Professional Documents

Culture Documents

Paper 4 Sample 1-1

Uploaded by

John HaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Paper 4 Sample 1-1

Uploaded by

John HaCopyright:

Available Formats

Safety & Health Officer Exam, Paper III Section 2

SAFETY AND HEALTH OFFICER

EXAMINATION (3/2004)

Paper III

Part 2: Workplace Assignment

Investigation of Hazards at Independent Oil

Terminal Project (IOT) of PPES Works (Sarawak)

Sdn. Bhd

BY

abcde

INDEX NO.: NS1234

Prepared by abcde

Page 1 of 17

Safety & Health Officer Exam, Paper III Section 2

TABLE OF CONTENTS

TOPIC

PAGE NUMBER

1. Abstract

2. Introduction

2.1

Project Scope

2.2

Machinery and equipment

2.3

Personnel

3. Objective

4. Methodology

4.1

Hazard Identification

4.2

Risk Assessment

4.3

Risk Control

10

5. Results and Discussion

12

6. Suggestion and Review

15

7. References/Sources

8. Appendices

8.1

Appendix 1: Layout of the site project

8.2

Appendix 2: The organization Chart of the Site Project

8.3

Appendix 3: The step by step method of Hazard Assessment

8.4

Appendix 4: Table of Summary of Hazards Identification, Risk Assessment and

Risk Control

Prepared by abcde

Page 2 of 17

Safety & Health Officer Exam, Paper III Section 2

1. ABSTRACT

This report is compiled and presented as a prerequisite to qualify a candidate to become a

Safety and Health Officer. It describes the construction of Independent Oil Terminal

(IOT) by PPES Works (Sarawak) Sdn. Bhd, a method on how to identify the hazard,

performing risk assessment and how to control the risk in order to eliminate, reduce or

control the hazards. From the HIRARC (Hazard Identification, Risk Assessment, Risk

Control) performed by the author, it was found out that excavation on the top of the hill

and canteen inside the site are the most significant safety and health hazard to the

workers. Proposals were put forward to control the above hazards in the suggestion.

2. INTRODUCTION

Occupational Safety and Health Management is become more significant due to the

awareness among the employer and also employee. Continuous commitment by the

government to reduce the accident rate is tremendously obvious after the enactment of

Occupational Safety and Health Act (OSHA) of Malaysia in 1994. Instead of enforcement

that is carry out by Department of Occupational Safety and Health (DOSH) on employers

to comply with regulations, pro active approach on Safety and Health by employers are

encouraged. These include providing adequate and effective training at workplace through

authorized training centre like National Institute of Occupational Safety and Health

(NIOSH). These trainings are monitored closely by Department of Occupational Safety

and Health (DOSH) in order to control the quality and effectiveness of the training.

Prepared by abcde

Page 3 of 17

Safety & Health Officer Exam, Paper III Section 2

Amongst the most important training is the certification Safety and Health Officer (SHO),

where this submission is an integral component of program.

The physical work required by this report was conducted at Independent Oil Terminal

(OIT), owned by Assar Chemicals Sdn Bhd. This project is managed by OGP Technical

Services consultant, a subsidiaries of Petronas and the construction is perform by PPES

(Works) Sdn. Bhd, as the main contractors.

2.1. Project Scope

This projected is located at Senari, 20 km from Kuchings City. The project area is

roughly 25 acres and nearby to Sarawak River. This project is called a Package 1

project where it ONLY involved in site preparation (Refer to Appendix 1). There will

be subsequent packages that will involve on the infrastructure construction and

mechanical and electrical set up. Under Package 1 project, below are the scopes of

the work:

a. Site clearing

b. Grubbing and excavation to 600mm deep

c. Installation of settlement measurement instruments

d. Hydraulic sandfilling

e. Installation of prefabricated vertical drain

f. Installation of RC Spun Piles and sheet piles

g. Construction of reinforced concrete riverwalls

h. Realignment of river channel

i. Construction of temporary facilities

Prepared by abcde

Page 4 of 17

Safety & Health Officer Exam, Paper III Section 2

2.2. Machinery and equipment

Most of the machinery and equipments that are involved in this project are use to

clearing the land, excavating the ground and performing the piling activities. Besides

that, welding machine is also being used to perform the filing and piping welding.

