Professional Documents

Culture Documents

2852-Polishing Metal Surfaces

Uploaded by

syllavethyjim0 ratings0% found this document useful (0 votes)

12 views1 pageGeometer Tips

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentGeometer Tips

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

12 views1 page2852-Polishing Metal Surfaces

Uploaded by

syllavethyjimGeometer Tips

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

.

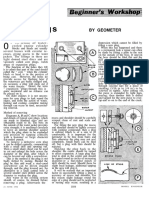

JOINTS

AND

: WASHERS

The main methods of sealing

various types of mating faces

and joints are described here

CLEARANCE

By GEOMETER

or full size,

it is essential for many

pipes and joints to be

proof against leakage of pressure

and liquids and, at the same time,

it must be possible to dismantle

and reassemble them. Meeting

the different conditions calls for

a variety of joints and washers,

since what is acceptable in one

HETHER MODEL

application may not be suitable in

another.

Some joints need to be pulled very

firmly together and withstand considerable heat, for exam le, motorcycle and car cylinder cads, t h e

former using thin annealed copper

joints, the latter copper-asbestos gaskets. Other joints require to be pulled

firmly together and withstand the

action of petrol or oil, for which

reason taps and union fittings usually

seat on a thin fibre washer.

Where there is less pressure, cork

washers can be used and these admit

of a degree of compression compensating for irregularities in surfaces.

Where both pressure and oil have to

be resisted, as on oil filters, special

rubber washers Neoprene are

used with the housing arranged so

they cannot be blown out.

Ordinary joints which may need

to be simply leakproof or to withstand

a moderate degree of pressure and

heat can be made by coating the

MODEL

ENGINEER

surfaces of components with jointing

compound, or by employing a thin

paper washer, this sometimes being

treated with compound or oil.

When dismantling, the types of

joints should be noted and similar

material used in assembly-or if the

work is commercial, the proper joints

or gaskets obtained.

Many joints are satisfactory with

merely a metal-to-metal fitting, where

accurate machining is possible. The

most common joint of this type is the

ordinary coned union, A, the pipe

being soldered in, and the joint pulled

tight with a gland nut. The cone

should be clean and fit snugly.

Another type of fitting employs a

loose cone or olive which is

slipped on the pipe and compressed

with the gland nut; after tightening a

few times, this fitting may give

trouble and necessitate renewing.

A larger coned fitting, B, is used

for exhaust pipes on cars as an alternative to a flat joint with copperasbestos washer. The end of the manifold is coned, the pipe flanged, and

the two gripped together by a clip

having two bolts.

This joint avoids the trouble of

burnt gaskets and seized nuts. The

faces should be free from scale, and it

should be observed that the clip is

clear on the neck, so as to grip on the

cone.

Model i.c. engine cylinder and head

joints are often the metal-to-metal

184

type. If the cylinder is linered, the

joint can conveniently be an internal

one, C, made on the end of the liner;

a solid cylinder can have an external

joint, D. In each case, slight clearance

is necessary for the faces to butt up.

Sealing on such a joint can be made

by light grinding with a smear of

paste, working head and cylinder

together with a twisting action.

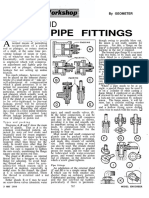

Imprisoned joints

The ordinary cover plate joint, E,

is flat and made with a paper washer.

Where there is pressure, as on a model

steam cylinder, slight roughness of

the surfaces (obtained by machining

with a round-nosed turning tool)

assists in gripping the washer.

Washers and joints, however, may

be imprisoned so as to resist splaying

on tightening, or to prevent blowing

out under pressure. Common examples

of this practice appear at F, G and H.

On a car petrol pump or filter, F,

the cap is sealed with a cork washer

and a fibre washer backed by a steel

washer is used for the holding setscrew-where the pressure is greater.

On a valve cover, G, a cork or rubber

strip is often used, placed in a groove,

with the gap at the top. This type of

joint permits of considerable compression, and allows for distortion

of the cover-though if the cover is

bent it should be straightened. An

internal oil filter, H, usually employs

two Neoprene washers as shown,

both imprisoned to resist pressure.

