Professional Documents

Culture Documents

CHE 414 Principles of Plant Design I Part 4A

Uploaded by

ifiokCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

CHE 414 Principles of Plant Design I Part 4A

Uploaded by

ifiokCopyright:

Available Formats

Covenant University Department of Chemical Engineering . CHE 414: Principles of Plant Design - Daniel Ayo, PhD.

Course Outline

WEEK

TOPIC

Process Design Principles

Flow-sheeting,

Piping and instrumentation.

Chemical Engineering Design of Mass and

Heat Transfer Equipment (Plate columns,

absorption towers, distillation columns, heat

exchangers, evaporators etc).

Mechanical Design of Equipments Pressure vessels, columns, storage tanks,

heat exchanger, etc.

Costing and Project Evaluation

1 2 3 4 5 6 7 8 9 10 11 12 13 1

4

Covenant University Department of Chemical Engineering . CHE 414: Principles of Plant Design - Daniel Ayo, PhD.

Chemical Engineering Design of Mass and Heat Transfer Equipment

Part A

Covenant University Department of Chemical Engineering . CHE 414: Principles of Plant Design - Daniel Ayo, PhD.

Chemical Engineering Design of Mass and Heat Transfer Equipment

Covenant University Department of Chemical Engineering . CHE 414: Principles of Plant Design - Daniel Ayo, PhD.

Distillation Column Design

The design of a distillation column can be divided into the following steps:

1. Specify the degree of separation required: set product specifications.

2. Select the operating conditions: batch or continuous; operating pressure.

3. Select the type of contacting device: plates or packing.

4. Determine the stage and reflux requirements: the number of equilibrium

stages.

5. Size the column: diameter, number of real stages.

6. Design the column internals: plates, distributors, packing supports.

7. Mechanical design: vessel and internal fittings.

The principal step will be to determine the stage and reflux requirements.

This is a relatively simple procedure when the feed is a binary mixture, but

a complex and difficult task when the feed contains more than two

components (multicomponent systems).

Chemical Engineering Design of Mass and Heat Transfer Equipment

Covenant University Department of Chemical Engineering . CHE 414: Principles of Plant Design - Daniel Ayo, PhD.

In the section below the feed, the more volatile components are stripped from the

liquid; this is known as the stripping section.

Above the feed, the concentration of the more volatile components is increased; this

is called the enrichment, or more commonly, the rectifying section.

Columns are occasionally used with more than one feed, and with side streams

withdrawn at points up the column. This does not alter the basic operation but

complicates the analysis of the process to some extent.

Chemical Engineering Design of Mass and Heat Transfer Equipment

Covenant University Department of Chemical Engineering . CHE 414: Principles of Plant Design - Daniel Ayo, PhD.

If the process requirement is to strip a volatile component from a relatively nonvolatile solvent, the rectifying section may be omitted, and the column would then

be called a stripping column.

In some operations, where the top product is required as a vapor, only sufficient

liquid is condensed to provide the reflux flow to the column, and the condenser is

referred to as a partial condenser.

When the liquid is totally condensed, the liquid returned to the column will have

the same composition as the top product. In a partial condenser the reflux will be in

equilibrium with the vapor leaving the condenser.

Virtually pure top and bottom products can be obtained in a single column from a

binary feed, but where the feed contains more than two components, only a single

pure product can be produced, either from the top or bottom of the column.

Several columns will be needed to separate a multi component feed into its

constituent parts.

Chemical Engineering Design of Mass and Heat Transfer Equipment

Covenant University Department of Chemical Engineering . CHE 414: Principles of Plant Design - Daniel Ayo, PhD.

Reflux Considerations

The number of stages required for a given separation will be dependent on

the reflux ratio used.

In an operating column, the effective reflux ratio will be increased by

vapor condensed within the column due to heat leakage through the walls.

With a well lagged column, the heat loss will be small, and no allowance is

normally made for this increased flow in design calculations

Chemical Engineering Design of Mass and Heat Transfer Equipment

Covenant University Department of Chemical Engineering . CHE 414: Principles of Plant Design - Daniel Ayo, PhD.

Total Reflux

Total reflux is the condition when all the condensate is returned to the

column as reflux: no product is taken off and there is no feed.

At total reflux the number of stages required for a given separation is the

minimum at which it is theoretically possible to achieve the separation.

It is a useful guide to the likely number of stages that will be needed.

