Professional Documents

Culture Documents

Samsung Pn60e550d1fxza Fast Track Guide

Uploaded by

edsel72Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Samsung Pn60e550d1fxza Fast Track Guide

Uploaded by

edsel72Copyright:

Available Formats

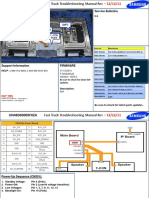

PN60E550D1FXZA

Fast Track Troubleshooting Manual Rev 6/13/12

Vs Va Vsc Ve

Label Voltages

XMAIN

SMPS

Y-MAIN

SERVICE BULLETINS

-6/6/12 ASC20120606001: Improve Eco

Sensor, replace Function Board & Upgrade

Firmware

-5/16/12 ASC20120515001: How to send

TVs emergency data WD & AR data to SEA

- Quick Parts: Verify before Ordering

X-Buffer

MAIN

Y-Buffer

Speaker L

LOGIC/Buffer

BOARD

Speaker R

Wi-Fi

FIRMWARE

Jog

Func.

HELP : 888-751-4086; 866-894-0637 FE)

GSPN

http://gspn3.samsungcsportal.com

PLUS ONE

http://my.plus1solutions.net/clientPortals/sam

sung

6/8/12 T-MST10PAUSC

6/2/12 T-MST10PAUSC Version 1013.3

resolves compatibility with DLNA

devices.

HOT TIPS

Avail on GSPN or Samsung,Com

-New 2012 Model always check for latest

bulletins and firmware updates.

-New combined Logic/Logic Buffer Board.

-New Pentile Panel (60 inch only)

Always check for latest updates

PN60E550D1FXZA

Fast Track Troubleshooting Manual

Logic/Buffer Board combined & located

partially behind Stand.

CN4003

X

DRIVE

CN5413

CN5414

CN4408

CN4000

CN5007

CN5415

CN4005

SMPS

CN5000

CN5005

CN5416

U2

CN5003

CN4004

CN804

Y

DRIVE

CN4002

CN801

CN201

CN5513

MAIN

BOARD

CN302

CN5514

CN4407

CN800S

CN5006

CN5004

CN4001

CN4404

CN5001

CN5002

CN1602

CN1201

CN5515

CN4403

CN5516

CN2003

CN2000

CN2000

Speaker

(R)

CN2505

CN2004

CN2005

LOGIC

BOARD

Speaker (L)

CN2704

B/T

Wi-fi

function

PN60E550 Power On Sequence

CN804 SMPS to CN4005 X Main

XMAIN

SMPS

X-Buffer

CN801 SMPS to CN201 Main

MAIN

LOGIC/Buffer

BOARD

1.

2.

3.

4.

5V STBY

PS_ON

PS_ON

VS_ON

Wi-Fi

Jog

Func.

Wi-Fi

Speaker R

Jog Func.

SMPS to Main

Main to SMPS (all Low Voltages on)

SMPS thru X-Board to Logic Board

Logic Board thru X-Board to SMPS

(VS & VA voltages turned on)

Fast Track Troubleshooting Manual

SMPS

Y-Main

Vs & Va

Vsc

SAMPLE VIEW & READINGS

.

Power Supply Trouble Shooting Notes:

2010/2011/2012 models

Will not be run with the X or Y main disconnected. The SMPS will shut

down immediately. However if a meter is first connected to the test point

when power is applied it will read the correct voltage briefly before shutting down.(You have enough time to check key voltages)

CAUTION: Do not reconnect any connectors to SMPS or Y/X Boards until

power has been turned off long enough for Vs to drop below 10V or damage

will occur to X or Y Boards. .

Over Current Protection

For the SMPS Power Supply... If a short circuit occurs on either the VS or

VA voltage lines, the SMPS stops operating, but should not fail. When the

short circuit is removed from the source line, the Power Supply will

operate normally again. Many SMPS Supplies are replaced needlessly!