Below is the list of the machinery and equipments that are used at the project site:

a. Excavator

b. Crane

c. Piling rig

d. Vertical drain rig

2.3. Personnel

There are three big groups of the personnel that are working at the project site.

a. Main contractors

b. Sub-contractors

c. Project management consultant

There are in average of 150 workers working at the project site. The overall

organization structure for the PPES Works (Sarawak) Sdn. Bhd is in the Appendix 2.

3. OBJECTIVE

To identify hazards at the workplace, assessing the risk and propose the solution to

eliminate, reduce or control the risk based on the significant risk resulted from the

assessment.

Prepared by abcde

Page 5 of 17

Safety & Health Officer Exam, Paper III Section 2

4. METHODOLOGY

A well known and common method that was used to perform the assessment for hazard

involved 4 main steps that can be summarized in the diagram below.

Identification

Assessment

Control

HAZARD

Continuous

Improvement

Review

Figure 1: PDCA Cycle for HIRARC

The above method is a common methodology that is used not just in Occupational Health

and Safety Management, but also applicable to other areas such as quality, problem

solving and cost reduction. This cycle normally call PDCA, named Plan, Do, Check and

Act is a very effective to identify, assess and control the hazards. This basic concept or

principle of Safety and Health audit procedure is universal and may applied to all any

types of situations and industries. However, the approach would vary from industry to

industry. For safety, the methodology is called HIRARC (introduced by NIOSH in SHOs

course) that stands for Hazard Identification, Risk Assessment and Risk Control, that is

also using PDCA concept.

4.1. Hazard Identification

Prepared by abcde

Page 6 of 17

Safety & Health Officer Exam, Paper III Section 2

Identification of hazards is critical steps in this methodology. A depth understanding

the meaning of hazard is significant because wrong identification of hazards can lead

to wrong assessment and control. Hazard that can be define as

HAZARD = anything (existent, inherent or likely to occur) that can cause harm (e.g

chemicals, electricity, working at height etc) to human.

It is also important to consider all type of hazards that can affect the employees

directly and also those who using the products and services. A complete understanding

at workplace is required to perform good and adequate hazard identification.

There are few methods that can be used to identify the hazards. The author

categorized it into 4 major categories as below:

Preview/

Reviewing

Observation

IDENTIFICATION

Analyzing

Consultation

Figure 2: Categories of identification step

The details of the categories are summarized in the table below:

No. Hazard Identification Category

1

Analyzing

Details of Identification

Analyzing any data or statistics from the records on accidents,

near misses cases & Safety and Health non conformance

Analyzing the work processes on the hazards that associate with

Prepared by abcde

Page 7 of 17

Safety & Health Officer Exam, Paper III Section 2

the work

Analyzing on needs and adequacy of training and knowledge

that required to work safely.

2

Consultation

Job safety analysis.

Discussion with employees/sub contractors on they job scope

that possible to create the hazards.

3

4

Observation

Seeking advice or consultation from specialists

Observe unsafe act and condition during the audit, surveys or

Preview & Review

inspection.

Previewing or reviewing on:

a. Legislation and supporting codes of practice and

guidance

b. Malaysian or international standards

c. Industry or trade association guidance

d. Information from designers or manufacturers

Information that is tabulated above is some of the methods that were used by author to

carry out the hazard identification.

4.2. Risk Assessment

As PPES Works has no formal or proper risk assessment matrix, for assessment of the

risk, the author used a qualitative method for evaluation (based on Safety and Health

Officer Course by NIOSH). Basically, the risk assessment matrix using 3 categories:

Prepared by abcde

Page 8 of 17

Safety & Health Officer Exam, Paper III Section 2

a. Probability of the injury or illness

b. Probability of exposure

c. Consequences of possible injury or illness

To give a brief idea or understanding the difference between hazard and risk, here is

the definition of risk:

RISK = Probability to expose to any hazards

Or Probability of Factor (PE) = Probability x Exposure to hazard

Here, it can be simplified as the chances for workers to expose to any possible injuries

(physical or health) due to the hazards. However, the consequences of the risk is also

very important in order for the author to classified the Risk is really dangerous to the

employees. Without the consequences factor, the author will cannot tell the severity of

the risk to employees in terms of physical injuries or health effect.

