Professional Documents

Culture Documents

United States Patent: 3,177,461 4/1965 Hagen Et Al................... 339/1840M)

Uploaded by

Abdelkader BenarbiaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

United States Patent: 3,177,461 4/1965 Hagen Et Al................... 339/1840M)

Uploaded by

Abdelkader BenarbiaCopyright:

Available Formats

United States Patent

[11] 3,582,867

[72] Inventors Wayne R. Thompson

Bainbridge;

3,177,461 4/1965 Hagen et al................... 339/1840M)

Le Roy W. Fairbairn, Sidney, both of, N.Y.

[21] Appl. No. 808,775

Mar. 20, 1969

[22] Filed

[45] Patented June 1, 1971

3,325,771

3,426,315

6/1967 Ruehlemann et al......... 339/184(M)

2/1969 De Tar.........................

339/105

Primary ExaminerMarvin A. Champion

AttorneysDale A. Bauer, John L. Weymour, Bauer and

Assistant ExaminerLawrence J. Staab

[73] Assignee The Bendix Corporation

Seymour and Plante, Arens, Hartz, Hix and Smith

[54] POLARIZATION MEANS FOR ELECTRICAL

CONNECTORS

6 Claims, 10 Drawing Figs.

[52] U.S. Cl........................................................

339/92,

339/184

[51] Int. Cl.........................................................H01r13/54,

H01r13/64

[50] Field of Search............................................ 339/184,

-

[56]

3,120,417

186, 221, 92

References Cited

UNITED STATES PATENTS

2/1964 Francis.........................

339/93

ABSTRACT: Polarizing means for the main parts of a separa

ble electrical connector which carry mating electrical con

tacts. The polarizing means has two polarizing inserts

removably mounted in selected angular positions on the

respective connector parts, such inserts having portions which

interfit to permit the connector parts to be mated only when

the correct connector parts are presented to each other. In the

embodiments shown, the polarizing inserts are made of yielda

ble plastic material, and are of such dimensions as to provide

sufficient tolerances to prevent binding between them when

the correct connector parts are mated.

3,582,867

PATENTED JUN Gl

SHEET 2 OF 2

F?TI?T

N

||| | | N

50

?>

BY

50

INVENTORS

LEROY W. FAIRBA|RN

WAYNE R. THOMPSON

AITORNEYS

3,582,867

2

with the respective ones of the fixedly mounted connector

bodies. Unless the connector bodies are correctly mated, mal

functioning of the apparatus will result; the apparatus may

also be severely damaged or ruined.

The connector polarizing means in accordance with the in

vention makes it possible to make all of the connectors per se

of the same construction, thereby permitting their economical

production and stocking. The polarizing means in accordance

with the invention includes pluglike parts which are received

in aligned seats in the connector bodies, the seats and the

pluglike parts being of such shape that the parts can be

POLARIZATION MEANS FOR ELECTRICAL

CONNECTORS

This invention relates to separable electrical connectors,

and more specifically relates to polarizing means for the main

parts of such connectors.

Among the objects of the invention is the provision of a

novel polarizing means for the parts of a separable electrical

Connector.

Another object of the invention is the provision of a polariz 10

ing means which is readily adjusted to a plurality of different

polarizing positions.

.

disposed in any one of a number of different angular positions

A further object of the invention is the provision of a in the seat. The outer end portions of such parts are of such

polarizing means having mating polarizing inserts arranged for configuration that they are mateable, when the connector

indexing upon the respective connector parts, the inserts 15 bodies are aligned and moved toward each other, only when

being securely retained in each of their indexed positions.

the two parts of the polarizing means are correctly oriented

Yet another object of the invention is the provision of a relative to each other. When such parts are not correctly

polarizing means wherein the parts thereof are resiliently oriented

to each other, they interfere and prevent the

yieldable and are made with such tolerances as to obviate 20 mating ofrelative

the connector bodies.

binding between the connector parts and their polarizing in

Turning now to the first embodiment of electrical connector

serts as the connector parts are mated.