Columns are often started up with no product takeoff and operated at total

reflux until steady conditions are attained. The testing of columns is also

conveniently carried out at total reflux.

Chemical Engineering Design of Mass and Heat Transfer Equipment

Covenant University Department of Chemical Engineering . CHE 414: Principles of Plant Design - Daniel Ayo, PhD.

Minimum Reflux

As the reflux ratio is reduced, a pinch point will occur at which the separation

can be achieved only with an infinite number of stages. This sets the minimum

possible reflux ratio for the specified separation

Chemical Engineering Design of Mass and Heat Transfer Equipment

Covenant University Department of Chemical Engineering . CHE 414: Principles of Plant Design - Daniel Ayo, PhD.

Optimum Reflux Ratio

Practical reflux ratios will lie somewhere between the minimum for the

specified separation and total reflux. The designer must select a value at

which the specified separation is achieved at minimum cost. Increasing the

reflux reduces the number of stages required, and hence the capital cost, but

increases the service requirements (steam and water) and the operating

costs. The optimum reflux ratio will be that which gives the lowest annual

operating cost. No hard and fast rules can be given for the selection of the

design reflux ratio, but for many systems the optimum will lie between 1.2

and 1.5 times the minimum reflux ratio.

For new designs, where the ratio cannot be decided from past experience,

the effect of reflux ratio on the number of stages can be investigated using

the shortcut design methods. This will usually indicate the best value to use

in more rigorous design methods.

Chemical Engineering Design of Mass and Heat Transfer Equipment

Covenant University Department of Chemical Engineering . CHE 414: Principles of Plant Design - Daniel Ayo, PhD.

Feed-Point Location

The precise location of the feed point will affect the number of stages required for

a specified separation and the subsequent operation of the column. As a general

rule, the feed should enter the column at the point that gives the best match

between the feed composition (vapor and liquid if two phases) and the vapor and

liquid streams in the column. In practice, it is wise to provide two or three feedpoint nozzles located around the predicted feed point to allow for uncertainties in

the design calculations and data, and possible changes in the feed composition

after start-up.

Chemical Engineering Design of Mass and Heat Transfer Equipment

Covenant University Department of Chemical Engineering . CHE 414: Principles of Plant Design - Daniel Ayo, PhD.

Selection of Column Pressure

Except when distilling heat-sensitive materials, the main consideration when selecting

the column operating-pressure will be to ensure that the dew point of the distillate is

above that which can be easily obtained with the plant cooling water. The maximum,

summer temperature of cooling water in US and Europe is usually taken as 300C. (In

Nigeria it depends on location of the plant. Well work with 300C for convenience). If

this means that high pressures will be needed, the provision of refrigerated brine cooling

should be considered. Vacuum operation is used to reduce the column temperatures for

the distillation of heat-sensitive materials and where very high temperatures would

otherwise be needed to distil relatively non-volatile materials.

When the stage and reflux requirements are calculated, it is usual to take the operating

pressure as constant throughout the column. In vacuum columns, the column pressure

drop will be a significant fraction of the total pressure, and the change in pressure up the

column should be allowed for when calculating the stage temperatures. This may require

a trial-and-error calculation, as clearly the pressure drop cannot be estimated before an

estimate of the number of stages is made.

Chemical Engineering Design of Mass and Heat Transfer Equipment

Covenant University Department of Chemical Engineering . CHE 414: Principles of Plant Design - Daniel Ayo, PhD.

CONTINUOUS DISTILLATION: BASIC PRINCIPLES

Chemical Engineering Design of Mass and Heat Transfer Equipment

Covenant University Department of Chemical Engineering . CHE 414: Principles of Plant Design - Daniel Ayo, PhD.

Equilibrium constants:

yi = Kixi

The performance of real stages is related to an equilibrium

stage by the concept of:

plate efficiencies for plate contactors and ;

height of an equivalent theoretical plate for packed

columns

Also summation equation for the liquid and vapor

compositions:

xi,n=yi,n=1

Chemical Engineering Design of Mass and Heat Transfer Equipment

Covenant University Department of Chemical Engineering . CHE 414: Principles of Plant Design - Daniel Ayo, PhD.

MESH equations for the stage:

Material balance:

Equilibrium: yi = Kixi

Summation: xi,n=yi,n=1

Heat (energy) balance equations.

MESH equations can be written for each stage and for the reboiler and condenser. The

solution of this set of equations forms the basis of the rigorous methods that have been

developed for the analysis for staged separation processes

Chemical Engineering Design of Mass and Heat Transfer Equipment

Covenant University Department of Chemical Engineering . CHE 414: Principles of Plant Design - Daniel Ayo, PhD.

