Professional Documents

Culture Documents

P Boulden Et Al

Uploaded by

Andy AcousticOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

P Boulden Et Al

Uploaded by

Andy AcousticCopyright:

Available Formats

Richmond Line Alliance A Case Study in Effective Project

Development and Delivery of a Complete Rail System

Mark Smith

MBA, CPEng, MIEAust, MIET, AMIRSE

AECOM

Peter Boulden

BEng (Hons), CPEng, MIEAust

AECOM

SUMMARY

This paper will present a case study of the Richmond Line Alliance in the delivery and development of a

major project underpinning urban passenger rail growth in the Sydney metropolitan area. A number of the

key advantages of a holistic Rail Systems approach to project delivery will be presented together with an

insight into the practical application of, and benefits from, an integrated project assurance philosophy

executed from a technical, safety and quality perspective. The paper will provide context from the earliest

stages of development through to detailed design and construction.

The Richmond Line Duplication Project is part of the NSW Governments Rail Clearways Program. It will

provide an additional rail track between Quakers Hill and Vineyard in north-west Sydney and includes

relocated Schofields Station, an upgrade of Riverstone Station and new Vineyard Station. The project will

provide capacity for additional peak services on the Richmond Branch Line to cater for future passenger

demand. The Richmond Line Alliance has been formed to deliver Stage 1 of this project which includes

construction of a new station and additional (duplicated) track between Quakers Hill Station and the existing

Schofields Station, as shown below.

The Richmond Line Duplication is being delivered on behalf of the NSW Government by Transport

Construction Authority (TCA) in an alliance known as the Richmond Line Alliance, which includes TCA,

Leighton Contractors, AECOM, Sinclair Knight Merz, MVM Rail and Ansaldo STS.

Conference On Railway Engineering

Wellington, Sept 12-15, 2010

Mark Smith and Peter Boulden

AECOM

Richmond Line Alliance A Case Study in Effective Project

Development and Delivery of a Complete Rail System

1

INTRODUCTION

The paper will use the Richmond Line Duplication

as a relevant case study to discuss good industry

practice, continuous improvement and lessons

learnt across the following facets of delivery:

client and project sponsor representation. It

also requires a solid platform of effective

communications and a means of testing the

designed outputs to expose conflicts or issues

of compatibility and consistency across the

many interfaces that constitute the project.

Interdisciplinary Coordination & Control;

Project Controls, Design Validation and

Product assurance (including stakeholder

management);

Value Engineering;

Designing for constructability, operability and

maintainability & safety; and

Project Safety Culture.

2

PROJECT DELIVERY

The alliance concept brings together designers,

architects, urban designers and constructors from

all relevant engineering disciplines into a single

integrated team operating under a common

incentivised commercial and delivery framework.

As is typical in alliances of this nature,

performance objectives are explicit and

established as measures through integral Key

Performance Indicators (KPIs) which are

designed to govern and motivate all aspects of

organisational behaviour and execution of the

works. In the earliest stages of conception

alliances typically establish a set of norms that

govern and align values and expectations

throughout the team.

In the case of Richmond Line Alliance (RLA) the

team were tasked to both define and execute

project scope and in doing so were challenged to

adopt the highest standards of project governance

in delivering an assured service and an endproduct aligned fully with user requirements that

met all engineering, design and implementation

criteria and presented value to stakeholders. The

processes key to meeting these project objectives

are outlined below.

2.1

Interdisciplinary

Coordination

and

Control

Front and centre of effective rail systems

design is the key objective to ensure

consistent Inter-Disciplinary Coordination

(IDC) which accounts for the sometimes

complex interaction between engineering

disciplines and features in and around the rail

corridor both existing and new. The key to

effective IDC is in the implementation of a

simple and agile system that can track and

flex with the volume and rate of change that

naturally occurs, particularly during the early

stages of the project while scope and

requirements are being defined. In particular

for IDC to be effective, the process requires

the complete subscription or buy in of all

design and construction functions as well as

In the case of RLA, the vehicle for IDC was a

series of workshops remitted to review the

latest designs. An inclusive and facilitated

process was established involving the linear

navigation of the rail corridor from beginning to

end of the project scope. The value emerged

as a result of the active discussion and

determination of engineering interface

solutions in and around pinch-points / conflicts

or data-gaps and / or ambiguities. Issues

were recorded on a simple spreadsheet and

allocated to an appropriate owner to resolve.