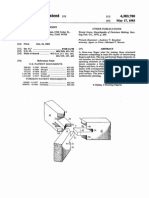

shown in FIGS. 15, inclusive, of the drawings, the connector

The above and further objects and novel features of the in

shown has a plug body 10 and a receptacle 11, the body

vention will more fully appear from the following description there

a projecting portion 12 thereon which is receivable

when the same is read in connection with the accompanying 25 in10ahaving

recess 14 in body 11. Portion 12 has a plurality of spaced

drawings. It is to be expressly understood, however, that the bores 15 therethrough which receive socket contacts, not

drawings are for the purpose of illustration only, and are not shown.

A plurality of pin contacts, also not shown, mounted

intended as a definition of the limits of the invention.

on

the

blind

end wall of recess 14, are disposed to be received

In the drawings, wherein like reference characters refer to within the sockets

when the connector bodies are fully mated.

like parts throughout the several views,

In the installation herein described, the connector plug 10 is

FIG. 1 is a fragmentary view in perspective of a separable 30 secured

to a chassis panel whereas the connector receptacle

electrical connector with the two parts or bodies thereof 11 is secured

to a flexible cable or to a printed circuit board.

aligned and about to be mated, such connector being provided

beyond the ends of portion 12 of body 10 there

with a first embodiment of polarizing means in accordance areOutwardly

ears

of

which

one is shown at 16 in FIG. 1. The body 11

with the invention, a portion of the lower body of the connec 35 has two end portions

the outer ends of recess 14, one

tor being broken away to show the respective part of the such end portion beingbeyond

shown at 17. When bodies 10 and 11

polarizing means;

ears 16 are disposed in alignment with the end

FIG. 2 is a view in vertical transverse section through the are mated,17.theMounted

in each of the ear 16 and the end por

upper body of the connector of FIG. 1, certain of the parts portions

tion 17 is a part 20 of a connector polarizing means. In this

being shown in elevation, the section being taken along the 40 embodiment

such two parts are identical, but are so mounted

line 22 of FIG. 1;

in the connector bodies that a large portion of the part 20 in

FIG. 3 is a view in vertical transverse section through the

10 extends outwardly beyond the surface 22 of body 10,

lower body of the connector of FIG. 1, certain of the parts body

but

somewhat

rearwardly of the forward surface of the part

being shown in elevation, the section being taken along the

12, whereas a relatively small portion of the part 20 in body 11

line 33 of FIG. 1;

45 extends outwardly beyond the surface 25 of body 11. Parts 20

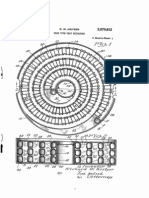

FIG. 4 is a view in plan of the portion of the connector part

made of resiliently yieldable plastic material such as nylon.

shown in FIG. 3, the view being taken from the line 44 of areThe

part 20 is in the form of a hexagonal rod having a hex

FIG. 3;

base portion 26 from one side of which there rises a

FIG. 5 is a view in vertical section through the connector - agonal

stem 27 which has a height substantially greater than the

body shown in FIGS. 3 and 4, the section being taken along

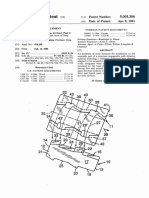

FIG. 6 is a fragmentary view partially in side elevation and

the line 55 of FIG. 4;

partially in longitudinal vertical section of a separable electri

cal connector with the two parts or bodies thereof in fully

mated position, the section being taken along lines 66 of the

polarizing means of FIG. 9, such connector being provided

50

55

FIG. 10 is a view similar to FIG. 9 of another embodiment of

polarizing means useful in the connector of FIGS. 68, inclu

Sive.

part 20, the cutting plane extending substantially between op

posite corners of the hexagonal rod. One part 20 is selectively

mounted in a desired angular position on body 10 by being

snapped into a relatively short hexagonal seat 21 in the body

10; the other part 20 is selectively mounted in a desired angu

with a second embodiment of polarizing means in accordance

with the invention;

FIG. 7 is a view on a reduced scale of the sectional portion

of the upper connector body of FIG. 6, certain of the parts

being shown in elevation;

FIG. 8 is a view on a reduced scale of the sectional portion

of the lower connector body of FIG. 6;

.

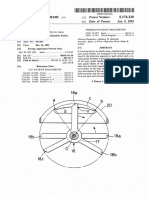

FIG. 9 is a view in perspective of the parts of the polarizing

means of the connector of FIGS. 68, inclusive, in aligned

spaced relationship; and

height of the portion 26. The stem 27 is, in effect, formed as

somewhat less than one-half the section of the outer portion of

lar position on body 11 by being snapped into a relatively long

hexagonal seat 24 in a desired angular position in body 11.