So, the overall assessment matrix can be simplified as below.

CONSEQUENCES

DISASTROUS

CRITICAL

SERIOUS

SIGNIFICANT

NOTICEABLE

13

25

23

20

16

11

PE = PROBABILITY X EXPOSURE

4-8

9 - 15

16 - 25

24

22

19

21

18

14

9

17

13

8

5

12

7

4

2

26 - 36

15

10

6

3

1

The details of the assessment showing the details of the assessment steps are in the

literature (Refer to Appendix 3)

4.3. Risk Control

Prepared by abcde

Page 9 of 17

Safety & Health Officer Exam, Paper III Section 2

After the author did the assessment, it is important to determine the significant of the

hazards based on the highest risk. This is important because it is difficult to control all the

hazards at one time. Besides of the difficulty to handle all the hazards at one time, other

factors that cause the constraints are:

a. Time

b. Man power

c. Financial

So it is important for the author to select the most significant hazards and present to the

management on the priority what risk that need to be handle first. Based on the HIRARC,

the author can plan and put the target or objectives that is endorsed by top management to

implement in order to control the risks.

Table below is the summary of level of risk that is used on what actions that need to take

to control the risks.

LEVEL OF RISK

VERY HIGH RISK

HIGH RISK

MODERATE RISK

LOW RISK

VERY LOW RISK

Prepared by abcde

RISK

ACTION TO CONTROL

SCORE

21 - 25 Not tolerable - IDLP; Immediate action; Interim and Long term controls

Notify management immediately; effective interim control; long term

16 - 20

control

11 - 15 Communicate hazard to affected people; Implement long term controls

6 10 Routine procedures; SOP

15

Team leader/workers to control

Page 10 of 17

Safety & Health Officer Exam, Paper III Section 2

5. RESULT AND DISCUSSION

From the observation and discussion with the workers, below are some of the comments by the

author:a.

Managements Commitment to Safety and Health

The commitment by management on Safety and Health is encouraging. The direct support

by the headquarter office is shown through HSE Policy, hiring a registered Safety and

Health Officer and Safety and Health Committee. HSE posters are posted around the site

office and regular HSE orientation training for new staff and subcontractors are

implemented.

b.

Workplace Safety and Health Rules

The HSE rules are clearly spelled out through the Safety Sign that are located from the

main entrance to the working area inside the construction. Some of the signs are the speed

limit, PPE signs and Safety First Banner. Regular toolbox was performed once a week for

all the subcontractors.

c. Health, Safety and Environment (HSE) Documentation

HSE documentation is sufficient to support any HSE activities although there are some

documents that need to be updated. Important documents such as Safety & Health

Committee Meeting minutes, Training attendance and Accident Report are well

documented. This is due to the implementation of ISO9001:2000 at PPES Works helps a

lot on the documentation system.

Prepared by abcde

Page 11 of 17

Safety & Health Officer Exam, Paper III Section 2

d. Emergency Response Plan (ERP)

Good and practical ERP is also available including the Muster Point and process flow.

However, drill has not been organized since the project started. A drill is necessary to

check the efficiency of the ERP and required to perform at least ONCE a year.

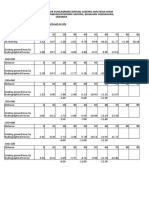

From the HIRARC table in appendix 4, the author can summarize that the MOST significant

hazards based on score are as follows:

1. Excavation on the top of the hill (Safety Hazard)

2. Crane Operation (Safety Hazard)

3. Piling Operation (Safety Hazard)

4. Canteen (Health Hazard)

5. Vertical Temporary Drain (Safety Hazard)

The HIRARC table shows the MOST Critical hazards are

1. Excavation on the top of the hill (Safety Hazard)

This activity was chosen by the author because it is due to the high probability (Scale 2:

High) of hill or highland collapsed due to the unstable hill/highland structure after that area

was explored for the construction of any facilities or infrastructure.