Dew Points and Bubble Points

For binary systems the equations can be solved more readily because the

component compositions are not independent; fixing one fixes the other.

For multicomponent mixtures, the temperature that satisfies these equations, at

a given system pressure, must be found by trial and error.

Chemical Engineering Design of Mass and Heat Transfer Equipment

Covenant University Department of Chemical Engineering . CHE 414: Principles of Plant Design - Daniel Ayo, PhD.

Equilibrium Flash Calculations

Chemical Engineering Design of Mass and Heat Transfer Equipment

Covenant University Department of Chemical Engineering . CHE 414: Principles of Plant Design - Daniel Ayo, PhD.

Take the equilibrium data from the De Priester charts given in Chapter 8 of

text (pages 467 and 468)

Solution: Example 11.1 in text

Chemical Engineering Design of Mass and Heat Transfer Equipment

Covenant University Department of Chemical Engineering . CHE 414: Principles of Plant Design - Daniel Ayo, PhD.

DESIGN VARIABLES IN DISTILLATION

(The Description rule)

Recall that the number of independent variables for any problem is equal to the

difference between the total number of variables and the number of linking

equations and other relationships.

When there are more than a few stages, the task of counting the variables and

equations becomes burdensome, the description rule may be applied:

The description rule states that:

to determine a separation process completely, the number of independent

variables that must be set (by the designer) will equal the number that are

set in the construction of the column or that can be controlled by external

means in its operation.

Chemical Engineering Design of Mass and Heat Transfer Equipment

Covenant University Department of Chemical Engineering . CHE 414: Principles of Plant Design - Daniel Ayo, PhD.

Independent Variables

Feed composition (N components)

Feed amount

Feed enthalpy

Pressure

Condenser duty

Reboiler Duty

Stages above feed

Stages below feed

Number

N-1

1

1

1

1

1

1

1

Total

N+6

Chemical Engineering Design of Mass and Heat Transfer Equipment

Covenant University Department of Chemical Engineering . CHE 414: Principles of Plant Design - Daniel Ayo, PhD.

Design Methods For Binary Systems

Chemical Engineering Design of Mass and Heat Transfer Equipment

Covenant University Department of Chemical Engineering . CHE 414: Principles of Plant Design - Daniel Ayo, PhD.

Chemical Engineering Design of Mass and Heat Transfer Equipment

Covenant University Department of Chemical Engineering . CHE 414: Principles of Plant Design - Daniel Ayo, PhD.

Lewis-Sorel Method (Equimolar Overflow)

Ln-1= Ln = Ln+1 = L

Ln-1= Ln = Ln+1 = L

Vn-1= Vn = Vn+1 = V

Vn-1= Vn = Vn+1 = V

Chemical Engineering Design of Mass and Heat Transfer Equipment

Covenant University Department of Chemical Engineering . CHE 414: Principles of Plant Design - Daniel Ayo, PhD.

Chemical Engineering Design of Mass and Heat Transfer Equipment

Covenant University Department of Chemical Engineering . CHE 414: Principles of Plant Design - Daniel Ayo, PhD.

McCabe-Thiele Method

Equations 11 and 12 and the equilibrium relationship are conveniently

solved by the graphical method developed by McCabe and Thiele

Chemical Engineering Design of Mass and Heat Transfer Equipment

Covenant University Department of Chemical Engineering . CHE 414: Principles of Plant Design - Daniel Ayo, PhD.

Chemical Engineering Design of Mass and Heat Transfer Equipment

Covenant University Department of Chemical Engineering . CHE 414: Principles of Plant Design - Daniel Ayo, PhD.

(Refer To Coulson And Richardsons Chemical Engineering Volume 2 - Page 569)

Chemical Engineering Design of Mass and Heat Transfer Equipment

Covenant University Department of Chemical Engineering . CHE 414: Principles of Plant Design - Daniel Ayo, PhD.

Though the reboiler and a partial condenser, if used, act as equilibrium

stages, in the design of a column, they are usually not counted as stage but

considered additional factors of safety.

Chemical Engineering Design of Mass and Heat Transfer Equipment

Covenant University Department of Chemical Engineering . CHE 414: Principles of Plant Design - Daniel Ayo, PhD.