60

65

When bodies 10 and 11 are aligned as shown the hexagonal

seats 21, 24 are similarly oriented and, in effect, form prolon

gations of each other.

It will be apparent that the hexagonal polarizing parts 20

permit any one of six different manners of polarization of the

connector bodies 10, 11 to be chosen. If similar mating

polarizing parts 20 are also used in the ear and end portion at

the other end of the bodies, a total of 36 different manners of

polarization are possible. It is obvious that the parts 20 may

have sections of other polygonal configurations, with more or

Separable electrical connectors of the type shown herein 70 less than six sides.

The polarizing parts 20 are securely but removably retained

are frequently employed, as in computer and control installa

in their respective seats 21, 24 by means which grip the base

tions. Frequently many such connectors are used, the connec

tor bodies of one type being stacked and mounted on a panel portions 26 of the parts 20 but leave the stems 27 thereof

whereas the connector bodies of the other type, which are

unencumbered and free for limited flexing. On two sets of op

connected to respective flexible cables, are selectively mated 75 posing surfaces of the seat 24 there are disposed ribs 30 which

3,582,867

3

compressively engage the base 26 of parts 20. Ribs 30 extend

from the bottom of seat 24 to about the outer surface 35 of

base 26 when part 20 is seated as shown in FIGS. 35, inclu

sive. Similarly, on two sets of opposing surfaces of the seat 21

there are disposed ribs 29 which extend from the bottom of

4

In FIG. 10 there is shown another embodiment of mating

polarizing parts which may be employed in the connector

shown in FIG. 6. Parts in FIG. 10 which are the same as those

5

seat 21 to about the level of the outer surface of base 26 as

shown in FIG, 2.

When the polarizing parts 20 are fully mated, under normal

conditions the outer end surfaces 34 of stems 27 of such parts

are appreciably spaced from each other, as are the confront

ing faces 31 of the opposed stems 27. The seats 21, 24 have

dimensions which substantially exceed those of the polarizing

in FIGS. 69, inclusive, are designated by the same reference

characters with an added prime. The parts shown in FIG. 10

differ from those in FIG. 9 as to the location of the cut

which produced the two protruding mating portions of the

polarizing parts. Whereas in FIG. 9, the plane of cut extends

10

between two alternate corners of the hexagon, in FIG: 10 the

cut is made slightly rearwardly of the axial plane between op

posite corners of the hexagon. Thus, in the construction of

FIG. 10, the polarizing parts 49' and 51' are of identical con

parts 20, as shown in FIG. 4. As a result, the stems 27 of the

struction.

free to yield resiliently to permit the connector parts 10, 11 to

be mated, if necessary. The stems 27 are sufficiently thick,

however, and are sufficiently rigid securely to prevent the

mating of connector bodies the polarizing parts 20 of which

closed embodiment and in that of FIG. 10, the polarizing

means is desirably simplified. In the first embodiment, the

polarizing parts 20 partially protrude from between connector

bodies and so can be removed manually and replaced in a dif

parts 20 not only are free to enter the opposing seats, but are 15 When the polarizing parts are identical, as in the first dis

are incorrectly oriented.

In the second disclosed embodiment of the invention,

shown in FIGS. 610, inclusive, parts which are the same as

in FIGS. 15, inclusive, are designated by the same reference

characters with an added prime. In this embodiment, sche

matically shown contact pins mounted on the bottom wall of

recess 14' are designated 13 in FIG. 6.

20

25

In the second disclosed embodiment, the connector bodies

10' and 11 are connected by screws 40, of which one is shown

in FIGS. 6 and 7. Screw 40 has a lower threaded end 41 above

which the stem 42 is of circular cylindrical configuration. The

screw 40 is held captive by means of an insert collar 44 which

is molded into the end portion 16' of the body 10, there being

30

ferent angular position if desired. The polarizing parts 20 are

securely held on the respective connector bodies at the bases

of such parts, the protruding stems 27 thereof being free to

flex if necessary, should it engage the stem of the other part

20, the wall of the opposing seat, or both. Thus, the polarizing

means does not impose any undesirable strain upon the mating

contacts of the connector. The polarizing means is compact

and adds little, if anything, to the bulk of the connector

bodies. In simple installations, as where only one connector is

used, it is not necessary to mount the polarizing parts 20, parts

49, 51, or parts 49', 51", upon the connector bodies.