The process was iterated on a weekly basis

with the key objective to regularly repeat the

reviews as more information, detail and

certainty was injected into the design, while

actively driving the issues count to zero.

The interface diagram below illustrates the key

interfaces managed throughout

design

development on RLA.

Con

Sig

Buil

Co

Elec

Stru

Civi

Trac

Arc

Legend:

Con = Control Systems

Sig = Signalling

Co = Communications

Buil=Building& Building Services

Elec=Electrification,OHW & E&B

Stru = Structures

Civi = Civil and Earthworks

Trac = Track

Arch = Architecture & Urban Design

Conference On Railway Engineering

Wellington, Sept 12-15, 2010

Mark Smith and Peter Boulden

AECOM

Richmond Line Alliance A Case Study in Effective Project

Development and Delivery of a Complete Rail System

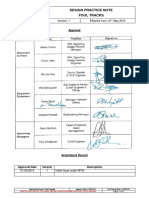

2.2

A key facet of IDC also involved engineering

ownership of the interfaces with discipline

specialists. This was realised by implementing a

mandatory sign-off at each design submission

stage whereby the lead designer was called upon

to review and certify (as far as IDC goes) that the

interfacing design was compliant and compatible.

This collaborative cross-function sign-off process

was key to the consistent understanding and

management of interface issues and implications.

Culturally and behaviourally the process served to

further reduce barriers between disciplines and

actively encouraged a multi-disciplinary approach

and attitude, to support effective rail system

definition.

The active IDC process was implemented to good

effect within RLA. Examples of tangible benefits

resulting from this value add process include:

Location & base construction of

telecommunications building at Schofields

Station (determining optimum position relative

to track, services and stage-works);

Provision of OHW Structure bases clear of

utilities and drainage routes and the

assessment of changes in location;

Final positioning of HV Aerial transmission

line catering for pole base positioning,

earthing and bonding infrastructure, and

location of the cable relative to existing and

proposed buildings and structures in the area

(with a view to maintaining adequate

clearance), as well as catering for the impact

of a new public footpath and cycle-way

introduced as part of the project; and

Optimum provision and location of Under

Line Crossings (ULXs) for the containment of

signalling, communications, power and utility

services determining best fit volume type

and positioning of these assets.

Project Controls, Design Validation and

Product Assurance

2.2.1 Project Controls

In the case of RLA, the owner (RailCorp), the

client and alliance partner (TCA) and the

alliance itself established and operated a

defined suite of processes within which project

development, design and implementation were

executed. RLA integrated these processes

into a single cohesive programme and

scheduling system

which administered

delivery to the client at all stages. Importantly,

RLA also resourced the Project Controls task

with a team responsible for governing delivery

and interface approvals throughout. Key to

success here was the adoption of a

Production Line approach which recognised

the sheer volume and production of design

packages

for

approval

and

ensured

stewardship for timely delivery.

This

generated a total of 81 design packages in the

26 weeks from July 2009 to December 2009.

2.2.2 Design Validation

The Richmond Line Duplication design is

progressed through distinct submission and

approval stage-gates at Pre-Concept design /

Concept design / Reference design / 30%

detailed design / 70% detailed design / 100%

detailed design and finally Approved for

Construction phases. At all stages, the owner

executes a right of review across each and

every of the multiple design packages. This

ensures requirements and preferences are

effectively articulated in the first instance. The

process of capturing and actioning comments

raised is voluminous and can be complex,

considering the inter-disciplinary interactions

of change. In addition, emerging or refined

information from site regarding the existing

asset (design inputs) can also require

accommodation as the designer seeks to

present the most accurate and up to date

design.

In the RLA, a key Critical Success Factor was

the early recognition of the complexity and

programme style discipline required to

manage client communications in this respect.