Depending on the state of the feed, the feed

lines will have different slopes. For example,

q = 0 (saturated vapour)

q = 1 (saturated liquid)

0 < q < 1 (mix of liquid and vapour)

q > 1 (subcooled liquid)

q < 0 (superheated vapour)

The q-lines for the various feed conditions are

shown in the diagram above

Chemical Engineering Design of Mass and Heat Transfer Equipment

Covenant University Department of Chemical Engineering . CHE 414: Principles of Plant Design - Daniel Ayo, PhD.

Using Operating Lines and the Feed Line in McCabe-Thiele Design

If we have information about the condition of the feed mixture, then we can construct the

q-line and use it in the McCabe-Thiele design. However, excluding the equilibrium line,

only two other pairs of lines can be used in the McCabe-Thiele procedure. These are:

feed-line and rectification section operating line

feed-line and stripping section operating line

stripping and rectification operating lines

This is because these pairs of lines determine the third.

When the condition of equimolar overflow cannot be assumed, the more

rigorous graphical method of Ponchon and Savarit can be used .

Nowadays, computer programs are available for the rigorous solution of

distillation problems

Chemical Engineering Design of Mass and Heat Transfer Equipment

Covenant University Department of Chemical Engineering . CHE 414: Principles of Plant Design - Daniel Ayo, PhD.

Annex: Solution to Example 11.1 in text

Chemical Engineering Design of Mass and Heat Transfer Equipment

Covenant University Department of Chemical Engineering . CHE 414: Principles of Plant Design - Daniel Ayo, PhD.

Annex: Solution to Example 11.1 in text

Chemical Engineering Design of Mass and Heat Transfer Equipment

Covenant University Department of Chemical Engineering . CHE 414: Principles of Plant Design - Daniel Ayo, PhD.

Annex: Solution to Example 11.1 in text

Chemical Engineering Design of Mass and Heat Transfer Equipment

Covenant University Department of Chemical Engineering . CHE 414: Principles of Plant Design - Daniel Ayo, PhD.

Low Product Concentrations

McCabe-Thiele diagram become very small and difficult to plot.

Operating and equilibrium lines can usually be taken as straight at low

concentrations

The number of stages required can be calculated using the equations

given by Robinson and Gilliland

Chemical Engineering Design of Mass and Heat Transfer Equipment

Covenant University Department of Chemical Engineering . CHE 414: Principles of Plant Design - Daniel Ayo, PhD.

Chemical Engineering Design of Mass and Heat Transfer Equipment

Covenant University Department of Chemical Engineering . CHE 414: Principles of Plant Design - Daniel Ayo, PhD.

Problem:

Acetone is to be recovered from an aqueous waste stream by continuous

distillation. The feed will contain 10% w/w acetone. Acetone of at least 98%

purity is wanted, and the aqueous effluent must not contain more than 50 ppm

acetone. The feed will be at 200C. Estimate the number of ideal stages required.

Estimate the number of ideal stages required below an acetone concentration of

0.04 (more volatile component) using the Robinson-Gilliland equation.

Solution: Examples 11.2 and 11.3 in Text

Chemical Engineering Design of Mass and Heat Transfer Equipment

Covenant University Department of Chemical Engineering . CHE 414: Principles of Plant Design - Daniel Ayo, PhD.

The Smoker Equations

Constant relative volatility

Particularly useful for low relative volatility resulting in large number of stages

thus making it impractical to draw a McCabe-Thiele diagram (e.g. in the

separation of close boiling isomers).

Chemical Engineering Design of Mass and Heat Transfer Equipment

Covenant University Department of Chemical Engineering . CHE 414: Principles of Plant Design - Daniel Ayo, PhD.

The Smoker Equations

Constant relative volatility

Particularly useful for low relative volatility resulting in large number of stages

thus making it impractical to draw a McCabe-Thiele diagram (e.g. in the

separation of close boiling isomers).

k is the value of the x ordinate at the point where the extended operating lines intersect the vaporliquid equilibrium curve.

Chemical Engineering Design of Mass and Heat Transfer Equipment

Covenant University Department of Chemical Engineering . CHE 414: Principles of Plant Design - Daniel Ayo, PhD.

Chemical Engineering Design of Mass and Heat Transfer Equipment

Covenant University Department of Chemical Engineering . CHE 414: Principles of Plant Design - Daniel Ayo, PhD.