Indeed, due to unforeseen raining weather will weaken the hill structure and cannot support

the weight of the excavator.

The exposure of this hazard is also high (Scale 2: Frequent) because the foot of the hill

facing to the river is the ONLY passage to go to the other site of the project.

That passage will become a common route for workers to move in and out from the both site.

The consequence of this hazard is disastrous because it can cause fatality and also delay the

work because the only passage to go to the other site of the project will be affected.

Prepared by abcde

Page 12 of 17

Safety & Health Officer Exam, Paper III Section 2

2. Canteen (Health Hazard)

Canteen is a COMPULSORY spot for the workers to fulfill the stomach to gain extra energy

after performing heavy duty work.

This activity was chosen by the author because of the moderate probability (Scale 3:

Moderate) of food poisoning is a common accident happen at the construction area due to

lack of hygiene awareness and personal hygiene.

In terms of the exposure of the hazard, it is high (Scale 2: Frequent) because the canteen is

located to the main entrance to the site. There will be a lot of trucks and lorries carrying the

soils, rocks and piling material in and out and this will generate a lot of dusts.

The consequences is serious because of the food poisoning due to the exposure of the food to

dusts generated by the truck if the food is not covered properly. It will cause the workers to be

hospitalized and this can delay the project due to shortage of staff.

Prepared by abcde

Page 13 of 17

Safety & Health Officer Exam, Paper III Section 2

6. SUGGESTION & REVIEW

a. Excavation on the top of the hill (Safety Hazard)

Some of the suggestions in order to eliminate, reduce or control of the hazard are as

below:Short Term

To barricade the area in order to control the workers flow into the affected area.

-

This can be done by putting the barricade tape, wood peg with rope with a

safety sign or safety cones

The barricade at least can control the workers to enter the dangerous site that

can be affected by the hazard.

Put safety signs at the designated area to remind the workers on the hazard

existence.

-

The safety sign will give information on the dangerous of the site where the

hazard activity is carry on.

This sign will give extra information on why the area was barricaded in order

to prevent any trespasser to the area

Regular inspection and audit at the designated area.

-

Extra precaution and inspection is needed when it involved this activity.

Take extra precaution especially after raining or wet period. This is due to the

hill/highland structure become weak and the possibility of the hill/highland

collapsed is very high.

Prepared by abcde

Page 14 of 17

Safety & Health Officer Exam, Paper III Section 2

This inspection will help to identify any possible weaknesses or mistakes due

to unsafe acts or conditions that can cause any mishaps caused by the activity.

Long Term

Create a new passage that is totally far from the hazard area

-

This will minimize the effect to those who are working near to the foot hill.

Besides that, it will prevent any workers using the danger passage nearby the

river during the activity.

However, the operator will face the hazard but it will reduce bigger

catastrophe to the bigger group.

Use light machine to perform the task.

-

Light equipment is suitable to be use to perform the task.

This will reduce the impact of the equipments weight to the structure of the

hill and reduce the chances the hill to collapse.

b. Canteen (Health Hazard)

Short Term

Spraying the water frequently

-

This can be done by spraying the water using the sprinkler.

This method will settle down all the dust that is generated from the move in

and out activities by the truck.

Control the activity of the trucks

-

This is done by fixing the truck movement to the site during eating time such

as breakfast, lunch or high tea.

Prepared by abcde

Page 15 of 17

Safety & Health Officer Exam, Paper III Section 2

This will reduce the food exposure to the dust and reduce the risk the

contaminated food that will harm the workers.

Long Term

To relocate the canteen

This is the best solution to eliminate the hazard.

The canteen can be located further from the construction area where the area is

clean and free from any dust.

To make sure all the Risk Control are implemented correctly and minimize the risk, reviewing the

risks is important. As explained in the Methodology and summarized in Figure 1, reviewing the

HIRARC is vital to make sure the risk control that was taken is correct, accurate and effective.

