Professional Documents

Culture Documents

ME6403-Engineering Materials and Metallurgy

Uploaded by

Suresh NatarajanCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

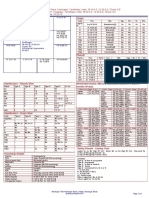

ME6403-Engineering Materials and Metallurgy

Uploaded by

Suresh NatarajanCopyright:

Available Formats

Downloaded from www.Rejinpaul.

com

ME 2253 EMM

Department of Mechanical Engineering

VEC

Valliammai Engineering College

Department of Mechanical Engineering

ME 6403 Engineering Materials and Metallurgy

Regulation 2013

Question Bank

Unit-1- Constitution of Alloys and Phase Diagrams

Part-A

1. When will interstitial solid solution occur?

2. What is isomorphous?

3. How is plain carbon steels classified? Define an alloy?

4. Classify the alloys.

5. What are solid solutions?

6. Differentiate substitutional and interstitial solid solutions with examples.

7. What are intermediate phases?

8. Define the term phase.

9. What is an equilibrium phase diagram?

10.Define eutectic reactions?

11.Define peritectic reactions?

12.Define eutectoid reactions?

13.Define peritectoid reactions?

14.Distinguish eutectic and eutectoid transformations.

15.Distinguish peritectic and peritectoid transformations.

16.What are the uses of grey cast iron?

17.What are chilled cast irons?

18.Why nodular cast iron is called ductile cast iron?

19.What are the advantages of alloy steels over plain carbon steels?

20.What is the effect of additions of chromium on the characteristics of steel?

Get Unique study materials from www.rejinpaul.com

1

Downloaded from www.Rejinpaul.com

ME 2253 EMM

Department of Mechanical Engineering

VEC

Part-B

1. Show the different steel and cast iron region in the iron carbon diagram with

its microstructure and write down its composition, mechanical properties and

application.

2. Draw a neat sketch and explain TTT diagram.

3. Draw Iron carbon diagram and label all fields?

4. Draw a typical equilibrium diagram for an isomorphous system and explain

the equilibrium cooling of any one alloy from the above diagram.

5. Draw a typical equilibrium diagram for a eutectic type of system with limited

solid solubility and explain its important features.

6. Explain the Peritectic temperature using a binary equilibrium peritectic phase

diagram

7. What is the effect of small quantities of

(a) Sulphur

(b) manganese

(c) phosphorus

(d) Silicon upon the properties of steel?

8. Explain the method of plotting an equilibrium diagram and derive the lever

rule as applied to equilibrium diagram.

9. Discuss the effect of Silicon, Manganese elements in cast iron.

10.Describe the composition, microstructure, properties and applications of grey

cast iron.

Get Unique study materials from www.rejinpaul.com

2

Downloaded from www.Rejinpaul.com

ME 2253 EMM

Department of Mechanical Engineering

VEC

Unit-II HEAT TREATMENT

Part-A

1.

2.

3.

4.

5.

Name various methods of heat treatment of steel.

When the annealing process is preferred?

Define full annealing.

Define heat treatment.

What is martensite and for eutectoid steel in what temperature range it is

generally formed?

6. What is the purpose of spheroidising annealing?

7. Define normalizing.

8. What is the purpose of normalizing?

9. What are the factors affecting the hardening process?

10.What is austempering process and what is the microstructure produced after

austempering?

11.What is martempering process and what is the purpose of this treatment?

12.Distinguish between hardness and hardenability.

13.Define carburizing.

14.What are the three methods of carburizing commonly employed?

15.What is the purpose of flame hardening and induction hardening of steel?

16.Name the four different methods used for flame hardening.

17.what steels are commonly used for nitriding?

18.What is the process of nitriding?

19.Define cyaniding.

20.What is the process of carbonitriding?

Get Unique study materials from www.rejinpaul.com

3

Downloaded from www.Rejinpaul.com

ME 2253 EMM

Department of Mechanical Engineering

VEC

Part-B

1. Describe the method of plotting isothermal transformation or TTT diagram?

2. Draw an IT diagram or TTT diagram for an eutectoid steel .Indicate the

various decomposition products on it and explain?

3. Draw a schematic CCT diagram for a carbon steel containing 0.8% C .Using

this diagram explain how different cooling curves lead to the

(a)Annealing heat treatment

(b) Normalizing heat treatment

(c) Hardening heat treatment

4. Explain how Jominy end quench test is used for determining the harden ability

of steels.

5. Describe the heat treatment cycle following carburizing.

6. Describe the process of carbonitriding. Differentiate between carburizing and

carbonitriding.

7. Explain flame hardening.

8. Explain Induction hardening.

9. Give a detailed account on

(a) Annealing (b) Normalizing (c) Austempering

(d) Case hardening.