X-Main

Ve

VITAL SIGNS check Vs, Va, Vsc & Ve

When troubleshooting, Its very important to first check Vs, Va, Vsc & Ve

If Vs is missing (0V), disconnect power and check for short. Use ohm meter to

measure resistance while disconnecting Y-Board & X-Board supply feeds one

at a time.

Turn Power On and Test SMPS with short connector removed for correct Vs

voltage verification. (It may only come up briefly but to full level). Again be

careful not to reconnect Power Connectors until Vs falls below 10V.

If Va is low or missing, disconnect Supply Feed to Address Boards and

Check to see if SMPS Supply is restored. (Note Va feed normally passes

through the Y-Drive to the Address Boards (Logic Buffer Boards).

If Vsc is low or missing and Vs was OK, the failure is with the Y-Board

. the Y-Board generate the Vsc voltage from the Vs supplied by the

since

SMPS.

If Ve is low or missing and Vs is OK, the failure is with the X-Board since the

Ve is generated by the X-Board from the Vs supplied by the SMPS. Please note

in some rare cases the Ve may be generated by the Y-Board feed to the XBoard.)

Other SMPS Voltages:

Check Low Voltage feeds to the Main Board and other supplied Assemblies.

Function Control Troubleshooting

Standby A3.3V

on Function

Connector, Pin

3.

All Pins should

read 3.3V

before

commands.

Press, at Key 1,

Pin 6. 3.3V to

0.0V DC

Left, Right, Up,

Down at

Key 2, Pin 7.

Check specific

voltages on

chart.

5

Fast Track Troubleshooting Manual (PNXXE8000 Video Signal Path Sample)

TROUBLESHOOTING VIDEO

PROBLEMS

1. Verify Video Operation:

A. Customer Picture Test

B. Display

C. If display & Customer Picture

Test are OK source is suspected

D. Substitute with known good

source and cabling.

2. Using Test Patterns in

Service Mode:

Customer Remote

A. Power off

B. Mute, 182, Power

Factory Remote:

A. Power On

B. Info, Test

3. Verify Echo-P Patterns

4. Verify Logic Patterns

If Logic Patterns are OK and EchoP are noisy, replace the

defective LVDS Cable or Main

Board.

If Echo-P and Logic Patterns are

both noisy check for specific

on screen noise error to

determine failure. (next slide)

ON SCREEN FAILURE EXAMPLES:

NOTE: X/Y MAIN Combined.

Fast Track Troubleshooting Manual

ALIGNMENTS:

1.

Check/Adj. VS, VA, VE, & VSC according to Panel Label

and Diffusion test. (see bulletins for any special notes

before making changes)

DIFFUSION TEST/ADJ. (cell miss-firing)

- Allow the unit to warm up 15 to 20 minutes

- Access the Burn Protect Sig. Pattern in Cust. Menu.

-Adjust the Vs volts until screen errors are gone in

both dark and bright areas.

-Adjust the Vs volts within +/- 10V on the panel label.

-NOTE: Diffusion may appear with aging panels.

New panels with Diffusion consult bulletins and/or report

problem.

2. Check/Set Option Bytes:

NOTE: Verify correct settings with latest tips!

60DSArd

You might also like

- Samsung Plasma TV Type PN60E8000GFXZA - Fast Track Troubleshooting Guide - Service ManualDocument7 pagesSamsung Plasma TV Type PN60E8000GFXZA - Fast Track Troubleshooting Guide - Service ManualNorlec HiFi75% (4)

- PN64E8000GFXZA Fast Track Guide PDFDocument7 pagesPN64E8000GFXZA Fast Track Guide PDFboroda2410No ratings yet

- Samsung PN51E490B4FXZA GuíaDocument8 pagesSamsung PN51E490B4FXZA GuíaHerber ChavezNo ratings yet

- Samsung PN43D490A 1DXZ Troubleshooting GuideDocument5 pagesSamsung PN43D490A 1DXZ Troubleshooting GuidemascrisNo ratings yet

- Pn58c6500tfxza Fast TrackDocument5 pagesPn58c6500tfxza Fast TracklamiradaNo ratings yet