Implementation of all the risk control must be followed up and observed. This process can be

done by performing the regular inspection and audit. Besides that, regular discussion and meeting

with sub contractors to discuss any problems or issues raised from the risk control is also

important. From the discussion, hopefully the committee can come out with new risk control in

order to identify the new solution to control the risk. The target is to reduce the risk level as low

as possible or totally eliminate the risk. The support from top management is important and cooperation from everybody especially sub contractors is critical on the success in controlling the

risk.

Prepared by abcde

Page 16 of 17

Safety & Health Officer Exam, Paper III Section 2

7. REFERENCES/SOURCES

a. Occupational Safety and Health Act (OSHA), 1994

b. Safety and Health Officer (SHO) Notes by National Institute of Occupational Safety

and Health (NIOSH)

c. Taylor, Easter & Hegnev, Enhancing Safety: An Australian Workplace Primer,

Technical Publication. 1996

8. APPENDICES

8.1. Appendix 1: Layout of the site project

8.2. Appendix 2: The organization Chart of the Site Project

8.3. Appendix 3: The step by step method of Hazard Assessment

8.4. Appendix 4: Table of Summary of Hazards Identification, Risk Assessment and Risk

Control

Prepared by abcde

Page 17 of 17

You might also like

- Sho Exam QuestionsDocument9 pagesSho Exam QuestionsElias Gor Yaman75% (4)

- Structural Risk Assessment & Method StatementDocument19 pagesStructural Risk Assessment & Method StatementNaresh DharmaNo ratings yet

- Labour & General Laws MCQ BookDocument264 pagesLabour & General Laws MCQ BookReshmi100% (7)

- Niosh SHO Exam Notes - Module 3 Question and Answer PDFDocument19 pagesNiosh SHO Exam Notes - Module 3 Question and Answer PDFExcellentdeals4all94% (51)

- Niosh SHO Exam Notes - Module 3 Question and Answer PDFDocument19 pagesNiosh SHO Exam Notes - Module 3 Question and Answer PDFExcellentdeals4all94% (51)

- Niosh SHO Exam Notes - Module 3 Question and Answer PDFDocument19 pagesNiosh SHO Exam Notes - Module 3 Question and Answer PDFExcellentdeals4all94% (51)

- Niosh SHO Exam Notes - Module 3 Question and Answer PDFDocument19 pagesNiosh SHO Exam Notes - Module 3 Question and Answer PDFExcellentdeals4all94% (51)

- Sample Exam Paper 1 SubjectiveDocument34 pagesSample Exam Paper 1 SubjectiveMohd Daud50% (2)

- Coates Truck Drivers GuideDocument66 pagesCoates Truck Drivers GuideSebastian ZarzyckiNo ratings yet

- Basic Safety Awareness ManualDocument16 pagesBasic Safety Awareness Manualsheldon cramer100% (1)

- Working Near Water Toolbox TalkDocument2 pagesWorking Near Water Toolbox TalkJohn Ha100% (2)

- Unisteel Technology HIRAC ProcedureDocument9 pagesUnisteel Technology HIRAC Procedurenarenmaniam100% (2)

- Sho ExamDocument13 pagesSho Examwantot86100% (3)

- HSE PlanDocument161 pagesHSE PlanAlai Abdel FattahNo ratings yet

- Aramco Work Permit Safety QuizDocument40 pagesAramco Work Permit Safety Quizதெய்வேந்திரன் கிருஷ்ணன்100% (5)

- Safety and Health Officer (SHO), Workplace Assignment WPA Paper 4 - HIRARC, NIOSH Malaysia.Document24 pagesSafety and Health Officer (SHO), Workplace Assignment WPA Paper 4 - HIRARC, NIOSH Malaysia.Zainorin AliNo ratings yet

- Niosh Sho Module 1 PDFDocument560 pagesNiosh Sho Module 1 PDFTivenesh Servai100% (6)

- Sho Exam PaperDocument8 pagesSho Exam PaperAqmal Arif100% (1)

- SHO Exam PaperDocument8 pagesSHO Exam Paperhalipzramlyz100% (1)

- Exam NIOSH Paper 3Document12 pagesExam NIOSH Paper 3halipzramlyz46% (13)