While the mechanics were managed using

standard tools of the trade such as

spreadsheets

and

tracker

programme

reporting the real differentiator was the

effective buy-in of the RailCorp owner and

approval body of the processes used by RLA

to manage client communications. This

required the consistent engagement of

RailCorps

asset

managers,

operators,

engineers and project management team. As

well as presenting the design stages and

effecting a project solution acceptable across

a wide range of stakeholders the project

succeeded at a human level, with issues and

Conference On Railway Engineering

Wellington, Sept 12-15, 2010

Mark Smith and Peter Boulden

AECOM

Richmond Line Alliance A Case Study in Effective Project

Development and Delivery of a Complete Rail System

user scenarios and considerations. This was

particularly relevant for interfaces and features

in and around Station areas. In the case of

RLA, this protocol leveraged particular benefits

across the following examples:

comments being actively resolved through

proactive interface at all levels with formal

communications and protocol in support. The

leverage of the relationships developed with

the owner (RailCorp) has effectively facilitated

preferential outcomes for RLA going forward.

Maintenance Access Track:

RLA

introduced a maintenance access route

along the western edge of the newly

duplicated railway. This proved to be a

complex exercise of accommodating the

owners

access

and

maintenance

requirements as well as negotiating

sufficient

land

envelope

with

neighbouring land-owners as part of the

land-acquisition process. The complexities

concerning the definition of this asset were

eased through clear and consistent lines

of communication with the operators and

maintainers within RailCorp who were able

to represent and interpret their user

specifications, addressing aspects such as

vehicular access (for maintenance and

renewal),

planned

and

emergency

conditions, train driver access and egress.

This enabled RLA to conduct land

negotiations in the knowledge that

operational as well as engineering

considerations were accounted for; and

2.2.3 Product Assurance

Modern project development and delivery

recognises compliance to relevant standards

or codes as only the first step towards the

presentation of an assured product. By

definition, this is characterised by an output

that is robust, carries a high degree of

certainty and provides reassurance to

stakeholders that concerns have been

addressed and expectations met many of

which are not captured by standards or codes.

In the case of RLA, the client, TCA deployed

assurance engineers into the team whose role

was to effectively verify and challenge the

design outputs applying a layer of rigour such

that the designed output was robust to go

forward for owner (RailCorp) consideration

and approval. In addition, RLA provided a

suite of Operational, Technical & Safety

Arguments in support of certain aspects of the

design. This had the effect of challenging the

design team to consider the designed-product

from a wider perspective and to ensure it was

robust when tested by a whole host of end-

New Schofields Station: The definition of

this major asset was key area where

operational and assurance engagement

proved invaluable. At the early concept

stages, the definition of the station

envelope to the west of the existing

corridor was key to determining and

defining land acquisition parameters. Once

the outline was determined, the alignment

was defined. This process called for the

engagement of RailCorp operators and

Station Working Group to develop all

aspects of the station asset specification.

Among the many issues tackled and

resolved was the definition of curvature of

the alignment through the station itself.

While within standards, the curve

presented concern and was tested by

developing technical and safety arguments

that assessed and presented risk / cost

and value for both the curved and

straightened scenarios. The resulting

analysis supported the original (slight)

curved provision and this was ultimately

authorised by stakeholders as the

preferred concept going forward.

2.3

Value Engineering (VE)

RLA engaged VE effort from the earliest

stages of project development. Operating as a

defined work-stream within the alliance, VE

was realised using staged and facilitated

workshops involving designers, constructors,

Conference On Railway Engineering

Wellington, Sept 12-15, 2010

Mark Smith and Peter Boulden

AECOM

Richmond Line Alliance A Case Study in Effective Project

Development and Delivery of a Complete Rail System

operators, project sponsors and client / owner

stakeholders. The process involved the

traditional development of a shopping list of

initiatives to increase value and / or reduce

cost. This list was then iteratively reduced

during a programme of focussed sessions as

each initiative was tested by developed

feasibility, value and cost reduction criteria.

The key advantage the VE process imposed in

the case of RLA centred on the early (preconcept) stage of engagement. This led to VE

initiatives being adopted proactively into the

scope and accounted for within the earliest

iterations of the Target Outturn Cost (TOC).

Examples of these included:

Building 11kV capability in Stage 1

duplication to Schofields to enable final

commissioning of 11kV in Stage 2

duplication to Vineyard;

Installing HV underground within the

combined services route in some areas,

but aerial in others; and

Location of the required Traction Power

Substation. At the very early concept

stages, this asset was located to the west

of the corridor and factored into the land

acquisition requirements. Subsequent reengineering regarding this asset resulted

in relocation to the east of the corridor

within a vacant lot. The key driver for this

was to optimise position relative to the rail

corridor and minimise land acquisition

envelope and costs to the project.