The embodiments of FIGS. 610, inclusive, are more

adapted to one final assembly of the polarizing means than

that of FIGS. 15, inclusive. However, the polarizing parts

49, 51 and 49', 51' may, if desired, be removed and reinserted

35 on location if necessary, the part 51 being withdrawn from its

seat by an appropriate tool.

Although only a limited number of embodiments of the in

vention have been illustrated in the accompanying drawings

and described in the foregoing specification, it is to be espe

40 cially understood that various changes, such as in the relative

of the parts, materials used, and the like, as well as

nector bodies 10' and 11" together when they are fully mated dimensions

the suggested manner of use of the apparatus of the invention,

as shown in FIG. 6. A polarizing insert part 51 is disposed in a

may be made therein without departing from the spirit and

seat in alignment with the nut 50, the part 51 having a protrud scope

of the invention, as will now be apparent to those skilled

ing portion which mates with a protruding portion of member 45 in the art.

49 so as to prevent the mismating of the plug and receptacle

Although the polarizing parts or inserts 20 of the first dis

parts of the connector. In the embodiment shown, the polariz

closed embodiment and the parts 49, 51, 49', 51' of the

ing parts 49 and 51 are of regular polygonal cross section, as second

and third disclosed embodiments are disclosed as

shown more clearly in FIG. 9. The part 49 is snugly but

being of regular polygonal section, they can be made of other

removably mounted in a hexagonal seat 52 in the part 16" of 50 shapes.

Thus the inserts and the seats which receive them may

the connector body 10'. Part 49 has a base portion 54 of full

be

of

any

multisided cross-sectional shapes such that the op

section, the part being in effect cut back between two al

posing inserts may be securely retained in any one of a number

ternate corners to form the protruding portion 55 of part 49.

of complementary, mating positions. In the embodiment of

The axially extending side face of portion 55 is designated 56, 55 FIGS.

68, inclusive, the passages in the plug body and

the axially outer end surface of the base 54 being designated receptacle

may, if desired, be provided with ribs therein

57.

.

similar

to

the

ribs 29 and 30 in the embodiment of FIGS. 15,

The other, mating polarizing part 51 is snugly received in a

inclusive.

hexagonal seat 59 in the part 17" of the body 11'. As is shown

The embodiments of the invention in which an exclusive

more clearly in FIG. 9, the part 51 has a base portion 60, the 60 property

or privilege I claim are defined as follows:

remainder of the part having been cut back in an axial

1.

In

a

separable electrical connector including bodies car

direction to yield a portion 61 which is, in effect, complemen

rying mateable contacts the improvement which comprises at

tary to the portion 55 of part 49. The portions 55 and 61 of the

least one connector-body polarizing means, said polarizing

parts 49 and 51 are so dimensioned that the axially extending

means including two parts of relatively rigid, though slightly

face 56 of part 49 and the axially extending face 62 of part 51 65 resilient material, each of which is mounted on a respective

fit together with appreciable spacing between them when the

connector body and is in the form of a rod having a base por

parts are mated as shown in FIG. 6. The parts 49 and 51 have

tion of multisided transverse section and a stem portion pro

the base portions and the cut back portions thereof of such jecting longitudinally from the base portion, recesses in the

lengths that the surface 58 is appreciably spaced from the sur connector bodies which confront and register with each other

face 64 and the surface 57 is similarly spaced from the surface 70 when the contacts are mated, the recesses having multisided

65 when the connector parts are fully mated. Such construc

transverse sections corresponding to but somewhat larger than

tion, as in the first disclosed embodiment, permits the polariz

the transverse sections of said base portions of the rods with

ing parts 49 and 51 to be mated without imposing any un

inwardly extending projections on the walls of the recesses

desirable sidewardly directed forces upon the pin and socket around said base portions for compressively engaging the sides

75

contacts of the connector.

an annular flange 45 on the stem 42 and disposed below the

collar 44 and a thumb knob 46 affixed to the upper end of the

stem above the collar by a cross pin 47. A polarizing insert

part 49 is pressed into a seat in portion 16', part 49 having a

bore therethrough receiving the stem 42 of the screw 40.