- Exam Niosh, BangiDocument2 pagesExam Niosh, BangiHaziq MnNo ratings yet

- KERTAS 1 / BAHAGIAN 1 (OBJEKTIF) Safety document objective questionsDocument5 pagesKERTAS 1 / BAHAGIAN 1 (OBJEKTIF) Safety document objective questionsMr.Safety77% (22)

- CourseDocument2 pagesCourseNitu TibrewalaNo ratings yet

- SHO Examination QuestionsDocument6 pagesSHO Examination QuestionsSiti Nursakinah Abdul Hadi89% (9)

- Subang ShoDocument9 pagesSubang ShoSaraswathy MahalingamNo ratings yet

- Factories and Machinery Act 1967 (FMA 1967) - Safety Related RegulationsDocument59 pagesFactories and Machinery Act 1967 (FMA 1967) - Safety Related RegulationsZainorin Ali87% (31)

- SHO Monthly REPORT StyleDocument2 pagesSHO Monthly REPORT StyleKiln Dry87% (15)

- 2 Sho Exam-June 2012Document6 pages2 Sho Exam-June 2012Hafiz SabriNo ratings yet

- Hazardous Material Handling ProcedureDocument7 pagesHazardous Material Handling ProcedureSinghaNo ratings yet

- Risk Screening and Assessment Procedure - PetrobelDocument68 pagesRisk Screening and Assessment Procedure - Petrobelbtjajadi100% (1)

- Koh Kiar Sing Wpa (Paper 4)Document32 pagesKoh Kiar Sing Wpa (Paper 4)Muhamad HarizNo ratings yet

- 1.1. Trial SHO ExaminationDocument5 pages1.1. Trial SHO ExaminationNaMeiNa100% (1)

- Application Occupational Safety and Health in IndustryDocument24 pagesApplication Occupational Safety and Health in IndustryVRAM003100% (1)

- Wpa Sho P4Document20 pagesWpa Sho P4Mohd Zulhaidy80% (5)

- Hazard Identification and Evalution in Construction IndustryDocument10 pagesHazard Identification and Evalution in Construction IndustryIJSTENo ratings yet

- Exam NIOSH Paper 2Document15 pagesExam NIOSH Paper 2halipzramlyz67% (3)

- Wpa PaperDocument12 pagesWpa Paperkhairul ezwan100% (1)

- SHO Sample QuestionsDocument87 pagesSHO Sample QuestionsFaiqah Nasir100% (3)

- DM-PH&SD-P4-TG02 - (Guidelines For Safety Audit Reports)Document5 pagesDM-PH&SD-P4-TG02 - (Guidelines For Safety Audit Reports)kevinNo ratings yet

- Kertas 1 (Baru)Document4 pagesKertas 1 (Baru)afiqahmyusof100% (1)

- Workplace Assignment (WPA) Paper 4 SHO NIOSHDocument56 pagesWorkplace Assignment (WPA) Paper 4 SHO NIOSHFiz92% (38)

- Sample ExamSHO 1Document74 pagesSample ExamSHO 1Hafiza Harun71% (14)

- WPA AizatDocument32 pagesWPA AizatTamesh Raj75% (4)

- Risk Management ToolkitDocument24 pagesRisk Management ToolkitusmancaNo ratings yet

- SHO Paper 2Document9 pagesSHO Paper 2Kenny Low100% (1)

- CBLM TLE-AFA LG GR. 9 HorticultureDocument249 pagesCBLM TLE-AFA LG GR. 9 HorticultureByron Dizon67% (3)

- Hirarc SampleDocument84 pagesHirarc SampleAbdul Samad100% (1)

- Niosh - Paper IVDocument61 pagesNiosh - Paper IVBmsh Kys100% (7)

- NIOSH SHO 02-Incident PreventionDocument31 pagesNIOSH SHO 02-Incident PreventionIkhmal IsmayatimNo ratings yet

- NIOSH SHO 02-Incident PreventionDocument31 pagesNIOSH SHO 02-Incident PreventionIkhmal IsmayatimNo ratings yet

- SHO Presentation 1Document17 pagesSHO Presentation 1Adrian Ilie33% (6)

- Fma 1967Document28 pagesFma 1967Zainorin Ali100% (1)

- Barbending HiracDocument2 pagesBarbending HiracJohn Ha71% (7)