Problem

A column is to be designed to separate a mixture of ethylbenzene and styrene. The

feed will contain 0.5 mol fraction styrene, and a styrene purity of 99.5% is

required, with a recovery of 85%. Estimate the number of equilibrium stages

Solution : Example 11.4 in text

Chemical Engineering Design of Mass and Heat Transfer Equipment

Covenant University Department of Chemical Engineering . CHE 414: Principles of Plant Design - Daniel Ayo, PhD.

MULTICOMPONENT DISTILLATION: GENERAL CONSIDERATIONS

The problem of determining the stage and reflux requirements for

multicomponent distillations is much more complex than for binary

mixtures. With a multicomponent mixture, fixing one component

composition does not uniquely determine the other component

compositions and the stage temperature. Also, when the feed contains

more than two components, it is not possible to specify the complete

composition of the top and bottom products independently. The

separation between the top and bottom products is specified by setting

limits on two key components, between which it is desired to make

the separation.

Chemical Engineering Design of Mass and Heat Transfer Equipment

Covenant University Department of Chemical Engineering . CHE 414: Principles of Plant Design - Daniel Ayo, PhD.

Though computer programs will normally be available for the

rigorous solution of the MESH equations, shortcut methods are

still useful in the preliminary design work and as an aid in

defining problems for computer solution. Intelligent use of the

shortcut methods can reduce the computer time and costs.

Chemical Engineering Design of Mass and Heat Transfer Equipment

Covenant University Department of Chemical Engineering . CHE 414: Principles of Plant Design - Daniel Ayo, PhD.

The shortcut methods available can be divided into two classes:

Simplification of the rigorous stage-by-stage procedures to enable the

calculations to be done by hand or graphically.

Empirical methods, which are based on the performance of operating

columns, or the results of rigorous designs.

Chemical Engineering Design of Mass and Heat Transfer Equipment

Covenant University Department of Chemical Engineering . CHE 414: Principles of Plant Design - Daniel Ayo, PhD.

Key Components

Before starting the column design, the designer must select the two key

components between which it is desired to make the separation. The

light key will be the component that it is desired to keep out of the

bottom product; and the heavy key, the component to be kept out of the

top product. Specifications will be set on the maximum concentrations

of the keys in the top and bottom products. The keys are known as

adjacent keys if they are adjacent in a listing of the components in

order of volatility, and split keys if some other component lies between

them in the order; they will usually be adjacent.

Chemical Engineering Design of Mass and Heat Transfer Equipment

Covenant University Department of Chemical Engineering . CHE 414: Principles of Plant Design - Daniel Ayo, PhD.

Number and Sequencing of Columns

It is not possible to obtain more than one pure component, one sharp separation, in

a single column. If a multicomponent feed is to be split into two or more virtually

pure products, several columns will be needed. Impure products can be taken off

as side streams, and the removal of a side stream from a stage where a minor

component is concentrated will reduce the concentration of that component in the

main product.

Chemical Engineering Design of Mass and Heat Transfer Equipment

Covenant University Department of Chemical Engineering . CHE 414: Principles of Plant Design - Daniel Ayo, PhD.

For separation of N components, with one essentially pure component

taken overhead, or from the bottom of each column, (N - 1) columns

will be needed to obtain complete separation of all components. For

example, to separate a mixture of benzene, toluene, and xylene, two

columns are needed (3 - 1). Benzene is taken overhead from the first

column, and the bottom product, essentially free of benzene, is fed to

the second column. This column separates the toluene and xylene.

Chemical Engineering Design of Mass and Heat Transfer Equipment

Covenant University Department of Chemical Engineering . CHE 414: Principles of Plant Design - Daniel Ayo, PhD.

The order in which the components are separated will determine the

capital and operating costs. Where there are several components, the

number of possible sequences can be very large; for example, with 5

components, the number is 14, whereas with 10 components, it is near

5000. When systems that require the separation of several components

are designed, efficient procedures are needed to determine the optimum

sequence of separation. Procedures for the sequencing of columns are

also available in the commercial process simulator programs; for

example, DISTIL in Aspen Technologys suite of programs

Chemical Engineering Design of Mass and Heat Transfer Equipment

Covenant University Department of Chemical Engineering . CHE 414: Principles of Plant Design - Daniel Ayo, PhD.

Heuristic Rules for Optimum Sequencing

1. Remove the components one at a time; as in the benzene-toluene-xylene

example.

2. Remove any components that are present in large excess early in the sequence.

3. With difficult separations, involving close boiling components, postpone the

most difficult separation to late in the sequence.