A nut 50 is molded into the part 17" of the connector body

11, as shown more clearly in FIG. 8. The nut 50 receives the

threaded portion 41 of the screw 40 so as to hold the two con

of the latter to center the same in the recesses, hold the same

3,582,867

5

against appreciable angular movement in the recesses and

yieldably resist axial movement of the same in the recesses,

whereby each recess receives and yieldably retains a said part

in any one of a number of angular positions, the stem portion

of each said part being so constructed and arranged that the

connector bodies are mateable only when such parts are in

complementary angular positions in their respective connec

6

internally threaded nut fixedly captured in one said body in

axial alignment with said recesses and a bolt rotatably cap

tured in the other said body and extending through said

polarizing parts into threaded engagement with said nut.

4. An electrical connector as claimed in claim 1 wherein the

said two parts of the polarizing means are of substantially the

same size and shape.

tor bodies.

2. An electrical connector as defined in claim 1 wherein the

5. An electrical connector as claimed in claim 1 wherein

base portions of said two parts of the polarizing means have

longitudinal openings therethrough, whereby the resiliency of

the same in response to the compressive action of said projec

10

portions of the said parts between them.

6. An electrical connector as defined in claim 5 wherein

tions is enhanced.

3. An electrical connector as defined in claim 2 comprising

means for securing the connector bodies together with the

contacts and polarizing parts in mated relation, including an

said projections are axially extending ribs on pairs of opposite

walls of the recesses, said ribs compressively engaging the base

15

20

25

30

35

40

45

50

55

60

65

70

75

said ribs are centrally disposed on the sidewalls of the recesses

and centrally engage sidewalls of said base portions of the

polarizing parts.

You might also like

- Calibrating Electric Measuring InstrumentsDocument3 pagesCalibrating Electric Measuring Instrumentsmohamed hemdanNo ratings yet

- Fig. Ib: Oct.8,1968 M - ,. - A. - KER - 3,404,545Document6 pagesFig. Ib: Oct.8,1968 M - ,. - A. - KER - 3,404,545Thiru MuruganNo ratings yet

- US2228469Document4 pagesUS2228469George AcostaNo ratings yet

- Exhibit Supply Co. v. Ace Patents Corp., 315 U.S. 126 (1942)Document9 pagesExhibit Supply Co. v. Ace Patents Corp., 315 U.S. 126 (1942)Scribd Government DocsNo ratings yet

- M © JG) - B) John Garlic/9r.: Sept-3, 1959 J. Gallo, SR 2,902,815Document3 pagesM © JG) - B) John Garlic/9r.: Sept-3, 1959 J. Gallo, SR 2,902,815James LindonNo ratings yet

- United States PatentDocument6 pagesUnited States Patentaless2056No ratings yet

- April 2, 1968.: Filed Sept 26, 1966Document7 pagesApril 2, 1968.: Filed Sept 26, 1966Pedja Bekic100% (1)

- UntitledDocument15 pagesUntitledAjay NishadNo ratings yet

- Us2470178 PDFDocument3 pagesUs2470178 PDFMilorad NozinicNo ratings yet

- Bob Teal Magnetically Operable Engine Us4093880Document7 pagesBob Teal Magnetically Operable Engine Us4093880MANNAJANELAGUNANo ratings yet

- Us2028583 PDFDocument8 pagesUs2028583 PDFMurthy YegginaNo ratings yet

- Us 4431376Document17 pagesUs 4431376mihailmiNo ratings yet

- Multiple Section Paper Tube and Method of Making Same Filed Dec.v 21, 1.956Document3 pagesMultiple Section Paper Tube and Method of Making Same Filed Dec.v 21, 1.956rodrigo_aguilar_4No ratings yet

- Us1955360 PDFDocument8 pagesUs1955360 PDFRodrigoPomaNo ratings yet

- Single screw actuated pivoted clampDocument2 pagesSingle screw actuated pivoted clampdevheadbot100% (1)