- Kertas 2Document2 pagesKertas 2Elias Gor Yaman100% (2)

- Usechh 2000Document15 pagesUsechh 2000Aldric Tinker Toyad80% (5)

- FMA 67 Vs OSHA 94Document6 pagesFMA 67 Vs OSHA 94Lukman Wan Mat Daud33% (3)

- Occupational Health and Toxicology GuideDocument19 pagesOccupational Health and Toxicology GuideChin Bing100% (1)

- Hirarc Final ZarifDocument20 pagesHirarc Final ZarifSurendran Surya100% (1)

- WPA CheahDocument26 pagesWPA Cheahmr5jalNo ratings yet

- Exam NIOSH Paper 1Document7 pagesExam NIOSH Paper 1halipzramlyz100% (3)

- En 1050 Risk - AssessmentDocument22 pagesEn 1050 Risk - AssessmentWillian Siqueira SartoriNo ratings yet

- Cpcs Theory Test Questions 1Document161 pagesCpcs Theory Test Questions 1Mihai Berbece100% (1)

- Reporting Occupational Accidents and DiseasesDocument25 pagesReporting Occupational Accidents and DiseasesHernani Hamid100% (1)

- WPA Sample ReportDocument33 pagesWPA Sample ReportMat Laut81% (16)

- Kertas 1Document2 pagesKertas 1Elias Gor Yaman78% (9)

- Paper 2 / Section B (SUBJECTIVE)Document15 pagesPaper 2 / Section B (SUBJECTIVE)Azlan RiswandyNo ratings yet

- HIRARC EXERCISE Full 2 PDFDocument44 pagesHIRARC EXERCISE Full 2 PDFSachi AnandNo ratings yet

- Paper 1Document7 pagesPaper 1Hafiz SabriNo ratings yet

- Safety Case Guidance - V5Document32 pagesSafety Case Guidance - V5MohamedNo ratings yet

- Ohd WpaDocument6 pagesOhd WpaWan Nur Afifah100% (1)

- NIOSH WPA - GlomaxDocument28 pagesNIOSH WPA - Glomaxyewminyun6098100% (4)

- Workplace Injury Case SummaryDocument9 pagesWorkplace Injury Case SummaryHariz HilmanNo ratings yet

- Paper 1 & 2: Key OSH Topics and Exam QuestionsDocument2 pagesPaper 1 & 2: Key OSH Topics and Exam QuestionsHaziq MnNo ratings yet

- WPA Report FSG301Document5 pagesWPA Report FSG301Nazirul Razali80% (5)

- The Handbook of Safety Engineering: Principles and ApplicationsFrom EverandThe Handbook of Safety Engineering: Principles and ApplicationsRating: 4 out of 5 stars4/5 (1)

- Causes and Implementation of Safety ManagementDocument10 pagesCauses and Implementation of Safety ManagementFatin NajwaNo ratings yet

- Hafizuddin Azfar (Els 1265)Document46 pagesHafizuddin Azfar (Els 1265)Mohd hafiz AzmiNo ratings yet

- PCM Part 2 Compilation PDFDocument53 pagesPCM Part 2 Compilation PDFmatt jaudianNo ratings yet

- Amendment To RulesDocument3 pagesAmendment To RulesJohn HaNo ratings yet

- 麥克群雄戰力表0706Document19 pages麥克群雄戰力表0706John HaNo ratings yet

- Borrow PitDocument1 pageBorrow PitJohn HaNo ratings yet

- NP ArocoatDocument4 pagesNP ArocoatJohn HaNo ratings yet

- FA - Programme Book BOSHDocument16 pagesFA - Programme Book BOSHJohn HaNo ratings yet

- 14 - Attach F-I (30 Sept 2019)Document10 pages14 - Attach F-I (30 Sept 2019)John HaNo ratings yet

- Heavy Machinery Passport For Non JKKP CertificationDocument1 pageHeavy Machinery Passport For Non JKKP CertificationJohn HaNo ratings yet

- Welding Hazards AFSCME Fact SheetDocument11 pagesWelding Hazards AFSCME Fact SheetMuhammad Attaulla KhanNo ratings yet