2 FEBRUARY 1956

You might also like

- A Book of Helpful Tips on Overhauling a Vintage Engine - Including Car, Motorbike and Lawn Mower EnginesFrom EverandA Book of Helpful Tips on Overhauling a Vintage Engine - Including Car, Motorbike and Lawn Mower EnginesRating: 5 out of 5 stars5/5 (1)

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceFrom EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceNo ratings yet

- Stern TubesDocument8 pagesStern Tubesweesweekwee8652No ratings yet

- Engine Construction 1Document11 pagesEngine Construction 1collins arogoNo ratings yet

- Identification of The Diesel Engine ComponentsDocument13 pagesIdentification of The Diesel Engine Componentsguswerino240% (1)

- Laporan Praktikum Sealing-BearingDocument26 pagesLaporan Praktikum Sealing-Bearinga2sn_elizNo ratings yet

- Parts and Functional Description of Diesel EngineDocument12 pagesParts and Functional Description of Diesel EngineVinay GirdharNo ratings yet

- Construction Maintenance Department: Mechanical Technician Qualification ModuleDocument109 pagesConstruction Maintenance Department: Mechanical Technician Qualification ModuleAndinata Sitepu100% (1)

- 2864-Poppet Valves & Seating PDFDocument1 page2864-Poppet Valves & Seating PDFsyllavethyjimNo ratings yet

- Inspection of Steel Penstocks and Pressure ConduitsDocument111 pagesInspection of Steel Penstocks and Pressure ConduitsNgoc Thach PhamNo ratings yet

- 06Document12 pages06JJNo ratings yet

- Stern TubesDocument9 pagesStern TubesArunNo ratings yet

- Hydraulics WhitepaperDocument4 pagesHydraulics WhitepaperHUERTANESTORNo ratings yet

- Hydraulic and PneumaticDocument15 pagesHydraulic and PneumaticDhvanirNo ratings yet

- Mechanicalpacking - Eng.1506.ltr 1Document16 pagesMechanicalpacking - Eng.1506.ltr 1Agustinus KNo ratings yet

- Pump Learning Guide1Document171 pagesPump Learning Guide1password2013No ratings yet

- Tech Talk Dry Gas SealsDocument5 pagesTech Talk Dry Gas SealsThe AKNo ratings yet

- Nok SealDocument6 pagesNok SealAdi Aja100% (2)

- Seals and GasketsDocument53 pagesSeals and GasketsMadan YadavNo ratings yet

- Stern Tubes PDFDocument8 pagesStern Tubes PDFrajishrrr100% (1)

- How Can Spiral Wound Gasket Selection and Installation Problems Be AvoidedDocument2 pagesHow Can Spiral Wound Gasket Selection and Installation Problems Be AvoidedTay Hua SetNo ratings yet

- GasketsDocument8 pagesGasketsRaj SharmaNo ratings yet

- Expansion Joints How To Select and Maintain ThemDocument6 pagesExpansion Joints How To Select and Maintain ThemSeungmin PaekNo ratings yet

- Flange LeakageDocument29 pagesFlange Leakageim4uim4uim4uNo ratings yet

- Flange LeakageDocument29 pagesFlange Leakagevrindk80% (5)

- Installing Spiral Wound GasketDocument2 pagesInstalling Spiral Wound Gasketm_stasys9939No ratings yet

- Mechanical SealDocument6 pagesMechanical SealysudharnnanNo ratings yet

- Adhesives Retain With Confidence Tech ArticleDocument4 pagesAdhesives Retain With Confidence Tech ArticlegobajasaeindiaNo ratings yet

- Plastics and Aircraft Part 2Document1 pagePlastics and Aircraft Part 2veence spenglerNo ratings yet

- 10 Hydraulics Tips You Need To Know: Outside Factors Are A Vital Component of Hydraulic SystemsDocument4 pages10 Hydraulics Tips You Need To Know: Outside Factors Are A Vital Component of Hydraulic SystemsGunjanNo ratings yet

- Informacion Bushing Tipo UDocument6 pagesInformacion Bushing Tipo Uarmandoa71565No ratings yet