- Us2415807 PDFDocument9 pagesUs2415807 PDFవేలుసామి లింగాసామిNo ratings yet

- Modular Hydraulic System ComponentsDocument12 pagesModular Hydraulic System ComponentsharisupayNo ratings yet

- E. B. Toot Walwe Construction For Wind Musical InstrumentsDocument5 pagesE. B. Toot Walwe Construction For Wind Musical InstrumentsLmute MedioliNo ratings yet

- U.S. Patent 2,911,871, Entitled "Magnetic Pickup Device" To Charles Schultz, Issued 1959.Document4 pagesU.S. Patent 2,911,871, Entitled "Magnetic Pickup Device" To Charles Schultz, Issued 1959.Anonymous a7S1qyXNo ratings yet

- Data Originating From Sources Other Than The EPO May Not Be Accurate, Complete, or Up To DateDocument3 pagesData Originating From Sources Other Than The EPO May Not Be Accurate, Complete, or Up To DateJaymar ManualNo ratings yet

- Hypoid Gear Cutting Machine PatentDocument9 pagesHypoid Gear Cutting Machine PatentHano LourensNo ratings yet

- Full Download Ebook PDF Issues and Ethics in The Helping Professions Updated With 2014 Aca Codes 9Th Edition Ebook PDF Docx Kindle Full ChapterDocument23 pagesFull Download Ebook PDF Issues and Ethics in The Helping Professions Updated With 2014 Aca Codes 9Th Edition Ebook PDF Docx Kindle Full Chapterpaul.shropshire768100% (29)

- May 29, 1945-L. H. B. Beer 2,377,175Document11 pagesMay 29, 1945-L. H. B. Beer 2,377,175Victor Von DoomNo ratings yet

- ESQUEMAS UNIONES MetalicasDocument165 pagesESQUEMAS UNIONES MetalicasGuillermo Hortigüela Cordoba100% (6)

- US Patent 1,915,858, Entitled "Method and Apparatus For The Production of Music" To Inventor, Miessner, 1933.Document9 pagesUS Patent 1,915,858, Entitled "Method and Apparatus For The Production of Music" To Inventor, Miessner, 1933.Anonymous a7S1qyXNo ratings yet

- Screw Propellers ExplainedDocument25 pagesScrew Propellers ExplainedAkashDudi100% (1)

- Hj-Wsatblll/E: ReceiverDocument9 pagesHj-Wsatblll/E: Receiverdavid19775891No ratings yet

- Method Manufactures High-Quality Helical Antenna Satellite CommunicationDocument7 pagesMethod Manufactures High-Quality Helical Antenna Satellite CommunicationShavel KumarNo ratings yet

- 3 Way Finger JointDocument5 pages3 Way Finger JointspaceskipperNo ratings yet

- Feb. 8, 1966 L.. H. Smith 3,233,345: Filed July Lí 1964 2 Sheets-Sheet LDocument6 pagesFeb. 8, 1966 L.. H. Smith 3,233,345: Filed July Lí 1964 2 Sheets-Sheet Lcvkkkk1No ratings yet

- @341 A É'Wqkammm: Filed July 28-, 1944Document3 pages@341 A É'Wqkammm: Filed July 28-, 1944devheadbotNo ratings yet

- (1956), June 14) US2970812 Drum Type Heat ExchangerDocument4 pages(1956), June 14) US2970812 Drum Type Heat ExchangeraegosmithNo ratings yet

- US2091376 - Surface Test Indicator - Julius R (JR) Reich, 1937Document6 pagesUS2091376 - Surface Test Indicator - Julius R (JR) Reich, 1937devheadbotNo ratings yet

- Us 5360355Document6 pagesUs 5360355kimscribd66No ratings yet

- Method for constructing and assembling a multiple valve unitDocument4 pagesMethod for constructing and assembling a multiple valve unitscibduser001No ratings yet

- Llo. 715,3l5. P Atsntad Dec. 9, I902.: Cigar CutterDocument3 pagesLlo. 715,3l5. P Atsntad Dec. 9, I902.: Cigar CutterRakeshNo ratings yet

- Bob Teal MagnaPulsion US4024421Document6 pagesBob Teal MagnaPulsion US4024421kishbudNo ratings yet

- AC Motor Winding - Generator Series Courseware - PengkyDocument9 pagesAC Motor Winding - Generator Series Courseware - PengkyPietNo ratings yet