2.4

Designing

for

constructability,

operability and maintainability and

Safety

Working definitions of these aspects of design

are as follows:Constructability: The ability to build the

designed in an optimum fashion within set

parameters (time, money, track access

etc);

Operability:- The degree to which the

user can realise network functionality and

train movements as defined for the project;

Maintainability:- The degree to which the

completed project and asset configuration

meets the owners requirements in terms of

access, asset life and performance. Issues

such as access and the deployment of

new or dissimilar technologies come into

play here; and

Safety In Design:- is a concept that

encourages (designers in particular) to

"design

out"

risks

during

design

development. The concept supports the

view that along with quality, and cost;

safety is determined during the design

stage.

On RLA, the design output at each stage was

actively tested by each of these parameters,

with reports generated as part of the

submissions detailing the project response

against each feature. Design development

was characterised by engaging client, owners

and operators with designers and constructors

to test the design against the terms of

reference specified at project definition. In the

area of Safety In Design RLA deployed a

number of TCA prescribed structured

processes and tools such as Preliminary

Hazard Analysis and Risk Assessment and

Quantification of the designed product. Of

particular note was the degree to which the

designers embraced and contributed to the

process. It was noted that RLA succeeded in

bringing Safety In Design to life, through the

deployment of a structured Risk ID Risk

Assessment Mitigation Allocation

Transfer protocol which drove the design

team to design out risk as far as was

possible. Once the process was exhausted

the risk was either allocated or transferred as

appropriate, without being lost.

A good example of where RLA brought Safety

In Design to present project benefit was in the

determination of OHW structure position, at

the concept design stage. A number of OHW

structures required to support the duplication

were reviewed with RailCorp as part of an

iterative hazard and risk review process.

Where some structures were found to be inbetween existing and proposed track sections

Conference On Railway Engineering

Wellington, Sept 12-15, 2010

Mark Smith and Peter Boulden

AECOM

the specific locations were re-engineered to

relocate the structures and prevent the

requirement for asset access between two live

tracks.

2.5

Project Safety Culture

RLA led safety from the front at all stages of

project development and delivery.

Developing, refining and publicising the

principles

governing

behaviour

and

expectations was addressed initially. The

safety culture programme was extensively

launched across all levels of the business

using Safety Passports as a tool to lead,

engage and personalise the safety message

such that commitment was facilitated. This

cultural paradigm was developed and

maintained through a concerted programme of

group and individual communications relating

all aspects of work and life to the safety

message underpinning the campaign.

Richmond Line Alliance A Case Study in Effective Project

Development and Delivery of a Complete Rail System

value-adding aspect of the designers portfolio

of deliverables and added a critical dimension

of meaning and relevance to the earliest

stages of design which is the ideal point in

the project lifecycle to inject this level of

thinking and approach.

The Project Safety Culture in RLA acted as a

positive enabler to ensure risks or safety

consideration presented by the rail system to

the constructor, client, owner, operator and the

travelling public were given due consideration

at the earliest stages of design

3

CONCLUSION

The Richmond Line Alliance has completed the

vast majority of the design task and is mobilising

major construction effort and resources ahead of

the planned 2011 completion for Stage 1.

Underpinning

this

performance

is

the

uncompromising adoption of the processes

described in this paper (among many others) as

an integral aspect of alliance operation. In addition

a programme and delivery discipline and focus

permeates the team as a key value and is a key

cornerstone of the delivery ethos from which RLA

has derived real benefit.

Considering the project, as delivered by RLA

both as a delivery manager on the inside and an

observer on the outside it is logical to conclude

that project performance, as characterised by the

designed and constructed legacy benefits

significantly from the adoption of processes as

described in this paper. Furthermore, this

reinforces the premise that successful project

development and delivery is so much more than

just technical design. This is a point of principle

that owners, clients, constructors and designers

alike should consider going forward.

From

a

designers

perspective,

RLA

successfully created a culture whereby safety

became a directly relevant parameter and

aspect to the design task. Designers were

effectively engaged to problem solve from a

safety perspective an activity hitherto the

domain of the constructor for the most part.