- Fast Track Troubleshooting Manual Key PointsDocument6 pagesFast Track Troubleshooting Manual Key PointsMichael McDonaldNo ratings yet

- PN42c430a1dxza Troubleshooting - GuideDocument6 pagesPN42c430a1dxza Troubleshooting - GuidemaapilarNo ratings yet

- Pn50c450b1dxza - How To Activate Power and Logic Board Test Patterns Without Main BoardDocument2 pagesPn50c450b1dxza - How To Activate Power and Logic Board Test Patterns Without Main Boardtaz1mxNo ratings yet

- PDP troubleshooting guideDocument100 pagesPDP troubleshooting guideJoaquim MartinsNo ratings yet

- Samsung PN43E450A1FXZA Fast Track Cr60512Document8 pagesSamsung PN43E450A1FXZA Fast Track Cr60512avi1991No ratings yet

- 2009-11!27!194320 Plasma TV Trouble Shooting DW3-No-pix-troubleshootDocument10 pages2009-11!27!194320 Plasma TV Trouble Shooting DW3-No-pix-troubleshootVernon NashNo ratings yet

- LG55EF9500, LG65EF9500 - OLED TV Testing ProcedureDocument6 pagesLG55EF9500, LG65EF9500 - OLED TV Testing ProcedureCarlos hugo Peña sotoNo ratings yet

- Falla Data CanDocument4 pagesFalla Data CanGrupo Alber SACNo ratings yet

- Identifying TV SMPS or Horizontal Output ProblemsDocument4 pagesIdentifying TV SMPS or Horizontal Output Problemsadrianocpoli4090No ratings yet

- Chassis Mc-059bDocument29 pagesChassis Mc-059bwhatthecussNo ratings yet

- LG Re-29fa33 Service ManualDocument41 pagesLG Re-29fa33 Service ManualgapjgNo ratings yet

- Samsung UN55D6300SFXZA - Fast - TrackDocument4 pagesSamsung UN55D6300SFXZA - Fast - TrackалександрNo ratings yet

- Fast Track Troubleshooting GuideDocument4 pagesFast Track Troubleshooting GuideRene G OramaNo ratings yet

- Hfe Classe Audio Cap-80 101 ServiceDocument19 pagesHfe Classe Audio Cap-80 101 Servicehesso1No ratings yet

- 21FG1RGDocument22 pages21FG1RGMelina Lara Lezama100% (1)

- Plasma TV SMPS TroubleshoutingDocument5 pagesPlasma TV SMPS TroubleshoutingmindjokerNo ratings yet

- LG PDP Monitor Service ManualDocument36 pagesLG PDP Monitor Service ManualAdam HansellNo ratings yet

- LG 21fs2alx Mc-049c Chassis (ET)Document29 pagesLG 21fs2alx Mc-049c Chassis (ET)Michael McintoshNo ratings yet

- Sas120v 10aDocument2 pagesSas120v 10anehaadhikari87No ratings yet

- LG 21fa20qpq - Cf-21q20eh Chassis Mc-014aDocument30 pagesLG 21fa20qpq - Cf-21q20eh Chassis Mc-014ajtpsonidoNo ratings yet

- LG 50PV450 Training ManualDocument160 pagesLG 50PV450 Training ManualDrew DumasNo ratings yet

- Fast Track Troubleshooting for Samsung UN60ES6100FXZADocument4 pagesFast Track Troubleshooting for Samsung UN60ES6100FXZAAndreyNo ratings yet

- Asl 1000Document54 pagesAsl 1000葉佐賢No ratings yet

- Troubleshooting: 6-1 Checkpoints by Error ModeDocument10 pagesTroubleshooting: 6-1 Checkpoints by Error Modegilberto gutierrezNo ratings yet

- LG 50PT85Document53 pagesLG 50PT85videosonNo ratings yet

- LG 42PC3D Service ManualDocument35 pagesLG 42PC3D Service ManualThomas OldburyNo ratings yet

- PN43E450A1FXZA: Fast Track Troubleshooting Manual - Rev 6/5/12Document8 pagesPN43E450A1FXZA: Fast Track Troubleshooting Manual - Rev 6/5/12nistoreduardcristianNo ratings yet

