis and ASME Code Calculations for Pressure VesselsDocument2 pagesFinite Element Analysis and ASME Code Calculations for Pressure Vesselsnaveen_86No ratings yet

- Migrating From QNX To Embedded LinuxDocument18 pagesMigrating From QNX To Embedded Linuxilie_vlassaNo ratings yet

- Steam HXDocument1 pageSteam HXrajachemNo ratings yet

- Flow Meter Sizing MOSDocument11 pagesFlow Meter Sizing MOSra9622No ratings yet

- Unit - 1 16 Marks Questions and Answers PDFDocument24 pagesUnit - 1 16 Marks Questions and Answers PDFGopi RaguNo ratings yet

- Sizing Pressure Regulators & Control ValvesDocument16 pagesSizing Pressure Regulators & Control ValvesCH1253No ratings yet

- Example 1: Size A 2-Phase Vertical Separator: Job SpecificationsDocument20 pagesExample 1: Size A 2-Phase Vertical Separator: Job SpecificationsLeonardo Ramirez GuzmanNo ratings yet

- Condensate Line SizingDocument2 pagesCondensate Line SizingAnonymous oVRvsdWzfBNo ratings yet

- PSV Sizing Psv-402 Update PsetDocument7 pagesPSV Sizing Psv-402 Update PsetBui Khoi NguyenNo ratings yet

- Reciprocating Compressor Calculation Sheet: Gas Properties, Flowrate and ConditionsDocument9 pagesReciprocating Compressor Calculation Sheet: Gas Properties, Flowrate and ConditionsSlim Toumi0% (1)

- 16 - Gas Line SizingDocument11 pages16 - Gas Line SizingJunaid MateenNo ratings yet

- Valve Sizing Calculation Sheet: Version: V3.1.0 Date: 20/01/2016Document4 pagesValve Sizing Calculation Sheet: Version: V3.1.0 Date: 20/01/2016JOSE MARTIN MORA RIVEROSNo ratings yet

- TD HE THE v2020.00Document43 pagesTD HE THE v2020.00Claudia BonocoreNo ratings yet

- Vent Line Sizing Metric Calculation Results DP WarningDocument2 pagesVent Line Sizing Metric Calculation Results DP WarningAjay TiwariNo ratings yet

- Process Data Sheet: Calculation of Pressure Drop in Fixed Catalyst BedsDocument1 pageProcess Data Sheet: Calculation of Pressure Drop in Fixed Catalyst BedsamitkrayNo ratings yet

- TW6151A - Wake Freq CalcaDocument2 pagesTW6151A - Wake Freq Calcakkd3No ratings yet

- H H. W W W 358.9628.D - .H 6.31533.W D.: AGA Flow Orifice Calculation RoutinesDocument24 pagesH H. W W W 358.9628.D - .H 6.31533.W D.: AGA Flow Orifice Calculation RoutinescincaohijauNo ratings yet

- Control Valve Sizing Based on Masonelian MethodDocument10 pagesControl Valve Sizing Based on Masonelian Methodmanoj_amritkarNo ratings yet

- 40863-001 Calc - Inline Heater PDFDocument3 pages40863-001 Calc - Inline Heater PDFomar equihuaNo ratings yet

- PSV Sizing Psv-414 UpdateDocument7 pagesPSV Sizing Psv-414 UpdateBui Khoi NguyenNo ratings yet

- Perancangan CycloneDocument20 pagesPerancangan CycloneDavid LambertNo ratings yet

- IEC Aero Noise Mass 4C R2Document23 pagesIEC Aero Noise Mass 4C R2JeromeNo ratings yet

- Solid-Liquid Separation: Batch Sedimentation: Experiment 2Document12 pagesSolid-Liquid Separation: Batch Sedimentation: Experiment 2Wan Muhammad FikriNo ratings yet

- Shell and Tube Heat Exchanger Design: Temperature of FluidsDocument6 pagesShell and Tube Heat Exchanger Design: Temperature of FluidsRashmi PariharNo ratings yet

- Midrex Process Water DegasserDocument2 pagesMidrex Process Water DegasserMorteza RafieiNo ratings yet

- Orifice calculation sheet parametersDocument2 pagesOrifice calculation sheet parameterstechkasambaNo ratings yet

- Book 1Document1 pageBook 1Manju NaikNo ratings yet

- Cvsize (Control Valve Sizing)Document8 pagesCvsize (Control Valve Sizing)EslamSheblNo ratings yet

- Kaybob Gas Plant Piping and Instrumentation DiagramDocument7 pagesKaybob Gas Plant Piping and Instrumentation DiagrampavanNo ratings yet

