Professional Documents

Culture Documents

Gas Turbines English PDF

Uploaded by

Sandi Nurmalik100%(1)100% found this document useful (1 vote)

41 views1 pageOriginal Title

gas_turbines_english.pdf

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

100%(1)100% found this document useful (1 vote)

41 views1 pageGas Turbines English PDF

Uploaded by

Sandi NurmalikCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

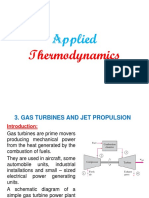

POWER ENGINES AND MACHINES GAS TURBINES

BASIC KNOWLEDGE

GAS TURBINES

Thermodynamic principle

Fields of application

Principle of a two-shaft gas turbine

The gas turbine works as an open cyclic process.

Typical for an open cycle is: the working medium

is taken from the environment and fed back to it

after the process.

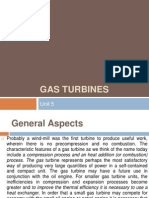

Gas turbines are used when high power and lightweight

are required. Contrary to piston engines, turbomachines

operate at high flow rates with compact dimensions:

A two-shaft gas turbine consists of two independent

turbines. The first turbine (the high-pressure turbine)

is coupled tightly to the compressor and drives the

compressor. The second turbine (the power turbine) is not

mechanically coupled with the high-pressure turbine and

generates the effective power of the system. A vehicle, a

propeller or a generator can be driven.

Adiabatic compression of the cold gas with

compressor (A) from ambient pressure p1 to

pressure p2, associated with temperature

rising from T1 to T2.

Isobaric heating of gas from T2 to T3

because of heat input. Heat input by burning

fuel with oxygen of the air in combustion

chamber (B).

driving aircraft with propeller or jet engine

driving fast ships, locomotives or heavy motor vehicles

driving generators in power plants

The advantage of the two-shaft gas turbine is that

compressor and high-pressure turbine are driven at

optimal speed for the respective power. Speed or torque

at the power turbine can be adapted optimised to the

respective drive function. Vehicles require a variable

speed, a synchronous generator needs constant speed.

driving compressors and pumps in the petroleum

and natural gas industries

Adiabatic expansion of hot gas in a turbine (C)

from pressure p2 to p1, associated with

temperature decreasing from T3 to T4.

One part of the mechanical power generated by

the turbine is used for driving the compressor.

The rest is available as effective power for driving a generator (D) etc.

D

A

Schematic of a simple gas turbine system:

A compressor, B combustion chamber,

C turbine, D generator;

Arrows: air (blue), fuel (red), exhaust (orange)

T-s diagram:

Illustration of the ideal gas turbine process

q1 heat input, q2 heat output, w effective work,

T temperature, s entropy

Quick starting is another advantage of gas turbines. They

run up quickly to full load and therefore are often used as

backup drives and for peak loads. In comparison to diesel

engines, the higher fuel consumption is a disadvantage.

Process schematic of two-shaft gas turbine ET 794 with independent power turbine and generator

The turbine is operated with combustion gas. An electrically driven auxiliary compressor (starter fan) starts the

turbine. At a certain minimum speed fuel gas is blown into

the combustion chamber and is electrically ignited. After

reaching idle speed, the auxiliary compressor is turned off

and the turbine runs on its own.

An oil circuit with thermostatically controlled oil-to-water

cooler, pump and filter lubricates and cools the turbine

bearings. The turbine shuts down if the oil temperature is

too high or the oil pressure is too low.

97

You might also like

- Gas Turbine 2Document22 pagesGas Turbine 2Atanda Babatunde MutiuNo ratings yet

- Gas Turbine Power Cycles Working Principle Brayton Cycle ApplicationsDocument7 pagesGas Turbine Power Cycles Working Principle Brayton Cycle ApplicationsAhmed Mohamed SalihNo ratings yet

- TurbinesDocument73 pagesTurbinesahmadNo ratings yet

- Basic Cycle BraytonDocument15 pagesBasic Cycle BraytonMarin Andreea100% (1)

- GENERATING ELECTRICITYDocument34 pagesGENERATING ELECTRICITYAdeniji OlusegunNo ratings yet

- Gas Power CycleDocument49 pagesGas Power CycleNafisa AnikaNo ratings yet

- GT22 Operation ManualDocument72 pagesGT22 Operation ManualSyed Asim Ur RahmanNo ratings yet