This cultural stamp established by RLA

enabled Safety In Design to be a tangible and

Conference On Railway Engineering

Wellington, Sept 12-15, 2010

You might also like

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- High Speed Train DerailmentsDocument10 pagesHigh Speed Train DerailmentsAndy AcousticNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Vehicle Activated SignsDocument15 pagesVehicle Activated SignsAndy AcousticNo ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- New Evolutions For High Speed Rail Line Bridge Design Criteria and Corresponding Design ProceduresDocument6 pagesNew Evolutions For High Speed Rail Line Bridge Design Criteria and Corresponding Design ProceduresAndy AcousticNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- Reducing railway risk through strategic contractingDocument5 pagesReducing railway risk through strategic contractingAndy AcousticNo ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- B JohnstonDocument9 pagesB JohnstonAndy AcousticNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- M McDonald Et AlDocument10 pagesM McDonald Et AlAndy AcousticNo ratings yet

- R JusticeDocument9 pagesR JusticeAndy AcousticNo ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- KiwiRail bridge inspection standards benchmarked internationallyDocument10 pagesKiwiRail bridge inspection standards benchmarked internationallyAndy AcousticNo ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- New Zealand's ETCS ExperienceDocument7 pagesNew Zealand's ETCS ExperienceAndy AcousticNo ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- G Perelmuter Et AlDocument12 pagesG Perelmuter Et AlAndy AcousticNo ratings yet

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- R Park Et AlDocument9 pagesR Park Et AlAndy AcousticNo ratings yet

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Design of Culvert and Small Bridge Rehabilitation For The Task and Required Lifespan - and The Implications OnDocument5 pagesDesign of Culvert and Small Bridge Rehabilitation For The Task and Required Lifespan - and The Implications OnAndy AcousticNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- CPN 25 - Fly Ash and Its Use in ConcreteDocument12 pagesCPN 25 - Fly Ash and Its Use in ConcreteAndy AcousticNo ratings yet

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- Bridge Girders-Strength at TransferDocument11 pagesBridge Girders-Strength at TransferAndy AcousticNo ratings yet

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- CPN 25 - Fly Ash and Its Use in Concrete PDFDocument8 pagesCPN 25 - Fly Ash and Its Use in Concrete PDFAndy AcousticNo ratings yet

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Building The Case For Rail - The Wellington Regional RailDocument12 pagesBuilding The Case For Rail - The Wellington Regional RailAndy AcousticNo ratings yet

- Prequalification of Mechanical Splices For Reinforcing Bars in Seismic ConditionsDocument8 pagesPrequalification of Mechanical Splices For Reinforcing Bars in Seismic ConditionsAndy AcousticNo ratings yet

- Stress-Wave Testing of PilesDocument5 pagesStress-Wave Testing of PilesDae Yeol KimNo ratings yet

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- R Bucher Et AlDocument9 pagesR Bucher Et AlAndy AcousticNo ratings yet

- R JusticeDocument9 pagesR JusticeAndy AcousticNo ratings yet

- MTR Int Land Use & Planning Core2008Document7 pagesMTR Int Land Use & Planning Core2008Andy AcousticNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Column Base Plate DesignDocument9 pagesColumn Base Plate DesignDeepakDhimanNo ratings yet

- Fatigue Design Bridges AustraliaDocument13 pagesFatigue Design Bridges Australiatsh3718No ratings yet

- Engg Spreadsheet NewDocument278 pagesEngg Spreadsheet NewAndy Acoustic100% (2)

- Bridge Technical Note On Collision ProtectionDocument9 pagesBridge Technical Note On Collision ProtectionAndy AcousticNo ratings yet

- Early Detection of Wheel Flats Using Wagon BodyDocument10 pagesEarly Detection of Wheel Flats Using Wagon BodyAndy AcousticNo ratings yet

- Repair & Modification of NZ Railway TunnelDocument12 pagesRepair & Modification of NZ Railway TunnelAndy AcousticNo ratings yet

- Pachora - Jamner Rail LineDocument6 pagesPachora - Jamner Rail LineHiraBallabhNo ratings yet