Difficult separations will require many stages, so the column diameter should be

made as small as possible to reduce cost. Column diameter is dependent on flow

rate; The further down the sequence, the smaller will be the amount of material

that the column has to handle.

Chemical Engineering Design of Mass and Heat Transfer Equipment

Covenant University Department of Chemical Engineering . CHE 414: Principles of Plant Design - Daniel Ayo, PhD.

Tall Columns

Where a large number of stages is required, it may be necessary to split a

column into two separate columns to reduce the height of the column, even

though the required separation could, theoretically, have been obtained in a

single column. This may also be done in vacuum distillations, to reduce the

column pressure drop and limit the bottom temperatures.

Chemical Engineering Design of Mass and Heat Transfer Equipment

Covenant University Department of Chemical Engineering . CHE 414: Principles of Plant Design - Daniel Ayo, PhD.

MULTICOMPONENT DISTILLATION: SHORTCUT METHODS

FOR STAGE AND REFLUX REQUIREMENTS

Some shortcut procedures can be used to estimate stage and reflux

requirements without the aid of computers. Most of the shortcut methods

were developed for the design of separation columns for hydrocarbon

systems in the petroleum and petrochemical systems industries, and

caution must be exercised when applying them to other systems. They

usually depend on the assumption of constant relative volatility and should

not be used for severely nonideal systems.

Chemical Engineering Design of Mass and Heat Transfer Equipment

Covenant University Department of Chemical Engineering . CHE 414: Principles of Plant Design - Daniel Ayo, PhD.

Pseudo-Binary Systems

If the presence of the other components does not significantly affect the volatility of

the key components, the keys can be treated as a pseudo-binary pair. The number of

stages can then be calculated using a McCabe-Thiele diagram or the other methods

developed for binary systems. This simplification can often be made when the

number of the nonkey components is small or where the components form nearideal mixtures.

Where the concentration of the nonkeys is small, say less than 10%, they can be

lumped in with the key components. For higher concentrations the method

proposed by Hengstebeck can be used to reduce the system to an equivalent binary

system.

Chemical Engineering Design of Mass and Heat Transfer Equipment

Covenant University Department of Chemical Engineering . CHE 414: Principles of Plant Design - Daniel Ayo, PhD.

Hengstebecks Method

For any component i, the Lewis-Sorel material balance equations and equilibrium

relationship can be written in terms of the individual component molar flow rates,

in place of the component composition:

Chemical Engineering Design of Mass and Heat Transfer Equipment

Covenant University Department of Chemical Engineering . CHE 414: Principles of Plant Design - Daniel Ayo, PhD.

Chemical Engineering Design of Mass and Heat Transfer Equipment

Covenant University Department of Chemical Engineering . CHE 414: Principles of Plant Design - Daniel Ayo, PhD.

Assume flow rates of each of the light nonkey components approaches a

constant, limiting rate in the rectifying section, and the flows of each of the

heavy nonkey components approach limiting flow rates in the stripping section.

Putting the flow rates of the nonkeys equal to these limiting rates in each section

enables the combined flows of the key components to be estimated.

Chemical Engineering Design of Mass and Heat Transfer Equipment

Covenant University Department of Chemical Engineering . CHE 414: Principles of Plant Design - Daniel Ayo, PhD.

Chemical Engineering Design of Mass and Heat Transfer Equipment

Covenant University Department of Chemical Engineering . CHE 414: Principles of Plant Design - Daniel Ayo, PhD.

Jenny proposed the following equations to estimate the limiting flow rates;

Chemical Engineering Design of Mass and Heat Transfer Equipment

Covenant University Department of Chemical Engineering . CHE 414: Principles of Plant Design - Daniel Ayo, PhD.

Chemical Engineering Design of Mass and Heat Transfer Equipment

Covenant University Department of Chemical Engineering . CHE 414: Principles of Plant Design - Daniel Ayo, PhD.

Problem: Estimate the number of ideal stages needed in the butane-pentane

splitter defined by the compositions given in the following table. The column

will operate at a pressure of 8.3 bar, with a reflux ratio of 2.5. The feed is at its

boiling point.