- Introduction To Gas Turbine:: Land Based Gas Turbines Are of Two TypesDocument9 pagesIntroduction To Gas Turbine:: Land Based Gas Turbines Are of Two TypesTahir MuneebNo ratings yet

- Gas TurbineDocument25 pagesGas TurbineMohammed AlsirajNo ratings yet

- Gas Turbine Power PlantDocument11 pagesGas Turbine Power PlantCK Godinez100% (1)

- Gas Turbine: Olar LoungeDocument34 pagesGas Turbine: Olar Loungepkdevan68100% (1)

- Chapter Five Gas Turbine Power PlantDocument23 pagesChapter Five Gas Turbine Power PlantBese Mat100% (1)

- Expt. 02 Stusy of A Gas Turbine Power PlantDocument5 pagesExpt. 02 Stusy of A Gas Turbine Power PlantSajeeb SarkerNo ratings yet

- Gas Turbines and Jet Engines ExplainedDocument55 pagesGas Turbines and Jet Engines ExplainedDigonto ChowdhuryNo ratings yet

- Gas Turbine Power Plant ExplainedDocument21 pagesGas Turbine Power Plant ExplainedBiniam Nega100% (1)

- Gas Turbine F1041 & F1065Document12 pagesGas Turbine F1041 & F1065syed arimiNo ratings yet

- MSR - Externally Fired Gas Combustion TurbineDocument10 pagesMSR - Externally Fired Gas Combustion TurbineAnonymous K3FaYFlNo ratings yet

- Gas TurbineDocument53 pagesGas TurbinedipakbagNo ratings yet

- Gas Turbine Power Plant PresentationDocument126 pagesGas Turbine Power Plant Presentationjehadyam100% (1)

- Pplied: ThermodynamicsDocument86 pagesPplied: ThermodynamicsAlaa Shammaa100% (1)

- Gas Turbine PPDocument49 pagesGas Turbine PPChersey DoctorNo ratings yet

- 2.gas Power CyclesDocument16 pages2.gas Power Cyclesstrategy onesmusNo ratings yet

- Gas Turbine Power Plant: Rajshahi University of Engineering & TechnologyDocument23 pagesGas Turbine Power Plant: Rajshahi University of Engineering & TechnologyTahsinur RahmanNo ratings yet

- Lec 05Document21 pagesLec 05Shamsuzzaman SharifNo ratings yet

- Unit 3 Gas Turbines AND JET PROPULSIONDocument99 pagesUnit 3 Gas Turbines AND JET PROPULSIONSANTHOSH NAGARAJANo ratings yet

- Power Plant Engineering (ME-321) : "Gas Turbine" Adeel Ahmed Khan, Assistant Professor (MED)Document6 pagesPower Plant Engineering (ME-321) : "Gas Turbine" Adeel Ahmed Khan, Assistant Professor (MED)Muhammad Omar AzadNo ratings yet

- Gas Turbine NotesDocument40 pagesGas Turbine NotesSarah Cohen92% (12)

- Gas Turbine 1Document21 pagesGas Turbine 1Md. Adnan NabibNo ratings yet

- Gas Turbine Thermal Power PlantDocument7 pagesGas Turbine Thermal Power PlantAkshay ManzaNo ratings yet

- How Gas Turbine Power Plants WorkDocument6 pagesHow Gas Turbine Power Plants Workchella2705100% (1)

- A Gas Turbine UnitDocument9 pagesA Gas Turbine UnitTITU NATHNo ratings yet

- GAS TURBINE ENGINES6/115oC1200oCDocument7 pagesGAS TURBINE ENGINES6/115oC1200oCVishal ReddyNo ratings yet

- University of Karbala Department of Mechanical Lecture Notes - Power Plants by Fadhel Al-MousawiDocument27 pagesUniversity of Karbala Department of Mechanical Lecture Notes - Power Plants by Fadhel Al-Mousawiحامد عبد الشهيد حميد مجيد100% (1)

- GALGALLA - Working Assignment 3 - Gas TurbineDocument5 pagesGALGALLA - Working Assignment 3 - Gas TurbineGodfrey Jr Jr.No ratings yet

- Plant Overview 7Document7 pagesPlant Overview 7vipulgupta2012No ratings yet

- Chapter 8B - Gas Power Plant Brayton CycleDocument17 pagesChapter 8B - Gas Power Plant Brayton CycleBF3nobel100% (1)