- CE 432 Wastewater treatment plant design optimizationDocument19 pagesCE 432 Wastewater treatment plant design optimizationjnmanivannanNo ratings yet

- Valve Sizing W IEC Noise - Gas VolumetricDocument64 pagesValve Sizing W IEC Noise - Gas VolumetricskalanidhiNo ratings yet

- CCC1Document5 pagesCCC1Uok RitchieNo ratings yet

- PLTDocument38 pagesPLThafezasadNo ratings yet

- Đánh giá hệ thống hiện hữu tăng công suất khí Saint-GobainDocument1 pageĐánh giá hệ thống hiện hữu tăng công suất khí Saint-GobainDuy Nguyễn VănNo ratings yet

- 1 Darcy Friction CalculatorDocument2 pages1 Darcy Friction CalculatorTinashe MutetwaNo ratings yet

- Orifice SizingDocument1 pageOrifice SizingMarco D'OnofrioNo ratings yet

- Deu PointDocument2 pagesDeu PointP.S.J.SarmaNo ratings yet

- Sizing of Control Valves For Non-Turbulent Flow (Laminar and Transitional)Document14 pagesSizing of Control Valves For Non-Turbulent Flow (Laminar and Transitional)JOSE MARTIN MORA RIVEROSNo ratings yet

- Insulation Thickness by UOPDocument4 pagesInsulation Thickness by UOPOmar EzzatNo ratings yet

- Restriction OrificeDocument8 pagesRestriction OrificekarthickNo ratings yet

- Nonboiling Liq Outflow F Vertical Cyl VesselDocument26 pagesNonboiling Liq Outflow F Vertical Cyl VesselSrihari KodimelaNo ratings yet

- 62577A Calculation of Orifice Coefficient Si UnitsDocument18 pages62577A Calculation of Orifice Coefficient Si UnitsUary Buza RegioNo ratings yet

- Steam Control Valve Sizing for Tag PV123Document2 pagesSteam Control Valve Sizing for Tag PV123dilip matalNo ratings yet

- Summary of anchor nozzle movementsDocument18 pagesSummary of anchor nozzle movementsreach_arindomNo ratings yet

- Calculation of Orifice CoefficientDocument18 pagesCalculation of Orifice Coefficientvinayjoshi270586No ratings yet

- Thermodynamics Tutorial ExampleDocument7 pagesThermodynamics Tutorial Examplecheckmeout803No ratings yet

- Natural Gas Tutorial 2Document22 pagesNatural Gas Tutorial 2Sylvester TetteyNo ratings yet

- Sensors: Using Smart Phone Sensors To Detect Transportation ModesDocument23 pagesSensors: Using Smart Phone Sensors To Detect Transportation Modesilie_vlassaNo ratings yet

- AGA8 TestDocument9 pagesAGA8 Testilie_vlassaNo ratings yet

- Low-Power P Supervisory Circuits With Battery-Backup Circuit and Chip-Enable GatingDocument21 pagesLow-Power P Supervisory Circuits With Battery-Backup Circuit and Chip-Enable Gatingilie_vlassaNo ratings yet

- Prover TestDocument1 pageProver Testilie_vlassaNo ratings yet

- Scurt Rezumat - Transcript - Jogn - MacArthurDocument5 pagesScurt Rezumat - Transcript - Jogn - MacArthurilie_vlassaNo ratings yet

- 1peter PDFDocument86 pages1peter PDFilie_vlassaNo ratings yet

- 2peter PDFDocument60 pages2peter PDFilie_vlassaNo ratings yet

- Photon Prog GuideDocument938 pagesPhoton Prog Guideilie_vlassa100% (1)

- Scurt Rezumat - Transcript - Jogn - MacArthurDocument5 pagesScurt Rezumat - Transcript - Jogn - MacArthurilie_vlassaNo ratings yet

- Scurt Rezumat Transcript Jogn MacArthurDocument19 pagesScurt Rezumat Transcript Jogn MacArthurilie_vlassaNo ratings yet

- 1Document13 pages1ilie_vlassaNo ratings yet

- Photon Prog GuideDocument938 pagesPhoton Prog Guideilie_vlassa100% (1)

- 1Document13 pages1ilie_vlassaNo ratings yet

- Processes: "Tour of The Black Holes of Computing!"Document25 pagesProcesses: "Tour of The Black Holes of Computing!"ilie_vlassaNo ratings yet

- CSB400 Series Commercial / Industrial Pressure Reducing RegulatorsDocument28 pagesCSB400 Series Commercial / Industrial Pressure Reducing Regulatorsilie_vlassaNo ratings yet