- LG 42pt85 MFLDocument55 pagesLG 42pt85 MFLvideosonNo ratings yet

- Provision 2122T CH - tv-2K Serwice ModeDocument9 pagesProvision 2122T CH - tv-2K Serwice ModeparutzuNo ratings yet

- Panasonic TX-21at1p Chassis Z-8tDocument22 pagesPanasonic TX-21at1p Chassis Z-8taureliancoNo ratings yet

- Color TV: Service ManualDocument31 pagesColor TV: Service Manualsaran_thapa100% (1)

- Service Manual for TX-21PZ1 Colour TelevisionDocument17 pagesService Manual for TX-21PZ1 Colour TelevisionStefan BiraNo ratings yet

- LORAIN POWER PLANT MICROPROCESSOR CONTROL PANELDocument22 pagesLORAIN POWER PLANT MICROPROCESSOR CONTROL PANELRajesh Sharma100% (1)

- Samsung UN32EH5000FXZA Fast Track TroubleshootingDocument8 pagesSamsung UN32EH5000FXZA Fast Track TroubleshootingelelolNo ratings yet

- TVVVVVVVVVVVVVVVVDocument4 pagesTVVVVVVVVVVVVVVVVccstcesar100% (1)

- CAN Data Link (RENR5059)Document3 pagesCAN Data Link (RENR5059)PramodNo ratings yet

- TX-32PM1 and TX-28PM1 Service ManualDocument28 pagesTX-32PM1 and TX-28PM1 Service ManualSean GuyNo ratings yet

- Shorted Inverter Test (LS16, Ultra, Plus) : 2 OverviewDocument4 pagesShorted Inverter Test (LS16, Ultra, Plus) : 2 OverviewСергейNo ratings yet

- ASC and N2 Bus Networking and Troubleshooting GuideDocument48 pagesASC and N2 Bus Networking and Troubleshooting Guideanon_437983481No ratings yet

- LG 29fx4bl CH Cw62a SMDocument30 pagesLG 29fx4bl CH Cw62a SMJesus Garcia Hernandez100% (1)

- PLCDocument41 pagesPLCmuhaned190100% (3)

- K-tv14m3 y K-tv21m3 Konka - KalleyDocument7 pagesK-tv14m3 y K-tv21m3 Konka - Kalleyandresriveram77No ratings yet

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1Rating: 2.5 out of 5 stars2.5/5 (3)

- Analog Circuit Design: A Tutorial Guide to Applications and SolutionsFrom EverandAnalog Circuit Design: A Tutorial Guide to Applications and SolutionsRating: 3.5 out of 5 stars3.5/5 (6)

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2No ratings yet

- STEM: Science, Technology, Engineering and Maths Principles Teachers Pack V10From EverandSTEM: Science, Technology, Engineering and Maths Principles Teachers Pack V10No ratings yet

- Radio Shack TRS-80 Expansion Interface: Operator's Manual: Catalog Numbers: 26-1140, 26-1141, 26-1142From EverandRadio Shack TRS-80 Expansion Interface: Operator's Manual: Catalog Numbers: 26-1140, 26-1141, 26-1142No ratings yet

- Samsung Ud6400 Ud6500 Ud6900Document74 pagesSamsung Ud6400 Ud6500 Ud6900edsel72No ratings yet

- MITSUBISHI WD738 Service ManualDocument89 pagesMITSUBISHI WD738 Service ManualBryan Kentner100% (1)

- LG 32LD320H MFL66280202 - 0 LCD TV SMDocument64 pagesLG 32LD320H MFL66280202 - 0 LCD TV SMedsel72No ratings yet

- LG 42PQ20 Plasma TV Training Manual ADocument123 pagesLG 42PQ20 Plasma TV Training Manual Aedsel72No ratings yet

- Zenith Rf03gb Chassis p50w38 PlasmaDocument81 pagesZenith Rf03gb Chassis p50w38 Plasmaedsel72No ratings yet