- Brayton CycleDocument5 pagesBrayton CycleDanang Wahdiat Aulia IshaqNo ratings yet

- Brayton Cycle Analysis for Propulsion ApplicationsDocument16 pagesBrayton Cycle Analysis for Propulsion ApplicationsagoezNo ratings yet

- Gas TurbinesDocument22 pagesGas Turbineswayzodeneeraj100% (1)

- Thermodynamics Lecture 6Document32 pagesThermodynamics Lecture 6MarkJude Morla100% (1)

- Heat Engines ME111Document43 pagesHeat Engines ME111Arct John Alfante ZamoraNo ratings yet

- General Characteristics: Combustion Internal-Combustion Engine CompressorDocument4 pagesGeneral Characteristics: Combustion Internal-Combustion Engine CompressorAnshuman KatakyNo ratings yet

- Combined Cycle Gas Turbine.Document9 pagesCombined Cycle Gas Turbine.Shailesh Sankdasariya100% (6)

- Ch-2-2 Thermal Power PlantDocument48 pagesCh-2-2 Thermal Power Planthussen belewNo ratings yet

- Gas Turbine Power PlantDocument15 pagesGas Turbine Power Plantrahul100% (1)

- GAS TURBINE PLANTDocument16 pagesGAS TURBINE PLANTSathya Raj SimiNo ratings yet

- Gas Turbines Definition Applications Working Components Types Design Advantages PDFDocument13 pagesGas Turbines Definition Applications Working Components Types Design Advantages PDFSaadi DzNo ratings yet

- Gas Turbine Cycles - LectureDocument18 pagesGas Turbine Cycles - LectureSrinu Reddy100% (1)

- Pcme301 CA2Document6 pagesPcme301 CA2soumyadeep naskarNo ratings yet

- Gas Power CyclesDocument9 pagesGas Power CyclesWaqar YusufNo ratings yet

- Literature Review: 2-1 Basic Gas Turbine OperationDocument21 pagesLiterature Review: 2-1 Basic Gas Turbine Operationsundas Shafiq100% (1)

- Sustainable Energy Conversion for Electricity and Coproducts: Principles, Technologies, and EquipmentFrom EverandSustainable Energy Conversion for Electricity and Coproducts: Principles, Technologies, and EquipmentNo ratings yet

- Thermodynamic analysis of geothermal heat pumps for civil air-conditioningFrom EverandThermodynamic analysis of geothermal heat pumps for civil air-conditioningRating: 5 out of 5 stars5/5 (2)

- Heat Pumps: Solving Energy and Environmental ChallengesFrom EverandHeat Pumps: Solving Energy and Environmental ChallengesTakamoto SaitoNo ratings yet

- Curriculum Vitae HermansyahDocument2 pagesCurriculum Vitae HermansyahSandi NurmalikNo ratings yet

- Coating Uses: 5380Dp 2F-1 Sermalon Reduce Roughness Smooth Surface Fouling Low PH Wet T 500 F (260 C) Thin ( 1.5 Mil)Document3 pagesCoating Uses: 5380Dp 2F-1 Sermalon Reduce Roughness Smooth Surface Fouling Low PH Wet T 500 F (260 C) Thin ( 1.5 Mil)Sandi NurmalikNo ratings yet

- CVindo Resume10!11!2014Document3 pagesCVindo Resume10!11!2014Sandi NurmalikNo ratings yet

- CV Dede Iswono Last Update PDFDocument4 pagesCV Dede Iswono Last Update PDFSandi NurmalikNo ratings yet

- Lesson 09 - Gas Turbines IDocument25 pagesLesson 09 - Gas Turbines ISandi NurmalikNo ratings yet

- Repair Rotor Presentation PDFDocument11 pagesRepair Rotor Presentation PDFSandi NurmalikNo ratings yet

- PT Nusantara Turbin & PropulsiDocument29 pagesPT Nusantara Turbin & PropulsiSandi NurmalikNo ratings yet

- Office PPT Template 036Document4 pagesOffice PPT Template 036Sandi NurmalikNo ratings yet

- Repair Rotor Presentation PDFDocument11 pagesRepair Rotor Presentation PDFSandi NurmalikNo ratings yet