- CLASS Regulations 2013 For Classifiers (Chemical Substances & Mixtures)Document5 pagesCLASS Regulations 2013 For Classifiers (Chemical Substances & Mixtures)John HaNo ratings yet

- 02A PreQ Notice JBALBDocument1 page02A PreQ Notice JBALBJohn HaNo ratings yet

- Level TableDocument32 pagesLevel TableJohn HaNo ratings yet

- Controlling Hazardous Fumes and Gases During WeldingDocument2 pagesControlling Hazardous Fumes and Gases During WeldingMohd MustafhaNo ratings yet

- Di Hadapan Pembinaan: 2 5 0 M KM/J 1 0 0 M KM/JDocument1 pageDi Hadapan Pembinaan: 2 5 0 M KM/J 1 0 0 M KM/JJohn HaNo ratings yet

- Method Statement SESCODocument1 pageMethod Statement SESCOJohn HaNo ratings yet

- Method Statement SESCODocument1 pageMethod Statement SESCOJohn HaNo ratings yet

- Project Introduction and ScopeDocument22 pagesProject Introduction and ScopeJohn HaNo ratings yet

- 02) Borang Permohonan PeperiksaanDocument15 pages02) Borang Permohonan PeperiksaanJohn Ha0% (1)

- 03 Osh MSDocument35 pages03 Osh MSJohn HaNo ratings yet

- Section 1: Identification: Rev Level: Rev DateDocument8 pagesSection 1: Identification: Rev Level: Rev DatesdsdvsdvsdNo ratings yet

- Safety Induction: School of Plant Biology University of Western AustraliaDocument61 pagesSafety Induction: School of Plant Biology University of Western AustraliaelvandiNo ratings yet

- Di Bagian Ship Building PT Dok Dan Perkapalan Surabaya: Risk Assessment Pada Pekerjaan Welding Confined SpaceDocument9 pagesDi Bagian Ship Building PT Dok Dan Perkapalan Surabaya: Risk Assessment Pada Pekerjaan Welding Confined Spacevansyah 01No ratings yet

- Sources of Labour Law in ZambiaDocument47 pagesSources of Labour Law in Zambiamundukuta chipunguNo ratings yet

- DIS Project Proforma 2015 PDFDocument7 pagesDIS Project Proforma 2015 PDFVidyesh Nair100% (2)

- Eia-Special Prog GRP OneDocument18 pagesEia-Special Prog GRP OneJames LaurentNo ratings yet

- Safety Data Sheet: Section 1. IdentificationDocument9 pagesSafety Data Sheet: Section 1. IdentificationWangunNo ratings yet

- Cis 49Document2 pagesCis 49tiagoulbraNo ratings yet

- Safety Data Sheet: 1: IdentificationDocument10 pagesSafety Data Sheet: 1: IdentificationManuel MoriveraNo ratings yet

- LIST OF ONLINE SHORT COURSES - UWI Open Campus Semester 2 2022 - 2023Document39 pagesLIST OF ONLINE SHORT COURSES - UWI Open Campus Semester 2 2022 - 2023Suelin LumfaiNo ratings yet

- Sipx MSDS Y&xDocument7 pagesSipx MSDS Y&xmishaNo ratings yet

- BL Ts Extra V 8 GBDocument20 pagesBL Ts Extra V 8 GBkhalidNo ratings yet

- Agra CasesDocument33 pagesAgra CasesMarielle Joyce G. AristonNo ratings yet

- JSL Jajpur-1975Document3 pagesJSL Jajpur-1975Roshan JhaNo ratings yet

- Msds Potassium Chloride: M S D SDocument1 pageMsds Potassium Chloride: M S D SQuality AssuranceNo ratings yet

- HSE evaluation of PT. Supraco Lines dredging servicesDocument4 pagesHSE evaluation of PT. Supraco Lines dredging serviceshannyNo ratings yet

- C10 Add Maths Answers Form 4 PDFDocument7 pagesC10 Add Maths Answers Form 4 PDFLee Sun TaiNo ratings yet

- Chemical WarehousingDocument17 pagesChemical Warehousingsubbu159No ratings yet