- Panasonic Plasma FHD TV S & ST Series Technical Guide 2013Document111 pagesPanasonic Plasma FHD TV S & ST Series Technical Guide 2013edsel72100% (3)

- Panasonic DMR-EZ48 Service ManualDocument128 pagesPanasonic DMR-EZ48 Service ManualEmjay111100% (10)

- LG 42PQ20 Plasma TV Training Manual ADocument123 pagesLG 42PQ20 Plasma TV Training Manual Aedsel72No ratings yet

- HD61Z456 SchematicsDocument105 pagesHD61Z456 SchematicsTonimarie MilewskiNo ratings yet

- 42HL196 SVMDocument36 pages42HL196 SVMsalc4749No ratings yet

- 47LG50 Spec SheetDocument2 pages47LG50 Spec Sheetedsel72No ratings yet

- Sharp Lc-46sb54u Lc-C4654u SuppDocument6 pagesSharp Lc-46sb54u Lc-C4654u Suppedsel72No ratings yet

- LC40 - 60le810unDocument96 pagesLC40 - 60le810unarek__84No ratings yet

- Vizio L37HDTVDocument133 pagesVizio L37HDTVamcomtechNo ratings yet

- Rca DLP-PTV Itc250-Slim Profile PTV SMDocument48 pagesRca DLP-PTV Itc250-Slim Profile PTV SMedsel72No ratings yet

- Sharp - Lc-32le631e, Le40le631e - Le46le631e Led TV Training ManualDocument87 pagesSharp - Lc-32le631e, Le40le631e - Le46le631e Led TV Training Manualedsel72No ratings yet

- Mitsubishi HDTV Manual PDFDocument108 pagesMitsubishi HDTV Manual PDFilm112800No ratings yet

- Samsung Fpt5884x-Xaa Chasis F35a Plasma TV SMDocument75 pagesSamsung Fpt5884x-Xaa Chasis F35a Plasma TV SMedsel72No ratings yet

- Pioneer Pro 111fdDocument54 pagesPioneer Pro 111fdedsel72No ratings yet

- Rca L32WD22Document82 pagesRca L32WD22Kleiner FunkeNo ratings yet

- Philips+PL9 1+LCD-TVDocument72 pagesPhilips+PL9 1+LCD-TVedsel72100% (1)

- AZ2-F Training 988839102 - SMDocument97 pagesAZ2-F Training 988839102 - SMedsel72No ratings yet

- LCD TV Service ManualDocument150 pagesLCD TV Service Manualedsel72No ratings yet

- LC40 - 60le810unDocument96 pagesLC40 - 60le810unarek__84No ratings yet

- Panasonic TC 26 32lx70Document75 pagesPanasonic TC 26 32lx70edsel72No ratings yet

- Sharp Lc40le800un Lc46le810un Lc52810un Lc60le810un Led TV SM FinalDocument96 pagesSharp Lc40le800un Lc46le810un Lc52810un Lc60le810un Led TV SM Finaledsel72100% (1)

- Service Manual: LCD Color TelevisionDocument58 pagesService Manual: LCD Color Televisionedsel72100% (1)

- Samsung Lnt2332hx - lnt2632hx - lnt3232hx - lnt3732hx - lnt4032hx LCD TV Training ManualDocument98 pagesSamsung Lnt2332hx - lnt2632hx - lnt3232hx - lnt3732hx - lnt4032hx LCD TV Training Manualedsel72No ratings yet

- TH 50PX75U Service ManualDocument132 pagesTH 50PX75U Service ManualJack L. Freeman100% (1)

- Electrical Load Calculations For Residential Panel - Online Load CalculatorDocument8 pagesElectrical Load Calculations For Residential Panel - Online Load CalculatorTabrez AlamNo ratings yet

- Chenbro: ES340 Chassis User ManualDocument21 pagesChenbro: ES340 Chassis User ManualEric NgNo ratings yet

- Danfoss HST Public Documents Web Content c022873Document8 pagesDanfoss HST Public Documents Web Content c022873Timon2005100% (1)