Solution: Example 11.5 in text

Chemical Engineering Design of Mass and Heat Transfer Equipment

You might also like

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Anon 2Document18 pagesAnon 2ifiokNo ratings yet

- Investing in BondsDocument6 pagesInvesting in BondsNicolloNo ratings yet

- ZeoliDocument11 pagesZeoliifiokNo ratings yet

- Chapter One 1.0 1.1. Background of The StudyDocument3 pagesChapter One 1.0 1.1. Background of The StudyifiokNo ratings yet

- EarningsDocument18 pagesEarningsArun KumarNo ratings yet

- Engine Oil and Oil in General Can Be Made From Several MaterialsDocument5 pagesEngine Oil and Oil in General Can Be Made From Several MaterialsifiokNo ratings yet

- Effects of Refining On Chemical and Physical Properties of Palm Oil ProductsDocument4 pagesEffects of Refining On Chemical and Physical Properties of Palm Oil ProductsifiokNo ratings yet

- AnonDocument26 pagesAnonifiokNo ratings yet

- Bleaching Effect On Palm OilDocument239 pagesBleaching Effect On Palm Oilde eagle100% (6)

- Auwal Paint2 Power PointDocument24 pagesAuwal Paint2 Power PointifiokNo ratings yet

- 2multicomponent Distillation CalculationsDocument1 page2multicomponent Distillation CalculationsifiokNo ratings yet

- Lecture - 3 - Heat and The First Law Example ProblemsDocument22 pagesLecture - 3 - Heat and The First Law Example ProblemsifiokNo ratings yet

- Biodiesel Production From Palm Kernel Oil Using CalciumDocument28 pagesBiodiesel Production From Palm Kernel Oil Using CalciumifiokNo ratings yet

- Template For Research ProjectDocument18 pagesTemplate For Research ProjectifiokNo ratings yet

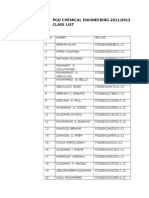

- PGD Chemical Engineering 2011/2012 Class ListDocument2 pagesPGD Chemical Engineering 2011/2012 Class ListifiokNo ratings yet

- CHE518 Introduction To Polymer Engineering and ProcessingDocument3 pagesCHE518 Introduction To Polymer Engineering and ProcessingifiokNo ratings yet

- Corrosion Class Coating SlideDocument27 pagesCorrosion Class Coating SlideIwuoha Maxrofuzo ChibuezeNo ratings yet

- Schematic Diagram: Water WaterDocument5 pagesSchematic Diagram: Water WaterifiokNo ratings yet

- CHEMICAL ENGINEERING PROCESS ANALYSIS COURSE COMPACTDocument4 pagesCHEMICAL ENGINEERING PROCESS ANALYSIS COURSE COMPACTCharles BaileyNo ratings yet

- Self Evaluation Skills: Dayo OdukoyaDocument17 pagesSelf Evaluation Skills: Dayo OdukoyaifiokNo ratings yet

- Stocks PDFDocument4 pagesStocks PDFifiokNo ratings yet

- Alkenes and Alkynes I. Addition Reactions: Chapter EightDocument68 pagesAlkenes and Alkynes I. Addition Reactions: Chapter EightifiokNo ratings yet

- Time Management by Owoeye S.TDocument10 pagesTime Management by Owoeye S.TifiokNo ratings yet

- EDS411 - Entrepreneurial Marketing777777777777777Document26 pagesEDS411 - Entrepreneurial Marketing777777777777777ifiokNo ratings yet

- CHE 414 Principles of Plant Design I Part 2Document30 pagesCHE 414 Principles of Plant Design I Part 2ifiokNo ratings yet

- CHE 414 Part 1Document87 pagesCHE 414 Part 1ifiokNo ratings yet

- CHE 414 Principles of Plant Design I Part 5BDocument35 pagesCHE 414 Principles of Plant Design I Part 5BifiokNo ratings yet

- Week 4Document45 pagesWeek 4Iwuoha Maxrofuzo ChibuezeNo ratings yet

- Che 414 Process Design e NoteDocument114 pagesChe 414 Process Design e Noteifiok100% (1)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Coriolis Flow MeasurementDocument19 pagesCoriolis Flow MeasurementtetiospamNo ratings yet

- PLGA Product ListDocument3 pagesPLGA Product ListNEHA MARADIYANo ratings yet

- Test For Presence of Oxidizable Substances in WaterDocument3 pagesTest For Presence of Oxidizable Substances in WaterAndreaNo ratings yet

- Herz&Garrison - Geological Methods For Archaeology PDFDocument352 pagesHerz&Garrison - Geological Methods For Archaeology PDFJorge Overkill100% (1)