10.Explain how surface hardening is achieved using flame hardening.

Get Unique study materials from www.rejinpaul.com

4

Downloaded from www.Rejinpaul.com

ME 2253 EMM

Department of Mechanical Engineering

VEC

Unit-III Ferrous and Non Ferrous Metals

Part-A

1.

2.

3.

4.

5.

6.

7.

What is the effect of chromium alloying element on the properties of steel?

What is cast iron?

What is HSLA?

What are advantages of alloy steels over plain carbon steels?

Discuss the general effects of alloying elements in steel.

Specify the effect of nickel on the properties of steel.

What advantages are derived by using a combination of nickel and chromium

in steel?

8. What are the principal alloying elements in triple alloy steel?

9. How is silicon useful as an alloying element in steel?

10.For what purpose is tungsten used in steel?

11.What are stainless steels? Why are these steels stainless?

12.What type of stainless steels is referred to as ferritic stainless steels?

13.What are tool steels? Classify them.

14.List the bearing materials that are commonly used?

15.What is meant by precipitation hardening?

16.What is duralumin?

17.Give composition and applications of duralumin?

18.List at least four types of brasses used.

19.List some bronze alloys.

20.How can you classify tool steels?

Get Unique study materials from www.rejinpaul.com

5

Downloaded from www.Rejinpaul.com

ME 2253 EMM

Department of Mechanical Engineering

VEC

Part-B

1. Write short note on compositions and properties of the following stainless

steels,

(a) Ferritic stainless steel

(b) Austenitic stainless steel

(c) Martensitic stainless steel

(d) Precipitation hardening stainless steel

2. State the types, compositions and properties of high speed steel.

3. Discuss Hadfield and Mar aging steels on the following lines

(a) Chemical composition

(b) Heat treatment

(c) Mechanical properties

(d) Applications

4. Explain the various methods to achieve high strength in HSLA steels.

5. Explain Bearing alloys.

6. Explain Tool steels.

7. Name different alloys of copper. Give its composition, properties and uses.

8. Explain Mar aging steels.

9. Explain Stainless steels, High speed steels.

10.Explain, bearing metals, Explain brasses

Get Unique study materials from www.rejinpaul.com

6

Downloaded from www.Rejinpaul.com

ME 2253 EMM

Department of Mechanical Engineering

Unit-IV NON METALLIC MATERILS

Part-A

1. What is PTFE?

2. What is PE?

3. What is PS?

4. Define the degree of polymerization.

5. What is PVC?

6. What is copolymerization?

7. What is PMMA?

8. What is PET?

9. What is ABS?

10.What is PI?

11.What is PAI?

12.What is PPO?

13.What is PPS?

14.What is PEEK?

15.What is PTFE?

16.What is PA?

17.What is PP?

18.What are acrylics? Mention their application.

19.Distinguish between hard and soft glasses.

20.How is alumina ceramics produced?

Get Unique study materials from www.rejinpaul.com

7

VEC

Downloaded from www.Rejinpaul.com

ME 2253 EMM

Department of Mechanical Engineering

VEC

Part-B

1. Explain the properties and application of the PVC,PE, PTFE, ABS

2. Give the detailed account on:

(a) Urea formaldehydes

(b) Fibre reinforced plastics

(c) Cellulose nitrate.

3. Explain PMMA.

4. What is polymerization? Describe addition polymerization and condensation

polymerization.

5. How plastic materials are classified? Explain each classification.

6. Write brief notes on following traditional ceramics

(a) Clay products

(b) Glasses

(c) Cements

(d) Refractory's

7. Describe the properties and applications of following structural ceramics

(a) Alumina

(b) Partially stabilized zirconia

(c) Silicon carbide (d) Silicon nitride (e) Sialon

8. Describe the structures, properties and applications of following commodity thermoplastic

polymers

(a) Polyethylene

(b) Polyvinylchloride

(c) Polystyrene

9. Describe the strictures, properties and applications of the following commodity

thermoplastic polymers

(a) Acrylonitrile Butadiene Styrene

(b) Polytetrafluoroethylene

(c) Nylons

(d) Polycarbonates

(e) Polyethylene terephthalate

10. Describe the structures, properties and applications of the following thermoset polymers

(a) Phenol formaldehyde

(b) Urea formaldehyde

(c) Epoxies

(d) Unsaturated polyesters

Get Unique study materials from www.rejinpaul.com

8

Downloaded from www.Rejinpaul.com

ME 2253 EMM

Department of Mechanical Engineering

VEC

Unit-V MECHANICAL PROPERTIES AND TESTING

Part-A

1.

2.

3.

4.

5.

6.

7.

Name the slip plane and slip direction for FCC crystal.

What is creep?

Define slip.

Name different types of facture.

What properties are determined from tensile testing of metallic products?

Distinguish between resilience and toughness.