- 2Document13 pages2ilie_vlassaNo ratings yet

- John MacArthur 1Document12 pagesJohn MacArthur 1ilie_vlassaNo ratings yet

- Programming c#1Document50 pagesProgramming c#1ilie_vlassaNo ratings yet

- Object Oriented Programming in C 4th Edition1Document9 pagesObject Oriented Programming in C 4th Edition1ilie_vlassaNo ratings yet

- Openenterprise: New Capability of Integrating Dcs and Scada Client / Server ArchitectureDocument20 pagesOpenenterprise: New Capability of Integrating Dcs and Scada Client / Server Architectureilie_vlassaNo ratings yet

- Visual C Programming Basics1Document19 pagesVisual C Programming Basics1ilie_vlassaNo ratings yet

- It CampDocument1 pageIt Campilie_vlassaNo ratings yet

- Openenterprise: New Capability of Integrating Dcs and Scada Client / Server ArchitectureDocument20 pagesOpenenterprise: New Capability of Integrating Dcs and Scada Client / Server Architectureilie_vlassaNo ratings yet

- CSB400Document28 pagesCSB400ilie_vlassaNo ratings yet

- CSB400Document28 pagesCSB400ilie_vlassaNo ratings yet

- Types of ReactorDocument6 pagesTypes of ReactorSalome ValeriaNo ratings yet

- Chapter 1Document16 pagesChapter 1Moyikaa MargaaNo ratings yet

- Stormwater Modeling GuideDocument71 pagesStormwater Modeling GuidesmrtnickNo ratings yet

- Sedimentation in large wastewater plantsDocument18 pagesSedimentation in large wastewater plantsAhmed AmediNo ratings yet

- NAIMA Facts About Insulation Requirements For Plastic PipingDocument6 pagesNAIMA Facts About Insulation Requirements For Plastic PipingBryan CarisNo ratings yet

- EHD enhancement of heat transfer reviewDocument19 pagesEHD enhancement of heat transfer reviewSadegh AhmadiNo ratings yet

- Hydraulic CalculationDocument46 pagesHydraulic CalculationBader ShrbajiNo ratings yet

- Design of AqueductDocument5 pagesDesign of Aqueducthari_shresthaNo ratings yet

- Assignment - Cpe603 - March 2019Document1 pageAssignment - Cpe603 - March 2019Fnur FatihahNo ratings yet

- Well DesignDocument17 pagesWell DesignabdulazizNo ratings yet

- Dae 15 Y764Document4 pagesDae 15 Y764Gerber GarciaNo ratings yet

- Env Health Pool Hydraulic Analysis FormDocument5 pagesEnv Health Pool Hydraulic Analysis Formhabib shuaibNo ratings yet

- Wilo-SCP pumps axially split housing leafletDocument46 pagesWilo-SCP pumps axially split housing leafletJair Jimenez HerreraNo ratings yet

- K-Flex India Brochure 2023Document6 pagesK-Flex India Brochure 2023Ishan PereraNo ratings yet

- Properties of SolutionsDocument18 pagesProperties of SolutionsstineNo ratings yet

- Thermodynamics 2 - Chapter 5 Part1Document29 pagesThermodynamics 2 - Chapter 5 Part1Amir SallehNo ratings yet

- WaveDocument3 pagesWavePrasad SnNo ratings yet

- Am220kxvjnh Id PDFDocument1 pageAm220kxvjnh Id PDFMarwene HlaouiNo ratings yet

- Section 6Document40 pagesSection 6Hafiz AkhtarNo ratings yet

- 6 YtDocument16 pages6 YtIR MA Al AzharNo ratings yet

- James 2020Document19 pagesJames 2020María Pía Arancibia BravoNo ratings yet

- The Assessment of A Characteristic Drying Curve For Milk Powder For Use in Computational Fluid Dynamics ModellingDocument6 pagesThe Assessment of A Characteristic Drying Curve For Milk Powder For Use in Computational Fluid Dynamics ModellingMario LlanoNo ratings yet

- Monostadio HorizonDocument44 pagesMonostadio HorizonMichele MaselliNo ratings yet

- Opt in Heat Transfer1Document2 pagesOpt in Heat Transfer1Renzel ReyesNo ratings yet

- Planning The Wet Scrubber On Auxiliary Boiler Unit at Pt. Indonesia Power Ujp Jabar 2 Pelabuhan RatuDocument13 pagesPlanning The Wet Scrubber On Auxiliary Boiler Unit at Pt. Indonesia Power Ujp Jabar 2 Pelabuhan RatuYuda HerdiantoNo ratings yet

- SPE 130655 High-Temperature Conformance Field Application Through Coiled Tubing: A Successful Case HistoryDocument10 pagesSPE 130655 High-Temperature Conformance Field Application Through Coiled Tubing: A Successful Case HistoryLeopold Roj DomNo ratings yet