- STELLAR STRUCTURE - O.L. Pols PDFDocument207 pagesSTELLAR STRUCTURE - O.L. Pols PDFguignanNo ratings yet

- Separation and Concentration Technologies in Food ProcessingDocument84 pagesSeparation and Concentration Technologies in Food Processingjoenni hansNo ratings yet

- JEE (Advanced) 2015 - A Detailed Analysis by Resonance Expert Team - Reso BlogDocument9 pagesJEE (Advanced) 2015 - A Detailed Analysis by Resonance Expert Team - Reso BlogGaurav YadavNo ratings yet

- Heat ConductionDocument8 pagesHeat ConductionJameel MalikNo ratings yet

- TN15 - Crushed Manufactured Sand and Natural SandDocument6 pagesTN15 - Crushed Manufactured Sand and Natural Sandpriyanka_kashyap_4No ratings yet

- Leslie Marie Red - Bs Che3A - Che 126 Pe 1: 1 1 A A B BDocument16 pagesLeslie Marie Red - Bs Che3A - Che 126 Pe 1: 1 1 A A B BJohn Patrick Sanay NunezNo ratings yet

- CHE 202 TUTORIAL QUESTIONSDocument6 pagesCHE 202 TUTORIAL QUESTIONSFawziyyah AgboolaNo ratings yet

- Dry Quenched Coke - Enabler To Enhance BF PerformanceDocument26 pagesDry Quenched Coke - Enabler To Enhance BF PerformanceSatyamKumarNo ratings yet

- Energy StoredDocument6 pagesEnergy StoredMae chelle San AndresNo ratings yet

- Hempel Topaz SG Enamel 524ME MsdsDocument10 pagesHempel Topaz SG Enamel 524ME MsdsM.FAIZAN ARSHADNo ratings yet

- Module 6 (Materials & Hardware) SubModule 6.4 (Corrosion)Document26 pagesModule 6 (Materials & Hardware) SubModule 6.4 (Corrosion)daniaNo ratings yet

- MIT2 2F13 Shapi5.18 SolutDocument4 pagesMIT2 2F13 Shapi5.18 SolutIhab OmarNo ratings yet

- In-Situ Spectroscopic Studies of Adsorption at The Electrode and ElectrocatalysisDocument10 pagesIn-Situ Spectroscopic Studies of Adsorption at The Electrode and ElectrocatalysisEudes SantosNo ratings yet

- ISO 8217 2017 FUEL STANDARDSDocument2 pagesISO 8217 2017 FUEL STANDARDSAnton100% (2)

- Diagnóstico Por Imagem - ThrallDocument764 pagesDiagnóstico Por Imagem - ThrallMariana de Queiroz Sampaio100% (1)

- Budget of Work Sci5Document1 pageBudget of Work Sci5Jhoy Angeles PinlacNo ratings yet

- Oregon Geology Map and Report DetailsDocument24 pagesOregon Geology Map and Report DetailskctreeNo ratings yet

- The University of DodomaDocument20 pagesThe University of DodomaIsrael MwanyeleleNo ratings yet

- Mock TestDocument4 pagesMock TestRufa NarioNo ratings yet

- TT 200 1 SC TT 200 2 SC Sample Concentrator DatasheetDocument4 pagesTT 200 1 SC TT 200 2 SC Sample Concentrator Datasheetlehieua8No ratings yet

- Topic: Co-Enzyme ChemistryDocument12 pagesTopic: Co-Enzyme ChemistryAshutosh PrasadNo ratings yet

- Phys p2Document17 pagesPhys p2Kalana GamageNo ratings yet

- PCHEM ISCO ISCR and Risk Reward Remediation Program Presentation PDFDocument93 pagesPCHEM ISCO ISCR and Risk Reward Remediation Program Presentation PDFMartin Daniel Palacios Quevedo100% (1)

- Vernier Calipers (Procedure) - Class 11 - Physics - Amrita Online LabDocument3 pagesVernier Calipers (Procedure) - Class 11 - Physics - Amrita Online Labgetashishvaid100% (1)

- Microstructure and Properties of AC HVAF Sprayed Ni60WC Composite Coating 2009 Journal of Alloys and CompoundsDocument5 pagesMicrostructure and Properties of AC HVAF Sprayed Ni60WC Composite Coating 2009 Journal of Alloys and CompoundsastronotusNo ratings yet

- FM Unit I, Ii & IvDocument58 pagesFM Unit I, Ii & IvChandramohan GNo ratings yet