- RL Optica P 80 Led PDFDocument1 pageRL Optica P 80 Led PDFDek AmeNo ratings yet

- Quectel GSM EVB User Guide V3.4Document35 pagesQuectel GSM EVB User Guide V3.4smhzzNo ratings yet

- Battery DesulfatorsDocument4 pagesBattery DesulfatorsAlex MaianoNo ratings yet

- SDANDR696: Double DIN Android Stereo Receiver & Camera DVR SystemDocument32 pagesSDANDR696: Double DIN Android Stereo Receiver & Camera DVR SystemShirlieNo ratings yet

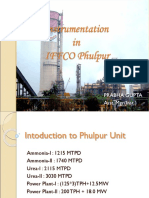

- Inst PrabhaDocument29 pagesInst Prabharaj guptaNo ratings yet

- TS AL BrochureDocument10 pagesTS AL BrochureAnupa Vinny100% (1)

- Alstom Otcf Ansi WebDocument8 pagesAlstom Otcf Ansi WebReji KurianNo ratings yet

- ELEX1 Lecture 01 PDFDocument10 pagesELEX1 Lecture 01 PDFBarn Go100% (1)

- Mechanical Engineering - Final PDFDocument248 pagesMechanical Engineering - Final PDFRubal SharmaNo ratings yet

- Manual For Canon EOS 1DsDocument176 pagesManual For Canon EOS 1DspriscillapumpkinNo ratings yet

- Automatic Control (ME1401)Document2 pagesAutomatic Control (ME1401)Mehroos AliNo ratings yet

- Sp540 (V) Vol. v.1 - Bid Drawings (Electrical Works) 1Document142 pagesSp540 (V) Vol. v.1 - Bid Drawings (Electrical Works) 1Jay Dee (JSD)No ratings yet

- Chapter 9 - Benzene and Its DerivativesDocument71 pagesChapter 9 - Benzene and Its Derivativesuypaul97No ratings yet

- MODULE 3 Optical Sources 1Document55 pagesMODULE 3 Optical Sources 1Yashavantha K MNo ratings yet

- Chapter 1Document36 pagesChapter 1Syazwan HafidziNo ratings yet

- CompactRIO CRIO-FRC 8 SlotDocument25 pagesCompactRIO CRIO-FRC 8 SlotHieu LENo ratings yet

- Sonos Sounder BeaconDocument1 pageSonos Sounder BeaconLe Quang AnNo ratings yet

- SCD-XB940 Service Manual - Comprehensive Guide to Repairing Sony Super Audio CD PlayerDocument73 pagesSCD-XB940 Service Manual - Comprehensive Guide to Repairing Sony Super Audio CD PlayerPietertje58No ratings yet

- Arduino Portenta H7: FeaturesDocument22 pagesArduino Portenta H7: Featuresssprakoso_gmailNo ratings yet

- Jaguar X-Type Body - From VIN C0034Document19 pagesJaguar X-Type Body - From VIN C0034Catalin TanaseNo ratings yet

- ECE 410 Digital Signal Processing D. Munson University of Illinois A. SingerDocument26 pagesECE 410 Digital Signal Processing D. Munson University of Illinois A. SingerFreddy PesantezNo ratings yet

- Flowmeter MT WDocument36 pagesFlowmeter MT WRangga K NegaraNo ratings yet

- TCH Availability Assignment Success RateDocument6 pagesTCH Availability Assignment Success RateMohamad SupriogiNo ratings yet

- HTML5 Next GenerationDocument18 pagesHTML5 Next GenerationChristianNo ratings yet

- 4th Quarterly Test Grade 9 AnsweredDocument2 pages4th Quarterly Test Grade 9 AnsweredHei Dee60% (5)

- Matlab Books - TittlesDocument2 pagesMatlab Books - TittlesVenugopal KonapalaNo ratings yet

- Communication Aids and Strategies Using Tools of TechnologyDocument42 pagesCommunication Aids and Strategies Using Tools of TechnologyAngelo AmayNo ratings yet