- Gasket, Gland Packing & ElastomersDocument12 pagesGasket, Gland Packing & ElastomersJaveed A. KhanNo ratings yet

- On-Stream Leak Repair Techniques - Part 2Document2 pagesOn-Stream Leak Repair Techniques - Part 2qaisarabbas9002100% (1)

- End Face Mechanical Seal: Navigation SearchDocument16 pagesEnd Face Mechanical Seal: Navigation SearchCarlito PantalunanNo ratings yet

- Compressor PartsDocument7 pagesCompressor PartsinamNo ratings yet

- PHASA Design GuideDocument16 pagesPHASA Design Guidejhlec054850No ratings yet

- Compressor Seal Selection Justification t32-18Document12 pagesCompressor Seal Selection Justification t32-18Pedro Diaz100% (1)

- Engine TechnologyDocument236 pagesEngine TechnologyjeffkwentrickksivorNo ratings yet

- Mechnical Seals Vs Packing GlandsDocument5 pagesMechnical Seals Vs Packing GlandsVon Russell Villordon CubilloNo ratings yet

- SEALING MANWAYSDocument6 pagesSEALING MANWAYSalokbdasNo ratings yet

- Maintain Hydraulic Systems EfficientlyDocument39 pagesMaintain Hydraulic Systems Efficientlyavinash babu100% (1)

- OWI 1000 DrawworksDocument54 pagesOWI 1000 DrawworksÖnder Büyükişcan100% (1)

- G Damage ChainsDocument17 pagesG Damage ChainsLicitatie CitatiebNo ratings yet

- Seal Off Centrifugal Pump ProblemsDocument6 pagesSeal Off Centrifugal Pump ProblemsArturo Valles TerrazasNo ratings yet

- Nozzle Design - The Weak Point of Every Equipment - Training & EngineeringDocument11 pagesNozzle Design - The Weak Point of Every Equipment - Training & EngineeringTC Capulcu Mustafa M0% (1)

- CHEVRON Maintenance Heat ExchangerDocument23 pagesCHEVRON Maintenance Heat Exchangerbabak mir50% (2)

- Half VW Assy. by TinkerDocument19 pagesHalf VW Assy. by TinkerJessie BechaydaNo ratings yet

- DISCLAIMER: The User of This Manual and The Associated Three Drawings Assumes AllDocument15 pagesDISCLAIMER: The User of This Manual and The Associated Three Drawings Assumes Allalonso malherNo ratings yet

- Hidráulica Sello Cilíndrico de Análisis de FallasDocument22 pagesHidráulica Sello Cilíndrico de Análisis de FallasPedro Cerna DiazNo ratings yet

- MP Dec2012 - Coating Flange FaceDocument2 pagesMP Dec2012 - Coating Flange FaceUgoRibeiroNo ratings yet

- Piston RingDocument43 pagesPiston RingSudath Kularathna67% (3)

- Transeals Identifying Hydraulic SealsDocument28 pagesTranseals Identifying Hydraulic Sealsvikram_007No ratings yet

- Lockheed FlarelessDocument20 pagesLockheed FlarelessGazpachoesiNo ratings yet

- The Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementFrom EverandThe Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementNo ratings yet

- Bearings And Bearing Metals: A Treatise Dealing with Various Types of Plain Bearings, the Compositions and Properties of Bearing Metals, Methods of Insuring Proper Lubrication, and Important Factors Governing the Design of Plain BearingsFrom EverandBearings And Bearing Metals: A Treatise Dealing with Various Types of Plain Bearings, the Compositions and Properties of Bearing Metals, Methods of Insuring Proper Lubrication, and Important Factors Governing the Design of Plain BearingsRating: 4 out of 5 stars4/5 (1)

- The Art of Lead Burning: A practical treatise explaining the apparatus and processesFrom EverandThe Art of Lead Burning: A practical treatise explaining the apparatus and processesNo ratings yet

- 2889-Further Drilling Methods PDFDocument1 page2889-Further Drilling Methods PDFsyllavethyjimNo ratings yet

- 2873-Cotters & Wedges PDFDocument1 page2873-Cotters & Wedges PDFsyllavethyjimNo ratings yet

- IMP Workshop ManualDocument336 pagesIMP Workshop Manualsyllavethyjim67% (3)