- TEPZZ 6 Z956A - T: European Patent ApplicationDocument10 pagesTEPZZ 6 Z956A - T: European Patent ApplicationDumitru ScortanuNo ratings yet

- United States Patent (191: Broadway Et Al. (45) Jul. 6, 1982Document9 pagesUnited States Patent (191: Broadway Et Al. (45) Jul. 6, 1982debasishmee5808No ratings yet

- Patented Sept. 15, 1891,: S. Wheeler, Wrapping or Toilet Paper, Roll, No. 459,516Document3 pagesPatented Sept. 15, 1891,: S. Wheeler, Wrapping or Toilet Paper, Roll, No. 459,516Oscar DorantesNo ratings yet

- Inversion of MechanismDocument6 pagesInversion of MechanismAakuchikuNo ratings yet

- Talyrond 51 Operating InstructionsDocument44 pagesTalyrond 51 Operating InstructionsAnenomeNo ratings yet

- US2145490 Miller Magnetic Pick Up For Musical Instruments 1939Document3 pagesUS2145490 Miller Magnetic Pick Up For Musical Instruments 1939Duane BlakeNo ratings yet

- Unlted States Patent (10) Patent N0.2 US 8,314,522 B2Document4 pagesUnlted States Patent (10) Patent N0.2 US 8,314,522 B2avalosheNo ratings yet

- RR PatentsDocument7 pagesRR PatentsAlan SmartNo ratings yet

- Us 3460614Document7 pagesUs 3460614scibduser001No ratings yet

- DC Solonied VechileDocument43 pagesDC Solonied VechilepruthihimanshuNo ratings yet

- Wave Anchor Soil Reinforcing Connector and MethodsDocument17 pagesWave Anchor Soil Reinforcing Connector and MethodsSoumya Prakash SahooNo ratings yet

- Aerial Tow Target (1943)Document4 pagesAerial Tow Target (1943)CAP History LibraryNo ratings yet

- Cloth Tow Target Low Drag Sleeve (1944)Document4 pagesCloth Tow Target Low Drag Sleeve (1944)CAP History LibraryNo ratings yet

- Us 5176330Document7 pagesUs 5176330ManivannanMudhaliarNo ratings yet

- Folding AparatusDocument4 pagesFolding AparatusUbunterNo ratings yet

- U.S. Patent 2,683,388, Entitled "Pickup Device For Stringed Instruments" To Keller, Issued 1954.Document4 pagesU.S. Patent 2,683,388, Entitled "Pickup Device For Stringed Instruments" To Keller, Issued 1954.Anonymous a7S1qyXNo ratings yet

- Studies On E-Field Distribution For Complex Electrode-Spacer Arrangements Used in HV SystemsDocument5 pagesStudies On E-Field Distribution For Complex Electrode-Spacer Arrangements Used in HV SystemsRudanekNo ratings yet

- Kom May-June 2013Document8 pagesKom May-June 2013nazeerabiaNo ratings yet

- Patent for Replaceable Wear Element with Reversible MountingDocument8 pagesPatent for Replaceable Wear Element with Reversible MountingMarcos ApablazaNo ratings yet

- Fluid Mechanics in Channel, Pipe and Aerodynamic Design Geometries 2From EverandFluid Mechanics in Channel, Pipe and Aerodynamic Design Geometries 2No ratings yet

- Kinematic Differential Geometry and Saddle Synthesis of LinkagesFrom EverandKinematic Differential Geometry and Saddle Synthesis of LinkagesNo ratings yet

- First Year Puc Model Question Paper 2013 New Syllabus: Instructions: Part A I Answer All The Following QuestionsDocument2 pagesFirst Year Puc Model Question Paper 2013 New Syllabus: Instructions: Part A I Answer All The Following QuestionsPrasad C M100% (7)

- Memories NotesDocument52 pagesMemories NotesDetroitNo ratings yet

- O LVL Chem Definitions ListDocument6 pagesO LVL Chem Definitions Listacsbr4science170% (10)

- Shaanxi Electronic Control Unit PDF Wiring Diagrams PinecuDocument7 pagesShaanxi Electronic Control Unit PDF Wiring Diagrams PinecuJefferson Elbrey0% (1)