Draw typical engineering stress strain curves for the following materials: (a)

Aluminum (b) Mild steel (c) Cast iron (d) Polymer

8. What do you mean by double shear test?

9. Define the hardness of a material.

10.State the advantage and limitation of Rockwell hardness test over the Brinell

and Vickers hardness test.

11.Differentiate between Charpy and Izod test results not useful in design?

12.What is fatigue test S-N curve?

13.Define endurance limit in fatigue test.

14.Define fatigue strength in fatigue test.

15.Differentiate between elasticity and plasticity.

16.Differentiate between ductility and malleability.

17.Define the terms brittleness and hardness.

18.How can you prevent the brittle fracture?

19.What is meant by creep fracture?

20.Sketch a creep curve explaining different stages of it.

Get Unique study materials from www.rejinpaul.com

9

Downloaded from www.Rejinpaul.com

ME 2253 EMM

Department of Mechanical Engineering

VEC

Part-B

1. Describe with neat sketch fatigue test.

2. Describe with neat sketch creep test.

3. Explain the mechanism of plastic deformation by slip and twinning with neat

sketch.

4. Describe how the torsion test is conducted and what are the properties deter

from this test?

5. Explain the testing procedure for Vickers hardness test and mention the

advantages and limitations.

6. Describe the procedure of Charpy impact testing and the properties obtained

from it.

7. Explain the method of testing the materials for fatigue and how is the fatigue

data presented.

8. Draw a typical creep curve and explain the various stages of creep.

9. What is meant by ductile fracture? Explain the mechanism of it.

10.Compare and contrast the Brinell, Vickers and Rockwell hardness tests.

Get Unique study materials from www.rejinpaul.com

10

You might also like

- Sacred Heart CollegeDocument122 pagesSacred Heart CollegeSuresh NatarajanNo ratings yet

- Jog Falls: A Pervasive Healthcare Platform For Diabetes ManagementDocument19 pagesJog Falls: A Pervasive Healthcare Platform For Diabetes ManagementSuresh NatarajanNo ratings yet

- VedicReport1 5 201810 26 53PMDocument54 pagesVedicReport1 5 201810 26 53PMSuresh NatarajanNo ratings yet

- Slip - BeltsDocument1 pageSlip - BeltsSuresh NatarajanNo ratings yet

- SurfacesMEG09 PDFDocument17 pagesSurfacesMEG09 PDFSuresh NatarajanNo ratings yet

- P.S.V College of Engineering and TechnologyDocument1 pageP.S.V College of Engineering and TechnologySuresh NatarajanNo ratings yet

- Hidden Surface RemovalDocument2 pagesHidden Surface RemovalSuresh NatarajanNo ratings yet

- Dynamics and Pattern of A Managed ConiferousDocument14 pagesDynamics and Pattern of A Managed ConiferousSuresh NatarajanNo ratings yet

- Great EscapDocument21 pagesGreat EscapSuresh NatarajanNo ratings yet

- Tree Planting On Private LandsDocument19 pagesTree Planting On Private LandsSuresh NatarajanNo ratings yet

- Freedom FightersDocument48 pagesFreedom FightersSuresh NatarajanNo ratings yet

- Foliar SpraysDocument10 pagesFoliar SpraysdevzNo ratings yet

- WetDocument8 pagesWetSuresh NatarajanNo ratings yet

- Cell PhoneDocument15 pagesCell PhoneSuresh NatarajanNo ratings yet

- 782 2360 1 PBDocument4 pages782 2360 1 PBSuresh NatarajanNo ratings yet

- Slip - BeltsDocument1 pageSlip - BeltsSuresh NatarajanNo ratings yet

- ME6403 EngineeringMaterialsandMetallurgyquestionbankDocument10 pagesME6403 EngineeringMaterialsandMetallurgyquestionbankSuresh NatarajanNo ratings yet

- VedicReport5 9 20187 10 48PMDocument5 pagesVedicReport5 9 20187 10 48PMSuresh NatarajanNo ratings yet

- WS Class 3 PDFDocument61 pagesWS Class 3 PDFumdb2205100% (1)

- Coordinate Systems: MW MW MW MW MWDocument4 pagesCoordinate Systems: MW MW MW MW MWSuresh NatarajanNo ratings yet

- How To Predict Certain Matter in KP PDFDocument20 pagesHow To Predict Certain Matter in KP PDFgunjaanthakurNo ratings yet

- Nadep MethodDocument8 pagesNadep MethodSandeep_AjmireNo ratings yet

- Sustainable Agricultural PracticesDocument101 pagesSustainable Agricultural Practicesperma_y100% (2)

- Page 39 SageDocument1 pagePage 39 SageSuresh NatarajanNo ratings yet

- WS Class 3 PDFDocument61 pagesWS Class 3 PDFumdb2205100% (1)