- Transformative Marketing: The Next 20 Years: V. KumarDocument12 pagesTransformative Marketing: The Next 20 Years: V. KumarFarsia Binte AlamNo ratings yet

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Is 174052020Document10 pagesIs 174052020agni.tuphanNo ratings yet

- High-Output Nexus Sounders & Beacons for Industrial ApplicationsDocument3 pagesHigh-Output Nexus Sounders & Beacons for Industrial Applicationsmathan_aeNo ratings yet

- Year Book 2018-19-English PDFDocument176 pagesYear Book 2018-19-English PDFFaisal Ahmed AhmedNo ratings yet

- Modern Traction Systems for Electric TrainsDocument30 pagesModern Traction Systems for Electric TrainsMuhammad Umair100% (1)

- Design Cost-Effective Aerospace Impact Test Drop TowerDocument70 pagesDesign Cost-Effective Aerospace Impact Test Drop TowerFABIAN FIENGONo ratings yet

- NIST-007.2.1 Infrastructure Drafting Standards Rev 1Document21 pagesNIST-007.2.1 Infrastructure Drafting Standards Rev 1CK TangNo ratings yet

- Monopoly of Indian RailwaysDocument18 pagesMonopoly of Indian RailwaysDevanshu TekriwalNo ratings yet

- 22 Trains from Vijayawada to RamagundamDocument2 pages22 Trains from Vijayawada to RamagundamSathish ChNo ratings yet

- L1-NAM-INS-030 - Foul Tracks Ver 1Document6 pagesL1-NAM-INS-030 - Foul Tracks Ver 1CK TangNo ratings yet

- The LanguageLab Library - The Oxford Duden Pictorial English DictionaryDocument821 pagesThe LanguageLab Library - The Oxford Duden Pictorial English DictionaryANA SOFIA FERNANDEZ67% (3)

- Etihad Rail 2F1 O & M Depot Project - Overview - 1Document10 pagesEtihad Rail 2F1 O & M Depot Project - Overview - 1Mustafa Hassan MalikNo ratings yet

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- BUILDING CONSTRUCTION and Maintenance EngineeringDocument65 pagesBUILDING CONSTRUCTION and Maintenance EngineeringAnkur Singh RajaNo ratings yet

- Man Riding Car RopeDocument7 pagesMan Riding Car RopeRahul GNo ratings yet

- Metro Railway BookletDocument12 pagesMetro Railway BookletNikhil FutaneNo ratings yet

- Scope of Bearings in Modern Four WheelersDocument67 pagesScope of Bearings in Modern Four Wheelersviveksharma19767% (3)

- Western Railway: ST NDDocument5 pagesWestern Railway: ST NDMUKESH SOLANKINo ratings yet

- Advantages of Road TransportationDocument4 pagesAdvantages of Road TransportationERICK MUGAMBINo ratings yet

- 23 Letter 66kv EquipmentDocument2 pages23 Letter 66kv EquipmentpavanNo ratings yet

- Letter To CommissionersDocument4 pagesLetter To CommissionersTyler SilvyNo ratings yet

- Padam SinghDocument28 pagesPadam SinghSimran KashyapNo ratings yet

- History of Indian RailwaysDocument12 pagesHistory of Indian Railwaysaaquib ansariNo ratings yet

- CanRail - User Guide v1.1Document51 pagesCanRail - User Guide v1.1Alex GeorgeNo ratings yet

- GERM8000-master-module Iss 2 PDFDocument1,452 pagesGERM8000-master-module Iss 2 PDFManoj Kumar MNo ratings yet

- MDDM WagonDocument2 pagesMDDM WagonMilovan SlavkovicNo ratings yet

- Pakistan Railway CrisisDocument31 pagesPakistan Railway CrisisEhsan UllahNo ratings yet

- Advantanges and Disadvantages of The Modes of TransportationDocument4 pagesAdvantanges and Disadvantages of The Modes of TransportationNathalie Sofia Caballero NietoNo ratings yet

- How Track Circuits Detect and Protect TrainsDocument7 pagesHow Track Circuits Detect and Protect Trainstco_99100% (1)

- Splice Plate Details Rock Bolt Sections Elevations PlansDocument1 pageSplice Plate Details Rock Bolt Sections Elevations PlansRohit BandagaleNo ratings yet