- Yaskawa V1000 CIMR VC ManualDocument418 pagesYaskawa V1000 CIMR VC Manualdanghe2006No ratings yet

- PMC200 User ManualDocument57 pagesPMC200 User ManualRiera Mejia Wendy MariaNo ratings yet

- Asr 44 - Asr Self Hold Thermal CutoutDocument4 pagesAsr 44 - Asr Self Hold Thermal CutoutHotel WijayaNo ratings yet

- AD-99 Encatalog 1705 SankoshaDocument100 pagesAD-99 Encatalog 1705 SankoshaLiliek Prasetyo WidiyonoNo ratings yet

- PTE10 ManualDocument10 pagesPTE10 ManualStefan CazacuNo ratings yet

- International Product Development (S EM2 AF-2022/3) 55-701896-AF-20223 Project Idea: Self-Cleaning Solar PanelsDocument19 pagesInternational Product Development (S EM2 AF-2022/3) 55-701896-AF-20223 Project Idea: Self-Cleaning Solar PanelsJerin James 3jNo ratings yet

- Wolkite University College of Engineering and Technology Department of Electrical and Computer EngineeringDocument12 pagesWolkite University College of Engineering and Technology Department of Electrical and Computer EngineeringsoresaNo ratings yet

- SN3500 82005 Im R Installation ManualDocument153 pagesSN3500 82005 Im R Installation ManualGino Concepcion100% (1)

- BehindTheLaplaceTransform IEEEspectrum91Document1 pageBehindTheLaplaceTransform IEEEspectrum91anabelle_23No ratings yet

- Datasheet Tlp434a Rlp434aDocument2 pagesDatasheet Tlp434a Rlp434ajorge_gcaNo ratings yet

- Ug1221 Zcu102 Base TRD PDFDocument88 pagesUg1221 Zcu102 Base TRD PDFjcxz6053No ratings yet

- ECE 5380 / 6380 Power Electronics Syllabus Spring 2012Document7 pagesECE 5380 / 6380 Power Electronics Syllabus Spring 2012Ref DocsNo ratings yet

- List of German ProfessorsDocument3 pagesList of German ProfessorsDr-Nikesh IngleNo ratings yet

- A New High-Speed Foreign Fiber Detection System With Machine VisionDocument23 pagesA New High-Speed Foreign Fiber Detection System With Machine VisionijtrobinNo ratings yet

- CTP Team Technologies: Bag Filter Vs Electrostatic PrecipitatorDocument8 pagesCTP Team Technologies: Bag Filter Vs Electrostatic PrecipitatorDaniel RicartNo ratings yet

- Oscilloscope Programmer GuideDocument714 pagesOscilloscope Programmer Guidechunkymonkey323No ratings yet

- gpg68 NoiseDocument67 pagesgpg68 NoiseMF100% (1)

- DR 800 (English - Datasheet)Document6 pagesDR 800 (English - Datasheet)Luise AquinoNo ratings yet

- Capacitance Level Measurement Working Principle Instrumentation ToolsDocument4 pagesCapacitance Level Measurement Working Principle Instrumentation ToolsAbarajithan RajendranNo ratings yet

- Essentials of MOSFETs: Transistors, Digital Circuits, and ApplicationsDocument24 pagesEssentials of MOSFETs: Transistors, Digital Circuits, and ApplicationsJeff HoNo ratings yet

- Oscillators and Wave Shaping Circuits ExplainedDocument20 pagesOscillators and Wave Shaping Circuits Explainedgebretsadkan abrhaNo ratings yet

- Lighting Lighting: Slimblend Square, RecessedDocument3 pagesLighting Lighting: Slimblend Square, RecessedAhmed YahiaNo ratings yet

- QSC KLA12 KLA181 Ground Stack Bundle Pack II ZZoundsDocument1 pageQSC KLA12 KLA181 Ground Stack Bundle Pack II ZZoundsmanuelNo ratings yet

- RW 2050 0100Document3 pagesRW 2050 0100mvasquez2011No ratings yet

- Cache Analysis Using CACTIDocument4 pagesCache Analysis Using CACTIMuhammad Arif SaidNo ratings yet

- Audio Systems Guide For Houses of Worship PDFDocument60 pagesAudio Systems Guide For Houses of Worship PDFMusicNo ratings yet