- 2890-Nuts & Spanners PDFDocument1 page2890-Nuts & Spanners PDFsyllavethyjimNo ratings yet

- 2878-Chains & Sprockets PDFDocument1 page2878-Chains & Sprockets PDFsyllavethyjimNo ratings yet

- Contours 1: Hile It CannotDocument1 pageContours 1: Hile It CannotsyllavethyjimNo ratings yet

- 2886-Stud Fitting & Removal PDFDocument1 page2886-Stud Fitting & Removal PDFsyllavethyjimNo ratings yet

- 2885-Dent & Bulge Removal PDFDocument1 page2885-Dent & Bulge Removal PDFsyllavethyjimNo ratings yet

- 2880-Supporting & Steadying PDFDocument1 page2880-Supporting & Steadying PDFsyllavethyjimNo ratings yet

- 2883-Metal Working PDFDocument1 page2883-Metal Working PDFsyllavethyjimNo ratings yet

- 2888-Oblique Drilling PDFDocument1 page2888-Oblique Drilling PDFsyllavethyjimNo ratings yet

- 2871-Circular Clips #1 PDFDocument1 page2871-Circular Clips #1 PDFsyllavethyjimNo ratings yet

- 2881-Radii Functions and Checking PDFDocument1 page2881-Radii Functions and Checking PDFsyllavethyjimNo ratings yet

- 2884-Panel Beating PDFDocument1 page2884-Panel Beating PDFsyllavethyjim100% (1)

- 2887-Broken Drills & Taps PDFDocument1 page2887-Broken Drills & Taps PDFsyllavethyjimNo ratings yet

- 2879-Clamping & Holding PDFDocument1 page2879-Clamping & Holding PDFsyllavethyjimNo ratings yet

- 2874-Fitting Core Plugs PDFDocument1 page2874-Fitting Core Plugs PDFsyllavethyjimNo ratings yet

- 2872-Circular Clips #2 PDFDocument1 page2872-Circular Clips #2 PDFsyllavethyjimNo ratings yet

- 2868-Glands & Pipe Fittings PDFDocument1 page2868-Glands & Pipe Fittings PDFsyllavethyjimNo ratings yet

- 2870-Simple Screw Assembly PDFDocument1 page2870-Simple Screw Assembly PDFsyllavethyjimNo ratings yet

- 2875-Belt Drives PDFDocument1 page2875-Belt Drives PDFsyllavethyjimNo ratings yet

- 2876-Belt Fasteners PDFDocument1 page2876-Belt Fasteners PDFsyllavethyjimNo ratings yet

- Roller Chains and Sprockets GuideDocument1 pageRoller Chains and Sprockets GuidesyllavethyjimNo ratings yet

- 2867 Case HardeningDocument1 page2867 Case HardeningEr Sukhwinder SinghNo ratings yet

- 2861-Wheel & Shaft PullersDocument1 page2861-Wheel & Shaft PullersSandra Barnett CrossanNo ratings yet

- 2869-Fitting & Joining Pipes PDFDocument1 page2869-Fitting & Joining Pipes PDFsyllavethyjimNo ratings yet

- 2865-Testing & Facing Valves PDFDocument1 page2865-Testing & Facing Valves PDFsyllavethyjimNo ratings yet

- 2863-Valve Seating Tools PDFDocument1 page2863-Valve Seating Tools PDFsyllavethyjimNo ratings yet

- 2866-Hardening & Tempering PDFDocument1 page2866-Hardening & Tempering PDFsyllavethyjimNo ratings yet

- 2864-Poppet Valves & Seating PDFDocument1 page2864-Poppet Valves & Seating PDFsyllavethyjimNo ratings yet

- Sejarah Unsur Kimia Bumi PDFDocument449 pagesSejarah Unsur Kimia Bumi PDFJon WheelerNo ratings yet

- Redirection & PipingDocument16 pagesRedirection & PipingPraveen PatelNo ratings yet

- BA (Hons) Philosophy CurriculumDocument123 pagesBA (Hons) Philosophy CurriculumDARSHAN RAAJANNo ratings yet