- Repair Rotor Presentation PDFDocument11 pagesRepair Rotor Presentation PDFSandi NurmalikNo ratings yet

- TTA R407C IOM - Apr 2016Document28 pagesTTA R407C IOM - Apr 2016hungstampNo ratings yet

- Parts View: Images For Illustration Purposes OnlyDocument2 pagesParts View: Images For Illustration Purposes OnlySteven FryeNo ratings yet

- 000 SLT2101316 Pe PiDocument27 pages000 SLT2101316 Pe PijaidikarimNo ratings yet

- Pneumatics Directional Control ValvesDocument28 pagesPneumatics Directional Control ValvesKelvin YipNo ratings yet

- CONTROL PANEL COMPONENTSDocument6 pagesCONTROL PANEL COMPONENTSjaved samaaNo ratings yet

- TransTec AW50-55Document72 pagesTransTec AW50-55Jim EberhartNo ratings yet

- 205-01 Drive Shaft PICKUP JMCDocument14 pages205-01 Drive Shaft PICKUP JMCRusonegroNo ratings yet

- General Notes and Specifications: Roof Line Roof LineDocument1 pageGeneral Notes and Specifications: Roof Line Roof LineCyril AleaNo ratings yet

- Remove and install heavy vehicle engineDocument8 pagesRemove and install heavy vehicle engineLUKASNo ratings yet

- Pe1024-Mb-Mfb030-011200 04 GT#1 Mba 2Document1 pagePe1024-Mb-Mfb030-011200 04 GT#1 Mba 2Aldo Quispe HuarachiNo ratings yet

- Type 3510 1 and Type 3510 7 Pneumatic Control Valves Type 3510 Micro Flow ValveDocument12 pagesType 3510 1 and Type 3510 7 Pneumatic Control Valves Type 3510 Micro Flow Valvepaulo cesar f machadoNo ratings yet

- ALAMARIN-JET OY Technical SpecificationDocument21 pagesALAMARIN-JET OY Technical SpecificationAndi PurwantoNo ratings yet

- Interpret OBD II Data with this GuideDocument8 pagesInterpret OBD II Data with this GuideMohamed WahiebNo ratings yet

- Quotation SKSDocument14 pagesQuotation SKSMohamdNo ratings yet

- Bid Evaluation TabulationDocument1 pageBid Evaluation Tabulationpeach5No ratings yet

- Fuel Injection Aua, Aub, Bby, BBZ, BkyDocument148 pagesFuel Injection Aua, Aub, Bby, BBZ, BkyAlpha100% (1)

- Recommended MaterialsDocument6 pagesRecommended MaterialspikipelukiNo ratings yet

- Gear TechnologyDocument31 pagesGear TechnologyRishabh GawriNo ratings yet

- Cam Less Eg NineDocument19 pagesCam Less Eg Ninesai ramanaNo ratings yet

- Fundamental Principles of Brake SystemsDocument8 pagesFundamental Principles of Brake SystemsmarranNo ratings yet

- Ansi B 16.34Document22 pagesAnsi B 16.34Vinoth Rajendra100% (2)

- Garelli Clymer ManualDocument121 pagesGarelli Clymer ManualLucas LorandiniNo ratings yet

- Tub EtambouDocument8 pagesTub EtambouSpeedy Gonzales Riba RibaNo ratings yet

- Hướng Dẫn Bảo Trì Sửa Chữa Xe Tải Hyundai HD120 (Full)Document680 pagesHướng Dẫn Bảo Trì Sửa Chữa Xe Tải Hyundai HD120 (Full)ThủyBìnhNo ratings yet

- Southern Luzon State UniversityDocument4 pagesSouthern Luzon State Universityshadow friendNo ratings yet

- Jaa Atpl Book 04 PowerplantDocument433 pagesJaa Atpl Book 04 Powerplantfoxtrot12No ratings yet

- List of Tools EimDocument3 pagesList of Tools EimMichael Angelo ChuaNo ratings yet

- Kubota Flat Rate ScheduleDocument133 pagesKubota Flat Rate ScheduleSteyn Visser0% (1)

- List of MaterialsDocument8 pagesList of Materialsryan malimbanNo ratings yet

- Catalog Js Tracked Excavators Crawler Excavator Controls, ExcavatorDocument6 pagesCatalog Js Tracked Excavators Crawler Excavator Controls, ExcavatorLeão tratoresNo ratings yet