- Number 1Document1 pageNumber 1Suresh NatarajanNo ratings yet

- ME6412 Thermal Engineering Lab IDocument65 pagesME6412 Thermal Engineering Lab IHimanshu ChaudhariNo ratings yet

- JASA 1st Anniversary Issue 2012 PDFDocument103 pagesJASA 1st Anniversary Issue 2012 PDFSuresh NatarajanNo ratings yet

- Me6403 Emm Rejinpaul April May 2015Document2 pagesMe6403 Emm Rejinpaul April May 2015Suresh NatarajanNo ratings yet

- RameshDocument1 pageRameshSuresh NatarajanNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (120)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Seminar Presentation PPT On Reactive Powder Concrete (Civil Engineering)Document39 pagesSeminar Presentation PPT On Reactive Powder Concrete (Civil Engineering)Siddhartha Siddhu100% (19)

- Finishing and Polishing Materials.9Document8 pagesFinishing and Polishing Materials.9Eman Azmi OmarNo ratings yet

- Finishing of WoodDocument40 pagesFinishing of WoodOsman Batur SalurNo ratings yet

- About VardhmanDocument34 pagesAbout VardhmanIshant GuptaNo ratings yet

- BQDocument136 pagesBQfateenhananeyNo ratings yet

- Proposal of Proofex PGP Watre Proofing MembraneDocument5 pagesProposal of Proofex PGP Watre Proofing MembraneVenkata Raju Kalidindi100% (1)

- Apro Introduction 2015Document20 pagesApro Introduction 2015urtzilegorburuNo ratings yet

- Sodium Silicate A Binder For The 21st Century PDFDocument6 pagesSodium Silicate A Binder For The 21st Century PDFZen AlkaffNo ratings yet

- World CementDocument4 pagesWorld CementMichael WarnerNo ratings yet

- Jindal UPVC Plus - Catalog 2015Document4 pagesJindal UPVC Plus - Catalog 2015Somu DahiyaNo ratings yet

- GyprexDocument20 pagesGyprexSourabha Bhatt100% (1)

- CeilingDocument43 pagesCeilingAnonymous RrwCr7aNo ratings yet

- M TP 014 2Document14 pagesM TP 014 2behnam197No ratings yet

- GGBSDocument10 pagesGGBSPalakJainNo ratings yet

- Aluminium Packaging ApplicationsDocument8 pagesAluminium Packaging ApplicationsedelapolloNo ratings yet

- Wall Sections-Built ExamplesDocument21 pagesWall Sections-Built ExamplesRoma Vadola100% (2)

- MoS BrickworkDocument4 pagesMoS BrickworkIvan DjordjicNo ratings yet

- UNIT-I (Constitution of Alloys and Phase Diagrams) Part-ADocument7 pagesUNIT-I (Constitution of Alloys and Phase Diagrams) Part-AkarthisanNo ratings yet

- Mechanical Behavior and Dynamic Mechanical Analysis Study On Nanoclay Filled Carbon-Epoxy CompositesDocument11 pagesMechanical Behavior and Dynamic Mechanical Analysis Study On Nanoclay Filled Carbon-Epoxy CompositesKarthikeyan MurugananthanNo ratings yet

- Neoplast TPV Extrusion GuideDocument6 pagesNeoplast TPV Extrusion GuidenechitamariusNo ratings yet

- Drawing: Visual Art With Drawing InstrumentsDocument25 pagesDrawing: Visual Art With Drawing InstrumentsPalani RajanNo ratings yet

- Nitofill WS60 : Crack Injection Resin For Stopping Water FlowDocument4 pagesNitofill WS60 : Crack Injection Resin For Stopping Water FlowmilanbrasinaNo ratings yet

- PolyethyleneDocument6 pagesPolyethylenetekkiNo ratings yet

- DocumentationDocument35 pagesDocumentationSiva Vadi100% (1)

- SAIC-H-2014 Rev 7Document3 pagesSAIC-H-2014 Rev 7mohammed siddiqNo ratings yet

- Concrete StructuresDocument693 pagesConcrete StructuresArzath Sajeer94% (18)

- Literature Review TOP CoatingDocument57 pagesLiterature Review TOP CoatingWo Ai NiNo ratings yet

- Jj508 Engineering Laboratory 3 Lab Report: Title: Metallographic Specimen PreparationDocument10 pagesJj508 Engineering Laboratory 3 Lab Report: Title: Metallographic Specimen PreparationOnsen Ong Min XuanNo ratings yet

- 73 Standard Boq Template Market Place 1Document8 pages73 Standard Boq Template Market Place 1racing.phreak100% (1)

- Mitubishi AJX PDFDocument20 pagesMitubishi AJX PDFZeljko StamatovicNo ratings yet