- Charger Energic Plus (Catalog)Document24 pagesCharger Energic Plus (Catalog)sugar44No ratings yet

- Drive Fundamentals and DC Motor CharacteristicsDocument6 pagesDrive Fundamentals and DC Motor CharacteristicsKawooya CharlesNo ratings yet

- Calculation of Optimum Fishing TimeDocument11 pagesCalculation of Optimum Fishing TimeÇağlar Öztürk100% (2)

- Danfoss PVE - Series - 7 - Technical - Information PDFDocument56 pagesDanfoss PVE - Series - 7 - Technical - Information PDFJuan Felipe Garza GNo ratings yet

- RC Beam Deflection and Stress AnalysisDocument4 pagesRC Beam Deflection and Stress AnalysisMaxNo ratings yet

- Probset 8Document7 pagesProbset 8Adrian PamintuanNo ratings yet

- LCD Interfacing PDFDocument37 pagesLCD Interfacing PDFPeeyush Kp100% (1)

- Adverb Clause of Time (Adverbial Cause of Time)Document9 pagesAdverb Clause of Time (Adverbial Cause of Time)Toh Choon HongNo ratings yet

- Animal and Plant CellDocument3 pagesAnimal and Plant CellElmer Tunggolh, Jr.No ratings yet

- Visual Studio C++ TutorialDocument324 pagesVisual Studio C++ TutorialFahadNo ratings yet

- Unisonic Technologies Co., LTD: 8-Channel Analog Multiplexers/DemultiplexersDocument7 pagesUnisonic Technologies Co., LTD: 8-Channel Analog Multiplexers/DemultiplexersNaresh KsNo ratings yet

- The Relative Pricing of High-Yield Debt: The Case of RJR Nabisco Holdings Capital CorporationDocument24 pagesThe Relative Pricing of High-Yield Debt: The Case of RJR Nabisco Holdings Capital CorporationAhsen Ali Siddiqui100% (1)

- Recurrent Neural Network-Based Robust NonsingularDocument13 pagesRecurrent Neural Network-Based Robust NonsingularDong HoangNo ratings yet

- Typescript Cheat Sheet: by ViaDocument2 pagesTypescript Cheat Sheet: by ViapbecicNo ratings yet

- Mid Drive Vs HubDocument15 pagesMid Drive Vs HubRivan PamungkasNo ratings yet

- Dell Emc Data Domain Dd3300 Faq: Frequently Asked QuestionsDocument14 pagesDell Emc Data Domain Dd3300 Faq: Frequently Asked QuestionseriquewNo ratings yet

- Generator Protection Application GuideDocument106 pagesGenerator Protection Application GuideJorge Alberto Chavarría Sacasa100% (1)

- Mechanical Technology Concepts: Applied ThermodynamicsDocument45 pagesMechanical Technology Concepts: Applied ThermodynamicsLe0 GamingNo ratings yet

- Unit2.SP - Mill.setting and ImbibitionDocument15 pagesUnit2.SP - Mill.setting and ImbibitionHari kantNo ratings yet

- P&ID ManualDocument35 pagesP&ID Manualdharan kumarNo ratings yet

- Convert Decimal To Binary Sunday ClassDocument14 pagesConvert Decimal To Binary Sunday ClassLaila HammadNo ratings yet

- Model For Calculating The Refractive Index of DiffDocument5 pagesModel For Calculating The Refractive Index of DiffNANNo ratings yet

- Periodic TableDocument1 pagePeriodic TableChemist MookaNo ratings yet

- Benzophenone/THF StillDocument3 pagesBenzophenone/THF Stillbloggsjoe1970No ratings yet

- Answer All The Questions. No Negative Marks For Wrong Answers. Please Do Not Mark Anything On The Question PaperDocument13 pagesAnswer All The Questions. No Negative Marks For Wrong Answers. Please Do Not Mark Anything On The Question PaperMainak DeNo ratings yet

- Custom Objects, Fields, Tabs, Related Lists, List ViewsDocument7 pagesCustom Objects, Fields, Tabs, Related Lists, List ViewsAjay GhugeNo ratings yet

- Oscillation MCQDocument7 pagesOscillation MCQUmer KhalidNo ratings yet